NOVOTEST T-UD2 User manual

HARDNESS TESTER

NOVOTEST Т-UD2

Operating Manual

2016

Development and manufacturing of non-

destructive testing equipment and system

Hardness tester NOVOTEST T-UD2

2

CONTENTS

1. Introduction 2

2. Appointment 2

3. Specifications 2

4. Packing list 4

5. Principle of operation 4

6. Preparations for operation 6

7. Basics of operation 7

8. Operation 8

9. Hardness measurement 15

10. Measurement modes 22

11. Calibration 24

12. Technical maintenance, special conditions of operation 34

13. Precautions and trouble shouting 36

14. Manufacturer’s guarantee and service maintenance 37

Development and manufacturing of non-

destructive testing equipment and system

Hardness tester NOVOTEST T-UD2

3

1. Introduction

The following operation manual explains the preparation, setup,

principles of operation, usage, and troubleshooting of the hardness

tester NOVOTEST T-UD2 and its versions T-U2, T-D2.

Please, read this instructions carefully for operate the hardness

tester NOVOTEST T-UD2 functions quickly and effectively.

In doing this you will be able to take full advantage of the function

range of the instrument. At the same time, you will also avoid errors

and wrong operation which in turn would cause incorrect test results

and thus could lead to injury and damage.

2. Appointment

The hardness tester NOVOTEST T-UD2 is handy, easy to operate

and can carry out tests quickly without any difficulties.

Hardness tester NOVOTEST T-UD2 is mainly suitable:

• for measurement hardness of low and non-alloyed steels;

• for measurement hardness of high-alloyed steels;

• for measurement hardness of nonferrous metals.

3. Specifications

3.1. Calibration scales

Device has 20 calibration scales of hardness that conventionally

divided into four scales and five materials for each:

Each of the scales can be additionally calibrated by 1 or 2 points.

Also, the unit measures in Leeb scale (with rebound probe) and

Tensile strength, through the automatic recalculation from the Brinell

scale.

Development and manufacturing of non-

destructive testing equipment and system

Hardness tester NOVOTEST T-UD2

4

3.2. The limits of permissible basic error of measurement

Hardness scale

Error (%)

Rockwell C

±1,5

Brinell

±3,0

Vickers

±3,0

Leeb

±3,0

Tensile strength

Not rated

3.3. Working conditions: -20°C to +40°C

3.4. Overall dimensions

Name

Overall dimensions, mm

Information processing unit

125x65x25

UCI probe

Ø25х140

Rebound probe

Ø20х150

3.5. Weight of the instrument and probe

Name

Weight, kg

Information processing unit

0,10

UCI probe

0,25

Rebound probe

0,10

3.6. Power supply

Battery operation: two 1.5V AA cells:

- AlMn (approx.15 hours operation);

- Alkaline (approx.8 hours operation);

- NiCd (approx. 15 hours operation);

- NiMH (approx. 20 hours operation).

3.7. To save battery charge in the menu there is setting of device

auto switch off.

Development and manufacturing of non-

destructive testing equipment and system

Hardness tester NOVOTEST T-UD2

5

3.8. Requirements for the test material

Surface roughness, not more, Ra

UCI (10N) probe U1

UCI (50N) probe U1

Rebound probe D1

1,5

2,5

3,2

Radius of curvature of the surface, mm

UCI probe U1

Rebound probe D1

5,0

10,0

Weight of the test material, not less, kg

UCI probe U1

Rebound probe D1

0,1

5,0

Thickness of the test material, not less, mm

UCI probe U1

Rebound probe D1

1,0

10,0

4. Packing list

4.1. Information processing unit 1 pc

4.2. Probes: UCI (10N) __ pc

UCI (50N) __ pc

UCI (98N) __ pc

Rebound (Leeb) __ pc

4.3. Charger 1 pc

4.4. Batteries 2 pc

4.5. USB cable 1 pc

4.6. Operation manual 1 pc

4.7. Carrying case 1 pc

5. Principle of operation

5.1. Rebound method

Rebound probe consists of an impact body and the capture. The

impact body has a carbide tip and a permanent magnet for

Development and manufacturing of non-

destructive testing equipment and system

Hardness tester NOVOTEST T-UD2

6

generating a voltage pulse; the impact device has a spring

mechanism for loading and impelling the impact body, and an

induction coil for detecting the magnet in the impact body. In the

rebound hardness testing method, the speed variation caused by

the impact of the impact body against the material surface is

measured.

The impact energy is adjusted via the spring for the measurement.

The impact body contained in the tube of the impact device is

impelled against the test surface by means of the release button. In

the course of this, the magnet of the impact body induces in the coil

a voltage signal whose height is proportional to the impact phase

speed. The impact causes a plastic deformation of the material and

a permanent spherical indentation is produced in the surface. This

plastic deformation leads to a loss of energy of the impact body and

thus to a lower speed after the actual rebound phase.

The speed ratio is determined exactly at the moment of

impact/rebound by means of the special signal processing. The

speed ratio is therefore unaffected by the impact direction. As

opposed to this, other rebound hardness testers require presetting

of the impact direction in fixed steps (influence of gravitation on the

speed ratio) - which constitutes a considerable disadvantage with

frequently changing test positions.

5.2. UCI method

The Vickers diamond is fixed to the tip of a round metal rod. This

metal rod is excited, to its resonant frequency of approx. 78 kHz,

into longitudinal oscillations. When the Vickers diamond contacts the

sample surface, the resonant frequency will change. This change

happens in relation to the size of the indent area from the Vickers

diamond. The size, in turn, is a measure for the hardness of the

tested material. Resonant frequencies can be measured very

accurately. This is why the UCI method is suited to make the

Development and manufacturing of non-

destructive testing equipment and system

Hardness tester NOVOTEST T-UD2

7

evaluation of Vickers indents, and thus of the complete test

procedure, so much easier and quicker.

There are also two additional advantages:

- the measurement is made under load. (No impairment of the

measurement due to elastic resilience);

- the hardness measurement is based on the area of the indent and

not on the length of the indent diagonals.

The measurement is thus less affected by surface roughness; even

gunmetal-finished surfaces can be measured.

Concerning the UCI method, the measurement value is also

dependent on the Young’s modulus of the material.

6. Preparations for operation

6.1. Battery supply

The hardness tester NOVOTEST T-UD2 is powered by batteries or

accumulators. For this you need two AA 1.5 V:

- dry cells (AlMn) or rechargeable (Nickel-Cadmium or Nickel-

Metalhydrid).

NOTE! The batteries must be fully charged before first use.

Using of batteries and accumulators.

Open the battery compartment. Insert the batteries, observing the

correct polarity. Close the battery compartment.

Used or defective batteries are special refuse and must be disposed

of according to the governing laws!

6.2. Connection of probes.

Socket for the probe is at the top of the information processing unit.

Connect the probe cable to the NOVOTEST T-UD2 socket in

accordance with the marks on the connector.

Development and manufacturing of non-

destructive testing equipment and system

Hardness tester NOVOTEST T-UD2

8

7. Basics of operation

7.1. Keys

Turn on/off; left soft key

Right soft key

Modes switch

Selection of hardness scale

Navigation key; increase

Navigation key; decrease

7.2. Selection of measurement method.

7.2.1. Rebound method of measuring hardness is appropriate for:

- testing objects weighing more than 5 kg and a wall thickness more

than 10 mm;

- massive products, products with a coarse-grained structure, forged

and cast products;

- testing objects with minimal preparation of the surface.

7.2.2. UCI method of measuring hardness is appropriate for:

- testing objects with low mass and small wall thickness;

Development and manufacturing of non-

destructive testing equipment and system

Hardness tester NOVOTEST T-UD2

9

- testing objects with a glossy surface (with special requirements to

the minimum size of the imprint);

- surfaces of the testing objects with hardened layers.

8. Operation

8.1. Preparation of the test material.

The surface must be clean and free of oil, grease and dust.

The surface roughness of the material should meet the requirements

of a specific probe (paragraph 3.8).

8.2. Features of the methods of measurement of metal hardness:

8.2.1.UCI method:

Distinct reading variations may especially occur with a mass lower

than 0.1 kg and a specimen thickness of less than 1 mm if the test

material is excited to resonance or sympathetic oscillations.

Otherwise, such test materials must be fixed to a solid base, e.g.

using a viscous paste. The same applies to the hardness test

blocks.

8.2.2. Rebound method:

With smaller and less heavy test objects, the impact effect of the

impact device may cause vibrations which could produce distorted

measurement results.

- Test objects weighing less than 2 kg must in any case be fixed to

the support using couplant so that there are no any vibrations.

- Test objects weighing between 2 kg and 5 kg must be placed on a

large metal support (e.g. a table) in such a way that they are not

moved or caused to vibrate by the impact.

Development and manufacturing of non-

destructive testing equipment and system

Hardness tester NOVOTEST T-UD2

10

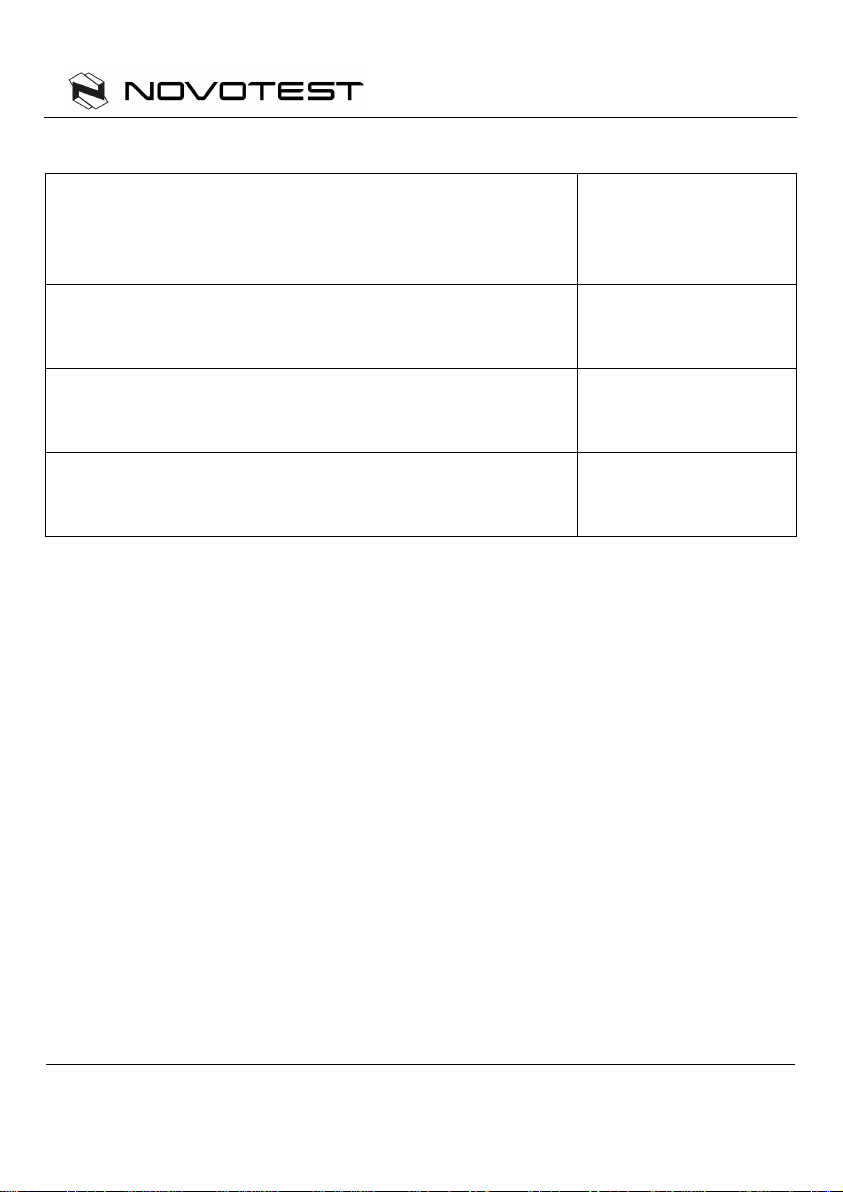

8.3. Device menu

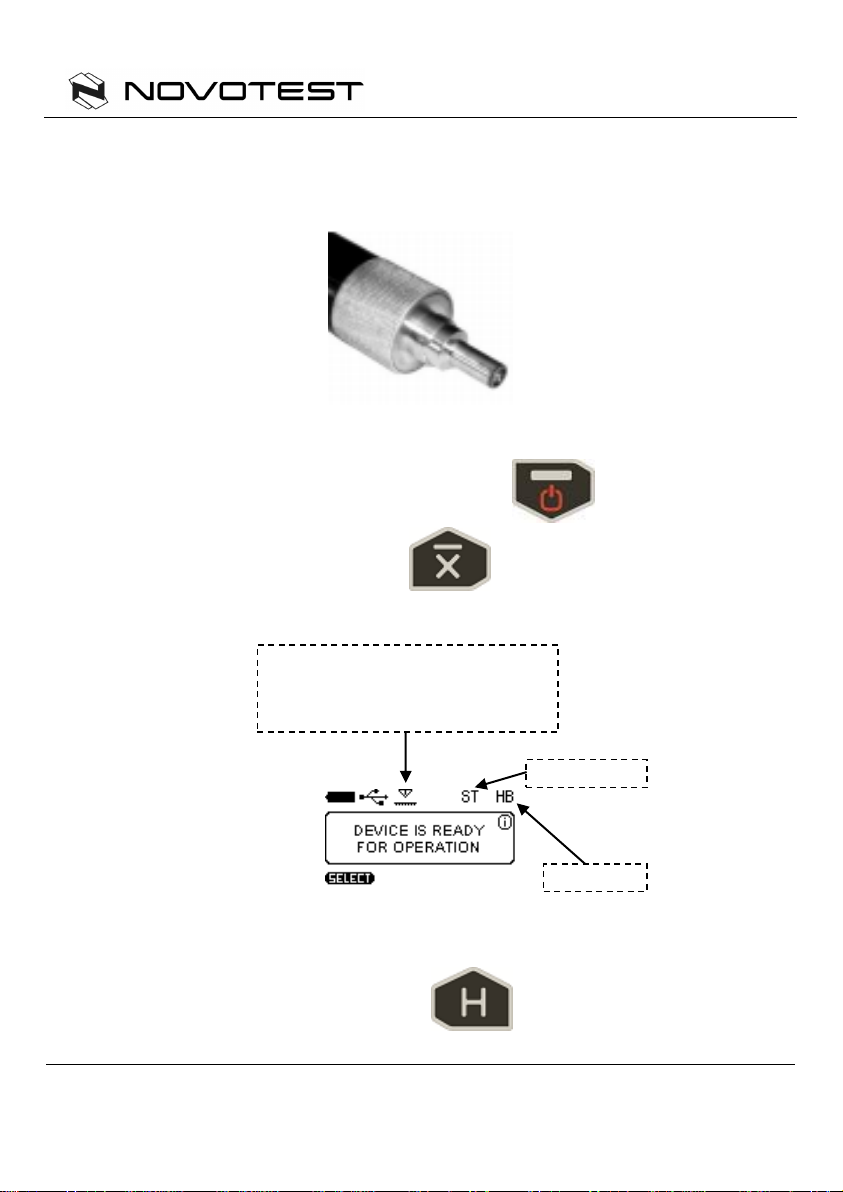

After connecting the probe, hold TURN ON button until logo

appears on the display:

Then, you get to the main menu of the device:

The menu consists of 6 sections:

1. Measuring

2. Calibration

3. Archive

4. Settings

5. Memory card

6. Information

Scroll through the menu using the navigation keys and

, for entering press soft key SELECT using .

Soft keys

Development and manufacturing of non-

destructive testing equipment and system

Hardness tester NOVOTEST T-UD2

11

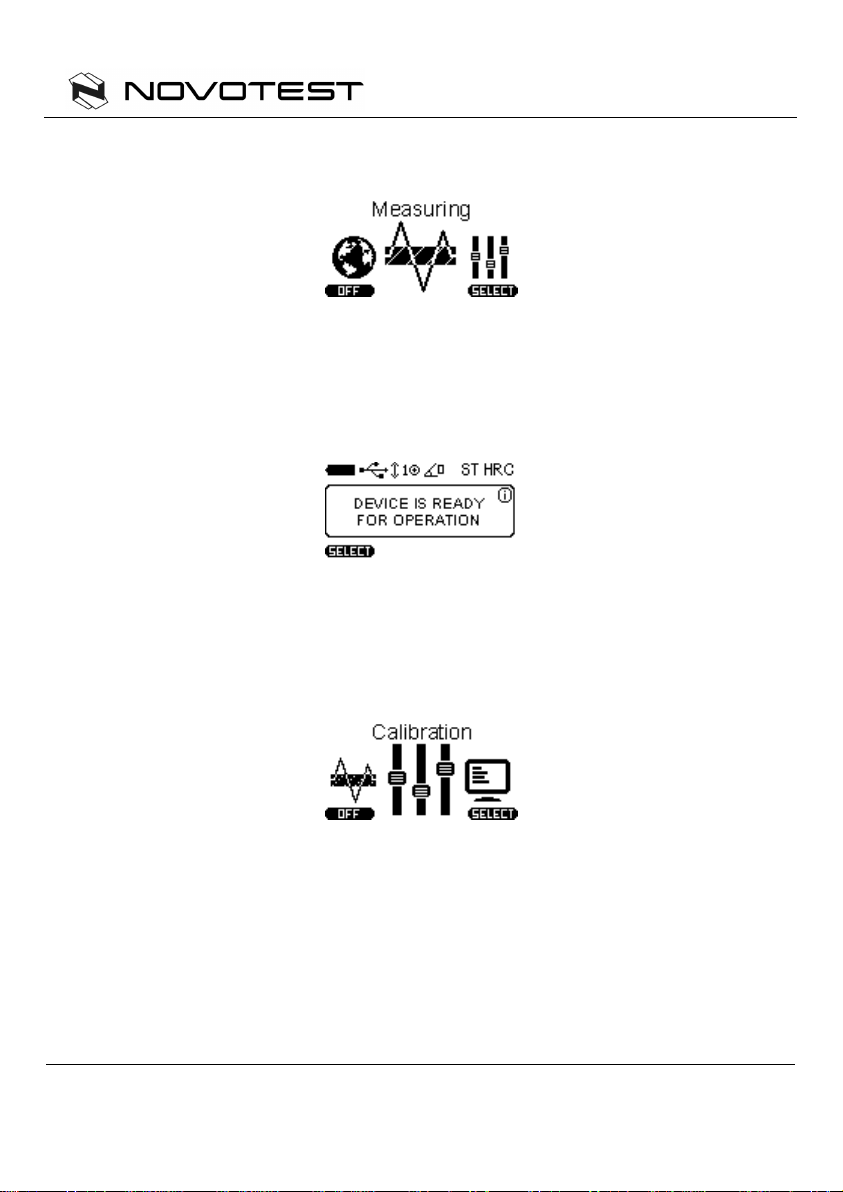

8.3.1. Measuring

Selecting Measuring, you go to the measurement of hardness

mode, depending on the probe at the top of the screen will display

the angle of the probe (for rebound probe), or the state of the

diamond indenter (for UCI probe).

Detailed description of the measurement of hardness, see

paragraph 9.

8.3.2. Calibration

Selecting Calibration, you go to the table of calibrations where the

scale conventionally divided into four hardness scales: Rockwell

(HRC), Brinell (HB), Vickers (HV), User (U1). Each of the scales can

be calibrated to 5 conventional materials: Steel (ST), Alloy Steel

(AST), Stainless steel (SST), Cast Iron (CI), User material (U1).

Detailed description of the calibration process, see paragraph 11.

Development and manufacturing of non-

destructive testing equipment and system

Hardness tester NOVOTEST T-UD2

12

8.3.3. Archive

Selecting Archive you go to the list of saved measurements, which

displays Measurement name, Scale, Material and Average Value.

You can store in memory up to 1024 measurements.

Scroll through the list using the navigation keys and

.

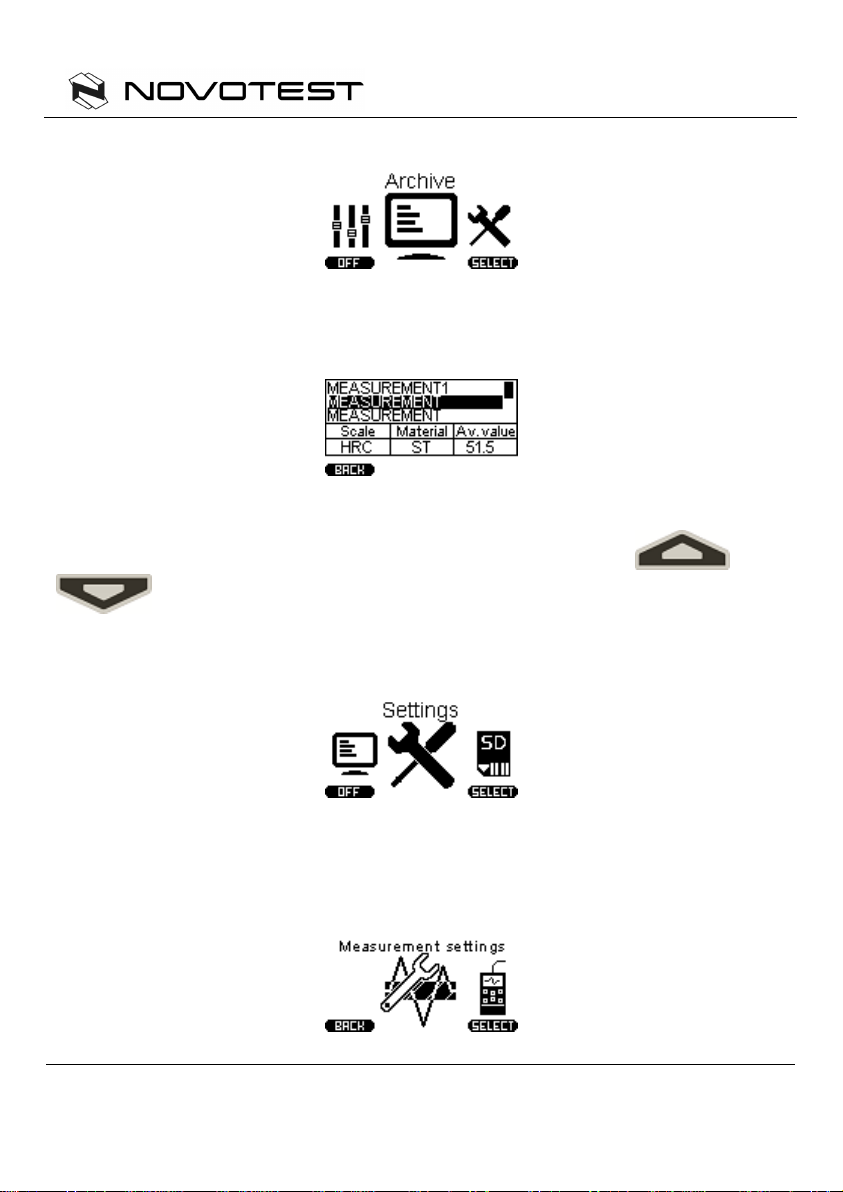

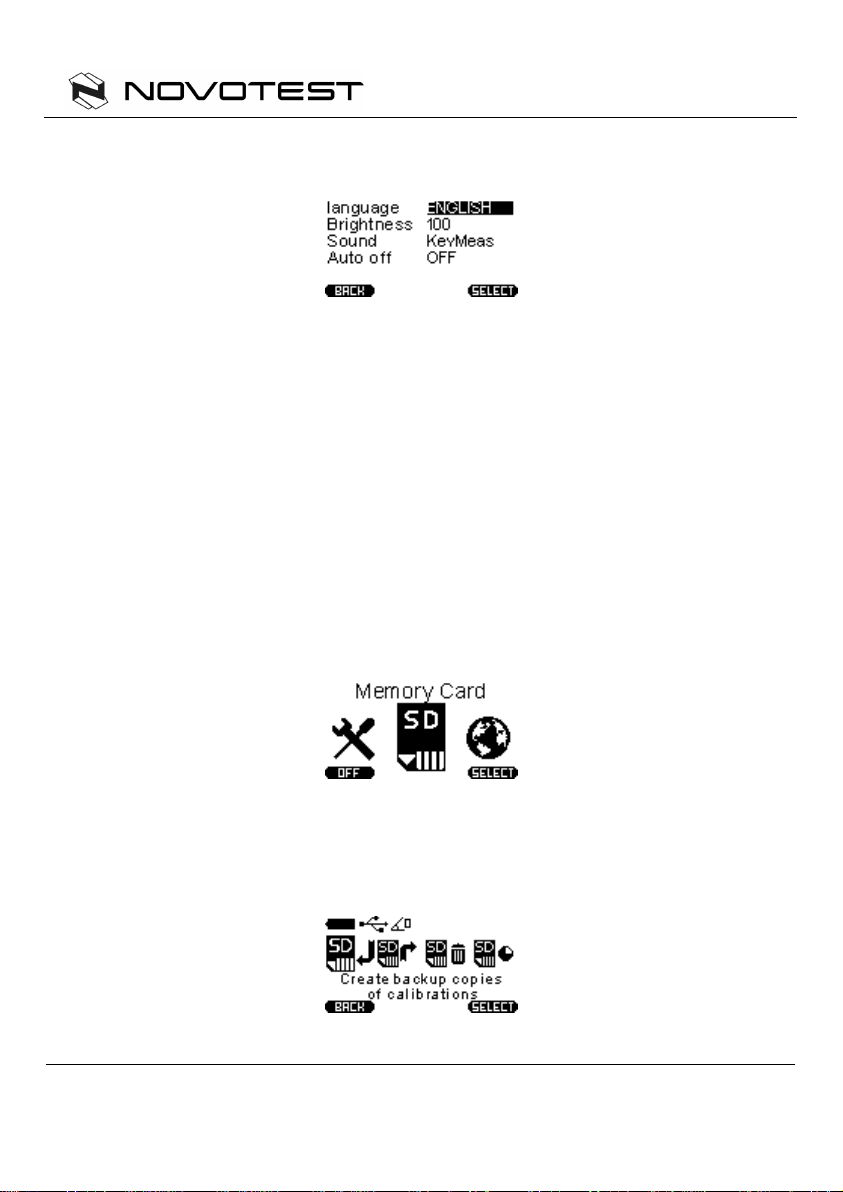

8.3.4. Settings

Selecting Settings you go to the settings menu, there are 2:

-Measurement settings:

Development and manufacturing of non-

destructive testing equipment and system

Hardness tester NOVOTEST T-UD2

13

- Device settings:

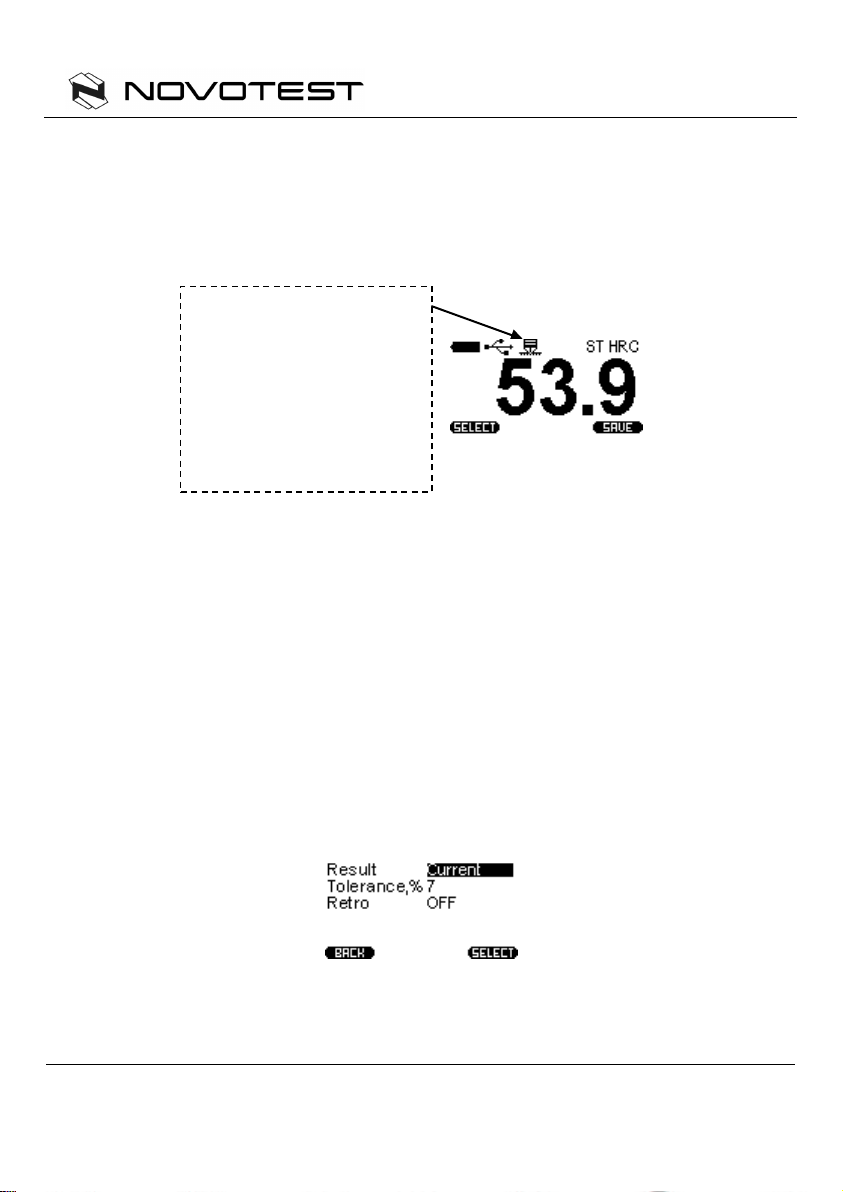

8.3.4.1. Measurement settings

By selecting Measurement settings you can configure the following

settings:

Result: displaying measurement results can be Current (display

instantaneous values of measurements) and Average (unit

accumulates the series of measurements and display average value

of hardness).

Tolerance, %: This parameter is used only for Smart mode. Set the

% value adjusts the range of deviations of measurements to be

included in the calculation of the average for the series in Smart

mode. Detailed description of the Smart mode, see paragraph 10.3.

Retro: allows you to return to the measurement mode with saved

last measurements after restarting of the device.

Development and manufacturing of non-

destructive testing equipment and system

Hardness tester NOVOTEST T-UD2

14

8.3.4.2. Device settings

Language: selection language of the device menu (available

English, Spanish, Russian).

Brightness: setting the brightness of the backlight.

Sound: there are 4 modes of device sound (Off, Key, Measurement,

Key and Measurement)

Auto Off: setting of the automatic shutdown device when it is not in

use.

8.3.5. Memory Card

Selecting Memory Card you go to the menu of memory.

8.3.5.1. Create backup copies of calibrations.

Development and manufacturing of non-

destructive testing equipment and system

Hardness tester NOVOTEST T-UD2

15

After calibration of the probe is recommended to create a backup

copy of the calibration (usually the manufacturer makes the

calibration of 1-2 scales, to check the probe). This is done in order to

be able to resume adequate calibration after incorrect settings in the

future.

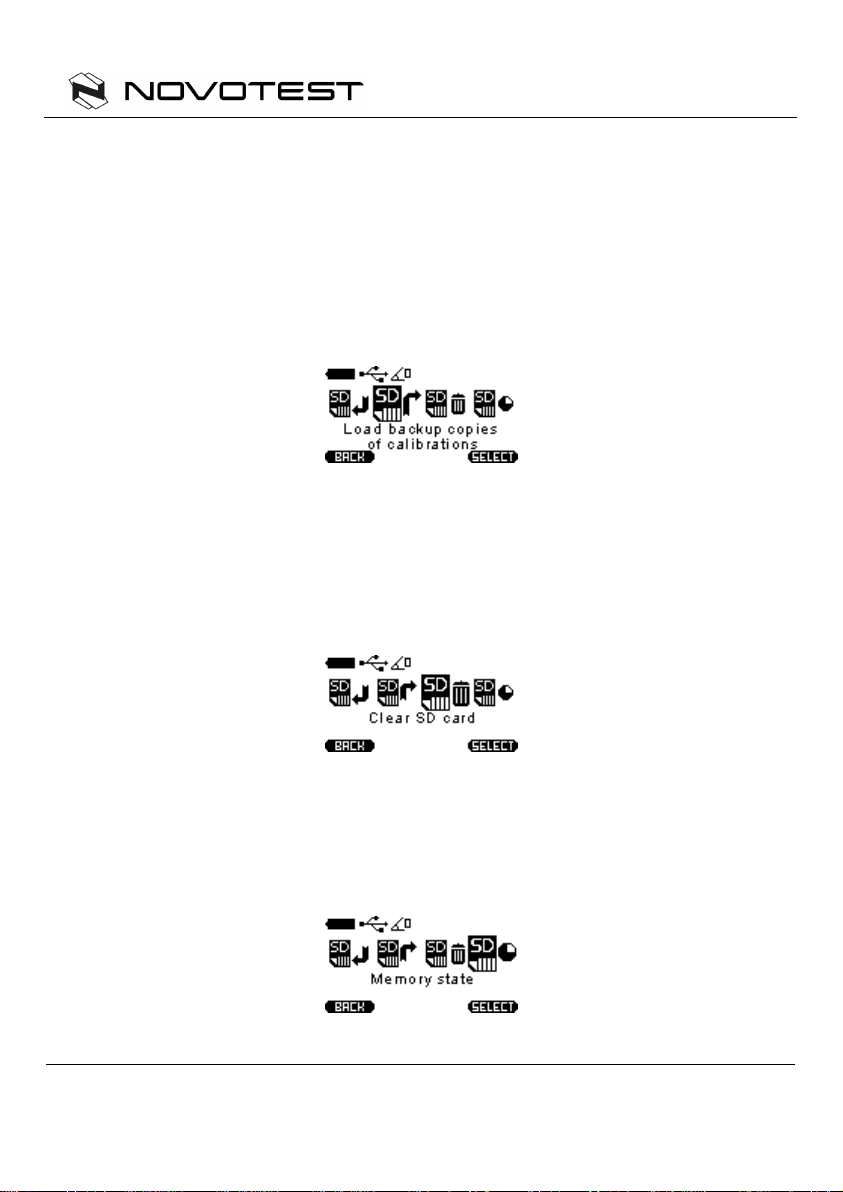

8.3.5.2. Load backup copies of calibrations.

After the initial save of calibrations you can always download it to

the probe. This function is needed for the resumption of adequate

calibration in case of wrong settings of the probe.

8.3.5.3. Clear SD card

Clearing saved records in the archive, after clearing SD card the

archive will be empty.

8.3.5.4. Memory state

Development and manufacturing of non-

destructive testing equipment and system

Hardness tester NOVOTEST T-UD2

16

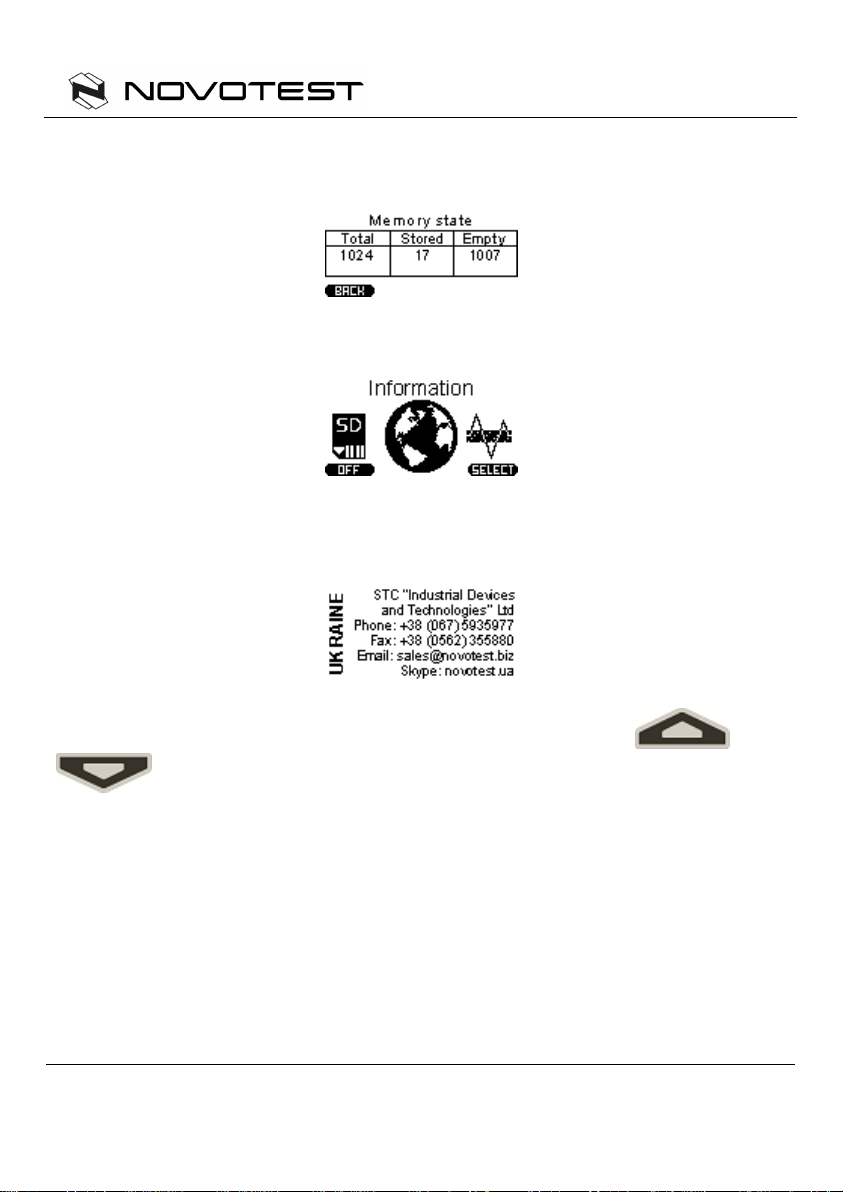

This menu displays the total, used and empty memory cells.

8.3.6. Information

In this menu you can view information about the manufacturer and

offices around the world.

Scroll through the list using the navigation keys and

to see NOVOTEST dealers and general information about

the device.

9. Hardness measurement

9.1. Using of the UCI method

The design of UCI Probe is shown in Figure 1a. Probe has a special

removable collapsible nozzle with the puck (Figure 1b). The puck

provides the convenience of positioning the probe relative to the

testing object and a clip for the measurements

Development and manufacturing of non-

destructive testing equipment and system

Hardness tester NOVOTEST T-UD2

17

.

Figure 1a. UCI Probe U1

1 –Probe’s body; 2 –Collapsible nozzle;

3 –Puck; 4 –Place for fingers

Figure 1b. Demounted nozzle

1 –Probe’s body; 2 –Nozzle main part;

3 –Puck; 4 –Protective tube;

5 –Diamond.

One side of the puck is flat to using probe on flat surfaces. Another

side has grooves for using a probe on cylindrical surfaces.

It is marked slots designed for ease of measurement of hardness on

cylindrical products of various diameters. Probe with demounted

nozzle is usually using to measure hardness in difficult places, such

as narrow or deep groove.

Development and manufacturing of non-

destructive testing equipment and system

Hardness tester NOVOTEST T-UD2

18

The probe may be removed from the nozzle is used for measuring

the hardness in the narrow and hard to reach places.

Figure 2

Turn on the hardness tester pressing , and select the

measurement mode by pressing . Detailed description of the

modes, see paragraph 10.

Then select the scale and material hardness for which there is a

proper calibration (How to calibrate device see paragraph 11). For

select the hardness scales press and chose the scale by

Material

Scale

The state of the diamond

indenter (ready for

measurement)

Development and manufacturing of non-

destructive testing equipment and system

Hardness tester NOVOTEST T-UD2

19

keys and , then press and chose the

material.

During the measurement you can select other hardness scale. The

displayed measurement reading will be converted according with the

new hardness scale if it is calibrated.

NOTE! Calibration of UCI probe is carried out by the direct method,

so the conversion is carried out on the basis of pre-calibration, and

does not correspond to any standard.

Install the probe puck on the sample surface, keeping it in the tough

skirt as shown in Figure 3a. By clicking on the skirt thrust both hands

to bring the diamond tip of the probe perpendicularly to the sample

surface to the touch (Figure 3b). Slowly (in about 0.5 seconds) by

pressing with a force of (5 or 1 kg depending on probe type) thrust

skirt, push the diamond tip into the metal surface, preventing

swinging (Figure 3c). After the beep, remove the probe from the

tested object.

a b c

Figure 3

Development and manufacturing of non-

destructive testing equipment and system

Hardness tester NOVOTEST T-UD2

20

The display shows the value of hardness. The result of

measurement is displayed on the display until the next

measurement.

WARNING! Not allowed a sharp click and scratching sample by

indenter, this may lead to exceeding the allowable value of error and

damage the diamond indenter.

NOTE! The "exciter" in the probe is powered from the batteries. If

the batteries are depleted you will get erratic test results.

You can get the value of the current measurement or the average

for the series of measurements, depending on the settings in

Measurement settings menu Current or Average:

This symbol indicates

that the diamond

indenter is in contact

with the testing object

or device is not ready

for the next

measurement

Table of contents

Other NOVOTEST Test Equipment manuals