Product Specification Sheet

1. Product Information:

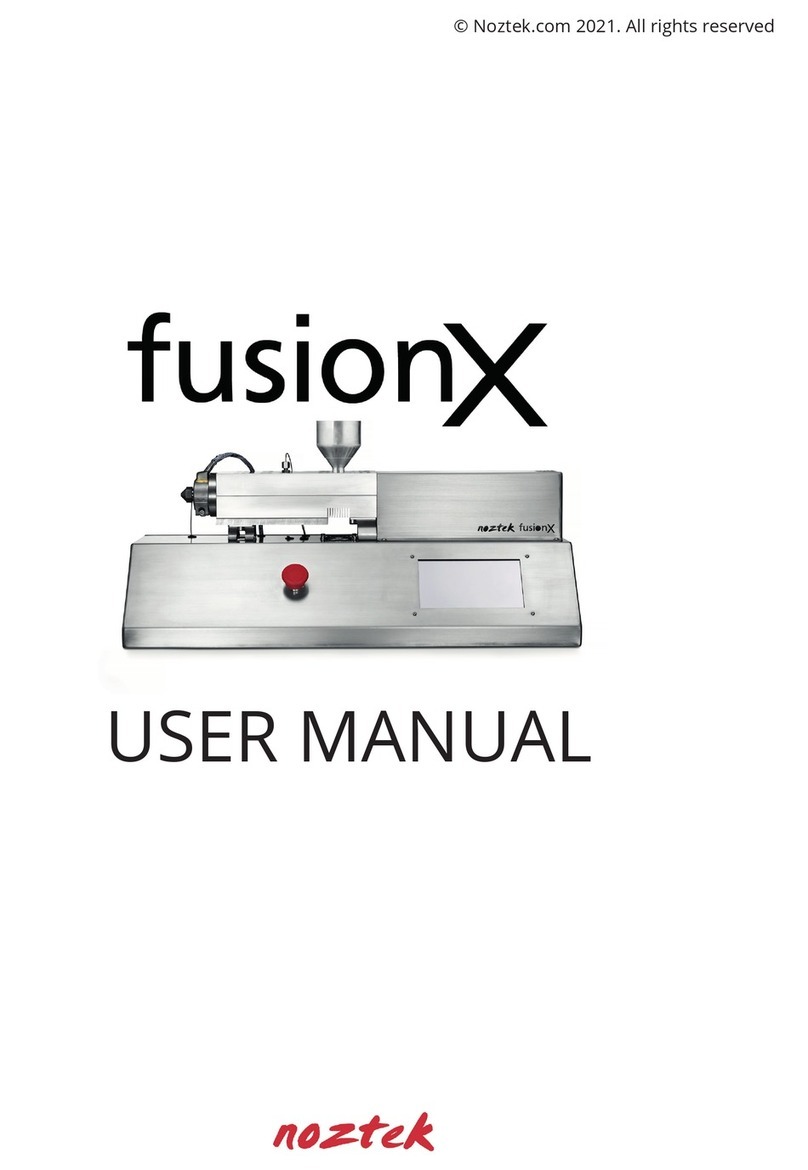

• Pro uct Name/Mo el: Noztek PRO/PRO HT filament extru er.

• Bran /Manufacturer: Noztek

• Serial Number: See invoice

• Date of Manufacture: 2023

2. General Description:

The Noztek PRO/PRO HT, a versatile single screw esktop extru er, has been

meticulously esigne for the precise pro uction of high-quality filament

extrusion. Equippe with two heater ban s, manual temperature control, an a

robust 50rpm 20nm motor, it effortlessly elivers superior filament from an

extensive array of materials an polymers.

The stan ar Noztek PRO is configure with heater ban s capable of reaching up

to 250°C, while the Noztek PRO HT boasts an impressive 600°C capacity.

This extru er's a aptability exten s its value across iverse in ustries, inclu ing

pharmaceuticals, 3D printing, an the chemical sector, offering a cost-effective

an efficient means to shape an process materials into top-tier filaments.

For optimal results, we recommen utilizing extrusion-gra e pellets.

3. Technical Specifications:

• Voltage Requirements: 220VC or 110VC.

• Power Rating: 10A.

• Frequency (Hz): 50 Hz or 60 Hz.

• Operating Temperature Range: -40°C to 85°C (-40°F to 185°F)

• Dimensions (inclu ing weight an size): 80cm x 15cm x 54cm. 10 KG.

• Material Composition: Steel. Barrel an Screw: Stainless steel

• Color/Finish: Re pow er coat

• Motor: 50RPM, 162 kg-cm of torque

4. Key Features:

Manual Control over Temperature with High Precision PID Controller:

The Noztek PRO/PRO HT is equippe with a sophisticate high precision PID

(Proportional-Integral-Derivative) controller, provi ing users with manual control

over the extrusion temperature. This allows for precise a justments to

accommo ate various materials an achieve optimal extrusion con itions. The

PID controller ensures stability by continuously monitoring an a justing the

temperature to maintain a consistent an accurate level throughout the

extrusion process.

4