Fluke 5623B User manual

Other Fluke Test Equipment manuals

Fluke

Fluke 7080 User manual

Fluke

Fluke NetTool User manual

Fluke

Fluke BT5300 Series User manual

Fluke

Fluke 2AC VoltAlert Instruction manual

Fluke

Fluke 1662 User manual

Fluke

Fluke T50 User manual

Fluke

Fluke 5560A User manual

Fluke

Fluke 1625 User manual

Fluke

Fluke AIRCHECK User manual

Fluke

Fluke 724 Use and care manual

Fluke

Fluke 5080A User manual

Fluke

Fluke 6109A User manual

Fluke

Fluke Series II Manual

Fluke

Fluke CombiScope PM3370B User manual

Fluke

Fluke P5515-V User manual

Fluke

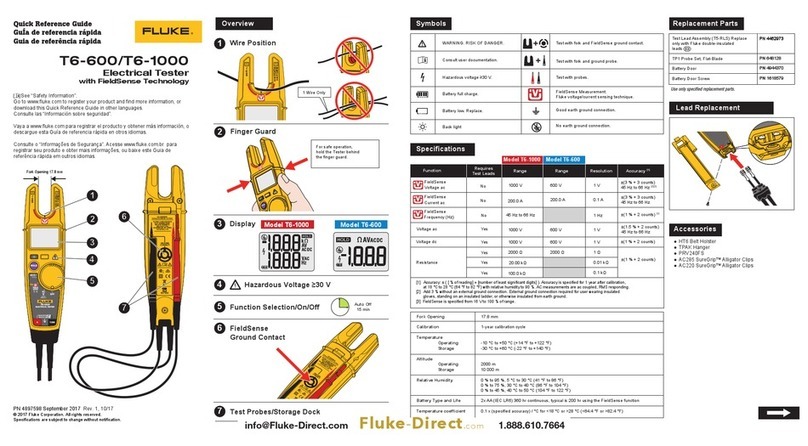

Fluke T6-600 User manual

Fluke

Fluke SimpliFiber Pro User manual

Fluke

Fluke 1550C User manual

Fluke

Fluke 3130-G2M User manual

Fluke

Fluke HART 744 User manual

Popular Test Equipment manuals by other brands

SMART

SMART KANAAD SBT XTREME 3G Series user manual

Agilent Technologies

Agilent Technologies BERT Serial Getting started

Agilent Technologies

Agilent Technologies N3280A user guide

Lifeloc

Lifeloc R.A.D.A.R. quick start guide

Mercury

Mercury TSL01 user manual

MAHA

MAHA MBT Series Original operating instructions