Novanta Precession Elephant 2 User manual

PRECESSION ELEPHANT 2 Scan Head 2

Instruction Manual 2021-09-22

Product

Type: PRECESSION ELEPHANT 2 Scan Head

Version: 2

Document

Type: Original Instruction Manual

Version: 2021-09-22

Manufacturer

Address: Novanta, Werk 4, 92442 Wackersdorf, Germany

Phone: +49 9431 7984-0

Fax: +49 9431 7984-300

E-mail: [email protected]

Internet: www.novantaphotonics.com

Service

Address: Novanta, Werk 4, 92442 Wackersdorf, Germany

Phone: +49 9431 7984-0

Fax: +49 9431 7984-300

E-mail: [email protected]

Internet: www.novantaphotonics.com

Copyright

© Novanta Corporation, 2021

Distribution or reproduction of this document, use and communication of its contents

are prohibited unless expressly permitted. Offenders will be liable for damages. All

rights in the case of patent or registration of a utility model or design are reserved.

2

PRECESSION ELEPHANT 2 Scan Head 2

Instruction Manual 2021-09-22

Table of contents

1 How to use this document 6

1.1

Pictographs and signal words..........................................................................6

1.2

Notation conventions.......................................................................................7

1.3

Storage and replacement ................................................................................7

1.4

Specifics and structure of this document...................................................7

2 General safety instructions 8

2.1

Audience and qualification ..............................................................................8

2.2

Normal use......................................................................................................8

2.3

Safety instruction.............................................................................................8

2.4 General risks........................................................................................................9

2.4.1

Laser generated air contaminants.......................................................9

2.4.2

Laser radiation ..................................................................................10

3 Overview 13

3.1

Function ........................................................................................................13

3.2

Controls and signals......................................................................................14

3.3

Labeling ........................................................................................................14

4 Tools needed 16

5 Installing 17

5.1

Audience and qualification ............................................................................17

5.2

Environmental conditions for operation ..................................................17

5.3

Safety precautions ........................................................................................18

5.4

Installation.............................................................................................18

5.5

How to use the cooling water quick coupling...........................................26

5.6

How to use the gas supplies quick connector................................................28

6 Commissioning 29

6.1

Audience and qualification ............................................................................29

6.2

Safety precautions ........................................................................................29

3

PRECESSION ELEPHANT 2 Scan Head 2

Instruction Manual 2021-09-22

6.3

Begin commissioning ....................................................................................29

6.4

Checking the video capture devices ..............................................................30

6.5

Checking the settings on the ASC system controller .....................................32

6.5.1 Head device ..........................................................................................32

6.5.2

Optional vcsel device ........................................................................33

6.5.3

Optional afemlight device........................................................34

6.5.4

Optional shutter device...............................................................34

6.5.5 Laser device..........................................................................................35

6.6

Setting up the laser beam..............................................................................35

6.7

Setting up the scan head...............................................................................43

6.7.1

Adjusting the optional attenuator.................................................43

6.7.2

Adjusting the focus .....................................................................46

6.7.3

Setting the offset ........................................................................50

6.7.4

Setting the ON and OFF delay ..........................................................52

6.7.5

Correcting the scan field ...................................................................54

6.7.6

Testing the settings ...........................................................................56

6.7.7

Adjusting the laser beam to circular polarization ..........................57

6.8

Setting up the optional through-the-lens vision camera ...........................59

6.8.1

Activating scan field illumination .................................................59

6.8.2 Focusing the camera .............................................................................61

6.9

Complete commissioning ..............................................................................62

7 Operating 63

7.1

Audience and qualification ............................................................................63

7.2

Safety precautions ........................................................................................63

7.3

Control and signaling by the InScript software ........................................63

7.4

External control devices that are not described here ...............................64

8 Maintaining and repairing 65

8.1

Audience and qualification ............................................................................65

8.2

Safety precautions ........................................................................................65

8.3

Maintenance plan..........................................................................................65

8.4

Removing the protective window at the beam entrance...........................65

8.5

Removing the protective window at the beam exit...................................67

8.6

Cleaning optics..............................................................................................70

8.7

Replacing the complete focusing unit .....................................................72

9 Spare parts list 74

10 Decommissioning and removing from the machine 78

4

PRECESSION ELEPHANT 2 Scan Head 2

Instruction Manual 2021-09-22

11 Transporting and Storing 80

12 Disposal 83

13 Technical specification 84

13.1

General specification.....................................................................................84

13.2 Cameras ............................................................................................................85

13.3

Dimensions, possibilities for mounting and weight ..................................85

13.4

Power supply.................................................................................................86

13.5

Cooling water ........................................................................................86

13.6

Gasses and particle extraction ......................................................................86

13.7

Environmental conditions ..............................................................................88

13.8

Options..........................................................................................................89

13.9

Typical process parameters ..........................................................................89

13.10

Electrical and electronical interfaces .............................................................90

13.10.1 XY4-100 - SLAVE LINK.........................................................................90

13.10.2 DATA I/O...............................................................................................92

13.10.3 SERVICE ..............................................................................................97

13.10.4 DC INPUT .............................................................................................98

13.10.5 SYNC ....................................................................................................99

13.10.6 BEAM SWITCH...................................................................................100

13.10.7 USB 1, USB 2, USB 3 ......................................................................... 101

13.10.8 ETHERNET.........................................................................................101

14 Bibliography 103

5

PRECESSION ELEPHANT 2 Scan Head 2

Instruction Manual 2021-09-22

1

How to use this document

1.1

Pictographs and signal words

This document uses the following pictographs and signal words for information of

particular importance.

WARNING

… indicates a hazardous situation with

average degree of risk

which, if not avoided,

could result in death or serious injury.

CAUTION

… indicates a hazardous situation with

low degree of risk

which, if not avoided,

could

result in minor or moderate injury.

NOTICE

… is used to address a practice which, if not followed, could result in material damage.

TIP

…

is used to address a practice which facilitates work.

6

PRECESSION ELEPHANT 2 Scan Head 2

Instruction Manual 2021-09-22

1.2 Notation conventions

Table 1: Notation conventions

Notation

Meaning

Underlined

cross reference or hyperlink

[<ID>]

cross reference to external document listed in chapter 14 on page 103

Bold

element in the graphical user interface that shall be clicked

Italic

name of element in the graphical user interface or emphasized text

Teletype

text to be typed in by the user, file name or location in the file system

1.3 Storage and replacement

Keep this document with the product to access the information at any time during the

product’s lifetime.

This document is part of the product. When selling the product also deliver this

document to the new owner.

You can request replacement for this document at the manufacturer.

1.4

Specifics and structure of this document

This document is geared to the product’s life cycle.

7

PRECESSION ELEPHANT 2 Scan Head 2

Instruction Manual 2021-09-22

2

General safety instructions

2.1 Audience and qualification

Before installing and commissioning the scan head, completely read through this

instruction manual to employ all functions in a correct and safe way.

This instruction manual addresses qualified personnel who are assigned with installing,

commissioning and maintaining or operating the machine where the scan head is

incorporated.

Installing, commissioning and maintaining the scan head is only allowed for personnel

with electro-technical or mechatronic profession or personnel trained in handling highly

sensitive electronic and optical equipment.

Operating the scan head is only allowed for personnel trained in operating the scan

head, i.e. the machine where it is incorporated.

2.2

Normal use

The scan head is to be incorporated into a machine, where it is used in combination

with a 3

rd

party class 4 laser for laser material processing.

To read, understand and follow this instruction manual is part of normal use.

Any other use is not considered normal.

2.3

Safety

instruction

Operating the scan head is prohibited until it has been established that the machine

into which the scan head is incorporated complies with all essential requirements of the

2006-42-EG Machinery Directive and the safety requirements and measures of standard

DIN EN ISO 11553-1:2009-03

Safety of machinery

–

Laser processing machines

–

Part 1:

General safety requirements

.

8

PRECESSION ELEPHANT 2 Scan Head 2

Instruction Manual 2021-09-22

2.4

General risks

2.4.1

Laser generated air contaminants

WARNING

Hazardous material is emitted during laser materials processing

Health hazard

•

Always provide an adequate exhaustion and subsequent proper disposal of these

hazardous materials.

In laser material processing matter will be evaporated when laser beams interact with

matter.

Laser Generated Air Contaminants, abbreviated LGAC can compose of multitude

hazardous products, such as nickel, chrome, alumina, zinc, butanol, toluol, xylene and

formaldehyde. The concentration and the quantity of these aerosols and particles are

variable in a wide range.

These LGAC could be hazardous to humans even if they will be respired in lowest

concentrations over a long time and can cause sickness, vomiting, cauterization of the

respiratory tract, nervous diseases, allergic reactions, spasms and cancer. Even skin

contact can cause in hazardous skin irritations and contact eczema.

Because of these risks in all laser thermal processes the LGAC should be complete

exhausted by adequate exhaust ventilation with a high air throughput and special

paper or active carbon filters.

The customer respectively user of the material processing laser is responsible for the

safe exhausting of the LGAC and the right disposal in accordance with local, state and

regional threshold limit values for chemical substances. If there are any doubts, these

aspects have to be discussed with the relevant authorities and, if necessary,

a contaminant measurement can be carried out.

Be sure that all generated fumes, dust and particles will be completely exhausted, even

if only a little amount of material shall be processed, or in case of short time laser

material processing.

The following safety information has to be taken into account for safe handling of

LGAC in laser material processing:

9

PRECESSION ELEPHANT 2 Scan Head 2

Instruction Manual 2021-09-22

•

Be sure, that an adequate working exhaust ventilation system is connected to

the material processing laser, that the exhaust ventilation tube is not damaged

or plugged, and that the whole exhaust ventilation passage is open

•

Be sure, that the exhausting volume flow is adequate. A very low exhausting

volume flow, an obstructed exhaust ventilation tube or an obstructed exhausting

nozzle can caused a very dirty laser processing area covered with laser generated

dust and particles

•

Be sure, that the dust filters of the exhaust ventilation system are suitable for the

laser material processing. If other materials will be processed by the laser than

those intended, ensure that the incorporated filters are suitable for the LGAC of

these materials

•

Exchanging of dust filters or exhaust ventilation tubes of an exhaust ventilation

system has only to be done with suitable respiratory protection, eye protection

glasses and protection gloves. Raised dust or fume must not be inhaled and must

not get in contact with the human skin

•

Exchanged dust filters or exhaust ventilation tubes have to be professionally

disposed as hazardous waste, if required

•

If the laser processing area with the incorporated components like focusing

optics, exhausting nozzles and work piece holders should be cleaned, suitable

personal protection devices have to be worn, such as respiratory protection, eye

protection glasses and protection gloves. Raised dust or fume must not be

inhaled and must not get in contact with the human skin

•

If you notice or smell any kind of LGAC probably coming from the material

processing laser, you have to immediately switch off the laser system and check

the correct function of the exhaust ventilation system and the whole exhaust

ventilation passage. If required, exchange the dust filters and clean the laser

processing area. The working area around the material processing laser should

be well ventilated before starting the laser again

•

All personnel operating the material processing laser has to be instructed about

the hazards with LGAC and the required safety measures

2.4.2

Laser radiation

During commissioning it is necessary to adjust the laser beam to the scan head and to

observe the laser beam.

10

PRECESSION ELEPHANT 2 Scan Head 2

Instruction Manual 2021-09-22

CAUTION

Visible or invisible laser radiation during commissioning

could cause damage to eye or skin.

•

Wear protective glasses that are appropriate for adjusting your laser.

•

Avoid eye or skin exposure to direct or scattered radiation.

•

Parametrize the laser for visual set up with average power and pulse repetition

rate as low as possible.

Protective goggles

The mandatory protective glasses provide protection against direct radiation,

reflected radiation and scattered radiation. None the less, even if you are

wearing protective glasses never look directly into the beam or into a reflected

beam. Intense laser radiation is capable of destroying the protective filter.

If alignment or maintenance work on class 4 laser equipment is necessary,

everyone in the laser area has to wear appropriate protective glasses. The glasses

have to meet the safety requirements for the laser output power in question.

As the filter in the protective glasses only provides protection for a narrow band

of wavelengths, make sure you are wearing the right glasses for the laser device

in question. Using the wrong type of protective glasses is dangerous. The most

commonly used protective glasses for CO

2

lasers do not, say, protect against the

radiation from an Nd:YAG laser.

•

Before putting on the protective glasses check them for any obvious

defects. If any of the following defects occur then use protective glasses

that are undamaged:

o

Fissures on the protective filter

o

Scratches on the protective filter

o

Modifications in color

o

Modifications in the light permeability

oLoosen screws

o

Cracks in the frame

11

PRECESSION ELEPHANT 2 Scan Head 2

Instruction Manual 2021-09-22

•

For the cleaning of dirty laser glasses should be used only water, which is

enriched with a common table-ware detergent. Do never use alcohol,

benzine, acetone or similar solvents.

Protective

clothing

Although the skin can withstand considerably higher radiation intensity than the

eyes, tissue may be burned to a greater or lesser degree depending on the

irradiation time and the irradiation intensity. Appropriate protective clothing

should be worn to protect the skin whenever necessary.

CAUTION

Class 4 laser with high optical output power during commissioning

Fire hazard

•

Before opening the beam path take appropriate fire prevention.

•

Parametrize the laser for visual set up with average power and pulse repetition

rate as low as possible.

Paper (circuit diagrams, leaflets or posters on the wall), curtains that are not

impregnated with fire retardants, thin wooden panels or similar materials can be

easily set on fire by direct or reflected laser radiation.

Containers holding flammable or explosive cleaning agents, (e.g. used for

maintenance) have to be kept away from areas where the laser beam is exposed.

Major fires and explosions can quickly result when containers of this kind are

accidentally exposed to and destroyed by the intense laser beam.

Nontransparent, hardly inflammable protectors, e.g. laser protectors can help to

prevent that laser radiation and scattered radiation discharge from the work

area.

12

PRECESSION ELEPHANT 2 Scan Head 2

Instruction Manual 2021-09-22

3

Overview

3.1 Function

About precession scanning

Precession scan heads allow not only the positioning of a laser beam, but also the

setting of the incidence angle of the beam at each point of the workpiece. For a drilling

process, the incidence angle is also called the precession angle. When drilling a

borehole with high precision, the inclination of the internal hole surface, the so-called

taper angle, can only be produced in a reliable and reproducible way if a precession

scan head is used. The production of defined edge angles in laser cutting or laser

micromachining also requires the use of precession heads.

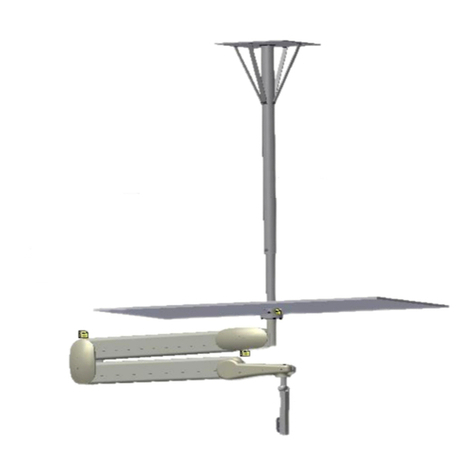

About the PRECESSION ELEPHANT 2 scan head

The PRECESSION ELEPHANT 2 scan head is designed for high-precision laser drilling,

cutting and micromachining applications. It can be used 24/7 in production facilities.

The PRECESSION ELEPHANT 2 scan head offers maximum flexibility for the drilling of

innovative borehole- and edge geometries of differing conicity, taper angles and

shapes, and allows the production of perfectly round, elliptical and custom-shaped

micro holes. The PRECESSION ELEPHANT 2 is available for ultraviolet, green and two

infrared wavelength ranges, each with two different focal lengths.

The scan head can be used

with

all major ultra-short pulsed laser sources available on

the market today. In addition, the PRECESSION ELEPHANT 2 makes

it

possible

to

monitor the laser process and the laser beam properties during production. The scan

head offers improved particle extraction, beam attenuation control and additional

functionalities designed

for

mass production

of

the highest quality. Several other

options, such as tools

for

the setting and calibration

of

the polarization, simplify the set-

up

of

the scan head and minimize downtimes for the end-user.

13

PRECESSION ELEPHANT 2 Scan Head 2

Instruction Manual 2021-09-22

⑦

⑥

⑤

①

④

②

③

3.2

Controls and signals

At the scan head during normal operation neither there are controls that have to be

handled manually nor there are optical or acoustical signals that could be observed.

Controls that need to be operated during commissioning of the scan head are described

in the respective sections of chapter 6 on pages 29 ff.

3.3 Labeling

Figure 1: Labels

Table 2: Legend to Figure 1

No. Label Description / Action

①

Triangular Laser beam warning label

②

Laser radiation emitted from this aperture

label

14

PRECESSION ELEPHANT 2 Scan Head 2

Instruction Manual 2021-09-22

No. Label Description / Action

③

Laser parameters

label

The parameters refer to the built-in laser for scan

field illumination.

•

Place an additional label for your

processing laser according to

EN 60825-1:2014.

④

Laser radiation

Avoid direct exposure to beam

Laser class 3B label

This label refers to the built-in laser for scan field

illumination.

•

Place an additional label for your

processing laser according to

EN 60825-1:2014.

⑤

Component for Incorporation

This product is intended as a component for

incorporation into a laser product, and as such

requires additional features for laser safety and

to comply with IEC EN 60825-1 and 21 CFR

1040.10 label

⑥

PRECESSION ELEPHANT 2 scan head

designed for XXXX nm

S/N XXXXXXXX, Year XXXX

Novanta Europe GmbH, Werke 4, 92442

Wackersdorf, Germany, www.arges.de

Scan head type

label, where the wavelength

range is given that the scan head is designed for

as well as the serial number, the year of

manufacture and the manifactruer’s address

⑦

Warranty void if seal is broken

label

15

PRECESSION ELEPHANT 2 Scan Head 2

Instruction Manual 2021-09-22

4

Tools needed

•

Hexagon socket screw key set

•

Torx key set

•

Cutter to cut the cooling water tubes and gas tubes in length

•

Tissues to wipe of small amounts of cooling water

•

Laser safety glasses appropriate to the laser in use

•

If necessary, a suitable indicator card to make an invisible laser beam visible

•

uEye Cockpit

software [uEye] for viewing the images delivered by the

2 adjustment cameras and the optional through-the-lens vision camera

•

Gauge block between 0 mm and 1.5 mm in height to set the distance from the

nozzle to the work piece

•

Several sheets of metal with a thickness of 0.2 mm as a work piece for drilling

tests

•

Microscope

•

Glan-Thompson polarization meter

•

Power measurement device

•

Optics spanner wrench for cleaning/replacing protective windows at the beam

entrance/exit

16

PRECESSION ELEPHANT 2 Scan Head 2

Instruction Manual 2021-09-22

5

Installing

5.1 Audience and qualification

Installing the scan head is only allowed for personnel with electro-technical or

mechatronic profession or personnel trained in handling highly sensitive electronic and

optical equipment.

5.2 Environmental conditions for operation

Table 3: Environmental conditions for operation

Environmental conditions for operation

Environment

Operate indoors only in a dry and clean

environment

Degree of protection by enclosure

IP41

Ambient operation temperature

10 to 40 °C (283

–

313 K)

Non-condensing humidity

10 to 80 %

Allowed altitude

2,000 m (a. s. l.)

Allowed vibration and shock

Due to the intended processing results in

microscopic dimensions the scan head has

to be mounted on a vibration-cushioned

optical table or an equivalent frame.

Noise emission

[to be defined]

17

PRECESSION ELEPHANT 2 Scan Head 2

Instruction Manual 2021-09-22

5.3

Safety precautions

•

Switch off the machine, where the scan head shall be incorporated, from mains,

in particular the laser, the scan head itself and eventually present translation

stages.

5.4 Installation

The following procedure describes the installation of a minimal system. A minimal

system consists of an ASC system controller, a laser, a scan head and the InScript

software. The installation of the scan head is embedded in this procedure.

Install a minimal system in the order as described in the procedure below.

Find further information regarding each step of the following procedure in the

corresponding manual in the respective chapter.

Tools

•

Hexagon socket screw key set

•

Torx key set

•

Cutter to cut the cooling water tubes and gas tubes in length

•

Tissues to wipe of small amounts of cooling water

Requirements

•The ASC system controller is installed, as described in reference [ASC].

•

The laser is installed, as described in reference [ASC] and in the laser

documentation.

18

PRECESSION ELEPHANT 2 Scan Head 2

Instruction Manual 2021-09-22

Procedure

NOTICE

Force applied to focusing optics

could cause damage to the focusing optics.

•

NEVER lift scan heads at the focusing optics.

1.

Remove the transportation lock plate from the scan head beam entry,

see Figure 2

, no.

⑩

on page 20.

2.

Remove the tape from the scan head beam exit, see Figure 2

, no.

⑫

on page 20.

3.

Mount the scan head into your system.

Please find the scan head dimensions in the respective engineering drawing. This

engineering drawing can be obtained either by downloading it from our

homepage or directly on request from our engineering and design division.

4.

Install the scan head:

Connect the scan head to the supplies, see Figure 2, Table 4 on page 20 ff., and

to the ASC system controller, see Figure 3 and Table 5 on page 25 ff.

19

This manual suits for next models

1

Table of contents

Other Novanta Medical Equipment manuals