Novexx Solutions AP 4.4 User manual

04/09 Rev. 5.01-02 SERVICE MANUAL

AP4.4 – AP5.4 – AP7.t

Fault Location

Error sources ................................................ 2

Notes about fault location .......................... 2

Data transmission ..................................... 2

Display ...................................................... 2

Gap detection ............................................ 2

Material transport ...................................... 3

Ribbon, ribbon guide ................................. 3

Print roller .................................................. 3

Position of the print image .........................4

Print quality ............................................... 4

Plug-in card (AP5.4/AP7.t) ....................... 5

Cut function, cutter (AP5.4/AP7.t) ............ 5

Cut function, TCS (AP7.t) .........................6

Reading out diagnosis data ...........................7

Reading out via serial interface .................8

Storing on CF card ...................................10

04/09 Rev. 5.01-02 SERVICE MANUAL Fault Location

AP4.4 – AP5.4 – AP7.t

2

Error sources

Notes about fault location

Status reports should be printed to check the mechanical and electronic function

capabilities – provided that no obvious no defectives are evident.

Data transmission

Display

Gap detection

Problem Possible cause Solution

No or damaged data Faulty data cable Check, if the right data cable is applied

Wrong interface selected Check, if parameter INTERF. PARAM.>

EASYPLUGINTERPR> Interface is set correctly

Setting of transmission

parameters incorrect

Check, if the transmission parameters forthe

selected interface are set correctly (not for

Centronics)

Faulty pin assignment of

the data cable

Change or replace data cable. The pin as-

signment of the interfaces can be found in

topic section „Service Electronics“, chapter

„CPU board“, „Connectors“.

Incorrect handshake

signals Check parameter setting (only for serial inter-

face)

Selection Select standard character set

CPU board defective Check and if necessary replace CPU board

Permitted cable length

exceeded Do not exceed cable length

[Tab. 1]Possible faults caused by data transmission

Problem Possible cause Solution

Display dark Plug connector loose Check and if necessary plug in again

Display defective Check and if necessary replace display

CPU board defective Check and if necessary replace mainboard

Button function faulty

Plug connector loose Check and if necessary plug in again

Buttons defective Check and if necessary replace buttons or

display board

CPU board defective Check and if necessary replace mainboard

[Tab. 2]Possible faults at the display

Problem Possible cause Solution

Gap detection not

possible

Photoelectric switch defec-

tive Check with SERVICE FUNCTION> Sensor test, if

necessary replace the photoelectric switch

Photoelectric switches set

incorrectly Use parameter SYSTEM PARAMETER >

Sens. punch-LS to alter sensitivity

False photoelectric switch

selected Select "Punched" or "Reflex" using the pa-

rameter SYSTEM PARAMETER > Light sens. type

[Tab. 3]Possible faults caused by the gap detection

04/09 Rev. 5.01-02 SERVICE MANUAL Fault Location

AP4.4 – AP5.4 – AP7.t

3

Material transport

Ribbon, ribbon guide

Print roller

Print position shifted

in or against print di-

rection

Gap position not recog-

nised consistently due to

gap contour

Correct photoelectric switch zero line using

parameter PRINT PARAMETERS > Punch offset

Problem Possible cause Solution

[Tab. 3]Possible faults caused by the gap detection

Problem Possible cause Solution

Material guide (green

part) loosens Friction is set to low

Modify the setting. Instruction see service

manual, topic section Service Mechanics ,

chapter „Material transport“, „Setting the fric-

tion of the material guide“.

No feed function

Stepper motor plug loose Check and if necessary plug in

Stepper motor defective Check and if necessary replace motor

CPU board defective Check and if necessary replace mainboard

Feed button defective Check and if necessary replace display board

Jolted print image Material unwinder blocked Check and if necessary loosen

Material shifts Material guide set

incorrectly Check and if necessary set

[Tab. 4]Possible faults caused by material transport

Problem Possible cause Solution

Unfounded ribbon

end message Ribbon unwind mandrel is

not turned Fix core to mandrel (spring plate), shift spring

plate if the thread has stripped.

Photoelectric switch defec-

tive Check and if necessary replace (see also pa-

rameter SERVICE FUNCTIONS> Sensor test)

Ribbon produces

folds

Ribbon guiding plate at the

printhead adjusted incor-

rectly

Check and readjust positioning of the guiding

plate

Ribbon is not being

rolled up Ribbon core slips through Fix core to mandrel (spring plate), shift spring

plate if the thread has stripped.

Toothed belt defective Check and if necessary replace the belt

Ribbon tears during

printing process Printhead temperature is

too high

Check setting of print contrast (press Prog.

button in on-line mode or parameter

PRINT PARAMETER > Printcontrast) and if neces-

sary correct.

[Tab. 5]Possible faults caused by the ribbon guiding

Problem Possible cause Solution

Wear High running performance Replace roller

Printhead pressure too high Check and if necessary correct

Material deposits Clean the roller

[Tab. 6]Possible faults caused by the Print roller

04/09 Rev. 5.01-02 SERVICE MANUAL Fault Location

AP4.4 – AP5.4 – AP7.t

4

Position of the print image

Print quality

Ink residue Ribbon prints directly on

feed roller Clean and prevent direct printing on roller

Deformation

Printing directly on roller Use sufficient wide material/foil

High running performance Replace roller

Power setting too high for

printhead

Check print contrast setting (press Prog. but-

ton in on-line mode or parameter

PRINT PARAMETER> Print contrast) and if neces-

sary correct.

Damage by operator Replace roller and draw attention to proper

care

Problem Possible cause Solution

[Tab. 6]Possible faults caused by the Print roller

Problem Possible cause Solution

Print position shifted

in or against print di-

rection

Incorrect parameter setting Check parameter PRINT PARAMETER> Y-Print

offset or Easy Plug command (#Jx), if neces-

sary correct

Gap position is recognised

incorrectly due to gap con-

tour

Correct sensor zero line with parameter

PRINT PARAMETER> Gap offset

Material unrolling blocked

or too sluggish Check and if necessary correct

Material guide set too

narrowly Check and if necessary set

Pressure rollers positioned

incorrectly or not at all Check and if necessary set

Print shifted at right

angles to document Material guide not set

correctly Check and if necessary set

[Tab. 7]Unsatisfactory print position and the possible reasons.

Problem Possible cause Solution

Print faded

Printhead dirty or defective

Clean or replace thermal bar.

¯Clean printhead regularly to ensure opti-

mal print head condition. It is recommended

this is done when replacing the roll of foil us-

ing cleaning paper (article number 5030).

Printhead setting incorrect Check settings (e.g. print contrast, print head

resistance) and alter if necessary

Ribbon and material not

aligned Check ribbon type and material type, if nec.

alter

Ribbon possibly super-

imposed Insert new ribbon

Poor or uneven print Print roller damaged or

soiled Check and if necessary clean or replace roller

[Tab. 8]Unsatisfactory print quality and the possible reasons

04/09 Rev. 5.01-02 SERVICE MANUAL Fault Location

AP4.4 – AP5.4 – AP7.t

5

Plug-in card (AP5.4/AP7.t)

Cut function, cutter (AP5.4/AP7.t)

Feed in order but no

print image

Printhead setting too low

Check setting print contrast (press Prog. but-

ton in on-line mode or parameter

PRINT PARAMETER> Print contrast) and if nec.

correct.

Ribbon inserted incorrectly

(colour side) Check and if necessary correct

Printhead not fixed to

bracket Fix thumb screw

Printhead defective Check printhead and if necessary replace it

Printhead cable not or in-

correctly plugged in Check and if necessary plug in again

CPU board defective Check and if necessary replace mainboard

Problem Possible cause Solution

[Tab. 8]Unsatisfactory print quality and the possible reasons

Problem Possible cause Solution

Plug-in cards are not

recognised

Contacts dirty Check and if necessary replace

Card defective Check and if necessary replace

Card type does not corre-

spond to approved type Check and if necessary replace

[Tab. 9]Possible problems with plug-in cards

Problem Possible cause Solution

No cutter function

Connector loose Plug in connector firmly.

Cutter function not activat-

ed Select and activate "Cutter" setting for param-

eter SYSTEM PARAMETER> Peripheral device

Photoelectric switch defec-

tive Check and if necessary replace switch

Stepper motor or output

stage board defective Check and if necessary replace

Material is only par-

tially cut or not cut at

all

Setting of cutter position Check photoelectric switch or position of os-

cillator disc and if necessary correct

Cutter blunt or dirty Check and if necessary clean or replace

Material problem Only use approved materials

Cut next to recog-

nised gap Gap detection Check setting for parameter

PRINT PARAMETER>Cut position and if neces-

sary correct the setting

Cut offset to impres-

sion Cutter position incorrect Check and if necessary set

Material moves

above or under cutter Unwinding too sluggish, roll

weighs too much Check and if necessary correct

Cutter cuts twice Double cut programmed Check setting of cut function (Parameter

Print Parameter> Double Cut)

[Tab. 10]Problems possibly caused by a cutter (if mounted).

04/09 Rev. 5.01-02 SERVICE MANUAL Fault Location

AP4.4 – AP5.4 – AP7.t

6

Cut function, TCS (AP7.t)

Problem Possible cause Solution

No function

Connector loose Plug in connector firmly.

TCS function not activated Select and activate "TCS" setting for parame-

ter SYSTEM PARAMETER> Peripheral device

Photoelectric switch

defective Check and if necessary replace switch

Stepper motor or output

stage board defective Check and if necessary replace

Cover open Check and if necessary close cover

Cover contact switch not

correctly adjusted Check and if necessary adjust

Material is only

partially cut or not cut

at all

Setting of motor light barrier Check light barrier or position of switch flag

and if necessary correct

Cutter blunt or dirty Check and if necessary clean or replace

Material problem Only use approved materials

Cut next to recog-

nised gap Gap detection Check setting for parameter

PRINT PARAMETER>Cut position and if neces-

sary correct the setting

Cut offset to impres-

sion Cutter position incorrect Check and if necessary set

[Tab. 11]Problems possibly caused by a TCS (if mounted).

7

04/09 Rev. 5.01-02 SERVICE MANUAL Fault Location

AP4.4 – AP5.4 – AP7.t

Reading out diagnosis data

With the diagnose dump function, device inter-

nal operation states can be read via serial con-

nectionandbesavedin atext file.Thisway,the

last device internal communication can be cap-

tured and analysed (comparable to the black

box in an airplane).

The function is helpful, if the device got in an

undefined state. This happened for example,

if…

•printing suddenly stops.

•the status message „unmanaged interrupt“

appears on the display.

•the device suddenly doesn´t react on key-

strokes any more.

In those cases, the log file is generated auto-

matically.

There are two ways of storing the log file:

•Reading out via the serial interface and

storing it on the host PC.

•Storing on CF card.

¯Alternatively, the log file can be read out us-

inganotherthantheserialinterfaceorusingthe

debug interface, see Easy-Plug manual,

#!XM command.

8

04/09 Rev. 5.01-02 SERVICE MANUAL Fault Location

AP4.4 – AP5.4 – AP7.t

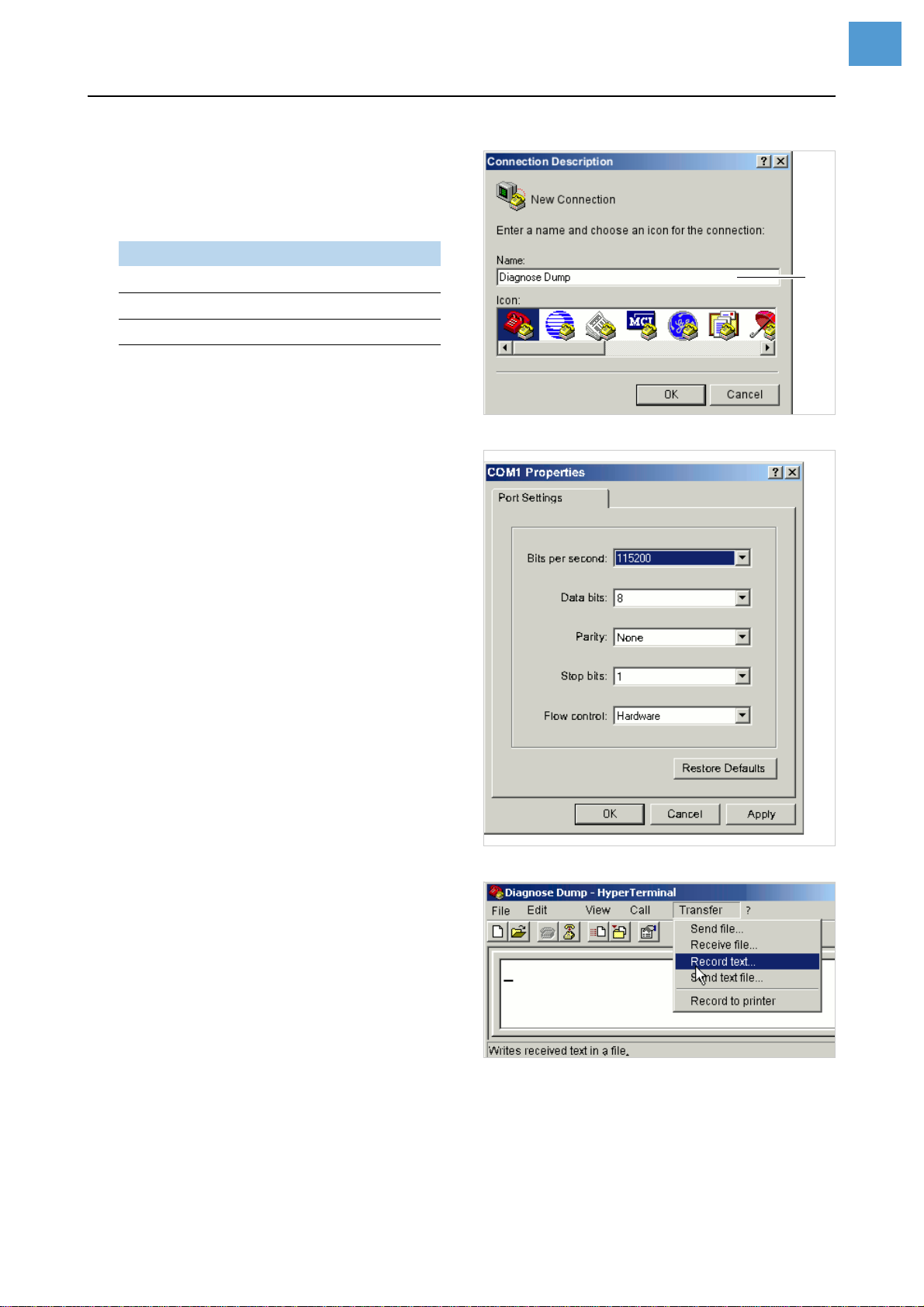

Reading out via serial interface

Prerequisites

•Firmware (at least):

•Terminal program, e. g. „Hyperterminal“ (is

delivered with Windows operating sys-

tems).

Carrying out

1. Connect the printing device to a PC, using

the serial interface. Set the transfer param-

eters to 115kB, n, 8, 1 (default setting).

2. Start Hyperterminal.

The window „Connection Description“ [1]

opens.

3. Name the new connection [1A]. Click OK.

The window „Connect“ opens.

4. Select the serial port of the PC and click

OK.

Thewindow„COM1Properties“[2]opens(if

COM1 was selected).

5. Set the transfer parameters to

115kB, n, 8, 1 and click OK.

The Hyperterminal main window opens.

6. Open the menu „Transfer“ and click

„Record Text“ [3]. An input window opens.

Enter the file name for the record file and

click „Start“.

7. At the printer operation panel press all four

buttons simultaneously.

This starts data being read out of the print-

ing device and being displayed in the

Hyperterminal main window [4]. At the

same time, the data are saved in the record

file.

8. To stop the transmission, click „Cancel“ in

the menu „Transfer > Record text...“.

Generating further record files:

«Close Hyperterminal and start new.

Version Printing device

3.22 AP4.4 (16MB), AP5.4, AP7.t

4.22 64-xx Gen. 2, DPM, ALX92x

5.02 64-xx Gen. 3, PEM

[1] Enter a name (A) for the new connection.

[2] Set the transfer parameters.

[3] Hyperterminal main window.

A

9

04/09 Rev. 5.01-02 SERVICE MANUAL Fault Location

AP4.4 – AP5.4 – AP7.t

[4] Read out data.

«Send the generated files with a descriptioin

ofthe circumstancesinwhich theerror occured

per email to the technical support at Avery Den-

nison.

10

04/09 Rev. 5.01-02 SERVICE MANUAL Fault Location

AP4.4 – AP5.4 – AP7.t

Storing on CF card

Prerequisites

Firmware (at least):

Carrying out

1. Call SERVICE/DIAGNOS. > Diagnosis to CF.

The second line shows the initial 16 charac-

ters of the default file name. The complete

file name is:

„Diagnose AP 5.4 203 Dpi

A429403110613.log“

–AP 5.4 203 Dpi: Printer type and print-

head resolution

–A429403110613: Serial number of the

CPU board; equals the string in

SERVICE DATA > CPU BOARD DATA > Serial

number

2. Press the online button twice to acknowl-

edge and to store the file name.

Typing in a new file name:

1. Press the prog button to dismiss the default

file name.

2. Select each character of the new file name

by pressing the cut/feed buttons and ac-

knowledge it by pressing the online button.

3. Finally press the online button twice to ac-

knowledge and store the file.

¯Alternatively, type in the file name onan op-

tional keyboard connected to the printer and

acknowledge by pressing online.

The log file will be stored in the \LOGFILES di-

rectory on CF card.

Version Printing device

3.31 AP4.4 (16MB), AP5.4, AP7.t

4.31 64-xx Gen. 2, DPM, ALX92x

5.31 64-xx Gen. 3

Diagnosis to CF

Diagnose AP 5.4

Other manuals for AP 4.4

1

This manual suits for next models

2

Table of contents

Other Novexx Solutions Printer Accessories manuals

Popular Printer Accessories manuals by other brands

Star Micronics

Star Micronics TSP800 Series install guide

Citizen

Citizen CBM-202PC Series user manual

Canon

Canon Color imageCLASS MF8170c installation instructions

Codonics

Codonics Virtua 1VCX-LR833 Technical brief

Roland

Roland DU2-64 Supplementary manual

TonerRefillKits

TonerRefillKits ReChargX RX126 instructions