Norwood The Grain Handler 8 User manual

P/N 10-5-00007

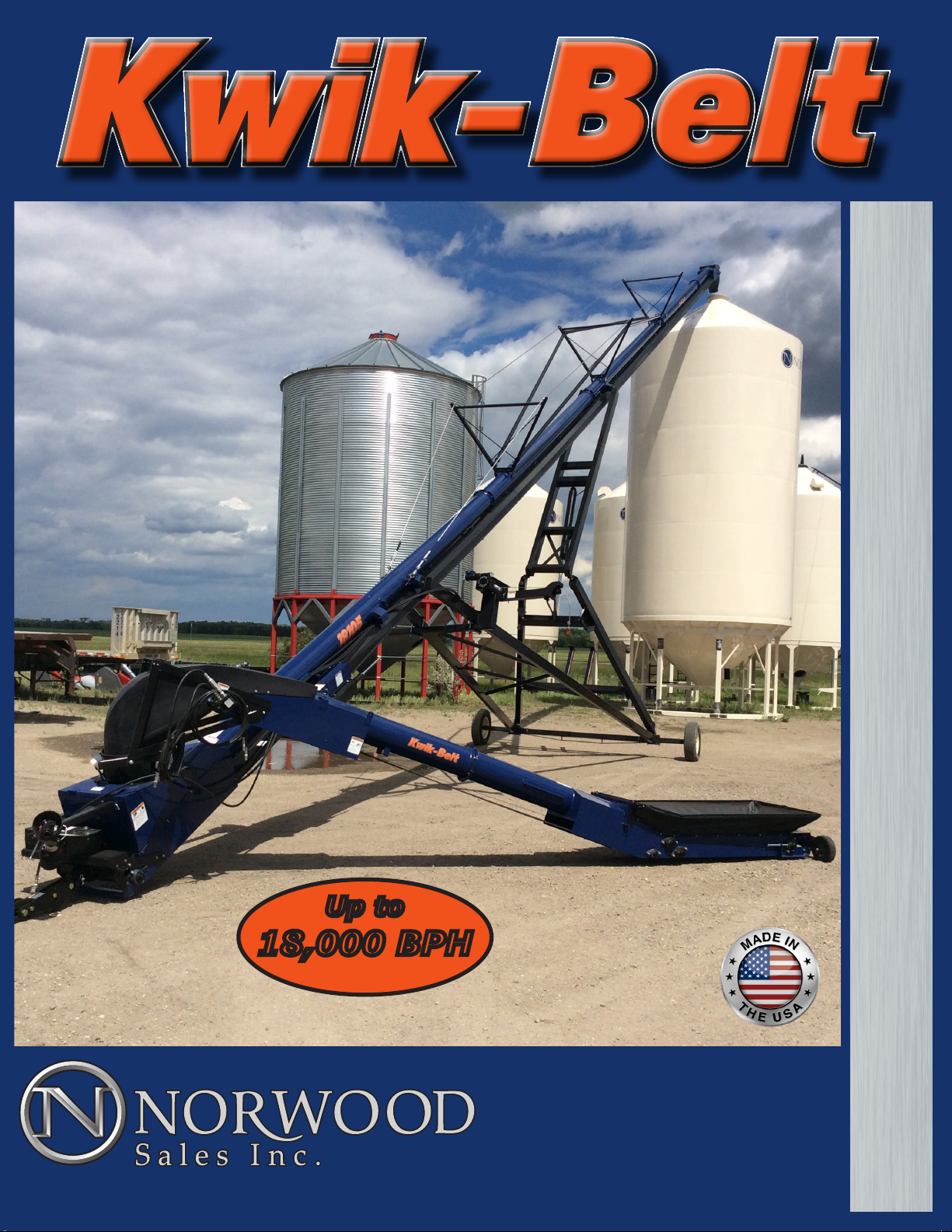

The Grain Handler

U-Trough Power Sweep

Operator’s Manual

Models: 8” & 10” U-Trough Power Sweeps

Sizes 18’ 19’ 21’ 24’ 27’ 30’ 33’ 36’ 42’ 48’ 54’ 60’

Optional Equipment

(Kwik-Belt Top Drive

Field Loader

Model 1843)

(The Grain Handler

U-Trough 10” X 48’

Power Sweep Shown)

Horace, ND : 701.588.4000Horace, ND : 701.588.4000

Cooperstown, ND : 701.797.3684Cooperstown, ND : 701.797.3684

Union, NE : 402.263.2100Union, NE : 402.263.2100

www.Norwoodsales.com 1.800.446.0316www.Norwoodsales.com 1.800.446.0316

Belt Conveyors & AccessoriesBelt Conveyors & Accessories

8SWR

%3+

•• Larger Capacity, Non-Leaking TransitionLarger Capacity, Non-Leaking Transition

•• Controlled Vertical Discharge FlowControlled Vertical Discharge Flow

•• Larger Heavy Duty PEER BearingsLarger Heavy Duty PEER Bearings

•• Heavier Duty UndercarriageHeavier Duty Undercarriage

•• Thicker Walled TubingThicker Walled Tubing

•• Wider Conveyor BeltsWider Conveyor Belts

(50% higher capacity than(50% higher capacity than

similar sized tubes)similar sized tubes)

Kwik Belt Literature Rev C.indd 1Kwik Belt Literature Rev C.indd 1 5/27/2021 9:44:33 AM5/27/2021 9:44:33 AM

i

Disclaimer

This document is based on information available at the time of its publication. While eorts have been made to be accurate,

the information contained herein does not purport to cover all details or variations, nor to provide for every possible contin-

gency in connection with installation, operation, or maintenance. Features may be described herein which are not present

in all systems. Norwood Sales Inc. assumes no obligation of notice to holders of this document with respect to changes

subsequently made.

Norwood Sales Inc. makes no representation or warranty, expressed, implied, or statutory with respect to, and assumes no

responsibility for the accuracy, completeness, suciency, or usefulness of the information contained herein. No warranties

of merchantability or tness for purpose shall apply.

Trademark Information

Read and Understand

WARNING

Read and follow all instructions and safety precautions in this

manual and all other manuals for products associated with this

machine as well as in all on-product warning decals. Failure

to do so could result in death or serious injury, or property

damage. Contact your Norwood dealer if any of your manuals

are missing or illegible or you have questions.

Preface

This Operator's Manual is intended for use with the following: The Grain Handler U-Trough Power Sweep

Models:

8” U-Trough Power Sweeps

Sizes: 18’ 19’ 21’ 24’ 27’ 30’ 33’ 36’ 42’ 48’

10” U-Trough Power Sweeps

Sizes: 18’ 19’ 21’ 24’ 27’ 30’ 33’ 36’ 42’ 48’ 54’ 60’

Revision History

Issue Date Reasons for Change

10-5-00007 April 4th 2021 Initial Release

OSHA® Is a registered trademark of the Occupational Safety

& Health Administration and is so acknowledged.

ASABE® Is a registered trademark of the American Society of

Agricultural and Biological Engineers and is so acknowledged.

NFPA® Is a registered trademark of the National Fire

Protection Association and is so acknowledged.

ANSI® Is a registered trademark of the American National

Standards Institute and is so acknowledged.

NEMA® Is a registered trademark of the National Electrical

Manufacturers Association and is so acknowledged.

Any trademarks not directly mentioned are also acknowledged.

ii

Contents

1.0 - GENERAL INFORMATION ....................................................................................................1-1

Note to the Owner.................................................................................................................................................. 1-1

Intended Use ......................................................................................................................................................... 1-1

Power Sweep Operator’s Manual Location............................................................................................................ 1-2

Determining Left and Right Side of the Machine ................................................................................................... 1-5

Determining Orientation Using Directional Arrows................................................................................................. 1-5

2.0 - SAFETY INFORMATION .......................................................................................................2-1

Safety Rules And Signal Word Denitions ............................................................................................................. 2-1

Personal Safety:..................................................................................................................................................... 2-1

Machine Safety & Informational: ............................................................................................................................ 2-1

Safety Rules........................................................................................................................................................... 2-2

General Safety ......................................................................................................................................... 2-2

Operating Safety ...................................................................................................................................... 2-3

Prepare for Emergencies ......................................................................................................................... 2-3

Personal Protective Equipment (PPE) ..................................................................................................... 2-3

Grain Bin Safety ....................................................................................................................................... 2-4

SUFFOCATION FROM FLOWING GRAIN............................................................................................................ 2-4

Always follow these safety precautions: ................................................................................................................ 2-4

Grain Bin Safety Contd. ........................................................................................................................... 2-5

Combustible Dust................................................................................................................................................... 2-5

Grain Bin Safety Contd. ........................................................................................................................... 2-6

Collapse of Bridged Grain...................................................................................................................................... 2-6

Collapse of a Vertical Wall of Grain........................................................................................................................ 2-6

Flowing Grain......................................................................................................................................................... 2-6

Grain Bin Safety Contd. ........................................................................................................................... 2-7

Grain Bin Entry Safety ........................................................................................................................................... 2-7

Roof Entry .............................................................................................................................................................. 2-7

Lock-Out Tag-Out Safety ......................................................................................................................... 2-7

Non-Permissible Use ............................................................................................................................... 2-7

General Maintenance Safety ................................................................................................................... 2-8

Remove Paint Before Welding or Heating

................................................................................................ 2-8

Avoid Heating Near Pressurized Fluid Lines

................................................................................................. 2-8

Avoid Overhead Power Lines .................................................................................................................. 2-9

Electrical Storm Safety ............................................................................................................................ 2-9

Working at Heights (If Applicable) ............................................................................................................ 2-9

Noise Level Safety ................................................................................................................................... 2-9

Chemical Safety and the Environment .................................................................................................. 2-10

Handle Chemical Products Safely ......................................................................................................... 2-10

Decommissioning: Proper Recycling and Disposal of Fluids and Components .................................... 2-11

Safety Decals....................................................................................................................................................... 2-13

Safety Decal Locations Cont’d............................................................................................................................. 2-14

Important, Notice, & Informational Decal Locations ........................................................................................ 2-23

Safety Features.................................................................................................................................................... 2-27

3.0 INSTALLATION ........................................................................................................................3-1

Installation Safety .................................................................................................................................... 3-1

To Install Power Sweep System In A Concrete Foundation: .................................................................................. 3-2

To install Power Sweep System in Drying, Aeration or Full Floor Systems: .......................................................... 3-2

Service Procedure: ................................................................................................................................................ 3-2

iii

Power Sweep Stop Installation ............................................................................................................................ 3-11

Power Sweep Backboard Extension Installation.................................................................................................. 3-13

Clump Buster Installation ..................................................................................................................................... 3-15

Horizontal Powerhead Installation ....................................................................................................................... 3-17

Inclined Powerhead Installation ........................................................................................................................... 3-24

Standard Or Buzz Drive Wheel Installation.......................................................................................................... 3-26

Power Sweep Carrier Wheel Installation ............................................................................................................ 3-33

Carrier Wheel Parts: ............................................................................................................................................ 3-38

10-2-00150 Assembly, Carrier Wheels................................................................................................................ 3-38

4.0 - WORKING OPERATIONS .....................................................................................................4-1

Operating Safety ...................................................................................................................................... 4-1

To The Operator Or Owner .................................................................................................................................... 4-1

Machine Components ............................................................................................................................................ 4-1

Machine Components (Page 1 of 2) ...................................................................................................................... 4-2

Machine Components (Page 2 of 2) ...................................................................................................................... 4-3

SIZING SPECIFICATIONS .................................................................................................................................... 4-4

MACHINE BREAK-IN ............................................................................................................................................ 4-4

PRE-OPERATION CHECKLIST ............................................................................................................................ 4-4

CONTROLS ........................................................................................................................................................... 4-5

Discharge Slide Gates ........................................................................................................................................... 4-5

Electrical Power On/O Switch .............................................................................................................................. 4-5

Power Sweep Engagement Lever ......................................................................................................................... 4-6

Motor Mount Belt Tension Lever ............................................................................................................................ 4-6

Field Operation ...................................................................................................................................................... 4-7

Before Filling the Bin with Grain............................................................................................................................. 4-7

Machine Placement ............................................................................................................................................... 4-8

Emptying the Grain Bin .......................................................................................................................................... 4-8

Unload Grain From the Center Sump .................................................................................................................... 4-9

Unload Grain From the Intermediate Sumps ....................................................................................................... 4-10

Unload Grain with the Power Sweep ................................................................................................................... 4-10

Emergency Shutdown.......................................................................................................................................... 4-11

Unplugging........................................................................................................................................................... 4-11

Restarting with Full U-Trough Auger .................................................................................................................... 4-11

5.0 MAINTENANCE .......................................................................................................................5-1

General Maintenance Safety ................................................................................................................... 5-1

Practice Safe Maintenance .................................................................................................................................... 5-1

Work in Clean Area ................................................................................................................................................ 5-1

FLUIDS AND LUBRICANTS .................................................................................................................................. 5-2

Hydraulic Oil:.......................................................................................................................................................... 5-2

Storing Lubricants: ................................................................................................................................................. 5-2

Grease: .................................................................................................................................................................. 5-2

Greasing ................................................................................................................................................................ 5-2

SERVICING INTERVALS....................................................................................................................................... 5-2

Lubrication Symbols............................................................................................................................................... 5-2

MAINTENANCE CHART........................................................................................................................................ 5-3

First 1 Hour Of Operation....................................................................................................................................... 5-4

Tension And Alignment of the Drive Belts .............................................................................................................. 5-4

First 1 Hour Of Operation....................................................................................................................................... 5-5

Visually Inspect The Equipment............................................................................................................................. 5-5

First 10 Hours Of Operation................................................................................................................................... 5-6

Check Tightness Of All Bolts, & Cap Screws ......................................................................................................... 5-6

First 10 Hours Of Operation................................................................................................................................... 5-7

50 Hours Or Weekly............................................................................................................................................... 5-7

Grease Universal Joints......................................................................................................................................... 5-7

Every 10 Hours Of Operation................................................................................................................................. 5-8

Grease Buzz Wheel ............................................................................................................................................... 5-8

100 Hours Or Monthly............................................................................................................................................ 5-9

This manual suits for next models

1

Table of contents

Other Norwood Farm Equipment manuals

Popular Farm Equipment manuals by other brands

Schaffert

Schaffert Rebounder Mounting instructions

Stocks AG

Stocks AG Fan Jet Pro Plus 65 Original Operating Manual and parts list

Cumberland

Cumberland Integra Feed-Link Installation and operation manual

BROWN

BROWN BDHP-1250 Owner's/operator's manual

Molon

Molon BCS operating instructions

Vaderstad

Vaderstad Rapid Series instructions