Novanta MDrive 23 User manual

Mechanical Specifications

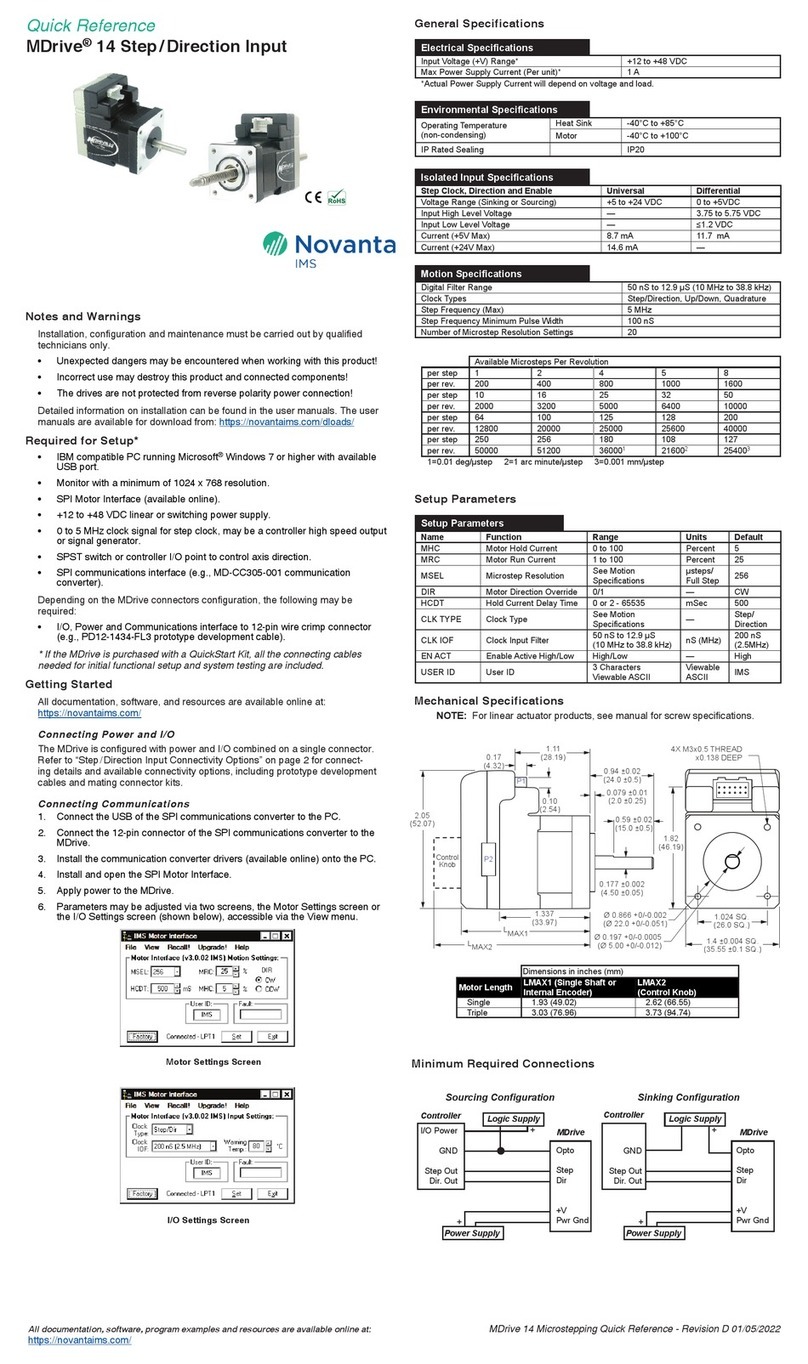

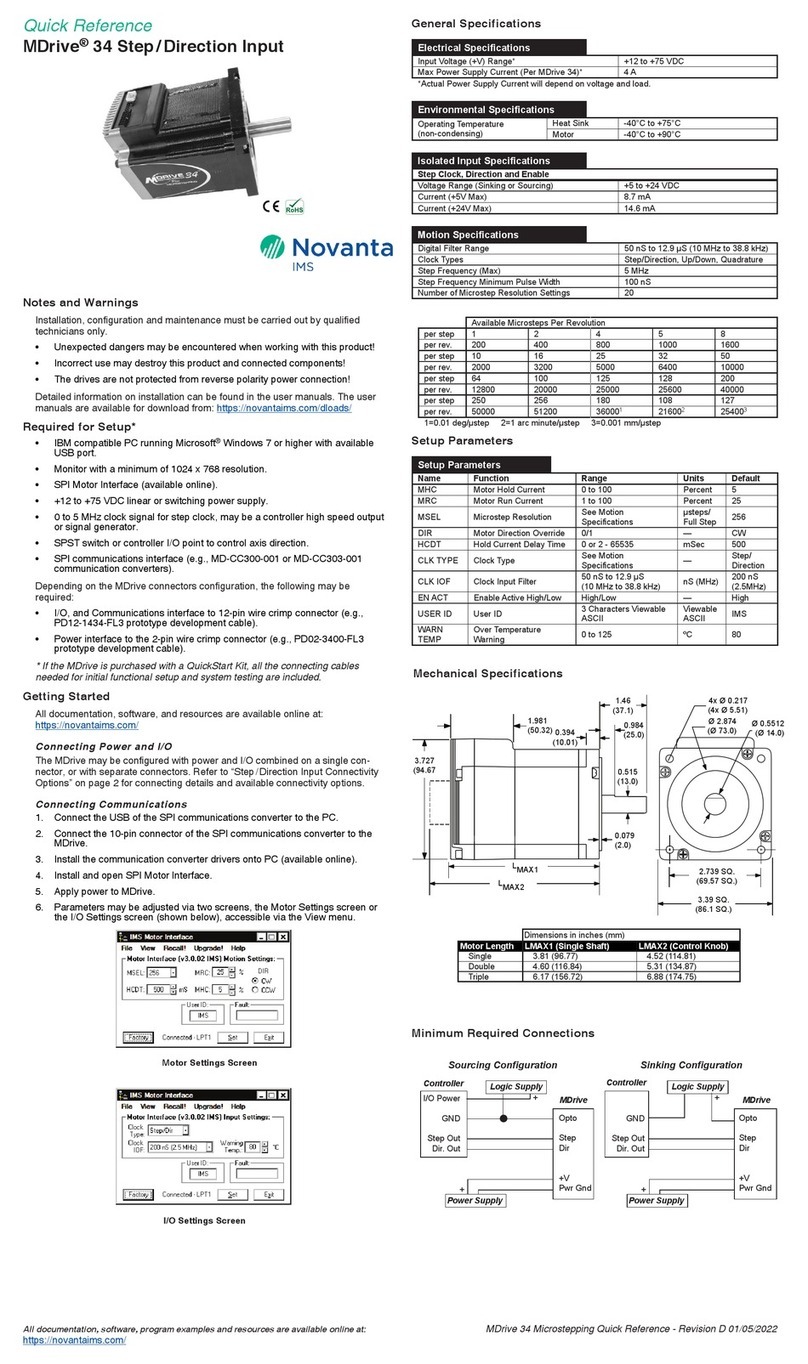

Quick Reference General Specifications

Electrical Specifications

Input Voltage (+V) Range* +12 to +75 VDC

Max Power Supply Current (Per MDrive 23)* 2 A

*Actual Power Supply Current will depend on voltage and load.

Environmental Specifications

Operating Temperature

(non-condensing)

Heat Sink -40°C to +85°C

Motor -40°C to +100°C

Isolated Input Specifications

Step Clock, Direction and Enable

Voltage Range (Sinking or Sourcing) +5 to +24 VDC

Current (+5V Max) 8.7 mA

Current (+24V Max) 14.6 mA

Motion Specifications

Digital Filter Range 50 nS to 12.9 µS (10 MHz to 38.8 kHz)

Clock Types Step/Direction, Up/Down, Quadrature

Step Frequency (Max) 5 MHz

Step Frequency Minimum Pulse Width 100 nS

Number of Microstep Resolution Settings 20

Available Microsteps Per Revolution

per step 1 2 4 5 8

per rev. 200 400 800 1000 1600

per step 10 16 25 32 50

per rev. 2000 3200 5000 6400 10000

per step 64 100 125 128 200

per rev. 12800 20000 25000 25600 40000

per step 250 256 180 108 127

per rev. 50000 51200 360001216002254003

1=0.01 deg/µstep 2=1 arc minute/µstep 3=0.001 mm/µstep

Setup Parameters

Setup Parameters

Name Function Range Units Default

MHC Motor Hold Current 0 to 100 Percent 5

MRC Motor Run Current 1 to 100 Percent 25

MSEL Microstep Resolution See Motion

Specifications

µsteps/

Full Step 256

DIR Motor Direction Override 0/1 — CW

HCDT Hold Current Delay Time 0 or 2 - 65535 mSec 500

CLK TYPE Clock Type See Motion

Specifications —Step/

Direction

CLK IOF Clock Input Filter 50 nS to 12.9 µS

(10 MHz to 38.8 kHz) nS (MHz) 200 nS

(2.5MHz)

EN ACT Enable Active High/Low High/Low — High

USER ID User ID 3 Characters Viewable

ASCII

Viewable

ASCII IMS

1.033

(26.2)

2.96

(75.2)

1.480

(37.6) LMAX1

0.230 ±0.004

(5.8 ±0.1)

2.042

(51.9)

P1

P2

LMAX2

2.02

(51.2)

Ø 0.25

(Ø 6.3)

2.22 SQ.

(56.4 SQ.)

Ø 0.197

(Ø 5.0)

1.63

(41.4)

1.856 SQ.

(47.1 SQ.)

0.81

(20.6)

MDrive®23 Step / Direction Input

with Industrial Connectors

Notes and Warnings

Installation, configuration and maintenance must be carried out by qualified

technicians only.

• Unexpected dangers may be encountered when working with this product!

• Incorrect use may destroy this product and connected components!

• The drives are not protected from reverse polarity power connection!

Detailed information on installation can be found in the user manuals. The user

manuals are available for download from: https://novantaims.com/dloads/

Required for Setup*

• IBM compatible PC running Microsoft®Windows 7 or higher with available

USB port.

• Monitor with a minimum of 1024 x 768 resolution.

• SPI Motor Interface (available online).

• +12 to +75 VDC linear or switching power supply.

• 0 to 5 MHz Clock signal for step clock, may be a controller high speed output

or signal generator.

• SPST switch or controller I/O point to control axis direction.

• SPI communications interface (recommended: MD-CC301-001 communica-

tion converter).

If not using the MD-CC301-001 for interfacing, the following may be required:

• I/O, Power and Communications interface to 19-pin M23 circular connector

(recommended: MD-CS100-000 prototype development cordset or equiva-

lent).

* If the MDrive is purchased with a QuickStart Kit, all the connecting cables

needed for initial functional setup and system testing are included.

Getting Started

All documentation, software, and resources are available online at:

https://novantaims.com/

Connecting Power and I/O

The MDrive is configured with power and I/O combined on a single connector.

Refer to “Step / Direction Input Connectivity Options” on page 1 for connecting

details and available connectivity options.

Connecting Communications

1. Connect the USB of the SPI communications converter to the PC.

2. Connect the 19-pin M23 connector of the SPI communications converter to

the MDrive.

3. Install the communication converter drivers onto PC (available online).

4. Install and open SPI Motor lnterface.

5. Apply power to MDrive.

6. Parameters may be adjusted via two screens, the Motor Settings screen or

the I/O Settings screen (shown below), accessible via the View menu.

Motor Settings Screen

I/O Settings Screen

MDrive 23 IP65 Microstepping Quick Reference - Revision D 01/05/2022

All documentation, software, program examples and resources are available online at:

https://novantaims.com/

Dimensions in inches (mm)

Motor Length LMAX1 (Single Shaft or

Internal Encoder)

LMAX2 (Control Knob or

External Encoder)

Single 2.82 (71.63) 3.48 (88.39)

Double 3.16 (80.26) 3.82 (97.03)

Triple 4.02 (102.11) 4.67 (118.62)

MDrive 23 IP65

Step / Direction Input

Connectivity Options

P1

I/O, Power and Communications

M23 industrial connector (male)

P1

Communications Converter p/n: MD-CC301-001

Electrically isolated in-line USB to SPI converter pre-wired with mating connector

to conveniently program and set configuration parameters. A secondary cable

from the mating connector provides interface to power and I/O.

Prototype Development Cordset p/n: MD-CS100/101-000

Speed test and development with pre-wired mating connector.

COM GND

+5VDC SPI Clock

MISO

CS

GND

Enable

DIR

Step Clock

+V

MOSI

Opto Ref

Shell

IDX-*

CH A-*

CH B+*

CH B-*

CH A+*

IDX+*

Outside: Pins 1 -12

2

1

11

10 987

6

5

4

3

12

Inside: Pins 13 -19

1918 15

14

17 16

13

*No Connect unless populated for the optional internal magnetic

differential encoder

To Power & I/O

To computer

USB port

6.0’ (1.8m)

in-line converter

6.0’ (1.8m)

13.0’ (4.0m)

To MDrive

19-pin M23 (male)

Connector

19-pin M23 (Female)

Wire Colors Function

Violet Opto Ref.

Red Enable

Blue +V

Black Comm GND

Green/Yellow Shell

Yellow/Brown Direction

Gray/Brown Step Clock

Brown Power GND

Optional Internal Encoder

Wire Colors Function

Gray IDX+

Red/Blue CH B+

Green CH B-

Gray/Pink CH A+

Brown/Green IDX -

White CH A-

To Power & I/O

13.0’ (4.0m)

To MDrive

19-pin M23 (male)

Connector

19-pin M23 (female)

Wire Colors Function

Violet Opto Ref.

Red Enable

Blue +V*

White/Green MOSI

White/Yellow CS

White/Gray +5 VDC

Black Comm GND

Green/Yellow Shell

Yellow/Brown Direction

Yellow SPI Clock

Pink MISO

Gray/Brown Step Clock

Brown Power GND*

Optional Internal Encoder

Wire Colors Function

Gray IDX+

Red/Blue CH B+

Green CH B-

Gray/Pink CH A+

Brown/Green IDX -

White CH A-

Minimum Required Connections

The diagrams below represent the minimum connections required to operate

the MDrive.

Opto

Step

Dir

+V

Pwr Gnd

Opto

Step

Dir

+V

Pwr Gnd

I/O Power

GND

Step Out

Dir. Out

GND

Step Out

Dir. Out

Power Supply

Logic Supply

+

+

Controller

MDrive

Power Supply

Logic Supply

+

+

Controller

MDrive

Sinking ConfigurationSourcing Configuration

Mating Connector Recommendations

The MD-CS100-000 is recommended with 19-pin M23 connector.

For comparable connector only, shop vendors:

Lumberg

Phoenix

Turck

RDE Connectors

MDrive 23 IP65 Microstepping Quick Reference - Revision D 01/05/2022

Copyright © Novanta IMS novantaims.com

Other Novanta Industrial Equipment manuals