50-60 Hanover Road, Florham Park, New Jersey 07 32

ASCO Valves

Page 2 of 2 Form No.V6855R1

IMPORTANT: These solenoid valves are intended for use on

clean dry air or inert gas, filtered to 50 micrometres or better.

The dew point of the media should be at least 10 C (18 F)

below the minimum temperature to which any portion of the

clean air/inert gas system could be exposed to prevent freezing.

If lubricated air is used, the lubricants must be compatible with

Buna N elastomers. iester oils may cause operational

problems. Instrument air in compliance with ANSI/ISA

Standard S7.3-1975 (R1981) exceeds the above requirements

and is, therefore, an acceptable media for these valves.

MAINTENANCE

WARNING: To prevent the possibility of personal

injury or property damage, turn off electrical power,

depressurize valve, and vent fluid to a safe area before

servicing the valve.

NOTE: It is not necessary to remove the valve body from the

pipeline for repairs. However, piping or tubing must be

removed from Port 3 connection.

Cleaning

All solenoid valves should be cleaned periodically. The time

between cleanings will vary depending on the medium and

service conditions. In general, if the voltage to the coil is

correct, sluggish valve operation, excessive noise or leakage will

indicate that cleaning is required. In the extreme case, faulty

valve operation will occur and the valve may fail to shift. Clean

strainer or filter when cleaning the valve.

Preventive Maintenance

Keep the medium flowing through the valve as free from

dirt and foreign material as possible.

While in service, the valve should be operated at least once

a month to insure proper opening and closing.

Depending on the medium and service condition, periodic

inspection of internal valve parts for damage or excessive

wear is recommended. Thoroughly clean all parts. If parts

are worn or damaged, install a complete ASCO Rebuild

Kit.

Causes of Improper Operation

Incorrect Pressure: Check valve pressure. Pressure to valve

must be within range specified on nameplate.

Excessive Leakage: Disassemble valve and install a

complete ASCO Rebuild Kit.

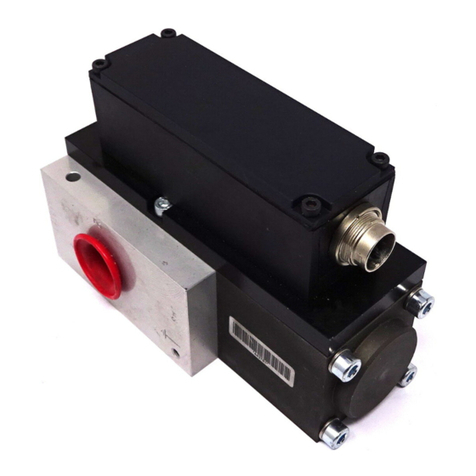

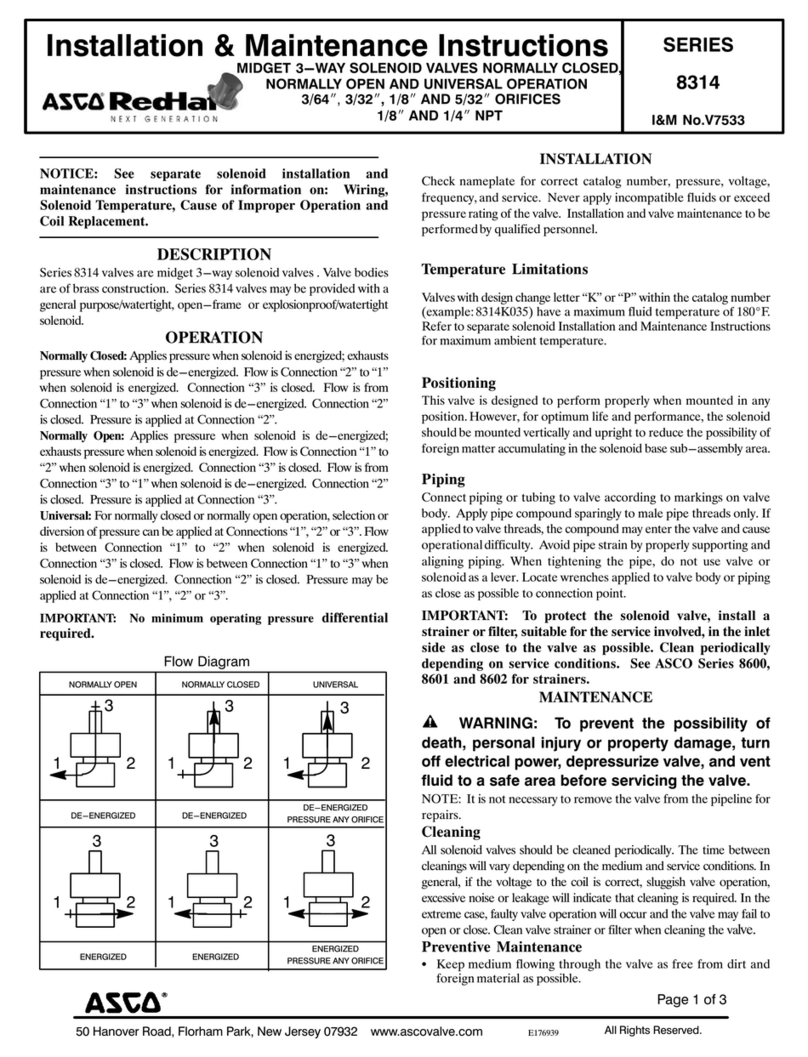

Valve isassembly

1. Disassemble valve in an orderly fashion using exploded

view for identification and placement of parts.

2. Remove solenoid, see separate instructions.

3. Unscrew cartridge assembly from valve body. Then

remove cartridge gasket and orifice gasket.

4. Clean valve and install a complete ASCO Rebuild Kit.

Valve Reassembly

1. Lubricate all gaskets with DOW CORNING 111

Compound lubricant or an equivalent high-grade silicone

grease.

2. Position cartridge gasket in valve body.

3. Install orifice gasket in recess in base of cartridge assembly.

4. Thread cartridge assembly with orifice gasket into valve

body. Then torque cartridge assembly to 175 ± 25 in-lbs

[19,8 ± 2,8 Nm].

5. Install solenoid see separate instructions. Then make up

piping and electrical connection to solenoid.

WARNING: To prevent the possibility of personal

injury or property damage, check valve for proper

operation before returning to service. Also perform

internal seat and external leakage tests with a

nonhazardous, noncombustible fluid.

6. Restore line pressure and electrical power supply to valve.

7. After maintenance is completed, operate the valve a few

times to be sure of proper operation.

OR ERING INFORMATION

FOR ASCO REBUIL KITS

Parts marked with an asterisk *) in the exploded view are supplied in

Rebuild Kits. When Ordering Rebuild Kits for ASCO valves, order

the Rebuild Kit number stamped on the valve nameplate. If the

number of the kit is not visible, order by indicating the number of kits

required, and the Catalog Number and Serial Number of the valve s)

for which they are intended.

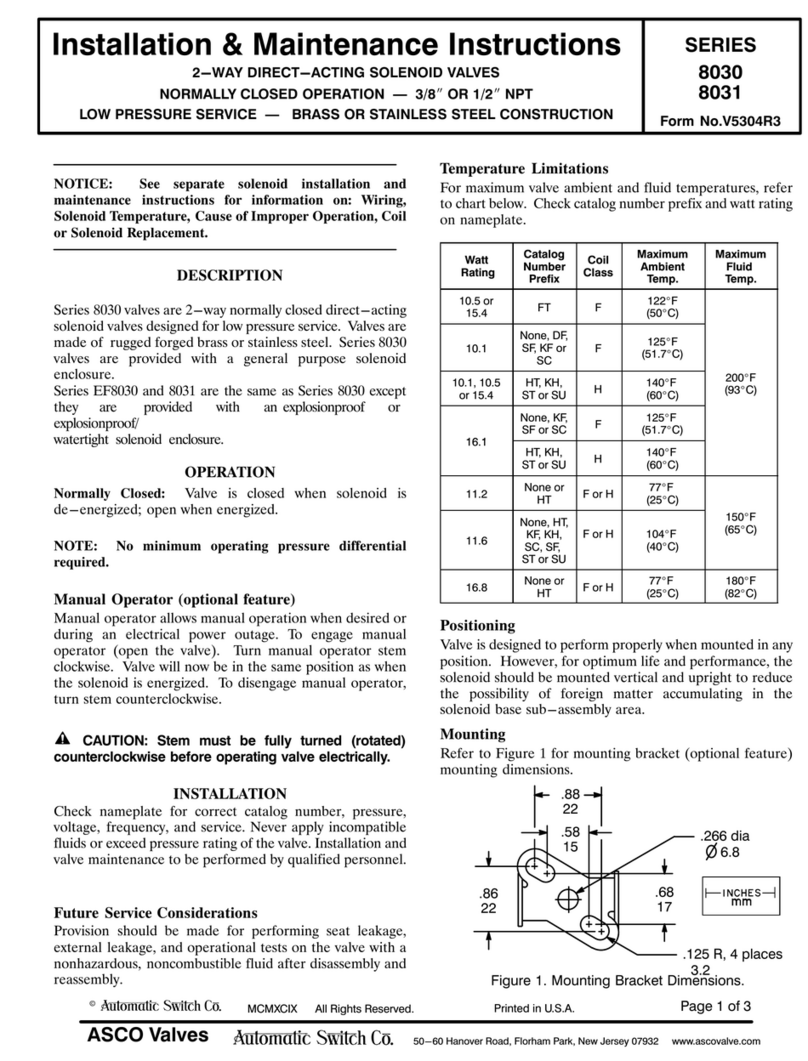

Torque Chart

Part Name Torque Value

In-lbs

Torque Value

Nm

Cartridge

Assembly 175 ± 25 1 ,8 ± 2,8

cartridge

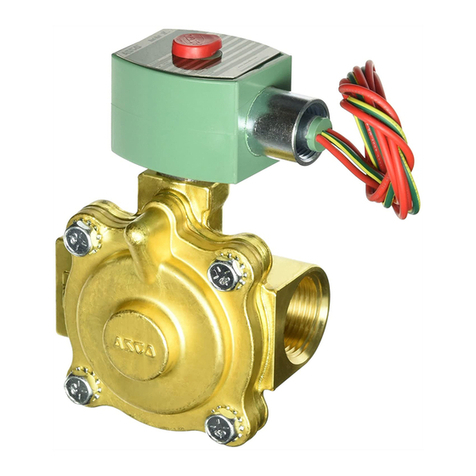

assembly

gasket

orifice

gasket

valve body

(stainless steel)

mounting

bracket

valve body

(brass)

cartridge

mounting

bracket

Indicates parts

supplied in

Rebuild Kit

1/8 NPT

wrenching flat

(See instructions in

Piping section)

Figure 3. Series 8314 without solenoid.