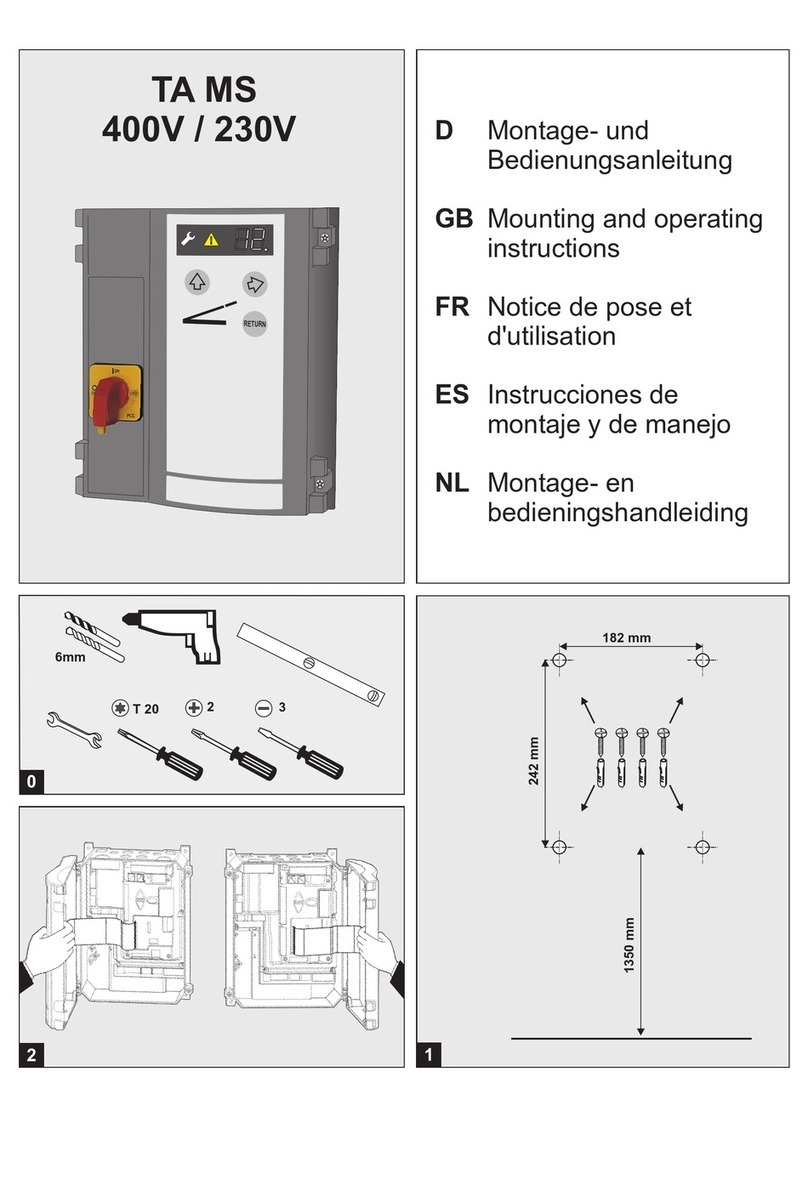

Installation

Benötigte Werkzeuge

Montage Steuerung

Öffnen der Steuerungsabdeckung

Anschlüsse

Benennung:

J1 Start / Impuls-Eingang (AUF / HALT / ZU)

J2 Sicherheitslichtschranke 2- oder 4-Draht

J3 Schließkantensicherung OSE / 8K2 / DW

J4 Not-Aus-Taster, Schlaffseil, Verriegelung

J7 Schlüsseltaster / Zugschalter

J9 Digitaler Endschalter - Motorkabel

J10 Anschluss Erweiterungssteuerungen

J11 Anschluss Funkempfänger

J12 Antenne

J13 Folientastatur

X1 Netzanschluss

X2 Netzausgang L, N (500 W / 230 V)

X3 Schutzleiterkontakt

X5 Potentialfreier Relais Kontakt 1,

Torstatusrelais

X6 Potentialfreier Relais Kontakt 2,

Torstatusrelais

X7 Torantrieb

X8 24V DC, max. 200mA

Netzanschluss

Die Steuerung ist mit einem CEE-Stecker 16A und

ca. 1m Kabel anschlussfertig entsprechend 4a

verdrahtet.

Netzanschluss muss entsprechend der

vorhandenen Netzspannung ausgeführt

!werden.

Motoranschlussleitung

Die Anschlussleitung ist für Motor und digitalen

Endschalter DES vorkonfektioniert - aufstecken.

Anschluss für Impulsgeber

6a/6b - Anschluss J1 für externe Befehlsgeber

Auf, Halt und Zu.

6c - Schaltfolge Auf-Halt-Zu, im Menü 51 den Wert 1

einstellen.

J1.3 - , -½ Toröffnung J1.4 volle Toröffnung

6d - Anschluss J7, Schaltfolge Auf-Zu

(Menü 50, Werkseinstellung) siehe auch

Betriebsanleitung Funktion Schlüsselschalter

Das Tor muss von dem Ort der

Bedienung aus einsehbar sein.

Anschluss für Lichtschranke

Im Menü 36 muss die Lichtschranke entsprechend

eingestellt werden.

7a 2-Drahtlichtschranke Ls2

Dabei darf die Schließfahrt nicht gestört

werden um keine falsche Position zu

erfassen.

7b 4-Drahtlichtschranke LS5 mit Testung

7c Reflexionslichtschranke

Wenn im Menü die Lichtschranke in der Zarge

montiert ausgewählt wurde, führt die Steuerung bei

der nächsten Fahrt in Zu eine Lernfahrt zur

Positionserkennung durch.

Anschluss für Schließkantensicherung

Bei Impulsbetrieb Zu ist eine Schliesskanten-

sicherung anzuschließen. Entsprechende im Menü

35 auswählen. Durch langen Tastendruck der Prog-

Taste auf Menü 35 wird der gemessene

Widerstandswert der 8K2 Schließkante angezeigt.

Bsp.: 82 bedeutet 8k2. Durch kurzes Betätigen der

Prog-Taste wird die Anzeige abgebrochen.

8a optische Schießkantensicherung OSE.

Elektrische Schließkantensicherung 8K2

mit 8,2 KOhmAbschlusswiderstand (Wert = 1).

Elektrische Schließkantensicherung 8K2 in

Reihenschaltung mit Schlaffseil- und

Schlupftürschalter (Wert = 3)

0

1

2

3

4

5

6

7

8

8b Druckwellenleiste und -Schalter mit

8,2 KOhm Schleifenwiderstand (Wert = 2)

Die Druckwellenleiste nur mit Testung

betreiben. Hierzu Menü 35 = 2 auswählen.

Anschluss Not-Halt

Anschluss Schlüsselschalter / Zugschalter

Bei Verwendung eines Schlüsselschalters /

Zugschalters ist im Menü 50 die gewünschte

Funktion auszuwählen.

Funkfernsteuerung

Empfängermodul (Option) auf J11 aufstecken und im

Menü 60, 61 oder 62 Handsender einlernen.

Relaisausgänge

2 Wechslerkontakte max. belastbar: 250VAC / 2A

oder 24VDC / 1A. Der 24V-Ausgang an X8 darf max.

mit 200mA belastet werden. Die Relaisfunktion ist in

den Menü 45 und 46 auszuwählen.

Ist in Menü 40 der AR-Betrieb (Menü 3 oder 4)

ausgewählt, dann ist X6 die Funktion Vorwarnlicht

zugeordnet. Die Einstellungen in Menü 46 sind

unwirksam.

12b Gegenseitige Verriegelung von 2 Toren

(Schleusenschaltung) Menü 50 Wert 2 oder 3 und.

Menü 45 Wert 0.

12c Gegenseitige Verriegelung von 3 Toren

(Schleusenschaltung) Menü 50 Wert 2 oder 3 und.

Menü 45 und 46 Wert 0.

13 Lichtgitter

Alternativ zur Schließkantensicherung kann ein

Lichtgitter verwendet werden. Hierzu ist das

Lichtgitter der Zeichnung 13a, 13bentsprechend

anzuklemmen. Menü 35 = 0 einstellen.

Programmieren der

Steuerung

Die Programmierung ist menügesteuert.

Toreinstellung bitte entsprechend dem Schema

durchführen. Nachfolgende Seite zeigt den

kompletten Menüumfang.

Einstellen Torendlagen (Menü 30 und 31)

Abhängig vom Antrieb muss das Tor feder-

!ausgeglichen sein.

Die obere und untere Endlage müssen direkt nach

einander eingestellt werden.

Nachlaufwegkorrektur (Menü 42)

Gleicht Veränderungen der Zuposition aus, die durch

Temperatur, Einlaufen des Getriebes usw. herrühren.

Bodenanpassung (Menü 43)

Gleicht Veränderungen der Zuposition aus, die durch

Seillängung bzw. durch Anheben des Fußbodens

entstehen. Die Endlage Zu wird durch die

Bodenberührungen der Schließkantesicherung

angepasst.

Zuvor erst genaue Zuposition einstellen, anschlies-

send Menü 43 einstellen.

In den Einstellungen 2, 3 und 4 werden die

eingelernten Positionen aus Menüs 31, 34 und 37

entsprechend angepasst.

Federbrucherkennung (Menü 47)

Bei Überschreitung des eingestellten Wertes wird

Fehl er F32 angezeigt.

Nach dem Erneuern der Federn sind die

Torendlagen neu einzustellen.

!

Motor 9.24/5.24: Eingabewert = U x Gewicht / 20Kg

Motor 9.20: Eingabewert = U x Gewicht / 16Kg

Motor 9.15: Eingabewert = U x Gewicht / 15Kg

Beispiel:

Motor 9.24, U = 8 Umdrehungen für Toröffnung

Torblattgewicht = 150Kg, bei 2 Federn trägt jede

75Kg. DieAbschaltung soll bei 60Kg erfolgen.

9

10

11

12

Eingabewert 24= 8 x 60Kg / 20Kg =

Einstellung ist bei Schnellentriegelung

erforderlich, andernfalls sind

Federbruchschalter anzuschließen.

Prüfung Federausgleich

Nachdem das Tor einmal komplett auf und zuge-

fahren wurde, Menü 47 anstatt kurz, die Taste 5

Sekunden lang drücken.

Wert gibt an, wie das Tor ausbalanciert ist:

Motor 9.24/5.24: F (Kg) = Anzeigewert x 20Kg / U

Motor 9.20: F (Kg) = Anzeigewert x 16Kg / U

Motor 9.15: F (Kg) = Anzeigewert x 15Kg / U

U = Anzahl der Umdrehungen für eine Toröffnung

Wenn Anzeigewert -2 bis -9, dann sind Federn zu

stark gespannt.

Die Ergebnisse sind nur annäherungsweise zu

betrachten. Zur genaueren Bestimmung ist eine

Kraftmessfahrt durchzuführen.

Bei Verwendung von 6.65DU weicht die Funktion

ab. Hierzu bitte den Abschnitt “Funktion

!DU”berücksichtigen.

Öffnungskraftbegrenzung (Menü 48)

Die Öffnungsfahrten werden mit der vorherigen

Fahrt verglichen. Bei Überschreitung mit dem

eingestellten Wert stoppt das Tor und F33 erscheint.

Das Tor kann anschließend nur im Totmann-

betrieb zugefahren werden. Ursache der

!Kraftüberschreitung beseitigen und danach das

Tor auf und zufahren.

Motor 9.24/5.24: Eingabewert = U x Gewicht / 20Kg

Motor 9.20: Eingabewert = U x Gewicht / 16Kg

Motor 9.15: Eingabewert = U x Gewicht / 15Kg

Die Ergebnisse sind nur annäherungsweise zu

betrachten. Zur genaueren Bestimmung ist eine

Kraftmessfahrt durchzuführen.

Bei Verwendung von 6.65DU weicht die Funktion

ab. Hierzu bitte den Abschnitt “Funktion

!DU”berücksichtigen.

Kraftmessfahrt

zur Bestimmung der Abschaltschwelle.

Nach Eingabe des Wertes 99 im Menü 48 führt die

Steuerung eine Kraftmessfahrt durch:

1. Ein Prüfgewicht (empfohlen ca. 20Kg) am Tor

befestigen und Tor komplett auf und zufahren.

2.Anschließend erscheint im Menü 48 der Wert

und wird alsAbschaltwert übernommen. Der

Wert kann geändert werden (doppelter Wert

gleich doppelte Kraft).

3. Prüfgewicht wieder entfernen und Tor wieder auf

und zufahren.

Einschaltdauer (Menü 49)

Die eingestellte Einschaltdauer verhindert die

Überhitzung des Antriebsmotors und vermeidet

Schäden.

Bei Einsatz des Motors 5.24 mit Kunststoff-

getriebe muss die Einschaltdauer auf 1 (3~) oder

!auf 2 (WS, 1~) eingestellt werden.

RWA-Funktion (Rauch-Wärme-Abzug)

Im Menü 55 die entsprechende Torposition

einstellen. Brandmeldeanlage an J7 anschließen

und im Menü 50 Wert 9 einstellen.

Auswahl Steuerungstyp (Menü 59)

In Menü 59 werden verschiedene Steuerungstypen

ausgewählt. Entsprechende Einstellungen sind den

Zusatzblättern zu entnehmen.