Novalynx 100-1950 User manual

NOVALYNX CORPORATION

MODEL 100-1950

WEATHER STATION

INSTRUCTION MANUAL

Receiving nd Unp cking

Carefully unpack all components and compare to packing list. Notify NovaLynx

Corporation immediately concerning any discrepancy. Inspect equipment to detect any

damage that may have occurred during shipment. In the event of damage, any claim for

loss must be filed immediately with the carrier by the consignee. amages to equipment

sent via Parcel Post or UPS require the consignee to contact NovaLynx Corporation for

instructions.

Returns

If equipment is to be returned to the factory for any reason, call NovaLynx between 8:00

A.M. and 4:00 P.M. Pacific Time and request a Return Authorization Number (RA#).

Include with the returned equipment, a description of the problem and the name, address,

and daytime phone number of the sender. Carefully pack the equipment to prevent

damage or additional damage in the return shipment. Call NovaLynx for packing

instructions in the case of delicate or sensitive items. If packing facilities are not available

take the equipment to the nearest Parcel Post, UPS, or freight service and obtain

assistance with the packaging. Write the RA# on the outside of the box.

W rr nty

NovaLynx Corporation warrants that its products are free from defects in material and

workmanship under normal use and service for a period of one year from the date of

shipment from the factory. NovaLynx Corporation's obligations under this warranty are

limited to, at NovaLynx's option: (i) replacing; or (ii) repairing; any product determined to

be defective. In no case shall NovaLynx Corporation's liability exceed product's original

purchase price. This warranty does not apply to any equipment that has been repaired or

altered, except by NovaLynx Corporation, or that has been subjected to misuse,

negligence, or accident. It is expressly agreed that this warranty will be in lieu of all

warranties of fitness and in lieu of the warranty of merchantability.

Address

Nov Lynx Corpor tion

4055 Gr ss V lley Highw y, Suite 102

Auburn, CA 95602

(530) 823-7185

FAX (530) 823-8997

Copyright © 1997 by NovaLynx Corporation

ii

TABLE OF CONTENTS

SECTION NO. P A G E N O .

1.0 GENERAL DESCRIPTION 1

1.1 Wind Speed nd Direction 1

1.2 Temper ture 1

1.3 Rel tive Humidity 1

1.4 B rometric Pressure 1

2.0 SPECIFICATIONS 2

3.0 INSTALLATION 2

4.0 THEORY OF OPERATION 3

4.1 Temper ture 3

4.2 B rometric Pressure 4

4.3 Rel tive Humidity 4

4.4 Wind Speed 4

4.5 Wind Direction 4

5.0 CALIBRATION 5

5.1 Wind Speed 5

5.2 Wind Direction 5

5.3 Temper ture 5

5.4 Rel tive Humidity 6

5.5 B rometric Pressure 6

6.0 MAINTENANCE 6

7.0 PARTS LIST 7

iii

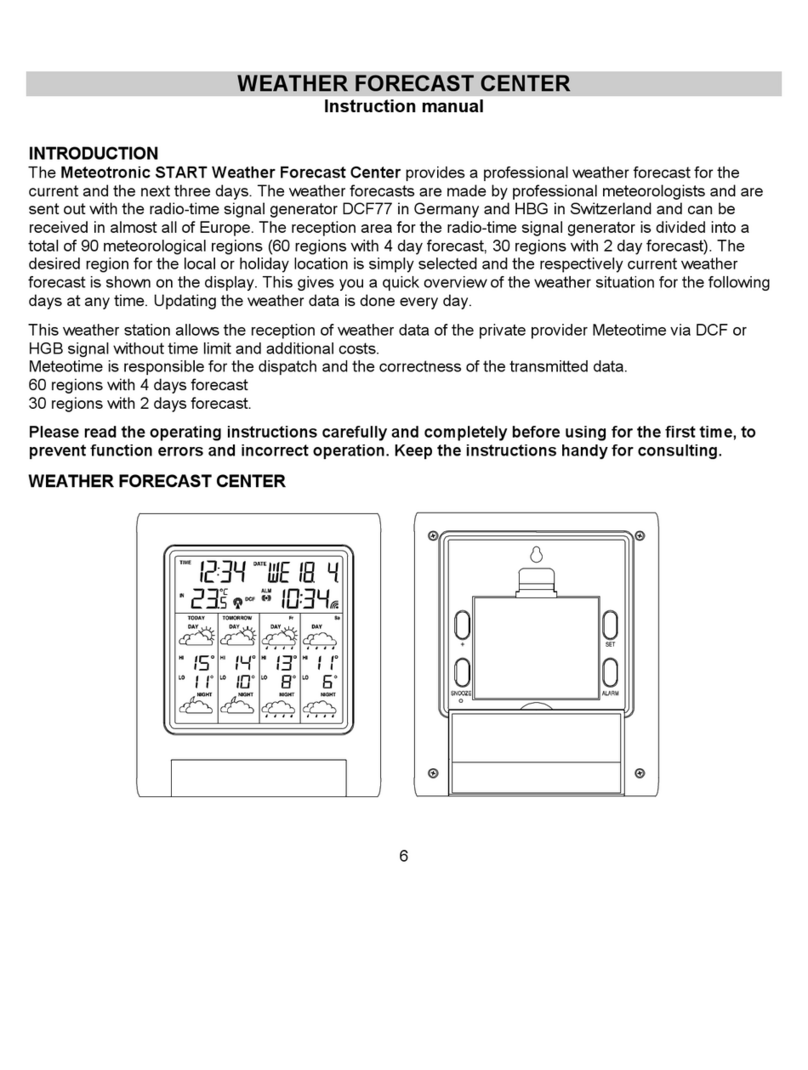

WEATHER STATION

Model 100-1950

1.0 GENERAL DESCRIPTION

NovaLynx Corporation provides a weather station, Model 100 -1950, that displays Wind

Speed, Wind irection, Temperature, Relative Humidity, and Barometric Pressure. The

weather displays are analog dials that are enclosed in an attractive wood frame suitable

for hanging on a wall.

1.1 Wind Speed nd Direction

The Wind Speed and Wind irection indicators are rectangular electrical meters with

needles that deflect with the changing winds. A combination anemometer and vane wind

sensor is mounted outdoors at an elevation that will give good exposure to the local winds.

The wind sensor is connected to a signal conditioning circuit board located behind the

meter case. The anemometer circuit is self generating while the vane circuit requires an

external power supply.

1.2 Temper ture

The other meters are mechanical devices. The temperature dial is connected to a

remotely located temperature sensor through a capillary tube. The temperature measured

at the end of the tube is indicated by the meter. The remote temperature sensor may be

located to measure either indoor or outdoor air temperatures.

1.3 Rel tive Humidity

The relative humidity dial is a self-contained meter with the sensing element housed inside

the meter. As the relative humidity changes, the meter will respond and its pointer will

indicate the new value.

1.4 B rometric Pressure

Similarly, the barometer dial contains the sensing element and indicates changes in the

atmospheric pressure. A moveable set-point needle allows the operator to determine

whether the barometer has risen or fallen since the last reading has been taken.

1

2.0 SPECIFICATIONS

Sensors:

Wind Speed: AC Generator

Wind irection: 120 ohm Potentiometer

Temperature: Vapor Capillary

Relative Humidity: Bonded Helical Coil

Barometer: Aneroid Cell

Measured Ranges:

Wind Speed: 0-25/25-100 mph

Wind irection: Nine Cardinal Points

Temperature: -40 to +140EF

Relative Humidity: 0 to 100 % R.H.

Barometer: 27 to 32 in. Hg

& 914 to 1086 mb

Wind Sensor Cable: 5 conductor, 20 AWG

Cable Length: 50 feet ( 15 m )

Temperature Tube: 6 ft ( length not extendable )

Front Panel Finish: ark Mahogany

Power requirements: 1 ea " " cell battery

isplay Size: 12" hi x 16.5" w x 3" d

( 305 x 419 x 76 mm )

Weight / Shipping: 16 lbs / 20 lbs

( 7 kg / 9 kg )

3.0 INSTALLATION

Installation of the weather station is relatively simple. The wind sensor and temperature

sensor are mounted outdoors with the wind sensor placed onto a mast and the

temperature sensor clamped onto a wall. The wind sensor has a mounting collar with

locking screws that allow it to be installed onto a 1" O. . mast or pipe. If the sensor is to

be located on the roof of a building, the mast should be located on the upwind side. For

small structures, the mast should be one and one half times as high as the building upon

which it sits. If this is not practical such as is the case for extremely tall buildings, then the

mast should be at least thirty feet high above the roof. The nature of the vane requires that

it be aligned to North. Alignment marks are provided on the sensor housing. Refer to the

sensor manual for specific instructions. Route the wind sensor cable in the most direct

2

manner to the display and connect the five pin IN plug into the matching connector

located on the side of the display panel.

The temperature sensor should be located on the North side of the structure and under an

eave or overhang if possible. The temperature sensor should be protected from exposure

to direct sun light and rain to avoid errors in the readings. If a temperature sensor shelter

is available, place the sensor inside the shelter. The temperature sensor must be installed

by routing the capillary tube from the display to the desired location of the sensor. In many

instances, the display will need to be positioned as close as possible to the outside wall

and next to the temperature sensor installation point. If possible, route the capillary tube

through the nearest window, taking care to avoid bending or deforming the tube in any

manner otherwise errors in the reading will result. If a window is not available, drill a hole

through the wall to get the temperature sensor to the outside. Fill the hole to prevent air

and moisture intrusion. Use a clamp or appropriate hardware to fasten the temperature

sensor to the wall or nearest support structure.

For both the wind sensor and the temperature sensor, the cable and capillary tube must

be secured to prevent being damaged by high winds. Clamp or tie down the wind sensor

cable every two to three feet using either plastic wire ties or other appropriate hardware to

suit the installation and the supporting structure. Secure the temperature sensor tube

being very careful to avoid crimping, sharp bends, and any deformation of the tube.

Please note that the temperature sensor tube contains a fluid and must not be cut open

for any reason. The temperature sensor tube can not be extended in length due to its

design.

Install one each " " cell battery into the battery holder inside the back of the display. The

battery provides power for the wind direction sensor and dial.

Upon completion of the installation of the wind sensor and temperature sensor, hang the

display onto the wall. Use the same methods as those employed to hang pictures. Avoid

placing the display panel near sources of heat and cold and humidity to eliminate errors

in the readings. Place the display at a height that will provide a convenient viewing of the

dials. Be sure to leave a small space behind the display to allow air flow for the relative

humidity sensor to operate properly.

Periodic checking of the sensors and dials will help ensure good readings from the dials.

4.0 THEORY OF OPERATION

4.1 Temper ture

The temperature dial movement is accomplished through the use of a vapor capillary

system. As the temperature at the sensing end increases, an increase in the pressure

inside the capillary tube occurs. The increase in pressure moves the meter pointer. The

3

meter has been designed and calibrated to give readings corresponding to the measured

temperatures.

4.2 B rometric Pressure

The barometer dial incorporates an aneroid cell as the sensing device. The cell

mechanically changes shape as the atmospheric pressure increases and decreases. The

aneroid cell is attached to the meter pointer. The dial mechanism moves the pointer in

relation to the measured pressure. A manually adjustable pointer is used to track whether

the pressure is rising or falling. Whenever a reading is made the pointer is placed over the

aneroid cell's pointer. At the next reading the observer can determine if the new reading

is greater than or less than the previous reading.

4.3 Rel tive Humidity

Relative humidity is measured by a coiled sensor with a special coating that is sensitive to

moisture. As the relative humidity of the surrounding air changes, the coating of the coiled

material either absorbs or releases moisture as it attempts to attain equilibrium with the air.

The coiled material expands with increasing moisture and contracts as the moisture

decreases. Movement of the coiled material is transmitted to the dial pointer and is

calibrated to reflect the relative humidity of the air.

4.4 Wind Speed

Wind speed is sensed by anemometer cups that turn as the wind speed increases above

the starting threshold of the sensor. The cups are coupled to an AC generator that

generates an AC signal as the cups rotate. The AC signal is transmitted by two wires to

the circuit board at the display panel. Electronic components rectify, filter, and scale the

signal into a calibrated C signal to drive the meter. A range switch enables the observer

to select the Low or High range in order to obtain the best resolution when making a

reading. For wind speeds below twenty-five miles per hour, the best reading is obtained

by setting the range switch to the Low position. For wind speeds above twenty-five mph,

use the High range switch position. The AC wind speed signal is not polarized electrically

and therefore reversal of the wind speed wiring will not harm or change the operation of

the signal conditioning circuit.

4.5 Wind Direction

Wind direction is sensed by a moving potentiometer that has been mechanically coupled

to the vane. Changes in the wind direction cause the vane to move the potentiometer. A

C signal from the " " cell battery powers the potentiometer. As the potentiometer moves

it creates a changing C voltage across its resistive element. The changing C signal is

presented at the wiper of the potentiometer and is connected to the signal conditioning

circuit at the display panel. The signal conditioning circuit provides an adjustment for "fine

4

tuning" of the wind direction meter. A three position switch allows the operator to select

the wind direction sensor, the calibration mode, or to disconnect the battery. Whenever

readings are to be made infrequently, it is recommended that the wind direction circuit be

disconnected to increase the life of the battery.

5.0 CALIBRATION

5.1 Wind Speed

Adjust the wind speed circuit by first setting the range switch to the Low range position.

Remove the anemometer cups and attach a wind speed spin-up motor to the generator

shaft. Rotate the shaft at a constant 300 rpm. For the standard wind sensor, the 300 rpm

represents 18.5 mph ( 8.2 m/s ). Adjust the wind speed range potentiometer located on

the signal conditioning circuit. If possible check the circuit operation at a higher wind speed

by rotating the anemometer shaft at one of the higher rpm values shown, such as 600 rpm.

Please note that the anemometer calibration is fixed and is determined by wind tunnel

tests. There is no adjustment as to the mph vs rpm values. Should the anemometer cups

become damaged the response of the cups to the wind will be affected and will result in

errors in the meter readings. Replace damaged cups as soon as possible. Worn

generator bearings can also result in wind speed errors. Replace the anemometer

bearings at least annually, and especially in areas that experience constant wind activity.

5.2 Wind Direction

As the vane rotates in a clockwise direction as viewed from above the sensor, the meter

will increase its reading from zero to 360 to a maximum indication of East. The full-scale

reading will vary as the battery loses its power over time. The full-scale adjustment should

be checked before taking readings, especially if readings are taken infrequently. Set the

front panel switch to the calibration check position. The sensor should be connected to the

meter circuit during this test. Adjust the front panel control until a full-scale reading is

obtained. If it is difficult to make the adjustment, it may be an indication that the battery

needs to be replaced. Notice that the full-scale deflection of the meter is East, or 90

degrees Azimuth.

5.3 Temper ture

The temperature meter and capillary tube do not have any user available adjustments.

The only check that can be made is to place the temperature sensor into a controlled or

stable temperature bath and compare the reading with that of glass thermometer or

another electronic thermometer. For temperature readings that appear to be slightly off

during the temperature check, make note of the difference and apply the value to the meter

readings whenever a reading is taken. Should the temperature reading appear to be

substantially in error the temperature sensor and meter may need replacement. Contact

5

NovaLynx for assistance.

5.4 Rel tive Humidity

Relative humidity has an adjustment screw located at the rear of the meter. Obtain the

local relative humidity by using a mechanical or an electronic psychrometer. Adjust the

screw to obtain the same reading on the humidity dial. Make only minor adjustments to the

meter at any one time. Allow the meter to stabilize for a few minutes and then repeat

should more adjustment be required. An agreement of three to five percent RH should be

acceptable for this type of meter.

5.5 B rometric Pressure

The barometer should be adjusted for the station elevation. Obtain the local barometric

pressure by calling the local airport or by listening to local weather forecasts. Adjust the

screw at the rear of the barometer to obtain the same reading. Follow the local readings

for several days and readjust the meter as required. Make only minor adjustments at any

time. o not use force or turn the screw by a large amount to avoid damaging the

barometer.

6.0 MAINTENANCE

Maintenance of the weather station is limited to keeping the display panel clean and free

of dust. Use only a damp cloth and water to clean the surfaces of the display panel. The

sensors should be free of debris and kept clean. The wind sensor should be checked for

worn bearings, damaged cable, and loose hardware. Periodic inspections should be made

to help maintain the accuracy of the data. Each time a reading is made, check the wind

sensor to ensure that it is rotating freely in the wind and there are no major problems.

6

7.0 PARTS LIST

MODEL 100-1950

WEATHER STATION

PART NO. ESCRIPTION QTY

100-2130 COMBINATION WIN SENSOR 1

100-19501 TEMPERATURE IAL ASSEMBLY 1

92080000 BAROMETRIC PRESSURE IAL 1

92080200 HUMI ITY IAL 1

92080300 WIN SPEE METER 1

92080400 WIN IRECTION METER 1

7

Table of contents

Other Novalynx Weather Station manuals

Popular Weather Station manuals by other brands

Ambient Weather

Ambient Weather WS-1090 user manual

La Crosse Technology

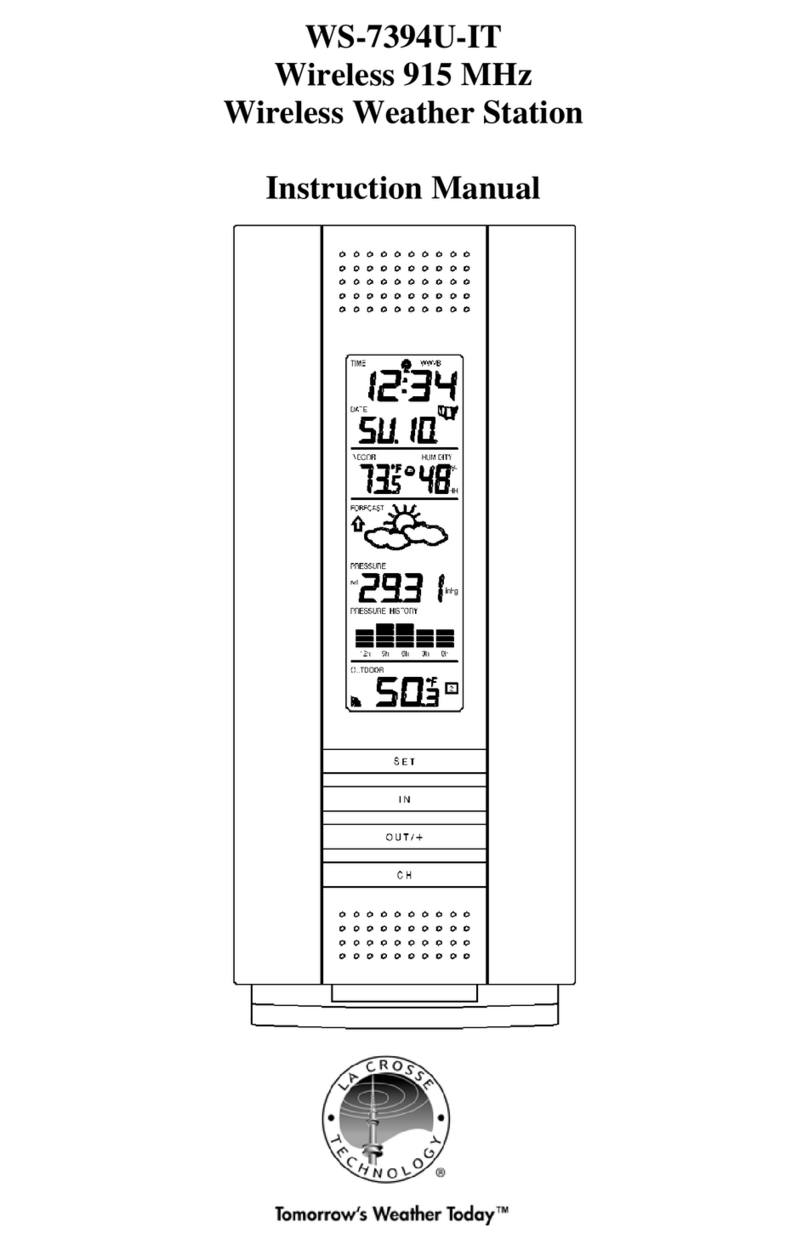

La Crosse Technology Tomorrow's Weather Today WS-7394U-IT instruction manual

Elma Instruments

Elma Instruments DTR 880A user manual

La Crosse Technology

La Crosse Technology 308-1451H instruction manual

Hama

Hama 00092659 EWS-165 operating instructions

TESA

TESA WS2980C-PRO Operation manual