Novanta Fiber Tiger User manual

Fiber Tiger Scan Head

User Manual

Read carefully before using.

Retain for future reference.

Manufacturer

Novanta, Werk 4, 92442 Wackersdorf, Germany

Tel.: +49 (0) 9431 7984-0

E-mail:

photonics@novanta.com

Customer support

Before contacting us for assistance, please review appropriate sections in this manual that

may answer your questions. After consulting the manual, please contact one of our world-

wide offices between 9 AM and 5 PM local time.

Novanta, Werk 4, 92442 Wackersdorf, Germany

Tel.: +49 (0) 9431 7984-0

Contact: https://www.novantaphotonics.com/support

iii

FIBER_TIGER_manual,

2021-11-29

Contents

1. How to use this document 1

1.1. Symbols and signal words . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2. Notation conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.3. Storage and replacement . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.4.

Specifics and structure

. . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.5.

Target audience and qualification

. . . . . . . . . . . . . . . . . . . . . 3

2. General safety instructions 4

2.1. Normal use

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.2.

Reasonably foreseeable misuse

. . . . . . . . . . . . . . . . . . . . . . . 4

2.3. Duty of care by the customer

. . . . . . . . . . . . . . . . . . . . . . . 5

2.4. Hazards

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.4.1. Laser radiation

. . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.4.2.

Laser generated air contaminants

. . . . . . . . . . . . . . . . . 5

2.4.3.

Hot laser-processed material

. . . . . . . . . . . . . . . . . . . . 6

2.4.4.

Coolant and coolant additives

. . . . . . . . . . . . . . . . . . . 6

2.4.5.

Electrostatic discharge

. . . . . . . . . . . . . . . . . . . . . . . 7

2.5.

Modifications and spare parts

. . . . . . . . . . . . . . . . . . . . . . . 8

2.6.

Fire extinguishing media

. . . . . . . . . . . . . . . . . . . . . . . . . . 8

3. Overview 9

3.1.

Labels ..................................................................................................................10

3.2.

Interfaces................................................................................................... 11

3.3.

Controls and indicators ....................................................................................12

4. Preparing for use 13

4.1.

Transporting and storing ......................................................................... 13

4.2.

Unpacking and verifying the scope of delivery..............................................14

4.3.

Installing.................................................................................................... 15

4.3.1.

Incorporating the scan head into a superordinate machine ..............15

4.3.2.

Affixing warning labels .........................................................................18

4.3.3.

Connecting the cooling................................................................. 19

4.3.4.

Connecting the purge gas ....................................................................23

4.3.5.

Connecting the ARGES system controller................................... 25

Contents

iv

FIBER_TIGER_manual,

2021-11-29

4.3.6.

Connecting the electric power supply...........................................................

26

4.3.7.

Connecting the laser fiber..........................................................................

27

4.3.8.

Do not connect the SAFETY interface ..................................................

29

4.3.9.

Do not connect the SERVICE interface ...................................................

29

4.4.

Commissioning ..............................................................................................................

30

4.4.1.

Adjusting the fiber coupling.......................................................................

30

4.4.2.

Correcting the scan field............................................................................

33

5. Operating 34

5.1.

Protection of persons and emergency measures are subject of the superor-

dinate machine ........................................................................................................

34

5.2.

Safe operation, safe functions and operational procedures....................................

34

5.3.

Observable signals ........................................................................................................

35

5.4.

Troubleshooting ......................................................................................................

35

6.

Cleaning, maintaining and repairing

37

6.1.

Maintenance plan ....................................................................................................

37

6.2.

Removing the protective window...........................................................................

37

6.3.

Cleaning the protective window .............................................................................

39

6.4.

Cleaning the fiber tips.............................................................................................

42

6.5.

Replacing the fiber or scan head ...........................................................................

42

7.

Decommissioning, returning and disposal

43

7.1.

Decommissioning ..........................................................................................................

43

7.2.

Returning.............................................................................................................

46

7.3.

Disposal ...................................................................................................................

46

A.

Spare parts

48

B.

Bibliography

50

C.

Declaration of incorporation

51

v

FIBER_TIGER_manual,

2021-11-29

List of Figures

3.1.

Position of labels......................................................................................................

10

3.2.

Position of interfaces at the top.............................................................................

11

3.3.

Position of interfaces at the bottom ......................................................................

12

3.4.

LEDs at the ARN interface and their meaning .....................................................

12

4.1.

Dimensions and mounting............................................................................................

16

4.2.

APERTURE label ................................................................................................

18

4.3.

Suggested locations for the APERTURE label .....................................................

18

4.4.

Laser parameter label ..............................................................................................

19

4.5.

Warning labels for laser radiation and laser class.....................................................

19

4.6.

Positioning of cooling water supply and return lines at the top..........................

20

4.7.

Self-sealing coupling plug to be connected to cooling water hose ........................

21

4.8.

Unplugging the self-sealing coupling ..........................................................................

23

4.9.

End piece of the cooling water quick connector ...................................................

23

4.10.

Position of purge gas inlet at the top ....................................................................

24

4.11.

End piece of the purge gas quick connector .........................................................

25

4.12.

Connector type of the ARN interface: RJ45 socket.............................................

26

4.13.

Connector type of the DC INPUT 48 V interface:

(D-Sub) DA-3W3S..............

27

4.14.

Connector type of the fiber coupling: Optoskand QBH.......................................

29

4.15.

Connector type of the SAFETY interface: RJ12 socket......................................

29

4.16.

Connector type of the SERVICE interface: USB Mini-B socket .........................

30

4.17.

Eight fixing screws for tilting..................................................................................

31

4.18.

Adjusting ring for tilting ..........................................................................................

31

4.19.

Six fixing screws for rotation ..................................................................................

32

4.20.

Adjusting ring for rotation.......................................................................................

32

7.1.

QBH fiber coupling with plugged in fiber ..............................................................

44

vi

FIBER_TIGER_manual,

2021-11-29

List of Tables

4.1.

Environmental conditions for transporting and storing ............................... 13

4.2.

Environmental conditions for installation and operation ............................. 15

4.3.

Mechanical data........................................................................................ 16

4.4.

Cooling water............................................................................................ 19

4.5.

Purge gas.................................................................................................. 24

4.6.

Pin assignment of the DC INPUT 48 V interface ..................................................27

4.7.

Laser beam supply............................................................................................ 28

5.1. Troubleshooting ....................................................................................... 36

A.1. List of spare parts ............................................................................................. 48

1

FIBER_TIGER_manual,

2021-11-29

WARNING

… indicates a hazardous situation with

average degree of risk

which

could

result in

death

or

serious injury

, if not avoided.

CAUTION

… indicates a hazardous situation with

low degree of risk

which

could

result in

minor

or moderate injury

, if not avoided.

NOTICE

… indicates a hazardous situation which is not related to personal injury and which

could

result in

material damage

, if not followed.

IMPORTANT

… indicates information considered important but not directly hazard related.

TIP

… indicates a practice which facilitates work.

1.

How to use this document

1.1.

Symbols and signal words

This manual uses the following symbols and signal words for information of importance.

2

FIBER_TIGER_manual,

2021-11-29

1.3. Storage and replacement 1. How to use this document

Procedure

... indicates a call to action. One or more steps to be executed are following this signal

word. An exception has been made for warning notices, where this signal word has been

omitted.

1.2.

Notation

conventions

This manual uses the following notation conventions that are given in the following table.

Notation conventions

Notation Meaning

Underlined

click-able cross reference or hyper link (only visible on-screen)

[

⟨

Number

⟩

] cross reference to a list of further reading on page 50

Bold

element in the graphical user interface that the user shall click

Italic

name of element in the graphical user interface or emphasized text

Typewriter

text to be typed in by the user or file name or path

1.3.

Storage and replacement

•

Keep this manual with the product to access it at any time during the product’s

lifetime.

•

You can request replacement for this manual at the manufacturer. You can request

the manual as PDF-file and as print.

•

This manual is part of the product. If the product ownership changes then this

manual must accompany the product.

1.4.

Specifics and structure

We reserve the right to update this manual at any time without prior notification.

3

FIBER_TIGER_manual,

2021-11-29

IMPORTANT

Only the target audience, who is listed in the beginning of each instructing section

in the following chapters, may perform the activities described there.

1. How to use this document

1.5. Target audience and qualification

This manual is limited to installation and commissioning instructions, troubleshooting and

maintenance.

•

For the sake of the environment print this PDF file only if necessary.

This PDF file forces duplex printing, if your printer can do that.

1.5.

Target audience and qualification

The persons, who are performing these activities, need to be of age.

The qualification of the target audience is defined below.

Laymen

without special qualification, who e. g. transport and store the boxed scan head

Operators, who are trained by the company that is operating the laser unit, where the

scan head is incorporated, in the use of that laser unit and who have confirmed the

training by signature

Experts in electrical engineering or mechatronics, who are successfully trained in handling

highly sensitive electronic and optical equipment. Experts must be trained by the

company that is operating the laser unit, where the scan head is incorporated, in the

use of that laser unit, and must confirm the training by signature

4

FIBER_TIGER_manual,

2021-11-29

2.

General safety instructions

2.1.

Normal use

•

The scan head is delivered as an OEM component for integration into a laser unit

that is used in a dry and clean indoor environment without electrically conductive

contamination.

•

Customers must know and apply the rules and regulations for safe operation of lasers

when installing and operating the scan head and the laser unit in which it is used.

Since Novanta has no influence over the employed laser device or the overall laser

unit, the customer is solely responsible for the laser safety of the entire laser unit.

The laser unit manufacturer bears responsibility for complying with the standards and

guidelines required for the CE (European Conformity) label. Please contact Novanta

for further information about this scan head and applicable guidelines.

•

Before installing and operating the scan head, carefully read this manual for your

protection.

•

Retain this manual for future reference.

2.2.

Reasonably

foreseeable

misuse

It is considered a misuse if you use the scan head without incorporating it into a laser unit

that complies with the standards required for the CE (European Conformity) label.

5

FIBER_TIGER_manual,

2021-11-29

IMPORTANT

Customers assume full responsibility for maintaining a laser-safe working environ-

ment.

Original Equipment Manufacturer (OEM) customers assume full responsibility

for CDRH (Center for Devices and Radiological Health) certification.

WARNING

Visible or invisible laser radiation

can cause severe retinal and corneal burns, burns on the skin, and may pose a fire

risk.

•

To avoid injury and reduce risk of fire, follow the control measures and safety

guidelines provided by the laser’s manufacturer, and those established by your

Laser Safety Officer (LSO), Radiation Safety Officer (RSO), or safety depart-

ment of your business or institution.

2. General safety instructions 2.3. Duty of care by the customer

2.3.

Duty of care by the customer

2.4.

Hazards

2.4.1.

Laser

radiation

The scan head is intended for use in combination with a class 4 laser.

2.4.2.

Laser generated air contaminants

During laser material processing matter is being evaporated. Laser generated air contami-

nants can compose of multitude hazardous products, such as nickel, chrome, alumina, zinc,

butanol, toluol, xylene, and formaldehyde. The concentration, size, and the quantity of

these aerosols and particles are variable in a wide range.

6

FIBER_TIGER_manual,

2021-11-29

WARNING

Laser generated air contaminants, even if respired in lowest concentrations over long

time or brought to skin contact,

can cause skin irritations, contact eczema, sickness, vomiting, cauterization of the

respiratory tract, nervous diseases, allergic reactions, spasms, and cancer.

•

To avoid injury, follow the control measures and safety guidelines provided by

the respective material safety datasheet, and those established by your Laser

Safety Officer (LSO), Radiation Safety Officer (RSO), or safety department

of your business or institution.

CAUTION

Hot laser-processed material

can cause skin burns.

•

If you are a system integrator, then place a sign at the laser processing area

that warns about hot surfaces.

•

When handling material by hand that was laser-processed shortly before then

wear heat resistant protective gloves.

2.4. Hazards

2. General safety instructions

2.4.3.

Hot laser-processed material

During materials processing with lasers, strong heating of the processed material may

arise.

2.4.4.

Coolant and coolant additives

Some controllers have a cooling loop and use perhaps a special coolant or coolant additives,

like calcination inhibitors, algae inhibitors, anti-corrosion, and anti-freeze agents.

7

FIBER_TIGER_manual,

2021-11-29

CAUTION

Coolant or coolant additives

may give rise, amongst other things, to allergies, eczema, and other irritations if

they get in contact with the skin or mucous membranes.

•

To avoid injury, follow the control measures and safety guidelines provided by

the respective material safety datasheet, and those established by your Laser

Safety Officer (LSO), Radiation Safety Officer (RSO), or safety department

of your business or institution.

NOTICE

Electrostatic discharge (ESD)

can damage the controller which is an electrostatic discharge-sensitive device.

•

Transport equipment only in anti-static packaging and a packaging equivalent

to that received with the shipment.

•

Keep the controller sealed until you are at a proper static control station.

2.

General safety instructions

2.4. Hazards

2.4.5.

Electrostatic

discharge

The controller contains parts that are sensitive to electrostatic discharge.

A proper static control station should include:

•

A soft grounded conductive tabletop or grounded conductive mat on the tabletop

•

A grounded wrist strap with the appropriate (1 M

Ω

) series resistor connected to the

tabletop mat and ground

•

An adequate earth ground connection, such as an uncoated water pipe or AC ground

•

Conductive bags, trays, totes, racks, or other storage

•

Properly grounded power tools

•

Personnel handling ESD items must wear ESD protective garments and ground straps

8

FIBER_TIGER_manual,

2021-11-29

2.5.

Modifications and spare parts 2. General safety instructions

2.5.

Modifications and spare parts

You are not allowed to modify the scan head.

You are not allowed to use spare parts other than specified by Novanta.

2.6.

Fire extinguishing media

•

Use carbon dioxide (CO

2

) as the fire extinguishing media for the scan head.

•

The scan head uses internally a direct-current voltage of 48 V. Pay attention to the

minimum distance between the fire extinguishing media aperture and live parts.

•

Harmonize the fire extinguishing media of scan head and laser unit.

•

Prior to installing the scan head, provide fire extinguishing equipment and observe

its instructions for use and its hazard notes.

9

FIBER_TIGER_manual,

2021-11-29

3.

Overview

A scan head is a device for laser beam shaping and laser beam guidance.

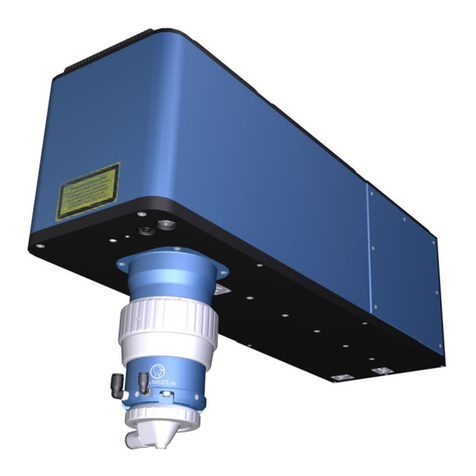

The FIBER TIGER Scan Head is an extremely compact and robust scan head for robot-

assisted laser processing and other “on-the-fly” type applications in the mid to high kW

range.

The scan head can be operated with all commercially available single- or multi-mode fiber

lasers. It is driven by an ARGES system controller and the InScript software or rather by

your own software and the

ControllerLib

application programming interface.

The scan head features a highly dynamical Z-axis for ultrafast and precise 3D laser material

processing. It has been designed especially for precise welding and cutting applications and

can be employed in a wide range of industrial sectors, for example automotive, aerospace

and machine construction. The FIBER TIGER Scan Head is suitable for industrial-scale

processing of all commonly used materials, such as metals, plastics and ceramics.

10

FIBER_TIGER_manual,

2021-11-29

1

1

1

1

2

TIP

Later on, during installation, you will affix some warning labels; see section 4.3.2 on

page 18.

3.1. Labels 3. Overview

3.1.

Labels

Figure 3.1.: Position of labels

Legend to figure 3.1

No. Label Description

1

Warranty seal

2

Type plate;

in particular designates the laser wave-

length that the scan head is build for, the

serial number, the year of manufacture

and the manufacturer’s address

11

FIBER_TIGER_manual,

2021-11-29

3. Overview 3.2. Interfaces

3.2.

Interfaces

1 2 3 4

8

8

7

6

5 4

Figure 3.2.: Position of interfaces at the top

Legend to figure 3.2

No.

Marking / function

See section

On page

1 SAFETY

4.3.8

29

2 SERVICE

4.3.9

29

3 ARN

4.3.5

25

4

Scan head cooling water supply / return

4.3.3

19

5 DC INPUT

4.3.6

26

6

Purge gas inlet

4.3.4

23

7

Fiber coupling

4.3.7

27

8

Fiber coupling cooling water supply / return

4.3.3 19

12

FIBER_TIGER_manual,

2021-11-29

3.3.

Controls and indicators

3. Overview

1

2

Figure 3.3.: Position of interfaces at the bottom

Legend to figure 3.3

No.

Marking / function

See section On page

1

Protective window andlaser aperture

6.2 37

2

Purge gas outlet

4.3.4 23

3.3.

Controls and indicators

The scan head has no physical controls. Operate the scan head as described in chapter 5

on page 34.

The LEDs at the ARN interface are the only direct indicators. They show rudimentary

information about the data link between the product and the ARGES system controller;

see figure 3.4 on page 12.

green yellow

Figure 3.4.: LEDs at the ARN interface and their meaning:

green = link, yellow = active

13

FIBER_TIGER_manual,

2021-11-29

4.

Preparing for use

This chapter describes all procedures necessary to get the controller ready for use.

4.1.

Transporting and storing

Target audience and qualification

Laymen, operators, and experts

Requirements

Table 4.1.: Environmental conditions for transporting and storing in the original packaging

Characteristic

Specification

Packaging dimensions

640 mm

×

560 mm

×

310 mm

Packaging volume 0.12 m

3

Mass (incl. scan head) approx. 16 kg

Temperature 0 to 50 °C (273 to 323 K)

Humidity

max. 85 %; non-condensing

Atmospheric pressure min. 0.65 bar (65 kPa); This corresponds to a height of ap-

proximately 3,500 m. In general the atmospheric pressure

does not fall below this value for air freight.

Vibration and shock [to be defined]

Procedure

•

Transport and store the scan head in its sealed original packaging with the environ-

14

FIBER_TIGER_manual,

2021-11-29

NOTICE

Contamination

can damage optics and the laser.

•

Leave the protective covers in place as long as possible to keep the optics

clean.

4.2.

Unpacking and verifying the scope of delivery

4. Preparing for use

mental conditions that are given in table 4.1 on page 13.

4.2.

Unpacking and verifying the scope of delivery

Target audience and qualification

Experts

Have ready

Utility knife

Procedure

1.

If any shock indicator is present and triggered, then block the delivery and inform the

sender.

2.

While carefully unpacking the scan head, keep in mind that you want to retain the

packaging for future use.

In case it will become necessary to return the scan head for some reason later, we

recommend documenting the unpacking e.g. by taking photographs.

3.

Check by the delivery note, whether all parts are present, in an evidently immaculate

mechanical state and whether the serial numbers correspond. If one of these is untrue,

then block the delivery and inform the sender.

4.

Retain the original packaging for future use.

Table of contents

Other Novanta Medical Equipment manuals

Popular Medical Equipment manuals by other brands

Getinge

Getinge Arjohuntleigh Nimbus 3 Professional Instructions for use

Mettler Electronics

Mettler Electronics Sonicator 730 Maintenance manual

Pressalit Care

Pressalit Care R1100 Mounting instruction

Denas MS

Denas MS DENAS-T operating manual

bort medical

bort medical ActiveColor quick guide

AccuVein

AccuVein AV400 user manual