Norwood LumberMax HD38 User manual

11 KW / 8 KW

ELECTRIC MOTOR PACKAGE

HD38-PP-11KW-400V-S3-SS, HD38-PP-11KW-230V-S3-SS, HD36V2-PP-11KW-400V-S3-SS, HD36V2-PP-11KW-230V-S3-SS,

HD36V2-PP-8KW-400V-S3-SS, HD36V2-PP-8KW-230V-S3-SS, LM30-PP-8KW-400V-S3-SS, LM30-PP-8KW-230V-S3-SS

ORIGINAL INSTRUCTIONS

»LumberMax HD38

»LumberPro HD36V2, HD36

»LumberMate LM30

ENSEMBLE DE MOTEUR

ÉLECTRIQUE DE

11 KW / 8 KW

INSTRUCTIONS ORIGINALES

11 KW / 8 KW

SÄHKÖMOOTTORIPAKKAUS

ALKUPERÄISET OHJEET

11 KW / 8 KW

ELEKTROMOTOR-PAKET

URSPRÜNGLICHE ANLEITUNG

11 KW / 8 KW ELEKTRISK

MOTORPAKKE

ORIGINAL ANVISNINGER

PACOTE DE MOTOR

ELÉTRICO DE 11 KW / 8 KW

INSTRUÇÕES ORIGINAIS

PAQUETE DE MOTOR

ELÉCTRICO DE 11 KW / 8 KW

INSTRUCCIONES ORIGINALES

11 KW / 8 KW

ELMOTORPAKET

BRUKSANVISNING ORIGINAL

MILL-ELEC-S3-YD-SS-INST (2022-11-24).indd 1MILL-ELEC-S3-YD-SS-INST (2022-11-24).indd 1 2022-11-25 11:31:28 AM2022-11-25 11:31:28 AM

MILL-ELEC-S3-YD-SS-INST (2022-11-24).indd 2MILL-ELEC-S3-YD-SS-INST (2022-11-24).indd 2 2022-11-25 11:31:28 AM2022-11-25 11:31:28 AM

EN–1 11 kW / 8 kW Electric Motor Package

EN–1 Safety Instructions

EN–6 Parts Lists

EN–11 Technical Data — HD38

EN–12 Technical Data — HD36v2

EN–13 Technical Data — LM30

EN–14 Assembly

EN–15 Motor Installation

EN–21 Safety Switch Assembly

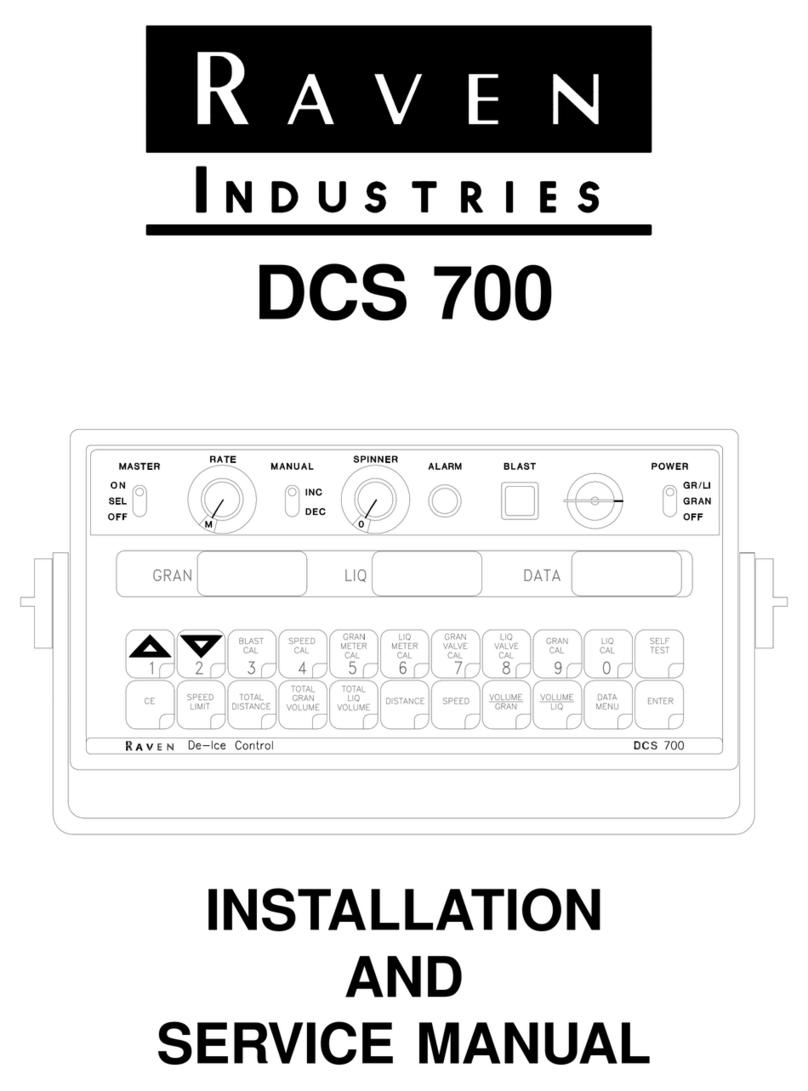

EN–25 Layout of Controls

EN–26 Operating the Electrical Equipment

EN–30 Wiring Diagram — 11 kW, 230 V (Soft Start) with 12 V

Transformer

EN–31 Wiring Diagram — 11 kW, 400 V (Soft Start) with 12 V

Transformer

FR–1 Ensemble de moteur électrique de 11 kW / 8 kW

FR–1 Instructions de sécurité

FR–6 Contenu des boîtes

FR–11 Données techniques — HD38

FR–12 Données techniques — HD36v2

FR–13 Données techniques — LM30

FR–14 Assemblage

FR–15 Installation du moteur

FR–21 Assemblage de l’interrupteur de sécurité

FR–25 Disposition des commandes

FR–26 Utilisation de l’équipement électrique

FR–28 Schéma de câblage — 8 kW, 230 V

FR–29 Schéma de câblage — 8 kW, 400 V

FR–30 Schéma de câblage — 11 kW, 230 V (démarrage à

chaud) avec transformateur de 12 V

FR–31 Schéma de câblage — 11 kW, 400 V (démarrage à

chaud) avec transformateur de 12 V

FI–1 11 kW / 8 kW Sähkömoottoripakkaus

FI–1 Turvallisuusohjeet

FI–6 Osaluettelo

FI–11 Tekniset tiedot — HD38

FI–12 Tekniset tiedot — HD36v2

FI–13 Tekniset tiedot — LM30

FI–14 Asennus

FI–15 Moottorin asennus

FI–21 Turvakytkimen asentaminen

FI–25 Ohjaimien sijainti

FI–26 Sähköjärjestelmien käyttö

FI–28 Johdotuskaavio — 8 kW, 230 V

FI–29 Johdotuskaavio — 8 kW, 400 V

FI–30 Johdotuskaavio — 11 kW, 230 V (pehmeä käynnistys) 12

V muuntajalla

FI–31 Johdotuskaavio — 11 kW, 400 V (pehmeä käynnistys) 12

V muuntajalla

DE–1 11 kW / 8 kW Elektromotor-Paket

DE–1 Sicherheitsanweisungen

DE–6 Teileliste

DE–11 Technische Daten — HD38

DE–12 Technische Daten — HD36v2

DE–13 Technische Daten — LM30

DE–14 Zusammenbau und Montage

DE–15 Motorinstallation

DE–21 Montage des Sicherheitsschalters

DE–25 Aufbau der Bedienelemente

DE–26 Bedienung der elektrischen Ausrüstung

DE–28 Schaltplan — 8 kW, 230 V

DE–29 Schaltplan — 8 kW, 400 V

DE–30 Schaltplan — 11 kW, 230 V (Sanftanlauf) mit 12 V

Transformator

DE–31 Schaltplan — 11 kW, 400 V (Sanftanlauf) mit 12 V

Transformator

NO–1 11 kW / 8 kW Elektrisk motorpakke

NO–1 Sikkerhetsinstruksjoner

NO–6 Deleliste

NO–11 Tekniske data — HD38

NO–12 Tekniske data — HD36v2

NO–13 Tekniske data — LM30

NO–14 Enhet

NO–15 Motorinstallasjon

NO–21 Montering av sikkerhetsbryter

NO–25 Slik ser styresystemet ut

NO–26 Slik bruker du utstyret

NO–28 Koblingsskjema — 8 kW, 230 V

NO–29 Koblingsskjema — 8 kW, 400 V

NO–30 Koblingsskjema — 11 kW, 230 V (Soft Start) med 12 V

transformator

NO–31 Koblingsskjema — 11 kW, 400 V (Soft Start) med 12 V

transformator

PT-1 Pacote de motor elétrico de 11 kW / 8 kW

PT-1 Instruções de Segurança

PT-6 Lista de Peças

PT-11 Dados Técnicos — HD38

PT-12 Dados Técnicos — HD36v2

PT-13 Dados Técnicos — LM30

PT-14 Montagem

PT-15 Instalação do Motor

PT-21 Conjunto do interruptor de segurança

PT-25 Layout de Controles

PT-26 Operando o Equipamento Elétrico

PT-28 Diagrama de fiação — 8 kW, 230 V

PT-29 Diagrama de fiação — 8 kW, 400 V

PT-30 Diagrama de fiação - 11 kW, 230 V (Partida suave) com

transformador de 12 V

PT-31 Diagrama de fiação - 11 kW, 400 V (Partida suave) com

transformador de 12 V

ES-1 Paquete de motor eléctrico de 11 kW / 8 kW

ES-1 Instrucciones de seguridad

ES-6 Lista de piezas

ES-11 Datos técnicos — HD38

ES-12 Datos técnicos — HD36v2

ES-13 Tekniset tiedot — LM30

ES-14 Montaje

ES-15 Instalación del motor

ES-21 Montaje del interruptor de seguridad

ES-25 Distribución de controles

ES-26 Manejo del equipo eléctrico

ES-28 Diagrama de cableado — 8 kW, 230 V

ES-29 Diagrama de cableado — 8 kW, 400 V

ES-30 Diagrama de cableado — 11 kW, 230 V (arrancador

suave) con transformador de 12 V

ES-31 Diagrama de cableado — 11 kW, 400 V (arrancador

suave) con transformador de 12 V

SV–1 11kW / 8kW elmotorpaket

SV–1 Säkerhetsinstruktioner

SV–6 Lista över delar

SV–11 Tekniska data – HD38

SV–12 Teknisk information – HD36v2

SV–13 Tekniska data – LM30

SV–14 Montering

SV–15 Installation av motorn

SV–21 Säkerhetsbrytarenhet

SV–25 Kontrollernas layout

SV–26 Användning av den elektriska utrustningen

SV–28 Kopplingsschema — 8 kW, 230 V

SV–29 Kopplingsschema — 8 kW, 400 V

SV–30 Kopplingsschema – 11 kW, 230 V (mjukstart) med 12 V

transformator

SV–31 Kopplingsschema – 11 kW, 400 V (mjukstart) med 12 V

transformator

MILL-ELEC-S3-YD-SS-INST (2022-11-24).indd 3MILL-ELEC-S3-YD-SS-INST (2022-11-24).indd 3 2022-11-25 11:31:29 AM2022-11-25 11:31:29 AM

Text: S. Cabrit

First Edition: 2020-09-20

Latest Revision: 2022-11-24

Copyright © 2020, 2022 Norwood Industries Inc.

All rights reserved. No part of this publication may

be reproduced in any form or by any means without

permission in writing from the publisher, Norwood

Industries Inc.

The color orange as it relates to sawmills, edgers, skidders & related

equipment, the “chevron” graphic, the LumberJack® mascot, and the

trade-names Norwood®, LumberMax®, LumberPro®, LumberMate®,

LumberMan®, LumberLite®, LM Pro®, PortaMill®, SkidMate®,

BladeMate®, SabreTooth®, SabreBar®, SabreChain®, HD38®,

HD36®, LM30®, MN27®, LM29®, MN26®, Trekker®, Duradeck®,

Sawyer-Assist®, Sawmill TV®, Omega®, IntelliSet®, Frontier®, OS®,

OS23®, OS27®, OS31®, “Forest. Fun. Freedom.” & MultiMate® are

registered trademarks owned by Norwood Industries Inc. in multiple

jurisdictions. Functional and design elements of Norwood sawmills

and log handling equipment are protected by registered patents and

pending patents in multiple jurisdictions.

U.S. Patent Nos. 6,932,555, 9,102,074, 7,784,387, 8,215,216,

8,261,645, 8,261,647, 8,276,493, 8,820,727, 9,676,116, 10,843,370,

D816742, D818013, D834623, D831711, D639,319, D654,101,

D638,040 & 8,479,628 — Canada Patent Nos. 2,432,863, 2,488,216,

132823, 2,541,734, 2,687,619, 2,687,622, 2,687,623, 2,688,407,

2,696,974, 2,782,909, 2,806,456, 2,800,791, 2,969,794, 3,037,006,

3,097,733, 3,092,814, 3,101,140, 134185, 133049, 169785, 169786,

169787, 196297 & 169788 — EU Patent Nos. EP 2,746,009 B1,

EP 2,332,706 B1, EP 2,332,683 B1, EP 2,684,631, EP 2,332,704,

EP 2,759,384, 1117196-0001; 001212393-0001; 001217277-0001,

001214662-0001, 003736255-0001, 003736255-0002, 003736255-

0003, 003736255-0004, 008465066-0001 — UK Patent Nos. 6124839,

6138704, 6151320 — Brazil Patent Nos. BR30 2012 003601-1, BR10

2013 025882-2, BR10 2013 025883-0, PI 1004044-7, PI 1010352-

0, DI 7001877-4, DI 7001876-6 & PI 1009180-7 — Australia Patent

Nos. 202111414, 201710613, 201710614, 201710616, 201710615 &

202016960; China Patent Nos. 4192870, ZL202130153443.5. Other

patents pending in multiple jurisdictions..

Norwood Industries Inc. is constantly developing its equipment.

Wereserve the right to make changes to the design, construction and

finish of our equipment without notice.

Photographs and illustrations in this manual may show optional

attachments or previous models and parts.

Telephone: +1-705-325-0030

E-mail: info@NorwoodSawmills.com

Website: www.NorwoodSawmills.com

Norwood Industries Inc.

2267 15/16 Side Road East

Oro-Medonte ON L0L 1T0

Canada

®

MILL-ELEC-S3-YD-SS-INST (2022-11-24).indd 4MILL-ELEC-S3-YD-SS-INST (2022-11-24).indd 4 2022-11-25 11:31:29 AM2022-11-25 11:31:29 AM

The sawmill, its options, accessories,

engine and blades (the “equipment”)

are extremely dangerous and can

cause severe injury or death. To avoid

serious injury, the equipment must always be

handled, operated and stored with the utmost

care and good judgment and in accordance

with all warnings, cautions, instructions and

procedures contained in this manual, in the

engine manual, in the instructions enclosed

with optional accessories and on the decals

posted on the equipment. Failure to use good

judgment or to follow any of these warnings,

cautions, instructions and procedures can

result in severe injury or death.

WARNING! This symbol means “Pay Extra

Attention” and is always followed by a warning

about a danger that can cause severe injury.

This symbol means “Pay Attention” and is

always followed by a caution or warning of

great importance for safety or sawing results.

For your own safety and the safety of others,

do not begin working with this equipment

before having read and understood this entire

manual, the engine manual, the instructions

enclosed with optional accessories and the decals

posted on the equipment.

Save all instructions for future reference. Keep all decals

in place, clean and readable. Replace any damaged or

missing decals without delay.

DISCLAIMER

Norwood Industries Inc. and Norwood Sawmills

U.S.A. Inc. disclaim any responsibility or

liability, in negligence or otherwise, for any

injuries, damages or losses of any kind arising

during the course of assembling, operating or

handling this equipment, options, accessories

or blades howsoever caused.

Responsibility for final inspection of the

sawmill parts and components, and the

assembly, maintenance and safe use of the

equipment, lies solely with the person(s) who

assembles and operates the equipment and

handles blades.

Persons under the age of 18 may not work with the

equipment or handle blades.

Only persons who meet all of the following

requirements are qualified to operate the equipment

or handle blades.

Qualified operators:

a. Have read and fully understood all the warnings,

cautions, instructions and procedures in this manual,

the engine manual and all instructions enclosed with

optional accessories, and on all decals posted on

the equipment,

b. Are well rested,

c. Are in good physical health with good eyesight,

d. Have not consumed alcohol or drugs, and

e. Are not taking medication that can impair judgment,

Safety Instructions

EN–1EN–1

EN

11 kW / 8 kW

Electric Motor

Package

MILL-ELEC-S3-YD-SS-INST (2022-11-24).indd 1MILL-ELEC-S3-YD-SS-INST (2022-11-24).indd 1 2022-11-25 11:31:31 AM2022-11-25 11:31:31 AM

reaction times, mobility, alertness or otherwise cause

negative side effects.

Persons who fail to meet any of these requirements are

not qualified to use the equipment or handle blades.

Wear protective gloves when working with the

equipment or handling blades. Risk of cutting

injuries when handling blades. Blades and

engine can be hot immediately after sawing.

Wear approved hearing protection when

operating the equipment. Hearing can

be permanently impaired after only short

exposure to high-frequency sounds.

Wear approved close-fitting safety goggles

when working with the equipment or handling

blades.

Wear approved protective footwear with saw

protection, steel toe-cap and non-slip sole

when working with the equipment or handling

blades.

Wear full-length protective pants when working

with the equipment or handling blades. Never

wear loose-fitting clothing, scarves, jewellery

or similar long items that can get caught when

working with the equipment. Always secure loose hair

before working with the equipment.

Wear respiration protection when working

with the equipment. Long term inhalation of

sawdust and the engine’s exhaust fumes can

represent a health risk.

WARNING! Cutting tools: Incorrect use of the

equipment or unsafe blade handling can cause

life-threatening injuries. Blades are extremely

sharp and dangerous.

WARNING! Sawhead drop danger: Pressing

downward, even slightly on the winch

adjustment knob/spring, will release the

winch brake. Releasing the winch brake will

cause the sawhead to drop quickly and violently causing

serious injury.

WARNING! Crush danger: The log rests

can drop quickly when the log rest lever is

activated causing serious injury to your hand.

Keep your hands clear of the log rests when

activating the log rest lever and where milling or log

handling operations may accidentally activate the log rest

lever.

Always stay behind the sawhead after the engine

has started.

Review and follow all of the safety instructions in the

sawmill manual and in the engine manual.

Installation Requirements

»Electrical system providing a RCD with a maximum

residual current of 0.03A should be provided.

Installation of over-voltage protection is needed.

»Steady state voltage: 0.9-1.1 of nominal voltage.

»Frequency: 0.99-1.01 of nominal frequency

continuously; 0.98-1.02 short time.

»HVF: ≤0.02.

The Worksite

Operate the equipment and handle blades in full

daylight or under adequate site lighting cast from at

least four sides to minimize shadows.

Keep the work area clean, free of clutter, pets,

children, obstacles, hazards or distractions.

Keep all children and animals well away from the

equipment and blades at all times.

A broken blade can be ejected out of the sawdust

chute at high velocity. Keep all people and pets

completely clear of the path of the sawdust chute.

Remember that, as the carriage moves, so do the

blade and the path of the sawdust chute.

The risk of blade breakage increases when a blade

is not properly and regularly profiled and maintained

and/or when a blade is used past its service life.

Illustration below depicts view of work site as

seen from above. It sets out the minimum safety

distance for persons other than the operator. While

operating the equipment, the operator must be within

the stipulated area* bounded between the broken

line and the nearest side of the sawmill.

While the equipment is running, persons other than

the operator must observe the safety distances

stipulated in the illustration.

The minimum safety distance away from the

equipment for persons other than the operator on the

left side of the sawmill (the side opposite the

operator’s side) is 15 m (50 ft) due to the risk of

blades being ejected out of the sawdust chute. On all

*Operator’s working space while sawing

6 m

20 ft

6 m

20 ft

15 m 50 ft

6 m 20 ft

EN–2

MILL-ELEC-S3-YD-SS-INST (2022-11-24).indd 2MILL-ELEC-S3-YD-SS-INST (2022-11-24).indd 2 2022-11-25 11:31:34 AM2022-11-25 11:31:34 AM

other sides of the equipment, the minimum distance

away from the equipment for persons other than the

operator is 6 m (20 ft).

Risk of being crushed by the carriage.

Risk of tripping on the rails or the cross-bunks.

Never walk on the rails or the cross-bunks.

Never step across the rails.

Risk of being crushed between the sawmill and a

moving log.

Set up the equipment on level ground so that there is

at least 3 m (10 ft) of level ground around the rails

and that there are no obstacles within that area.

Do not stand between the pile of logs and the

equipment.

Always stand at the side of the pile of logs when

handlings the logs. Never stand where you are at

risk of being hit by a rolling log.

Keep at least a 2.5 kg (5 lb) fully-charged ABC

dry-chemical fire extinguisher visible and easily

accessible at the worksite.

Keep a fully-stocked first-aid kit visible and easily

accessible at the worksite.

Never work alone. Make sure that there are other

adults within hearing distance should you need to

call for help.

Control Panel OFF Switch

The control panel is equipped with an OFF switch.

Test the OFF switch before each use once a day: Start

the electric motor ON and press the OFF switch. If it

does not shut the electric motor OFF, it is not working.

Therefore, stop using the equipment and contact

Norwood immediately to order a replacement.

Site Operating Conditions

»Altitude should not exceed 1000 m (3280 ft).

»Maximum ambient air temperature is +40 °C,

minimum ambient air temperature is not less than

0°C.

»The relative humidity does not exceed 50% at a

maximum temperature of +40 °C, higher relative

humidity may be permitted at lower temperature (e.g.

90% @ 20 °C).

»The machine can be stored or transported under

ambient temperatures between -25 °C and +55 °C.

Through poor conditions of the electrical MAINS,

short voltage drops can appear when starting the

EQUIPMENT.

This can influence other equipment (e.g. Blinking of

a lamp). If the MAINS-IMPEDANCE Zmax < 0.252 Ω,

such disturbances are not expected. (In case of need,

you may contact your local supply authority for further

information).

Before the machine is connected to TN-S power supply

system, the end user shall perform the test according to

clause 18.2 of EN 60204-1.

Operating the Equipment

Cutting tools: Stand behind the carriage and keep

both your hands on the push handle while operating

the equipment. Never stand in front of the carriage

or blade. Never pull the carriage through the cut.

Never open the blade and bandwheel guards while

the motor is running.

Before opening the blade and bandwheel guards,

turn the control panel to the OFF position and

disconnect (unplug) the power supply electrical cable

from your electrical outlet.

Coiled blades can spring apart with considerable

force and unpredictably in any direction. Handle

coiled blades, including those packaged in boxes,

with the utmost care.

The blade and bandwheel guards are shatter

resistant to temperatures as low as -28 °C. Never

operate the equipment in temperatures at or below

-28 °C.

Ensure that the equipment is assembled and

maintained in accordance with this manual, the

sawmill manual and the instructions enclosed with

optional accessories.

Never use the equipment to cut anything other than

wood.

Never add hardware or attachments of any kind to

the equipment other than those manufactured by

Norwood Industries Inc. specifically for the

equipment. Never modify the equipment.

Before operating the equipment, ensure that:

»all maintenance procedures have been properly

carried out;

»the blade is disengaged;

»the equipment stands firmly and securely and the

rails are fully supported along their full length;

»the carriage retaining keepers and bed end stops are

properly and securely installed;

»all components, fasteners, cables and parts are

properly and securely installed and in good working

order;

»all safety features are properly and securely installed

and in good working order including, but not limited

to, the electric motor circuit breaking safety switch,

the blade/bandwheel brake, the sawdust chute

cage, and blade and bandwheel guards are correctly

installed and securely locked; and

EN–3

MILL-ELEC-S3-YD-SS-INST (2022-11-24).indd 3MILL-ELEC-S3-YD-SS-INST (2022-11-24).indd 3 2022-11-25 11:31:34 AM2022-11-25 11:31:34 AM

»the blade is correctly installed, properly tensioned

and aligned, and can rotate freely in the correct

direction.

Before each cut, ensure that:

»no person other than the operator and no pets are

within the minimum safety distances;

»the worksite is free of objects that the operator can

trip over, hazards or distractions.

»the blade will clear the log posts and log dogs;

»the rails and track are free of debris;

»the log is firmly secured with the log clamping

mechanisms;

»the adjustable blade guide will clear the widest

portion of the next cut by one inch and is secured in

place;

»the blade and bandwheel guards are correctly

installed and securely locked; and

»the operator is wearing all personal protective

equipment.

At regular intervals during operation, ensure that no

person other than the operator and no pets are

within the minimum safety distances.

Turn the motor off if you are going to leave the

operating station behind the carriage, even just

temporarily, for example when loading or

repositioning logs or removing lumber.

Never overreach. Keep proper footing at all times.

Discontinue operating the equipment or handling

blades if you become fatigued or distracted.

Stay focused and alert. Watch what you are doing.

Use common sense.

If your sawmill is equipped with an electric powered

motor:

Risk of electric shock! Hazardous voltage inside the

disconnect box, starter box and at the electric motor

can cause shock, burns or death.

Electrical short danger! Ensure that you do not short

out any part of the electrical system. Shorting out

the electrical system can cause both of the sawhead

support cables to simultaneously break suddenly

and the sawhead to drop violently causing serious

injury.

Only a qualified electrician can open the electrical

equipment. All electrical installation, service and

maintenance work must be performed by a qualified

electrician and must be performed in accordance to

applicable electrical codes. Failure to do so can

result in serious injury or death.

Before installing, servicing or maintaining any of the

electrical equipment, turn the control panel to the

OFF position and disconnect (unplug) the power

supply electrical cable from your electrical outlet.

Follow all applicable electrical codes.

If you have any reason to suspect that there is

anything wrong with the electrical system,

immediately disconnect (unplug) the power supply

electrical cable from your electrical outlet, turn the

control panel to the OFF position and remove the

ignition key and contact a qualified electrician to

service the electrical equipment. Do not operate the

equipment until it has been serviced by a qualified

electrician and certified fully safe to operate.

Storing the Equipment

When storing the equipment, turn the control panel

to the OFF position and disconnect (unplug) the

power supply electrical cable from your electrical

outlet. Take any other measures necessary to

prevent unauthorized operators from accessing or

starting the equipment.

Ensure that the blade and bandwheel guards are

correctly installed and securely locked.

Lower the sawhead to its lowest position.

Always store the equipment in a secure and locked

location completely inaccessible by children or any

persons.

When not in use or when unattended, even for short

periods of time such as during breaks, remove the

blade from the sawmill and store it in a location

inaccessible by children or any persons. In addition

to being a wise safety precaution, removing the

blade from the sawmill ensures that it is not stored

under tension and so prevents premature blade

fatigue.

When not in use, take measures to secure the

carriage to the bed to prevent the carriage from

being blown or inadvertently rolled along the track.

Always store all blades in a secure and locked

location completely inaccessible by children or any

persons.

If your sawmill is equipped with the optional trailer

package: When storing the equipment, always

remove the drawbar and wheels and secure them in

a different location and take any other measures

necessary to prevent unauthorized persons from

accessing or moving the equipment.

The machine can be stored under ambient

temperatures between -25 °C and +55 °C.

When storing the equipment, turn the electric motor

OFF and remove the blade. Disconnect (unplug) the

power supply electrical cable from your electrical

outlet.

EN–4

MILL-ELEC-S3-YD-SS-INST (2022-11-24).indd 4MILL-ELEC-S3-YD-SS-INST (2022-11-24).indd 4 2022-11-25 11:31:35 AM2022-11-25 11:31:35 AM

EN–5

MILL-ELEC-S3-YD-SS-INST (2022-11-24).indd 5MILL-ELEC-S3-YD-SS-INST (2022-11-24).indd 5 2022-11-25 11:31:35 AM2022-11-25 11:31:35 AM

Qty. Description Norwood No.

For HD38-PP-11KW-400V-S3-SS

Loose-packed items

1 Electric - Motor - 11kW S3 duty, 2900 RPM, 230/400V, 50 Hz ENGE-11KW-230/400V-S3

ENGE-50HZ-MILL-BOX #8/11KW-YD/SS (LM30, HD38) (8kW/YD and 11kW/SS, 400/230V, S3, 3PH,

50HZ electric)

ENGE-50HZ-MILL-BOX

#8/11KW-YD/SS

1Sheave - 5.0" sheave (HD36) (bushing MILL-BUSH38MM req'd) MILL-SHV50IN

1Bushing - 38mm QD metric (for MILL-SHV46IN & MILL-SHV56IN sheaves) (HD36, LM29) MILL-BUSH38MM

1Manual - Y-D and soft start electric motor system (S3) (English)(LM30, HD36v2, HD38) MILL-ELEC-S3-YD-SS-MAN

MILLV2-BAG #ELECT - 400/230V, E.U. Electric MILLV2-BAG #ELECT-400/230V

10 3/8 nut - flanged nylon lock nut FASN-38LNF

63/8 nut - flanged (regular) FASN-38RFL

12 3/8 x 1" bolt - flanged bolt FASB-38X1L

5Cable tie - Reusable nylon 6" black DBKR-CTIE6

3Cable tie mount - Adhesive mount DBKR-CTMA

23/8 x 2" bolt - flanged bolt FASB-38X2F

43/8 x 1 1/2" bolt - flanged bolt FASB-3815F

ENGE-BOX #11KW-400V-S3-SS (11kW/SS, 400V, S3, 3PH, 50HZ Electric) ENGE-BOX #11KW-400V-S3-SS

1Electric - Control Panel w/controller, switches & 12v convertor - 8 to 11kW, soft-start, 400V, 3PH, S3 ENGE-400V-S3-SS-CP-12V

1Electric - Remote control box clamping bracket (LM29v2, MN26v2, HD36) MILL-EUELEC-0012

2Electric - Control panel clamp (38mm) (HD36, HD36v2, HD38) ENGE-38MM-CPCLAMP

1Hardware bag with cable tie, screws for guards and deadmen switches

2.5m 20mm diameter loom tube

For HD38-PP-11KW-230V-S3-SS

Loose-packed items

1 Electric - Motor - 11kW S3 duty, 2900 RPM, 230/400V, 50 Hz ENGE-11KW-230/400V-S3

ENGE-50HZ-MILL-BOX #8/11KW-YD/SS (LM30, HD38) (8kW/YD and 11kW/SS, 400/230V, S3, 3PH,

50HZ electric)

ENGE-50HZ-MILL-BOX

#8/11KW-YD/SS

1Sheave - 5.0" sheave (HD36) (bushing MILL-BUSH38MM req'd) MILL-SHV50IN

1Bushing - 38mm QD metric (for MILL-SHV46IN & MILL-SHV56IN sheaves) (HD36, LM29) MILL-BUSH38MM

1Manual - Y-D and soft start electric motor system (S3) (English)(LM30, HD36v2, HD38) MILL-ELEC-S3-YD/SS-MAN

MILLV2-BAG #ELECT - 400/230V, E.U. Electric MILLV2-BAG #ELECT-400/230V

10 3/8 nut - flanged nylon lock nut FASN-38LNF

63/8 nut - flanged (regular) FASN-38RFL

12 3/8 x 1" bolt - flanged bolt FASB-38X1L

5Cable tie - Reusable nylon 6" black DBKR-CTIE6

3Cable tie mount - Adhesive mount DBKR-CTMA

23/8 x 2" bolt - flanged bolt FASB-38X2F

Parts Lists

EN–6

MILL-ELEC-S3-YD-SS-INST (2022-11-24).indd 6MILL-ELEC-S3-YD-SS-INST (2022-11-24).indd 6 2022-11-25 11:31:35 AM2022-11-25 11:31:35 AM

Qty. Description Norwood No.

43/8 x 1 1/2" bolt - flanged bolt FASB-3815F

ENGE-BOX #11KW-400V-S3-SS (11kW/SS, 400V, S3, 3PH, 50HZ Electric) ENGE-BOX #11KW-400V-S3-SS

1Electric - Control Panel w/controller, switches & 12v convertor - 8 to 11kW, soft-start, 230V, 3PH, S3 ENGE-230V-S3-SS-CP-12V

1Electric - Remote control box clamping bracket (LM29v2, MN26v2, HD36) MILL-EUELEC-0012

2Electric - Control panel clamp (38mm) (HD36, HD36v2, HD38) ENGE-38MM-CPCLAMP

1Hardware bag with cable tie, screws for guards and deadmen switches

2.5m 20mm diameter loom tube

For HD36V2-PP-11KW-400V-S3-SS

Loose-packed items

1 Electric - Motor - 11kW S3 duty, 2900 RPM, 230/400V, 50 Hz ENGE-11KW-230/400V-S3

ENGE-50HZ-HD36V2-BOX #8/11KW-YD/SS (HD36v2) (8kW/YD and 11kW/SS, 400/230V, S3, 3PH,

50HZ electric)

ENGE-50HZ-HD36V2-BOX

#8/11KW-YD/SS

1 Belt - Drive belt (HD36 Electric) (B92-V) HD36-DBB92

1 Bushing - 38mm QD metric (for MILL-SHV46IN & MILL-SHV56IN sheaves) (HD36, LM29) MILL-BUSH38MM

1 Sheave - 6.8" sheave - bushing MILL-BUSH38MM required MILL-SHV68IN

2 Rear leg assembly (LM34, HD36) - Spacer LM34-C0220-SPC

2 Sawhead lift cable (HD36 ELECTRIC) (125" OAL) (Colored End) HD36-SHCBL-ELEC

1 Manual - Y-D and soft start electric motor system (S3) (English)(LM30, HD36v2, HD38) MILL-ELEC-S3-YD/SS-MAN

MILLV2-BAG #ELECT - 400/230V, E.U. Electric MILLV2-BAG #ELECT-400/230V

10 3/8 nut - flanged nylon lock nut FASN-38LNF

63/8 nut - flanged (regular) FASN-38RFL

12 3/8 x 1" bolt - flanged bolt FASB-38X1L

5Cable tie - Reusable nylon 6" black DBKR-CTIE6

3Cable tie mount - Adhesive mount DBKR-CTMA

23/8 x 2" bolt - flanged bolt FASB-38X2F

43/8 x 1 1/2" bolt - flanged bolt FASB-3815F

ENGE-BOX #11KW-400V-S3-SS (11kW/SS, 400V, S3, 3PH, 50HZ Electric) ENGE-BOX #11KW-400V-S3-SS

1Electric - Control Panel w/controller, switches & 12v convertor - 8 to 11kW, soft-start, 400V, 3PH, S3 ENGE-400V-S3-SS-CP-12V

1Electric - Remote control box clamping bracket (LM29v2, MN26v2, HD36) MILL-EUELEC-0012

2Electric - Control panel clamp (38mm) (HD36, HD36v2, HD38) ENGE-38MM-CPCLAMP

1Hardware bag with cable tie, screws for guards and deadmen switches

2.5m 20mm diameter loom tube

For HD36V2-PP-11KW-230V-S3-SS

Loose-packed items

1 Electric - Motor - 11kW S3 duty, 2900 RPM, 230/400V, 50 Hz ENGE-50HZ-HD36V2-BOX #8/11KW-YD/SS

ENGE-50HZ-HD36V2-BOX #8/11KW-YD/SS (HD36v2) (8kW/YD and 11kW/SS, 400/230V, S3, 3PH,

50HZ electric)

ENGE-50HZ-HD36V2-BOX

#8/11KW-YD/SS

1 Belt - Drive belt (HD36 Electric) (B92-V) HD36-DBB92

1 Bushing - 38mm QD metric (for MILL-SHV46IN & MILL-SHV56IN sheaves) (HD36, LM29) MILL-BUSH38MM

EN–7

MILL-ELEC-S3-YD-SS-INST (2022-11-24).indd 7MILL-ELEC-S3-YD-SS-INST (2022-11-24).indd 7 2022-11-25 11:31:35 AM2022-11-25 11:31:35 AM

Qty. Description Norwood No.

1 Sheave - 6.8" sheave - bushing MILL-BUSH38MM required MILL-SHV68IN

2 Rear leg assembly (LM34, HD36) - Spacer LM34-C0220-SPC

2 Sawhead lift cable (HD36 ELECTRIC) (125" OAL) (Colored End) HD36-SHCBL-ELEC

1 Manual - Y-D and soft start electric motor system (S3) (English)(LM30, HD36v2, HD38) MILL-ELEC-S3-YD/SS-MAN

MILLV2-BAG #ELECT - 400/230V, E.U. Electric MILLV2-BAG #ELECT-400/230V

10 3/8 nut - flanged nylon lock nut FASN-38LNF

63/8 nut - flanged (regular) FASN-38RFL

12 3/8 x 1" bolt - flanged bolt FASB-38X1L

5Cable tie - Reusable nylon 6" black DBKR-CTIE6

3Cable tie mount - Adhesive mount DBKR-CTMA

23/8 x 2" bolt - flanged bolt FASB-38X2F

43/8 x 1 1/2" bolt - flanged bolt FASB-3815F

ENGE-BOX #11KW-230V-S3-SS (11kW/SS, 230V, S3, 3PH, 50HZ Electric) ENGE-BOX #11W-230V-S3-SS

1Electric - Control Panel w/controller, switches & 12v convertor - 8 to 11kW, soft-start, 230V, 3PH, S3 ENGE-230V-S3-SS-CP-12V

1Electric - Remote control box clamping bracket (LM29v2, MN26v2, HD36) MILL-EUELEC-0012

2Electric - Control panel clamp (38mm) (HD36, HD36v2, HD38) ENGE-38MM-CPCLAMP

1Hardware bag with cable tie, screws for guards and deadmen switches

2.5m 20mm diameter loom tube

For HD36V2-PP-8KW-400V-S3-SS

Loose-packed items

1 Electric - Motor - 8kW S3 duty, 2900 RPM, 400/690V, 50 Hz (post 2021) ENGE-8KW-400/690V-S3

ENGE-50HZ-HD36V2-BOX #8/11KW-YD/SS (HD36v2) (8kW/YD and 11kW/SS, 400/230V, S3, 3PH,

50HZ electric)

ENGE-50HZ-HD36V2-BOX

#8/11KW-YD/SS

1 Belt - Drive belt (HD36 Electric) (B92-V) HD36-DBB92

1 Bushing - 38mm QD metric (for MILL-SHV46IN & MILL-SHV56IN sheaves) (HD36, LM29) MILL-BUSH38MM

1 Sheave - 6.8" sheave - bushing MILL-BUSH38MM required MILL-SHV68IN

2 Rear leg assembly (LM34, HD36) - Spacer LM34-C0220-SPC

2 Sawhead lift cable (HD36 ELECTRIC) (125" OAL) (Colored End) HD36-SHCBL-ELEC

1 Manual - Y-D and soft start electric motor system (S3) (English)(LM30, HD36v2, HD38) MILL-ELEC-S3-YD/SS-MAN

MILLV2-BAG #ELECT - 400/230V, E.U. Electric MILLV2-BAG #ELECT-400/230V

10 3/8 nut - flanged nylon lock nut FASN-38LNF

63/8 nut - flanged (regular) FASN-38RFL

12 3/8 x 1" bolt - flanged bolt FASB-38X1L

5Cable tie - Reusable nylon 6" black DBKR-CTIE6

3Cable tie mount - Adhesive mount DBKR-CTMA

23/8 x 2" bolt - flanged bolt FASB-38X2F

43/8 x 1 1/2" bolt - flanged bolt FASB-3815F

ENGE-BOX #8KW-400V-S3-YD (8kW/YD, 400V, S3, 3PH, 50HZ Electric) ENGE-BOX #8KW-400V-S3-YD

1Electric - Control Panel w/controller, switches & 12v convertor - 8 to 11kW, Y-D, 400V, 3PH, S3 ENGE-400V-S3-YD-CP-12V

1Electric - Remote control box clamping bracket (LM29v2, MN26v2, HD36) MILL-EUELEC-0012

EN–8

MILL-ELEC-S3-YD-SS-INST (2022-11-24).indd 8MILL-ELEC-S3-YD-SS-INST (2022-11-24).indd 8 2022-11-25 11:31:36 AM2022-11-25 11:31:36 AM

Qty. Description Norwood No.

1Electric motor - Control panel bracket (CE) (LM30, MN27) LM29-E0003

2Electric - Control panel clamp (38mm) (HD36, HD36v2, HD38) ENGE-38MM-CPCLAMP

1 Hardware bag with cable tie, screws for guards and deadmen switches

2.5m 20mm diameter loom tube

For HD36V2-PP-8KW-230V-S3-SS

Loose-packed items

1 Electric - Motor - 8kW S3 duty, 2900 RPM, 230/400V, 50 Hz ENGE-8KW-230/400V-S3

ENGE-50HZ-HD36V2-BOX #8/11KW-YD/SS (HD36v2) (8kW/YD and 11kW/SS, 400/230V, S3, 3PH,

50HZ electric)

ENGE-50HZ-HD36V2-BOX

#8/11KW-YD/SS

1 Belt - Drive belt (HD36 Electric) (B92-V) HD36-DBB92

1 Bushing - 38mm QD metric (for MILL-SHV46IN & MILL-SHV56IN sheaves) (HD36, LM29) MILL-BUSH38MM

1 Sheave - 6.8" sheave - bushing MILL-BUSH38MM required MILL-SHV68IN

2 Rear leg assembly (LM34, HD36) - Spacer LM34-C0220-SPC

2 Sawhead lift cable (HD36 ELECTRIC) (125" OAL) (Colored End) HD36-SHCBL-ELEC

1 Manual - Y-D and soft start electric motor system (S3) (English)(LM30, HD36v2, HD38) MILL-ELEC-S3-YD/SS-MAN

MILLV2-BAG #ELECT - 400/230V, E.U. Electric MILLV2-BAG #ELECT-400/230V

10 3/8 nut - flanged nylon lock nut FASN-38LNF

63/8 nut - flanged (regular) FASN-38RFL

12 3/8 x 1" bolt - flanged bolt FASB-38X1L

5Cable tie - Reusable nylon 6" black DBKR-CTIE6

3Cable tie mount - Adhesive mount DBKR-CTMA

23/8 x 2" bolt - flanged bolt FASB-38X2F

43/8 x 1 1/2" bolt - flanged bolt FASB-3815F

ENGE-BOX #8KW-2300V-S3-YD (8kW/YD, 230V, S3, 3PH, 50HZ Electric) ENGE-BOX #8KW-230V-S3-YD

1Electric - Control Panel w/controller, switches & 12v convertor - 8 to 11kW, Y-D, 230V, 3PH, S3 ENGE-230V-S3-YD-CP-12V

1Electric - Remote control box clamping bracket (LM29v2, MN26v2, HD36) MILL-EUELEC-0012

1Electric motor - Control panel bracket (CE) (LM30, MN27) LM29-E0003

2Electric - Control panel clamp (38mm) (HD36, HD36v2, HD38) ENGE-38MM-CPCLAMP

1 Hardware bag with cable tie, screws for guards and deadmen switches

2.5m 20mm diameter loom tube

For LM30-PP-8KW-400V-S3-SS

Loose-packed items

1 Electric - Motor - 8kW S3 duty, 2900 RPM, 400/690V, 50 Hz (post 2021) ENGE-8KW-400/690V-S3

ENGE-50HZ-MILL-BOX #8/11KW-YD/SS (LM30, HD38) (8kW/YD and 11kW/SS, 400/230V, S3, 3PH,

50HZ electric)

ENGE-50HZ-MILL-BOX

#8/11KW-YD/SS

1 Sheave - 5.0" sheave (HD36) (bushing MILL-BUSH38MM req'd) MILL-SHV50IN

1 Bushing - 38mm QD metric (for MILL-SHV46IN & MILL-SHV56IN sheaves) (HD36, LM29) MILL-BUSH38MM

1 Manual - Y-D and soft start electric motor system (S3) (English)(LM30, HD36v2, HD38) MILL-ELEC-S3-YD/SS-MAN

EN–9

MILL-ELEC-S3-YD-SS-INST (2022-11-24).indd 9MILL-ELEC-S3-YD-SS-INST (2022-11-24).indd 9 2022-11-25 11:31:36 AM2022-11-25 11:31:36 AM

Qty. Description Norwood No.

MILLV2-BAG #ELECT - 400/230V, E.U. Electric MILLV2-BAG #ELECT-400/230V

10 3/8 nut - flanged nylon lock nut FASN-38LNF

63/8 nut - flanged (regular) FASN-38RFL

12 3/8 x 1" bolt - flanged bolt FASB-38X1L

5Cable tie - Reusable nylon 6" black DBKR-CTIE6

3Cable tie mount - Adhesive mount DBKR-CTMA

23/8 x 2" bolt - flanged bolt FASB-38X2F

43/8 x 1 1/2" bolt - flanged bolt FASB-3815F

ENGE-BOX #8KW-400V-S3-YD (8kW/YD, 400V, S3, 3PH, 50HZ Electric) ENGE-BOX #8KW-400V-S3-YD

1Electric - Control Panel w/controller, switches & 12v convertor - 8 to 11kW, Y-D, 400V, 3PH, S3 ENGE-400V-S3-YD-CP-12V

1Electric - Remote control box clamping bracket (LM29v2, MN26v2, HD36) MILL-EUELEC-0012

1Electric motor - Control panel bracket (CE) (LM30, MN27) LM29-E0003

2Electric - Control panel clamp (38mm) (HD36, HD36v2, HD38) ENGE-38MM-CPCLAMP

1 Hardware bag with cable tie, screws for guards and deadmen switches

2.5m 20mm diameter loom tube

For LM30-PP-8KW-230V-S3-SS

Loose-packed items

1 Electric - Motor - 8kW S3 duty, 2900 RPM, 400/690V, 50 Hz (post 2021) ENGE-8KW-400/690V-S3

ENGE-50HZ-MILL-BOX #8/11KW-YD/SS (LM30, HD38) (8kW/YD and 11kW/SS, 400/230V, S3, 3PH,

50HZ electric)

ENGE-50HZ-MILL-BOX

#8/11KW-YD/SS

1 Sheave - 5.0" sheave (HD36) (bushing MILL-BUSH38MM req'd) MILL-SHV50IN

1 Bushing - 38mm QD metric (for MILL-SHV46IN & MILL-SHV56IN sheaves) (HD36, LM29) MILL-BUSH38MM

1 Manual - Y-D and soft start electric motor system (S3) (English)(LM30, HD36v2, HD38) MILL-ELEC-S3-YD/SS-MAN

MILLV2-BAG #ELECT - 400/230V, E.U. Electric MILLV2-BAG #ELECT-400/230V

10 3/8 nut - flanged nylon lock nut FASN-38LNF

63/8 nut - flanged (regular) FASN-38RFL

12 3/8 x 1" bolt - flanged bolt FASB-38X1L

5Cable tie - Reusable nylon 6" black DBKR-CTIE6

3Cable tie mount - Adhesive mount DBKR-CTMA

23/8 x 2" bolt - flanged bolt FASB-38X2F

43/8 x 1 1/2" bolt - flanged bolt FASB-3815F

ENGE-BOX #8KW-230V-S3-YD (8kW/YD, 230V, S3, 3PH, 50HZ Electric) ENGE-BOX #8KW-230V-S3-YD

1Electric - Control Panel w/controller, switches & 12v convertor - 8 to 11kW, Y-D, 230V, 3PH, S3 ENGE-230V-S3-YD-CP-12V

1Electric - Remote control box clamping bracket (LM29v2, MN26v2, HD36) MILL-EUELEC-0012

1Electric motor - Control panel bracket (CE) (LM30, MN27) LM29-E0003

2Electric - Control panel clamp (38mm) (HD36, HD36v2, HD38) ENGE-38MM-CPCLAMP

1 Hardware bag with cable tie, screws for guards and deadmen switches

2.5m 20mm diameter loom tube

EN–10

MILL-ELEC-S3-YD-SS-INST (2022-11-24).indd 10MILL-ELEC-S3-YD-SS-INST (2022-11-24).indd 10 2022-11-25 11:31:36 AM2022-11-25 11:31:36 AM

Technical Data — HD38

ELECTRICAL SYSTEM

Power 400 V, 50 Hz, 3/N/PE, 11 kW, 25 A

230 V, 50 Hz, 3/N/PE, 11 kW, 32 A

Protection class IP55

MOTOR SPECIFICATIONS

Weight 11 kW: 62 kg

Rotation speed 2945 rpm

Standard IEC

SOUND LEVELS

Sound Pressure in the Operator’s Area 88 dB(A) k=4 dB

Sound Power (Estimated) 109.4 dB(A) k=4 dB

Vibration Level < 2.5 m/s2

OTHER DATA

Water Container 12 L (3.2 US gal)

For HD38 with 11 kW

Attention! Through poor conditions of the electrical MAINS, short voltage drops can appear when starting

the EQUIPMENT. This can influence other equipment (e.g. Blinking of a lamp). If the MAINS-IMPEDANCE

Zmax<0.421 Ω, such disturbances are not expected. (In case of need, you may contact your local supply

authority for further information).

EN–11

MILL-ELEC-S3-YD-SS-INST (2022-11-24).indd 11MILL-ELEC-S3-YD-SS-INST (2022-11-24).indd 11 2022-11-25 11:31:36 AM2022-11-25 11:31:36 AM

ELECTRICAL SYSTEM

Power 400 V, 50 Hz, 3/N/PE, 11 kW, 25 A

230 V, 50 Hz, 3/N/PE, 11 kW, 32 A

400 V, 50 Hz, 3/N/PE, 8 kW, 16 A

230 V, 50 Hz, 3/N/PE, 8 kW, 32 A

Protection class IP55

MOTOR SPECIFICATIONS

Weight 11 kW: 62 kg

8 kW: 55 kg

Rotation speed 2945 rpm

Standard IEC

SOUND LEVELS

Sound Pressure in the Operator’s Area 88 dB(A) k=4 dB

Sound Power (Estimated) 109.4 dB(A) k=4 dB

Vibration Level < 2.5 m/s2

OTHER DATA

Water Container 12 L (3.2 US gal)

For HD36v2 with 11 kW

Attention! Through poor conditions of the electrical MAINS, short voltage drops can appear when starting

the EQUIPMENT. This can influence other equipment (e.g. Blinking of a lamp). If the MAINS-IMPEDANCE

Zmax<0.421 Ω, such disturbances are not expected. (In case of need, you may contact your local supply

authority for further information).

For HD36v2 with 8 kW

Attention! Through poor conditions of the electrical MAINS, short voltage drops can appear when starting

the EQUIPMENT. This can influence other equipment (eg. Blinking of a lamp). If the MAINS-IMPEDANCE

Zmax<0.372 Ω, such disturbances are not expected. (In case of need, you may contact your local supply

authority for further information).

EN–12

Technical Data — HD36v2

MILL-ELEC-S3-YD-SS-INST (2022-11-24).indd 12MILL-ELEC-S3-YD-SS-INST (2022-11-24).indd 12 2022-11-25 11:31:36 AM2022-11-25 11:31:36 AM

ELECTRICAL SYSTEM

Power 400 V, 50 Hz, 3/N/PE, 8 kW, 16 A

230 V, 50 Hz, 3/N/PE, 8 kW, 32 A

Protection class IP55

MOTOR SPECIFICATIONS

Weight 8 kW: 55 kg

Rotation speed 2945 rpm

Standard IEC

SOUND LEVELS

Sound Pressure in the Operator’s Area 88 dB(A) k=4 dB

Sound Power (Estimated) 109.4 dB(A) k=4 dB

Vibration Level < 2.5 m/s2

OTHER DATA

Water Container 12 L (3.2 US gal)

For LM30 with 8 kW

Attention! Through poor conditions of the electrical MAINS, short voltage drops can appear when starting

the EQUIPMENT. This can influence other equipment (e.g. Blinking of a lamp). If the MAINS-IMPEDANCE

Zmax<0.372 Ω, such disturbances are not expected. (In case of need, you may contact your local supply

authority for further information).

Technical Data — LM30

EN–13

MILL-ELEC-S3-YD-SS-INST (2022-11-24).indd 13MILL-ELEC-S3-YD-SS-INST (2022-11-24).indd 13 2022-11-25 11:31:37 AM2022-11-25 11:31:37 AM

Install the left (186) and right (187) rear

leg assemblies to the last 4 threaded

holes of the lower frames LOOSELY. DO

NOT TIGHTEN ANY BOLTS YET.

Use 3/8 x 3/4” flange bolts (33A). Finger

tight only.

Install the two rear leg assembly spacers

(LM34-C0220-SPC). Use the 3/8” x 1.0”

bolts and 3/8” nylon lock nuts.

Before assembly, inspect parts to detect any apparent

damage. If there are damaged or missing parts, inform

Norwood Sawmills immediately.

Note: these instructions are used to assemble the electric

motor package for your sawmill. Some parts and pictures

might not be identical to your sawmill but are similar.

Please use these instructions in conjunction with your

sawmill manual.

Two rear leg assembly Spacers (LM34-C0220-SPC) and

two 318 cm sawhead lift cables (HD36-SHCBL-ELEC) of the

HD36v2 electric motor package need to be installed before

the assembly of the electric motor package.

EN–14

Assembly

MILL-ELEC-S3-YD-SS-INST (2022-11-24).indd 14MILL-ELEC-S3-YD-SS-INST (2022-11-24).indd 14 2022-11-25 11:31:38 AM2022-11-25 11:31:38 AM

Install the electric motor on the sawhead

panel.

See hole locations shown in the

following steps for each model.

Install the push handle onto the carriage

using the 3/8” x 3/4” carriage bolts and

3/8” flanged Nyloc nuts.

For LumberMax HD38

Use the holes indicated here.

Secure the electric motor with the 3/8” x

1 ½” bolts and 3/8” flanged nuts.

EN–15

Motor Installation

MILL-ELEC-S3-YD-SS-INST (2022-11-24).indd 15MILL-ELEC-S3-YD-SS-INST (2022-11-24).indd 15 2022-11-25 11:31:41 AM2022-11-25 11:31:41 AM

For LumberPro HD36v2

Use the holes indicated here.

Secure the electric motor with the 3/8” x

1 ½” bolts and 3/8” flanged nuts.

For LumberMate LM30

Use the holes indicated here.

Secure the electric motor with the

3/8” x 1 ½” bolts and 3/8” flanged nuts.

Install the sheave and secure it with the

bushing onto the motor shaft. Secure it

using the 3 bolts provided inside the box

of the bushing.

EN–16

MILL-ELEC-S3-YD-SS-INST (2022-11-24).indd 16MILL-ELEC-S3-YD-SS-INST (2022-11-24).indd 16 2022-11-25 11:31:42 AM2022-11-25 11:31:42 AM

Other manuals for LumberMax HD38

5

This manual suits for next models

3

Table of contents

Languages:

Other Norwood Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

schmersal

schmersal AZM300B-ST-SD2P Instructions for operation

Elesa

Elesa DD51-E Instructions for use

Otec

Otec ECO mini dry operating instructions

ABB

ABB HT613159 Operation manual

Endress+Hauser

Endress+Hauser 51517656 CleanFit H CPA 475 operating instructions

Bosch

Bosch Rexroth IndraMotion MLC operating instructions