Norwood Kwik-Till HSD2500 User manual

11202 38th St S, Horace, ND 58047

P/N 55-5-00131

Operator’s Manual

Models: HSD2500, HSD3000, HSD3500, HSD4000, & HSD4500

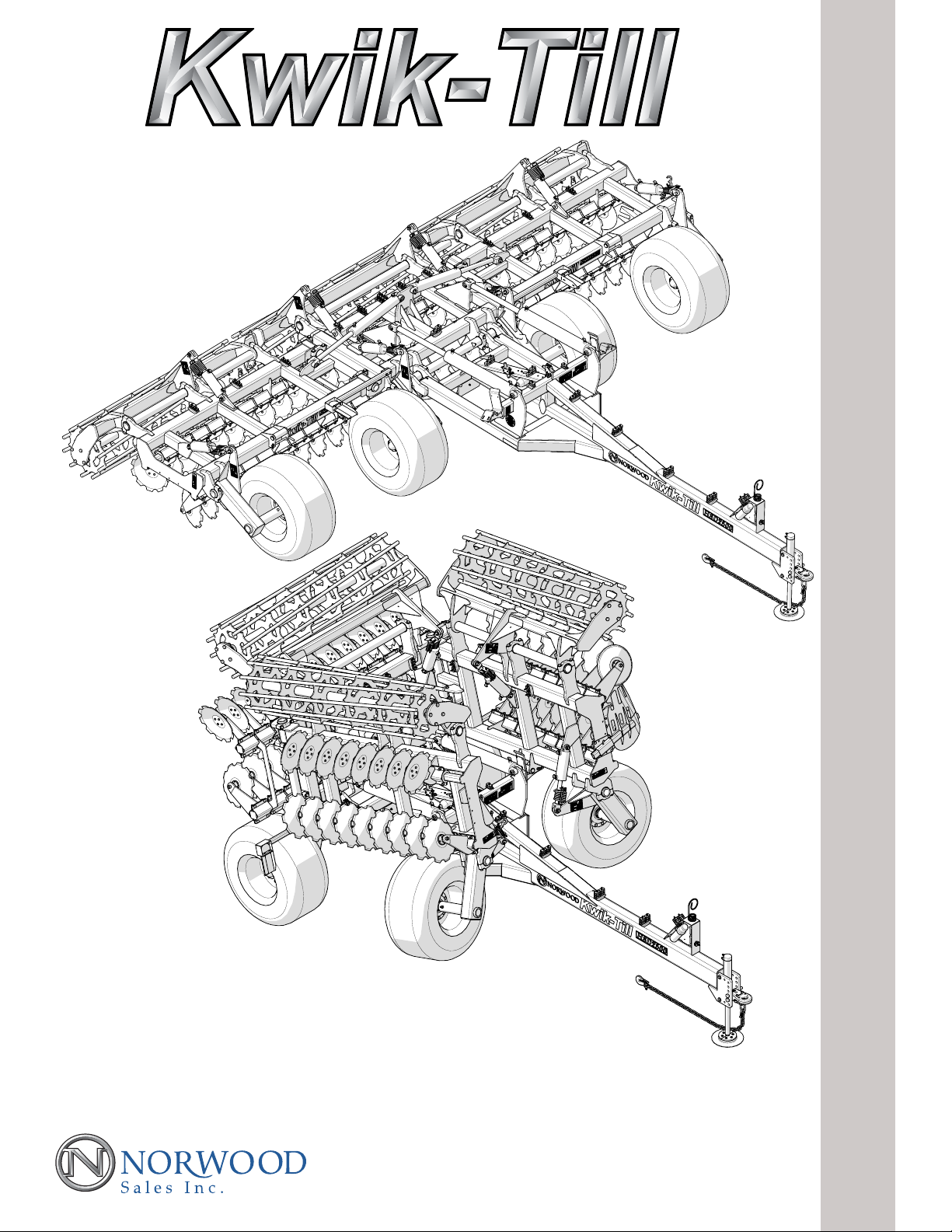

(Kwik-Till 3-Section Drawn High Speed Disk

Model HSD2500 Shown in Transport Position)

Kwik-Till 3-Section Drawn

High Speed Disk

(Kwik-Till 3-Section Drawn High Speed Disk

Model HSD2500 Shown in Field Raised Position)

i

Disclaimer

This document is based on information available at the time of its publication. While eorts have been made to be accurate,

the information contained herein does not purport to cover all details or variations, nor to provide for every possible contin-

gency in connection with installation, operation, or maintenance. Features may be described herein which are not present

in all systems. Norwood Sales Inc. assumes no obligation of notice to holders of this document with respect to changes

subsequently made.

Norwood Sales Inc. makes no representation or warranty, expressed, implied, or statutory with respect to, and assumes no

responsibility for the accuracy, completeness, suciency, or usefulness of the information contained herein. No warranties

of merchantability or tness for purpose shall apply.

Trademark Information

Read and Understand

WARNING

Read and follow all instructions and safety precautions in this

manual and all other manuals for products associated with this

planter as well as in all on-product warning decals. Failure

to do so could result in death or serious injury, or property

damage. Contact your Norwood dealer if any of your manuals

are missing or illegible or you have questions.

Preface

This manual is intended for use with the following Kwik-Till 3-Section Drawn High Speed Disk models:

HSD2500, HSD3000, HSD3500, HSD4000, & HSD4500

Revision History

Issue Date Reasons for Change

55-5-00131 February 20th 2020 Initial Release

Any trademarks not directly mentioned are acknowledged.

ii

Contents

1.0 - GENERAL INFORMATION ....................................................................................................1-1

Note to the Owner.................................................................................................................................................. 1-1

A Message to Our Customers................................................................................................................................ 1-1

Kwik-Till Operator’s Manual Location..................................................................................................................... 1-2

Kwik-Till Model / Serial Number Location ............................................................................................................. 1-2

Determining Left and Right Side of the Machine ................................................................................................... 1-3

Determining Orientation Using Directional Arrows................................................................................................. 1-3

2.0 - SAFETY INFORMATION .......................................................................................................2-1

Safety Rules And Signal Word Denitions ............................................................................................................. 2-1

Personal Safety...................................................................................................................................................... 2-1

Machine Safety ...................................................................................................................................................... 2-1

Safety Rules........................................................................................................................................................... 2-2

General Safety ......................................................................................................................................... 2-2

General Safety Cont’d. .......................................................................................................................... 2-3

Hydraulic Safety ...................................................................................................................................... 2-3

Operating Safety ...................................................................................................................................... 2-4

Prepare for Emergencies ......................................................................................................................... 2-4

Personal Protective Equipment (PPE) ..................................................................................................... 2-4

Lock-Out Tag-Out Safety ......................................................................................................................... 2-5

Non-Permissible Use ............................................................................................................................... 2-5

General Maintenance Safety ................................................................................................................... 2-5

Wheel and Tire Safety ............................................................................................................................. 2-6

Remove Paint Before Welding or Heating

................................................................................................ 2-6

Avoid Heating Near Pressurized Fluid Lines

................................................................................................. 2-6

Avoid Overhead Power Lines .................................................................................................................. 2-7

Use a Signal Person ................................................................................................................................ 2-7

Electrical Storm Safety ............................................................................................................................ 2-7

Working at Heights (If Applicable) ............................................................................................................ 2-7

Noise Level Safety ................................................................................................................................... 2-8

Chemical Safety and the Environment .................................................................................................... 2-8

Handle Chemical Products Safely ........................................................................................................... 2-8

Decommissioning: Proper Recycling and Disposal of Fluids and Components ...................................... 2-9

Use Safety Lights and Devices ................................................................................................................ 2-9

Observe Maximum Transport Speed ....................................................................................................... 2-9

Attaching and Detaching Kwik-Till To / From Tractor Safety .................................................................. 2-10

Use a Safety Chain ................................................................................................................................ 2-10

Tow Loads Safely .................................................................................................................................. 2-11

Keep Riders O Machine ....................................................................................................................... 2-11

Preparing For Transport Safety ............................................................................................................. 2-15

Safety Decals....................................................................................................................................................... 2-17

Safety Decal Locations Cont’d............................................................................................................................. 2-18

Safety Decal Locations Cont’d............................................................................................................................. 2-19

Safety Decal Locations Cont’d............................................................................................................................. 2-20

Important, Notice & Informational Decal Locations ......................................................................................... 2-28

Safety Features.................................................................................................................................................... 2-32

iii

Safety Features Cont’d... ..................................................................................................................................... 2-33

Safety Features Cont’d... ..................................................................................................................................... 2-34

3.0 TRANSPORT OPERATIONS ...................................................................................................3-1

Preparing The Tractor ............................................................................................................................................ 3-2

Use Tractor Operator’s Manual.............................................................................................................................. 3-2

Determine Tractor Requirements........................................................................................................................... 3-2

Hydraulic Requirements......................................................................................................................................... 3-2

Drawbar Requirements .......................................................................................................................................... 3-3

Secure Three-Point Hitch....................................................................................................................................... 3-3

Position Drawbar.................................................................................................................................................... 3-3

Prepare Hydraulic System ..................................................................................................................................... 3-4

Preparing Kwik-Till ................................................................................................................................................. 3-5

Drawbar Requirements .......................................................................................................................................... 3-5

Check Tire Pressure .............................................................................................................................................. 3-7

Check Wheel Hardware ......................................................................................................................................... 3-7

Attaching and Detaching Kwik-Till To/From Tractor ............................................................................................... 3-8

Use Your Tractor and Tillage Equipment Operator’s Manuals ............................................................................... 3-8

Attaching Kwik-Till To Tractor................................................................................................................................. 3-9

Using The Seven-Terminal Outlet ....................................................................................................................... 3-15

Kwik-Till Lighting .................................................................................................................................................. 3-16

Detaching Kwik-Till From Tractor......................................................................................................................... 3-17

4.0 - WORKING OPERATIONS .....................................................................................................4-1

Operating Safety............................................................................................................................................. 4-1

Machine Components (Page 1 of 3) ...................................................................................................................... 4-2

Machine Components (Page 2 of 3) ...................................................................................................................... 4-3

Machine Components Contd. ................................................................................................................................ 4-3

Machine Components (Page 3 of 3) ...................................................................................................................... 4-4

PRE-OPERATION CHECKLIST ............................................................................................................................ 4-5

Hydraulic Hitch Jack Ball Valve.............................................................................................................................. 4-6

Manual Depth Control ............................................................................................................................................ 4-7

Understanding Manual Depth Control.................................................................................................................... 4-7

Understanding Depth Control Components ........................................................................................................... 4-8

Manual Depth Control Procedure .......................................................................................................................... 4-9

Transport Locks ................................................................................................................................................... 4-10

Kwik-Till Unfolding................................................................................................................................................ 4-11

Kwik-Till Folding ................................................................................................................................................... 4-15

Before Entering Field Guidelines ......................................................................................................................... 4-18

Tighten Hardware................................................................................................................................................. 4-18

Leveling the Hitch ................................................................................................................................................ 4-18

Adjusting The Hitch Link ...................................................................................................................................... 4-20

In-Field Operation ................................................................................................................................................ 4-21

Headland Turns & Skipped Passes ..................................................................................................................... 4-22

Adjusting Soil Deector........................................................................................................................................ 4-23

Adjusting Rear Roller Deector............................................................................................................................ 4-24

5.0 MAINTENANCE .......................................................................................................................5-1

General Maintenance Safety ................................................................................................................... 5-1

Hydraulic Safety ...................................................................................................................................... 5-1

Replace Hydraulic Hoses....................................................................................................................................... 5-2

Practice Safe Maintenance .................................................................................................................................... 5-2

Work in Clean Area ................................................................................................................................................ 5-2

Use Safe Service Procedures................................................................................................................................ 5-2

Service Machine Safely ......................................................................................................................................... 5-3

Support Machine Properly ..................................................................................................................................... 5-3

Avoid Sharp Disks.................................................................................................................................................. 5-3

FLUIDS AND LUBRICANTS .................................................................................................................................. 5-4

Hydraulic Oil:.......................................................................................................................................................... 5-4

iv

Grease: .................................................................................................................................................................. 5-4

Greasing ................................................................................................................................................................ 5-4

SERVICING INTERVALS....................................................................................................................................... 5-4

Lubrication Symbols............................................................................................................................................... 5-4

MAINTENANCE CHART........................................................................................................................................ 5-5

Re-Torque Wheel Flange Nuts............................................................................................................................... 5-6

Check Tightness Of All Bolts, & Cap Screws ......................................................................................................... 5-7

Check For Hydraulic Leaks.................................................................................................................................... 5-8

Check For Damaged Hydraulic Hoses, Adapters, Crossovers, Junctions, & Hydraulic Cylinders......................... 5-9

Check Tire Pressures........................................................................................................................................... 5-10

DAILY................................................................................................................................................................... 5-11

Checking / Adjusting Scraper Alignment .............................................................................................................. 5-11

Scraper Blade Replacement & Alignment............................................................................................................ 5-12

Re-Torque Wheel Flange Nuts............................................................................................................................. 5-15

Check Tightness Of All Bolts, & Cap Screws ....................................................................................................... 5-16

Check Pivot Bushings For Wear .......................................................................................................................... 5-17

Check For Gap At Pivot Bushing Caps ................................................................................................................ 5-19

Grease Hitch Link Articulating Ball (If Equipped) ................................................................................................. 5-20

Check Disk Hub Nuts (Re-Torque If Needed) ...................................................................................................... 5-21

Check Disk Shank Cord Alignment ...................................................................................................................... 5-22

Adjusting Disk Shank Cords ................................................................................................................................ 5-22

Lubricate Wheel Hubs.......................................................................................................................................... 5-24

Check Disks For Damage And / Or Excessive Wear ........................................................................................... 5-25

Check Wheel Bearings ........................................................................................................................................ 5-26

Check Disk Hubs For Excessive Wear ................................................................................................................ 5-27

Check Accumulator .............................................................................................................................................. 5-29

Check Rear Roller Hubs For Wear ...................................................................................................................... 5-30

Clean And Wash The Machine............................................................................................................................. 5-31

Replace Pivot Bushings ....................................................................................................................................... 5-32

Repack Wheel Bearings ...................................................................................................................................... 5-33

Replace Rear Roller Hubs ................................................................................................................................... 5-35

SERVICE PROCEDURE: .................................................................................................................................... 5-35

STORAGE............................................................................................................................................................ 5-41

6.0 - TROUBLESHOOTING ...........................................................................................................6-1

Troubleshooting Field Problems ............................................................................................................................ 6-1

7.0 - SPECIFICATIONS..................................................................................................................7-1

Kwik-Till Specications:.......................................................................................................................................... 7-1

Tractor power requirements are shown in the following......................................................................................... 7-1

charts for each specic model of machine and working ........................................................................................ 7-1

Tractor Engine Power Requirements ..................................................................................................................... 7-1

Downward Force on Tractor Drawbar .................................................................................................................... 7-1

Machine Weight ..................................................................................................................................................... 7-1

Transport Width and Height ................................................................................................................................... 7-1

Ground Engaging................................................................................................................................................... 7-2

Disk Blades ............................................................................................................................................................ 7-2

Rear Attachments .................................................................................................................................................. 7-3

Tire Specications.................................................................................................................................................. 7-3

Torque – Hydraulic Tubes and Fittings................................................................................................................... 7-4

Torque – Fasteners ................................................................................................................................................ 7-5

8 - FORMS AND DECLARATIONS ................................................................................................8-1

1-1

1 - GENERAL INFORMATION

Fig. # 1-1 Kwik-Till 3-Section Drawn High Speed Disk

must be borne solely by the user. Compliance with and strict

adherence to the conditions of operation, service and repair

as specied by the manufacturer also constitute essential

elements for the intended use.

DO NOT use this machine for any purpose or in any manner

other than as described in the manual, decals, or other product

safety information provided with the machine. These materials

dene the machine's intended use.

Use only approved accessories and attachments designed

for your machine.

Consult your dealer on changes, additions or modications

that may be required for your machine.

DO NOT make any unauthorized modifications to your

machine. Any arbitrary modications carried out on this

machine will relieve the manufacturer of all liability for any

resulting damage or injury.

A Message to Our Customers

We appreciate the condence placed in us by the purchase

of this machine. To ensure that the machine performs at the

highest level, countless hours were spent designing and

testing, before this machine was produced. To achieve the

maximum performance, it is imperative that this machine is

operated in accordance with the procedures outlined in this

manual.

1.0 - GENERAL INFORMATION

Note to the Owner

This manual contains important information about the safe

operation, adjustment, and maintenance of your Kwik-Till

3-Section Drawn High Speed Disk. This manual should be

considered a permanent part of your machine and should

remain with the machine if you sell it.

Refer to the table of contents at the beginning or the Index

at the end of this manual for locating specic items about

your machine.

DO NOT operate or permit anyone to operate or service this

machine until you or the other persons have read this manual.

Use only trained operators who have demonstrated the ability

to operate and service this machine correctly and safely.

All persons who will be operating this machine shall possess

applicable local age work permits.

This Kwik-Till, with standard equipment and authorized

options, is intended to be used in customary agricultural or

similar operations for the purpose of tilling ground soil for

seed bed preparation and residue incorporation (“INTENDED

USE”). Use in any other way is considered as contrary to

the intended use. The manufacturer accepts no liability for

damage or injury resulting from this misuse, and these risks

1-2

1 - GENERAL INFORMATION

Kwik-Till Operator’s Manual Location

This Operator’s manual is to be stored in the “Operator’s

Manual Canister” on the right side of the machine on the

hose holder bracket for reference during eld operation. (See

Fig. # 1-2) Make sure this manual is complete and in good

condition. Contact your dealer to obtain additional manuals

and approved service parts. Your dealer has technicians

with special training that know the best methods of repair and

maintenance for your Kwik-Till.

Owner’s

Manual

Canister

Fig. # 1-2 Locating The Operator’s Manual Canister

Kwik-Till Model / Serial Number Location

Always give your authorized Kwik-Till dealer the Model

Number, and Serial Number of your Kwik-Till product when

ordering parts, requesting service, or any other information

to provide the most ecient service.

The Serial Number location is identied below. (See Fig. #

1-3)

Fig. # 1-3 Locating The Serial Number Plate

Serial Number

Plate

The Model Number location is indicated below. (See Fig.

# 1-4)

Fig. # 1-4 Locating Model Number Decal

Model Number

Decal

Make a copy of the number below and keep in a safe place.

If the machine is stolen, report the numbers to your local law

enforcement agency.

Write the Model Number, Serial Number, & Date Of Pur-

chase on the lines provided.

Model Number: _________________________________

Serial Number: _________________________________

Date Of Purchase: _______________________________

1-3

1 - GENERAL INFORMATION

Determining Left and Right Side of the Machine

Operator Orientation - The directions Front (1), Back (2), Left (3), and Right (4) as mentioned throughout the manual, are

determined when standing at the discharge spout and looking toward the intake hopper.

Determining Orientation Using Directional Arrows

The symbols shown below, may be illustrated on certain pages in this manual, and where indicated, determine the front of

the machine.

4

2

3

1

Fig. # 1-5

1-4

1 - GENERAL INFORMATION

This Page Is Intentionally Left Blank

2 - SAFETY INFORMATION

2-1

2.0 - SAFETY INFORMATION

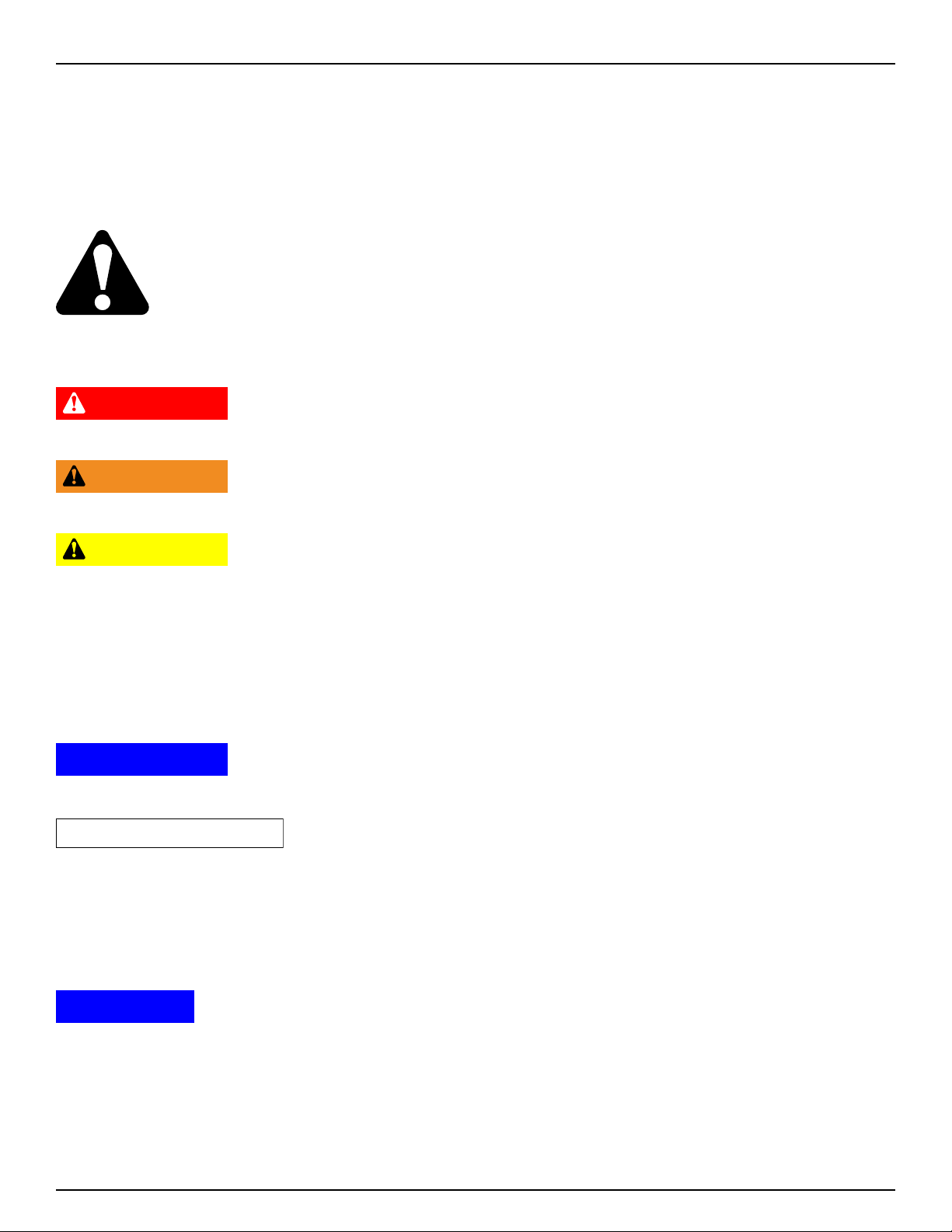

Safety Rules And Signal Word Denitions

Personal Safety

This is the safety alert symbol. It is used to alert you to potential personal injury hazards. Read and understand

all the safety messages in this manual and associated equipment manuals before you operate or service the

machine. Obey all safety messages that follow this symbol to avoid possible death or serious injury.

Throughout this manual and on machine decals, you will nd the signal words DANGER, WARNING, and CAUTION followed

by special instructions. These precautions are intended for the personal safety of you and those working with you.

DANGER

DANGER; Indicates a hazardous situation which, if not avoided, will result in death or serious

injury. The color associated with DANGER on the machine decals is RED.

WARNING

WARNING; Indicates a hazardous situation which, if not avoided, could result in death or serious

injury. The color associated with WARNING on the machine decals is ORANGE.

CAUTION

CAUTION; Used with the safety alert symbol, indicates a hazardous situation which, if not avoided,

could result in minor or moderate injury. CAUTION may also be used to alert against unsafe practices associated with events

which could lead to personal injury. The color associated with CAUTION on the machine decals is YELLOW.

FAILURE TO FOLLOW DANGER, WARNING, AND CAUTION MESSAGES COULD RESULT IN

DEATH OR SERIOUS INJURY.

Machine Safety

NOTICE

Notice indicates a situation which, if not avoided, could result in machine or property damage. The

color associated with Notice on the machine decals is BLUE.

IMPORTANT

Important indicates a situation which, if not avoided, could result in machine or property

damage. The color associated with Important on the machine decals is WHITE.

Throughout this manual you will nd the signal word Notice followed by special instructions to prevent machine or property

damage. The word Notice is used to address practices not related to personal safety.

Information

NOTE

Note indicates additional information which claries steps, procedures, or other information in this manual.

Throughout this manual you will nd the word Note followed by additional information about a step, procedure, or other

information in the manual. The word Note is not intended to address personal safety or property damage.

2 - SAFETY INFORMATION

2-2

Safety Rules

Read Entire Section Before Use.

Understand that your safety and the safety of other persons

is measured by how you service and operate this machine.

Know the positions and operations of all controls before you

try to operate. MAKE SURE YOU CHECK ALL CONTROLS

IN A SAFE AREA BEFORE STARTING YOUR WORK.

READ THIS MANUAL COMPLETELY AND MAKE SURE

YOU UNDERSTAND THE CONTROLS. All equipment has

a limit. Make sure you understand the stability and load

characteristics of this machine before you start to operate.

NOTE: Safety messages in this section point out specic

safety hazards which can be encountered during the normal

operation and maintenance of your machine. These safety

messages also give possible ways of dealing with these

conditions.

The safety information given in this manual does not replace

safety codes, insurance needs, federal, state and local laws.

Make sure your machine has the equipment required by the

local laws and regulations.

Owners must give operating instruc tions to operators or

employees before allowing them to operate the machine, and

at least annually thereafter per OSHA (Occupational Safety

and Health Administration) regulation 1928.57.

The most important safety device on this equipment is a SAFE

operator. It is the operator’s responsibility to read and under-

stand ALL Safety and Operating instructions in the manual

and to follow them. All acci dents can be avoided.

A person who has not read and understood all operating and

safety instructions is not qualied to operate the machine.

An untrained operator exposes himself and bystanders to

possible serious injury or death.

Additional safety messages are used in the text of the manual

to indicate specic safety hazards. See your dealer for more

information if you have any questions.

Use caution when operating the machine on slopes. Raised

equipment, partially full or full conveyor belt and other loads

will change the center of gravity of the machine. The machine

can tip or roll over when near ditches and embankments or

uneven surfaces.

Travel speed must be such that complete control and machine

stability is maintained at all times. Reduce speed when

turning, crossing slopes and when on rough, slick or muddy

surfaces.

Never permit anyone to ride on any part of the machine.

Some illustrations in this manual will show shields or cover

panels removed for purposes of clarity. DO NOT operate this

machine with any of the shields or cover panels removed.

Never operate the machine under the inuence of alcohol,

drugs or while otherwise impaired.

Pay attention to overhead power lines and hanging obstacles.

High voltage lines may require signicant clearance for safety.

Contact local authorities or utilities to obtain safe clearance

distances from high voltage power lines.

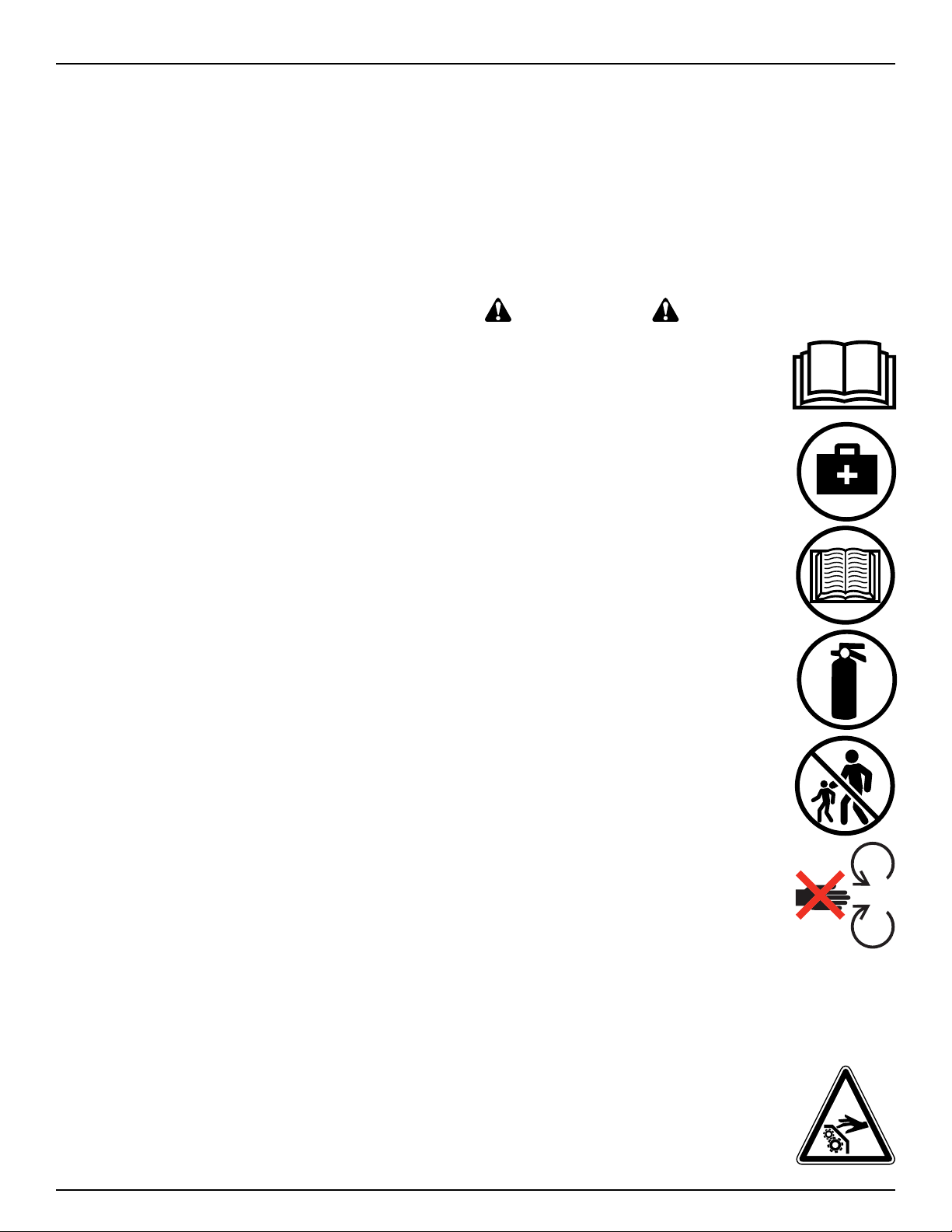

General Safety

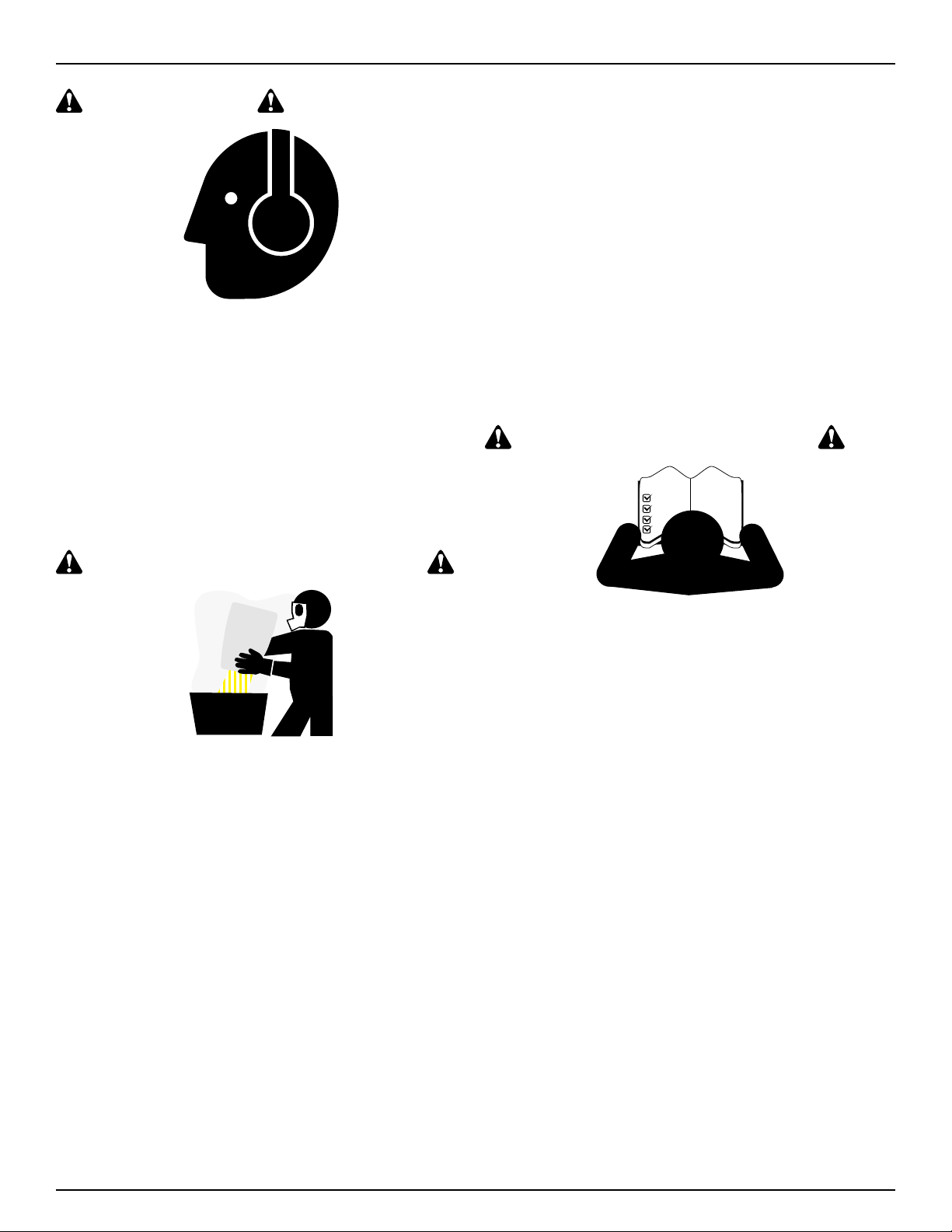

Read and understand the Operator’s Man-

ual and all safety decals before operating,

maintaining, adjusting or unplugging.

Have a rst-aid kit available for use should

the need arise and know how to use it.

Only trained persons shall operate the ma-

chine. An untrained operator is not qualied

to operate the machine.

Provide a re extinguisher for use in case of

an accident. Store in a highly visible place.

Do not allow children, spectators or by-

standers within hazard area of machine.

Keep clear of moving parts. Loose clothing,

jewelry, watches, long hair and other loose or

hanging items should be avoided as they can

become entangled in moving parts.

Wear personal protective equipment when appropriate.

DO NOT attempt to remove material from any part of the

machine while it is being operated or components are in

motion.

Make sure all guards and shields are in

good condition and properly installed before

operating the machine. Never operate the

machine with shields removed. Always close

access doors or panels before operating the

machine.

2 - SAFETY INFORMATION

2-3

General Safety Cont’d.

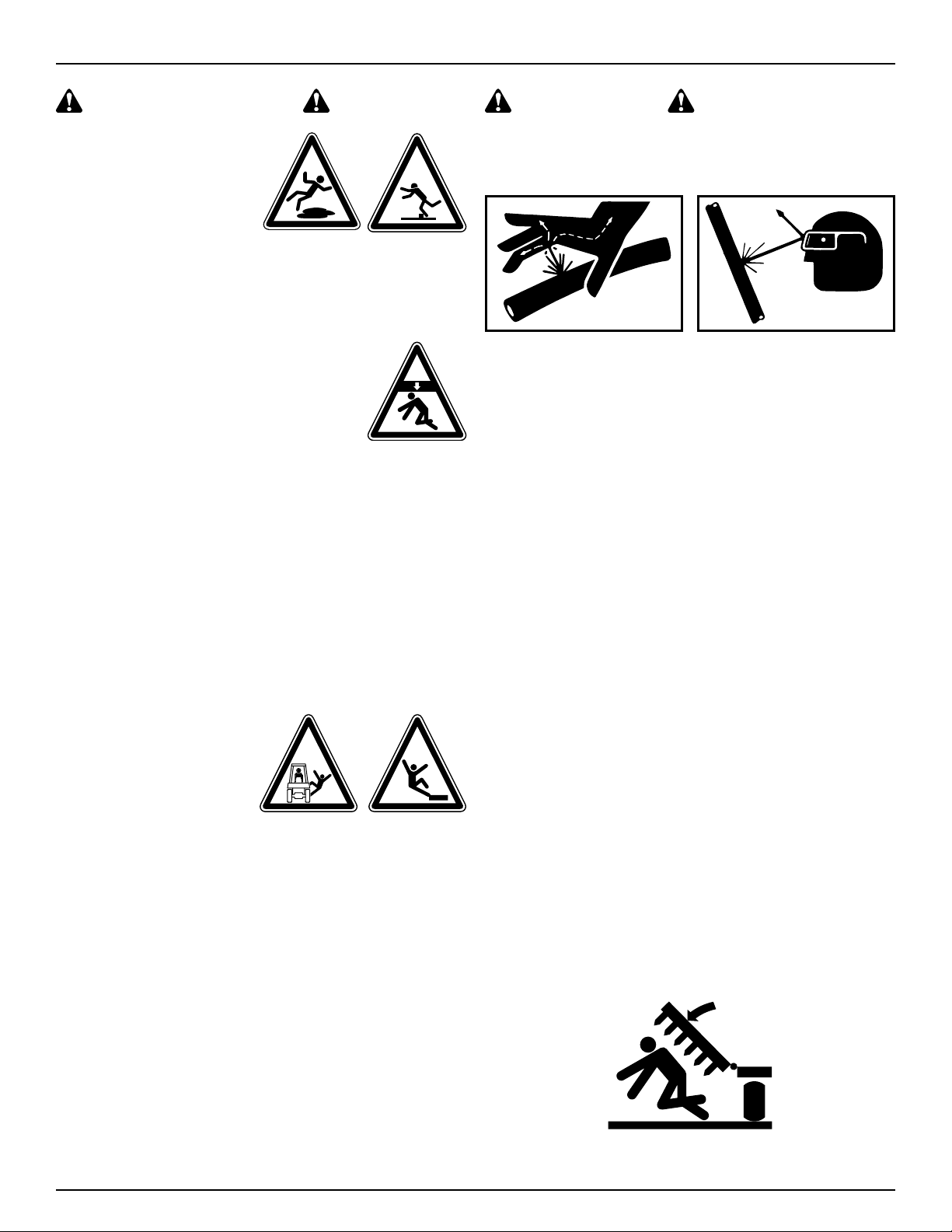

Dirty or slippery steps,

ladders, walkways and

platforms can cause falls.

Make sure these surfaces

remain clean and clear of

debris.

A person or pet within the operating area of a machine can be

struck or crushed by the machine or its equipment.

DO NOT allow anyone to enter the work area.

Raised equipment and/or loads can fall

unexpectedly and crush persons underneath.

Never allow anyone to enter the area

underneath raised equipment at any time.

Always use a safety support when working on,

under, or around machine. Transport/Service

locks can be used for this purpose. Shut o tractor engine

and remove key when working on machine. If air has been

allowed to enter hydraulic hoses or cylinders, bleed hydraulic

system before use. If there is a failure in hydraulic system,

unsupported raised equipment could suddenly lower, causing

serious personal injury or death. If support is not available,

completely lower wings and frame, relieve hydraulic pressure

and disconnect hoses from tractor.

Review this manual and any other associated manuals before

each season of use.

Use extreme care when cleaning, or servicing the machine.

Keep riders o. Riders on

the implement or tractor

are subject to injury such

as being struck by foreign

objects and being thrown o

of the machine.

Hydraulic Safety

Hydraulic oil leaking under pressure can penetrate the skin,

causing death or serious injury, or infection.

DO NOT use your hand to check for leaks. Use a piece of

cardboard or plywood.

Stop engine, remove key and relieve the pressure before

connecting or disconnecting uid lines.

Make sure all components are in good condition and tighten

all connections before starting the engine or pressurizing the

system.

Do not attempt any makeshift repairs to the hydraulic ttings

or hoses by using tape, clamps or cements. The hydraulic

system operates under extremely high-pressure. Such repairs

will fail suddenly and create a hazardous and unsafe condition.

Replace any worn, cut, abraded, attened or crimped hoses.

If hydraulic uid penetrates the skin, seek medical attention

immediately. Any uid injected into the skin must be surgically

removed within a few hours or gangrene may result. Doctors

unfamiliar with this type of injury should reference a

knowledgeable medical source.

Continuous long term contact with hydraulic uid may cause

skin cancer. Avoid long term contact and wash the skin

promptly with soap and water.

Avoid serious injury or death while working under a raised

implement. Hydraulic hoses between the lift cylinders and

hydraulic lockup valves should be inspected frequently for

leakage, kinking, cuts, cracks, abrasion, blisters, corrosion,

exposed wire braid, or any other signs of wear or damage.

Worn or damaged hose assemblies can malfunction during

use and should be replaced immediately.

See your Kwik-Till dealer for replacement hoses.

2 - SAFETY INFORMATION

2-4

Operating Safety

1. Read and understand the Operator’s Manual and all safety

decals before using.

2. Park on a level surface, engage park brake, place trans-

mission in PARK, shut o engine, remove key, and wait

for all moving parts to stop before leaving tractor cab.

3. Clear the area of bystanders, especially children, before

starting.

4. Be familiar with the machine hazard area. If anyone enters

hazard area, shut down machine immediately. Clear the area

before restarting.

5. Keep hands, feet, hair and clothing away from all moving and/

or rotating parts.

6. Keep riders o. Riders on the implement are subject to

injury such as being struck by foreign objects and being

thrown o of the machine.

7. Stay away from overhead obstructions and power lines during

operation and transporting. Electrocution can occur without

direct contact.

8. Be sure that area around machine is clear before raising or

lowering machine frame or wings.

9. Do not operate with wings partially folded.

10. Do not operate close to the edge of a ditch, creek, gully, or

steep embankment.

11. Avoid holes, ditches, and obstructions which can cause trac-

tor, machine, or towed equipment to roll over, especially on

hillsides.

12. Avoid sharp turns on hillsides.

13. Slow down when turning or traveling over rough ground and

when turning on inclines.

14. Always shut o tractor and shift to park or set brakes when

leaving tractor. Remove key when leaving tractor unattended.

15. Always have tractor stopped on level ground when raising or

lowering wings.

16. Operate machine from tractor seat only.

17. If chemicals are used, follow manufacturer’s recommendations

for their handling and storage.

18. Tow machine behind a properly equipped tractor only.

Prepare for Emergencies

911

Be prepared if a re starts.

Keep a rst aid kit and re extinguisher handy.

Keep emergency numbers for doctors, ambulance service,

hospital, and re department near your telephone.

Personal Protective Equipment (PPE)

Wear personal protective equipment. This list Includes but

is not limited to:

• A hard hat

• Protective shoes with slip resistant shoes

• Safety glasses or goggles

• Heavy gloves

• Hearing protection

• Respirator or lter mask

• Protective clothing

• A face shield (when grinding)

2 - SAFETY INFORMATION

2-5

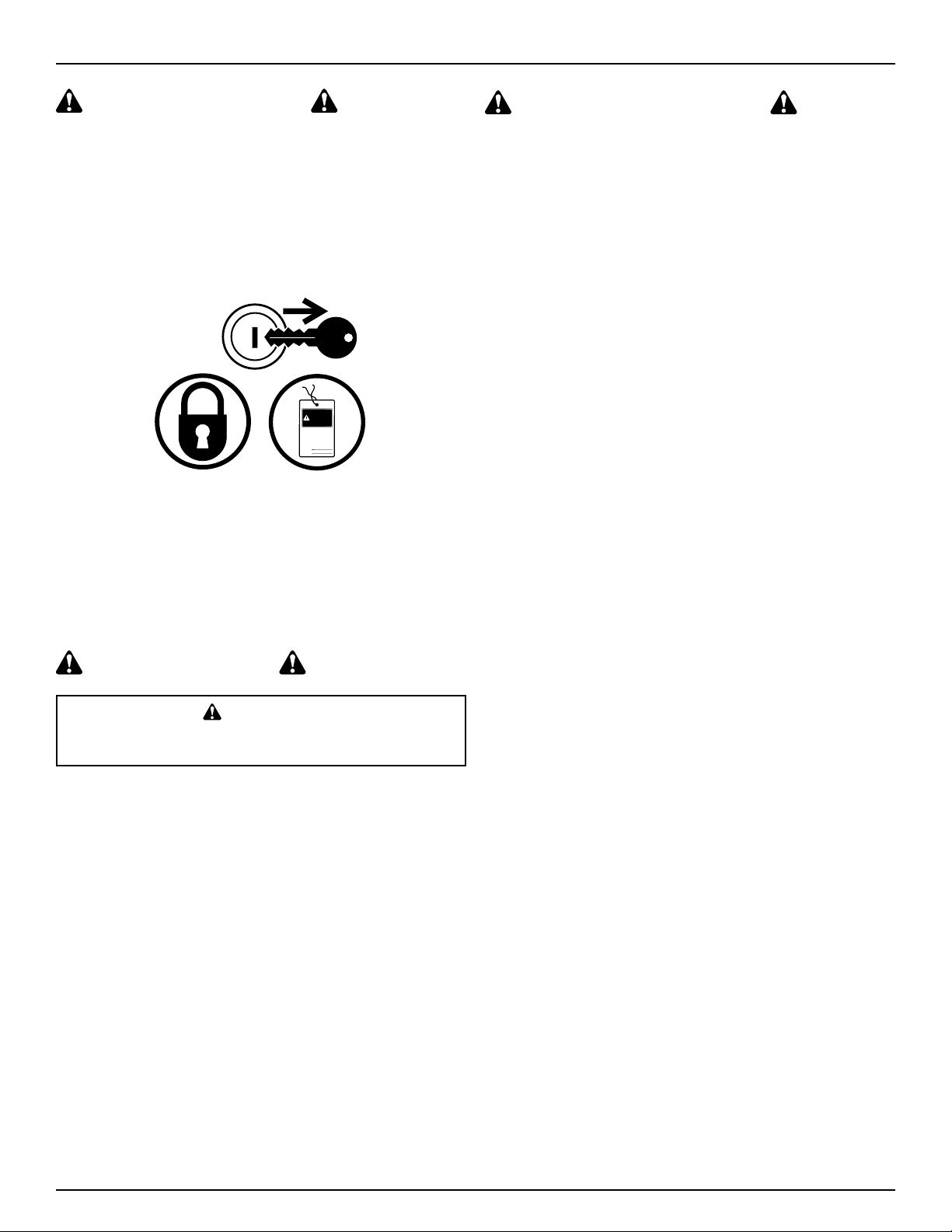

Lock-Out Tag-Out Safety

Before you start servicing the machine:

If machine is connected to a tractor, Park on a level surface,

engage park brake, place transmission in PARK, shut o

engine, remove key, and wait for all moving parts to stop

before leaving tractor cab.

If machine is detached from tractor, block wheels and use

safety stands to prevent movement.

Attach a “Do Not Operate” warning tag to the machine in an

area that will be visible.

do not

operate

signed by

date

WARNING

1. Establish a formal Lock-Out Tag-Out program for your

operation.

2. Train all operators and service personnel before allowing

them to work around the area.

3. Provide tags on the machine and a sign-up sheet to record

tag out details.

Non-Permissible Use

CAUTION

Working on an uncleaned and non-maintained machine

poses unnecessary danger and is therefore forbidden.

Pay attention to the following applications for which the

machine is not suitable:

Machine usage in non-customary tillable agricultural elds,

such as forests, dirt, gravel, or other roads.

Machine usage to move large rocks from elds.

General Maintenance Safety

1. Review the Operator’s Manual and all safety items before

working with, maintaining or operating the Kwik-Till.

2. If machine is connected to a tractor, Park on a level sur-

face, engage park brake, place transmission in PARK,

shut o engine, remove key, and wait for all moving parts

to stop before leaving tractor cab.

If machine is detached from tractor, block wheels and use

safety stands to prevent movement.

3. Do not attempt to clean, lubricate, clear obstructions or make

adjustments to the machine while it is in motion or while the

engine is running.

4. Follow good shop practices:

- Keep service area clean and dry.

- Be sure electrical outlets and tools are properly

grounded.

- Use adequate light for the job at hand.

5. Before applying pressure to a hydraulic system, make sure

all components are tight and that hoses and couplings are

in good condition.

6. Relieve pressure from hydraulic circuit before servicing or

disconnecting from tractor.

7. Clear the area of bystanders, especially children, when

carrying out any maintenance and repairs or making any

adjustments.

8. Place stands or blocks under the frame before working

beneath the machine.

9. Before resuming work, install and secure all guards when

maintenance work is completed.

10. Keep safety decals clean. Replace any decal that is dam-

aged or not clearly visible.

11. Always make sure working area is clear of tools, parts, other

persons and pets before you start operating the machine.

12. Chock wheels.

13. On towed implements, disconnect wiring harnesses from

tractor before servicing electrical system components or

welding on machine.

2 - SAFETY INFORMATION

2-6

Wheel and Tire Safety

Make sure tires are correctly inated. Do not exceed recommended

load or pressure. Follow instructions in the manual for proper tire

ination.

Always have a qualied tire technician service the tires and rims.

If a tire has lost all pressure, take the tire and rim to a tire shop

or your dealer for service. Explosive separation of the tire can

cause death or serious injury.

• DO NOT attempt to mount a tire unless you have the proper

equipment and experience to do the job. Failure to follow

proper procedures when mounting a tire on a wheel or rim

can produce an explosive separation, which may result in

serious injury or death.

• Have a qualied tire dealer or repair service perform required

tire maintenance.

• When replacing worn tires, make sure they meet the original

tire specications. Never undersize the replacement tire.

• DO NOT weld on the tire rim with the tire

mounted on the rim. The heat can cause an

increase in air pressure, resulting in a tire

explosion which could result in serious in-

jury or death. Also welding can structurally

weaken or deform the wheel.

• Inate tires to the manufacturer’s recom-

mended pressure.

• Tires should not be operated at speeds higher than their

rated speed.

• Keep wheel lug nuts tightened to manufac-

turer’s recommendations.

• Never reinate a tire that has been run at or seriously un-

der-inated without removing the tire from the wheel. Have

the tire and wheel closely inspected for damage before

remounting.

Remove Paint Before Welding or Heating

Avoid potentially toxic fumes and dust.

Hazardous fumes can be generated when paint is heated by

welding, soldering, or using a torch.

Remove paint before heating:

• Remove paint a minimum of 100 mm (4 in.) from area to

be aected by heating. If paint cannot be removed, wear

an approved respirator before heating or welding.

• If you sand or grind paint, avoid breathing the dust. Wear

an approved respirator.

• If you use solvent or paint stripper, remove stripper with

soap and water before welding. Remove solvent or paint

stripper containers and other ammable material from

area. Allow fumes to disperse at least 15 minutes before

welding or heating.

• Do Not use a chlorinated solvent in areas where welding

will take place.

• Do all work in an area that is well ventilated to carry toxic

fumes and dust away.

• Dispose of paint and solvent properly.

Avoid Heating Near Pressurized Fluid Lines

Flammable spray can be generated by heating near pres-

surized uid lines, resulting in severe burns to yourself and

bystanders. Do not heat by welding, soldering, or using a

torch near pressurized uid lines or other ammable materi-

als. Pressurized lines can accidentally burst when heat goes

beyond the immediate ame area.

2 - SAFETY INFORMATION

2-7

Avoid Overhead Power Lines

CAUTION

Keep away from overhead power lines.

Serious injury or death can result. Proceed

cautiously under overhead power lines and

around utility poles. Know the transport

height of your machine. Electrocution can

occur without direct contact with overhead

electrical lines.

Use a Signal Person

Use a signal person to direct movement of the tractor/im-

plement combination whenever the tractor operator’s view

is obstructed.

Designate one individual as the signal person. Always have

signal person stand in clear view. Be sure that signal per-

son stays a safe distance away from the machine when it is

moving.

Before starting the tractor, discuss hand signals and what

each signal means to avoid misunderstandings and confu-

sion, which could result in a serious injury or fatal accident

for someone.

Keep all bystanders away whenever the machine is moved.

Electrical Storm Safety

Do not operate machine during an electrical storm.

If you are on the ground during an electrical storm, stay away

from machinery and equipment. Seek shelter in a permanent,

protected structure.

If an electrical storm should strike during operation, remain in the

cab. Do not leave the cab. Do not make contact with the ground

or objects outside the machine.

Working at Heights (If Applicable)

Do not stand on surfaces which are not designed as steps or

platforms.

Do not use the machine as a lift, ladder or platform for working

at heights.

2 - SAFETY INFORMATION

2-8

Noise Level Safety

There are many variables that aect the sound level range,

including machine conguration, condition and maintenance

level of the machine, ground surface, operating environmental,

duty cycles, ambient noise, and attachments.

Exposure to loud noise can cause impairment or loss of

hearing.

Always wear hearing protection. Wear a suitable hearing

protective device such as earmus or earplugs to protect

against objectionable or uncomfortable loud noises.

Chemical Safety and the Environment

Soil, air, and water are vital factors of agriculture and life in

general. When legislation does not yet rule the treatment of some

of the substances which are required by advanced technology,

sound judgment should govern the use and disposal of products

of a chemical and petrochemical nature.

NOTICE: The following are recommendations which may be of

assistance:

• Become acquainted with and ensure that you understand

the relative legislation applicable to your country.

• Where no legislation exists, obtain information from suppliers

of oils, lters, batteries, fuels, antifreeze, cleaning agents,

etc., with regard to their eect on man and nature and how

to safely store, use and dispose of these substances.

• Agricultural consultants will, in many cases, be able to help

you as well.

Helpful Hints

• Avoid lling tanks using cans which may cause considerable

spillage.

• In general, avoid skin contact with all fuels, oils, acids, sol-

vents, etc. Most of them contain substances which may be

harmful to your health.

• Modern oils contain additives. Do not burn contaminated

fuels and or waste oils in ordinary heating systems.

• Avoid spillage when draining o used gearbox and hydraulic

oils, etc. Do not mix drained uids with lubricants. Store

drained uids safely until they can be disposed of properly

to comply with local legislation and available resources.

• Repair any leaks or defects in the hydraulic system imme-

diately.

• Do not increase the pressure in a pressurized circuit as this

may lead to a component failure.

• Protect hoses during welding as penetrating weld splatter

may burn a hole or weaken them, allowing the loss of hy-

draulic uid.

Handle Chemical Products Safely

M

S

D

S

Direct exposure to hazardous chemicals can cause serious

injury. Potentially hazardous chemicals used with Kwik-Till

equipment include such items as lubricants, uids, paints,

and adhesives.

A Material Safety Data Sheet (MSDS) provides specic details

on chemical products: physical and health hazards, safety

procedures, and emergency response techniques.

Check the MSDS before you start any job using a hazardous

chemical. That way you will know exactly what the risks are

and how to do the job safely. Then follow procedures and

recommended equipment.

(See your Kwik-Till dealer for MSDS’s on chemical products

used with Kwik-Till equipment.)

2 - SAFETY INFORMATION

2-9

Decommissioning: Proper Recycling and

Disposal of Fluids and Components

Safety and environmental stewardship measures must be

taken into account when decommissioning a machine and/or

component. These measures include the following:

• Use appropriate tools and personal protective equipment

such as clothing, gloves, face shields or glasses, during

the removal or handling of objects and materials.

• Follow instructions for specialized components.

• Release stored energy by lowering suspended machine

elements, relaxing springs, disconnecting the battery or

other electrical power, and releasing pressure in hydraulic

components, accumulators, and other similar systems.

• Minimize exposure to components which may have res-

idue from agricultural chemicals, such as fertilizers and

pesticides. Handle and dispose of these components

appropriately.

• Carefully drain engines, fuel tanks, radiators, hydraulic

cylinders, reservoirs, and lines before recycling compo-

nents. Use leak-proof containers when draining uids. Do

not use food or beverage containers.

• Do not pour waste uids onto the ground, down a drain,

or into any water source.

• Observe all national, state, and local laws, regulations, or

ordinances governing the handling or disposal of waste

uids (example: oil, fuel, coolant, brake uid); lters;

batteries; and, other substances or parts. Burning of

ammable uids or components in other than specially

designed incinerators may be prohibited by law and could

result in exposure to harmful fumes or ashes.

• Service and dispose of air conditioning systems appro-

priately. Government regulations may require a certied

service center to recover and recycle air conditioning re-

frigerants which could damage the atmosphere if allowed

to escape.

• Evaluate recycling options for tires, metal, plastic, glass,

rubber, and electronic components which may be recy-

clable, in part or completely.

• Contact your local environmental or recycling center, or

your Kwik-Till dealer for information on the proper way to

recycle or dispose of waste.

Use Safety Lights and Devices

Prevent collisions between other road users, slow moving

tractors with attachments or towed equipment, and self-pro-

pelled machines on public roads. Frequently check for trac

from the rear, especially in turns, and use turn signal lights.

Use headlights, ashing warning lights, and turn signals day

and night. Follow local regulations for equipment lighting

and marking. Keep lighting and marking visible, clean, and

in good working order. Replace or repair lighting and mark-

ing that has been damaged or lost. An implement safety

lighting kit is available from your Kwik-Till dealer.

Observe Maximum Transport Speed

The maximum transport speed for this implement is 20

mph (32 km/h).

Some tractors are capable of operating at speeds that exceed

the maximum transport speed of this implement. Regardless

of the maximum speed capability of the tractor being used to

tow this implement, do not exceed the implement’s maximum

transport speed.

Exceeding the implement’s maximum transport speed can

result in:

• Loss of control of the tractor/implement combination.

• Reduced or no ability to stop during braking.

• Implement tire failure.

• Damage to the implement structure or its components.

2 - SAFETY INFORMATION

2-10

Use additional caution and reduce speed when towing un-

der adverse surface conditions, when turning, and when on

inclines.

Do Not attempt transport if the fully loaded implement weighs

more than 1.5 t (3,300 lb) and more than 1.5 times the weight

of the tractor.

CAUTION

Never tow this implement with a motor vehicle. Tow

only with a properly ballasted tractor.

Attaching and Detaching Kwik-Till To / From

Tractor Safety

Never let another person stand between the tractor and the

implement during hitching. Too fast of an approach or the

operator’s foot slipping from the clutch can lead to injury or

death to the person standing nearby.

DANGER

UPENDING HAZARD

TONGUE CAN WHIP UPWARDS WHEN UNHITCHING

The tractor MUST be equipped with a clevis hitch to

prevent the Kwik-Till from tipping upward while unfolding

from transport position, and folding into transport position.

To avoid bodily injury, lower the machine before removing

the hitch pin.

If negative tongue weight exists, the hitch tongue may

suddenly raise, and the rear section would come crash-

ing down. Only disconnect when the jack is lowered,

there is positive tongue weight, the unit is on level

ground, and in the proper transport or eld position.

Never disconnect the Kwik-Till from the tractor if the rear sec-

tions of the machine are partially raised. Keep others away.

DANGER

CRUSH HAZARD

Stand clear when raising or lowering the Kwik-Till.

Keep feet, legs, and body clear when raising and lowering

the Kwik-Till. Keep others away.

DANGER

CRUSH HAZARD

Avoid being crushed in between the tractor and the

implement.

When working in the danger area between the Kwik-Till

and the tractor always ensure that the Tractor engine is

turned o and the Key removed. Keep others away.

Use a Safety Chain

This manual suits for next models

4

Table of contents

Other Norwood Farm Equipment manuals

Popular Farm Equipment manuals by other brands

Schaffert

Schaffert Rebounder Mounting instructions

Stocks AG

Stocks AG Fan Jet Pro Plus 65 Original Operating Manual and parts list

Cumberland

Cumberland Integra Feed-Link Installation and operation manual

BROWN

BROWN BDHP-1250 Owner's/operator's manual

Molon

Molon BCS operating instructions

Vaderstad

Vaderstad Rapid Series instructions