Robust trolley carries portable MIG welder and gas bottle, making

relocation of welding equipment quick and easy. Fitted with two fixed

wheels and two castors for excellent manoeuvrability and supplied

with bottle retaining chains and cable stowage hooks.

Upper tray for MIG welder and two lower trays for associated items.

Suitable for portable MIG welders up to 300mm wide and 480mm

long.

Suitable for Sealey Welders: PMG110 and S0771. Also PM140XT,

PM150XT, PMG135XT, PMG155XT with wheels and axle removed.

DO NOT put more than one bottle on the trolley.

Always seat the bottle in the upright position.

Always secure the bottle tightly to the trolley with the chains

provided.

Only use the trolley on firm, level, unobstructed surfaces which

are capable of supporting the trolley and its load.

DO NOT use the trolley on sloping surfaces.

DO NOT allow others to ride on the trolley.

DO NOT attempt to move the trolley by pulling on the earth or

torch cable.

DO NOT attach the welder’s earth clamp to the metal frame of

the trolley as this may result in accidental arcing from the torch.

Replace or repair damaged parts. Use only recommended

parts. Unauthorised parts may be dangerous and will invalidate the

warranty.

Store gas cylinders in a vertical position only and ensure the

storage area is correctly secured.

DO NOT store gas cylinders in areas where temperature

exceeds 50°C. DO NOT use direct heat on a cylinder. Always

keep gas cylinders cool.

DO NOT attempt to repair or modify any part of a gas cylinder

or valve, and DO NOT puncture or damage a cylinder.

DO NOT obscure or remove any official labels from a cylinder.

Always check the gas identity before use.

Avoid getting gas cylinders oily or greasy.

DO NOT try to lift or handle cylinder by its cap, guard or valve.

Always keep caps and guards in place and close valve when

not in use.

Gas cylinders are heavy, use mechanical lifting equipment.

Warning! Failure to comply with these instructions may result in loss

of load, damage to trolley or other property and/or personal injury.

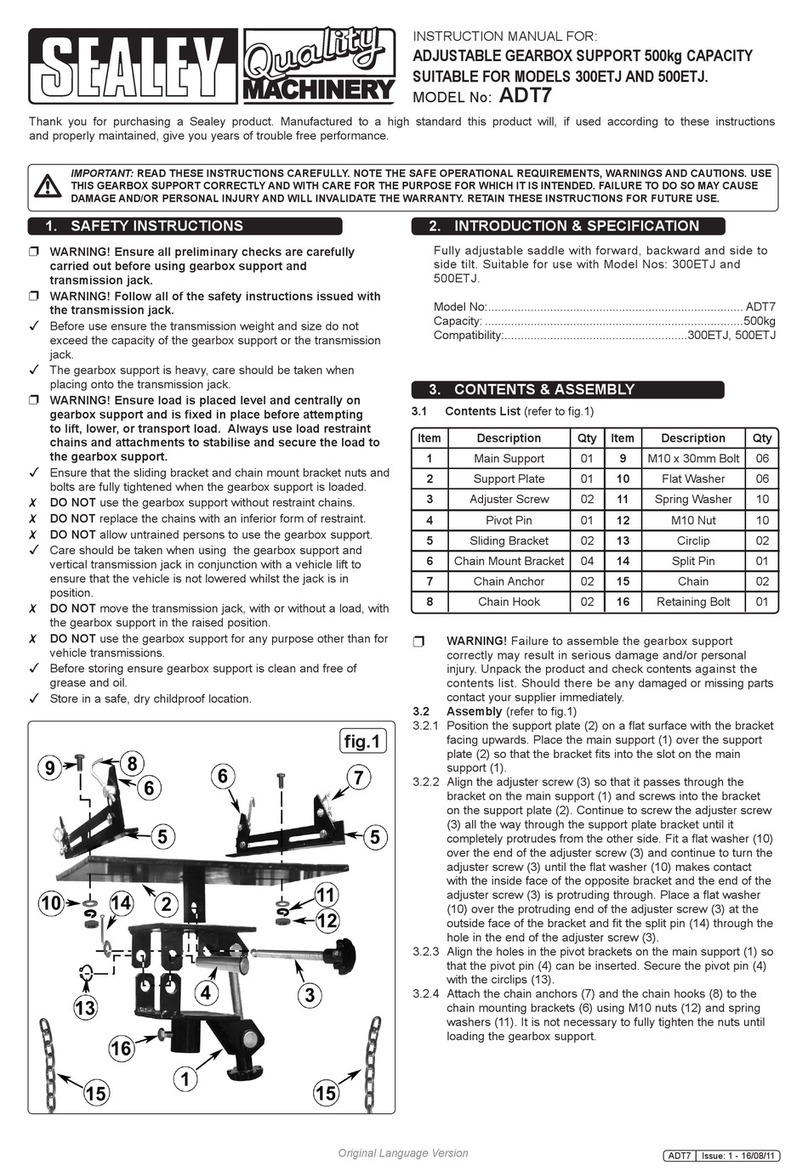

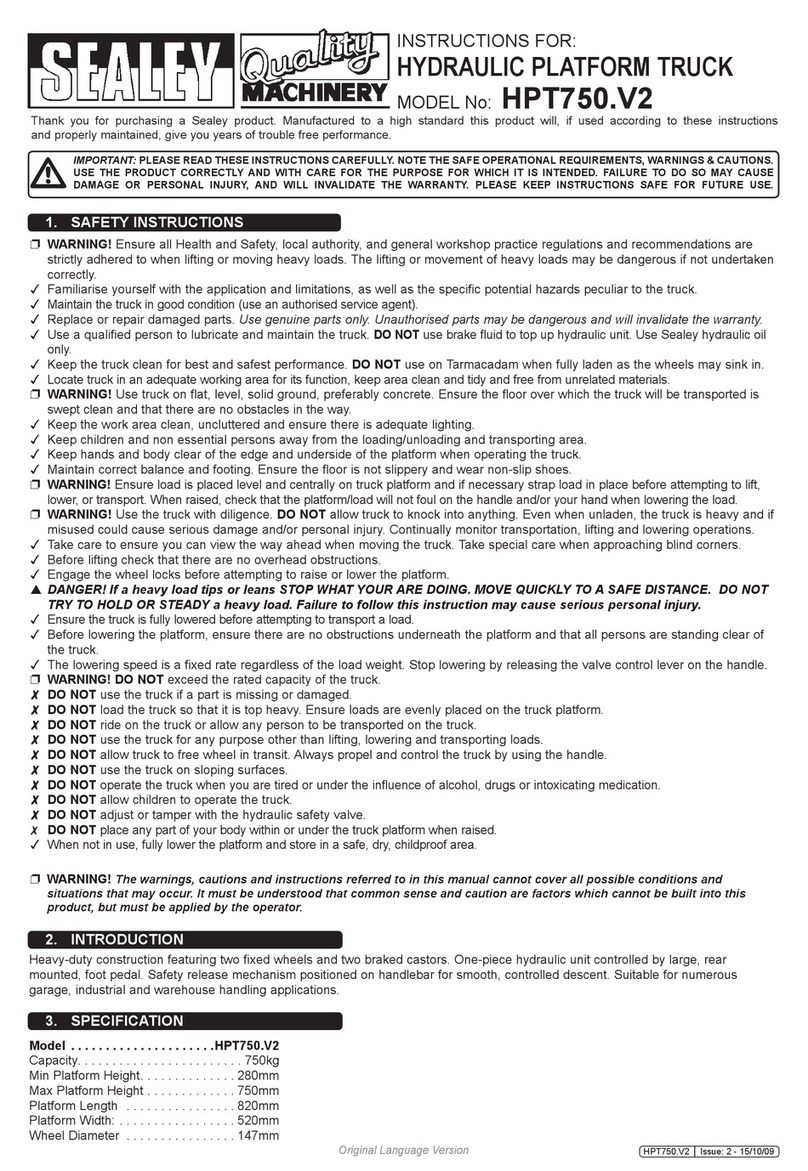

No. Description Qty.

1Top Tray 1

2 Hook 2

3Middle Tray 1

4Left support 1

5Bottom Tray 1

6Front Castor Wheel 2

7 Hex-nut 34

8Right Support 1

9 Hex-bolt 34

10 Split Pin 2

11 Flat Washer 4

12 Rear Wheel 2

13 Axle Support 2

14 Axle 1

15 Back Panel 1

16 Chain 2

3.1 Using the diagram below as a guide; loosely assemble the

trolley.

3.2 Slide the axle supports (13) through the slots in the base (5)

so the axle may be inserted into the supports.

3.3 When the wheels (12 and 6), back panel (15), shelves (1, 3

and 5), upright supports (4 and 8) and the hooks (2) are in

place,tightenallxings.

NOTE! When attaching the back panel (15) ensure the slots for the

chains are facing downwards.

UNIVERSAL TROLLEY FOR PORTABLE MIG

WELDERS

MODEL NO: BTR4.V2

1. SAFETY

2. INTRODUCTION

3. ASSEMBLY

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS & CAUTIONS. USE THE PRODUCT

CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE DAMAGE AND/OR PERSONAL INJURY AND WILL

INVALIDATE THE WARRANTY. KEEP THESE INSTRUCTIONS SAFE FOR FUTURE USE.

Thank you for purchasing a Sealey product. Manufactured to a high standard, this product will, if used according to these

instructions and maintained properly, give you years of trouble free performance.

Refer to instruction

manual

BTR4.V2 Issue:3(HF)- 22/03/18

© Jack Sealey Limited Original Language Version