START UP GUIDE

The Noztek Xcalibur features an illuminated on/o switch on the back and a red emergency shutdown

button on the front. In an emergency simply hit the button and the machine will completely switch o.

To restart, simply untwist the button (anti-clockwise), to release.

First attach the hopper; the bolts are located in the bolt holes in the barrel. Then you are ready to swicth

on the power.

Once powered up, the Xcalibur will take a short period to boot before presenting the touch screen user

interface

It is recommended that you read through all intructions BEFORE turning on your machine for the rst

time, to get aquainted with the process of operating the machine.

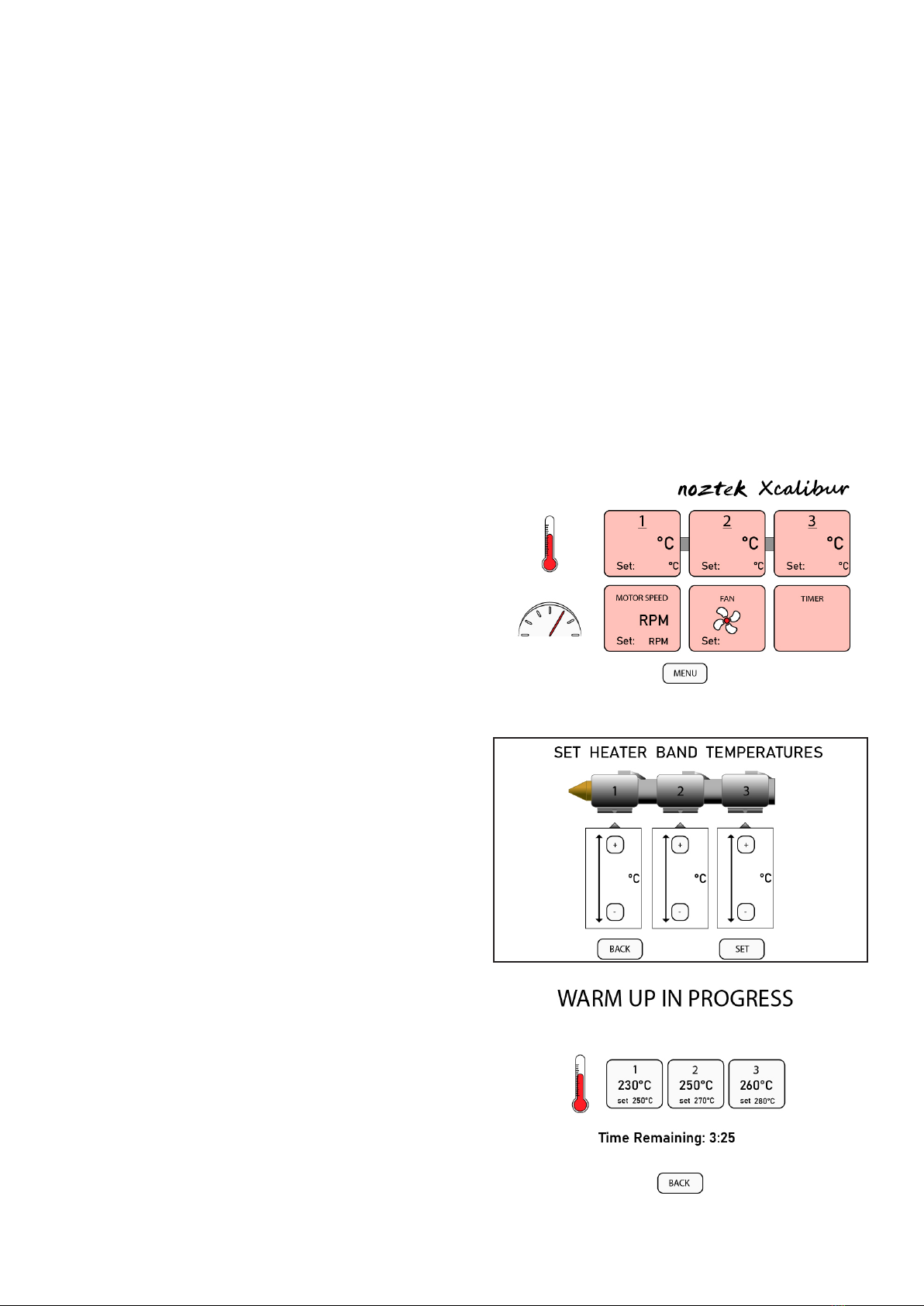

USER INTERFACE

This screen shows the current temperature of each

heating band, the speed of the motor, the fan status,

the timer progress, and access to the Menu screen.

You can alter each of the settings either through the

corresponding red box, or through the menu screen.

Temperature Settings Screen

Control each heater band from here. Upon acti-

vating the heating bands, the Xcalibur display will

switch to the“warm up” screen while each band

heats up.

If you would like to cancel your modications, press

BACK.

Warm-up Screen

This screen is displayed when you heat for the rst

time or when the temperature dropped under the

target. This warm up is to ensure that the barrel has

reached a certain temperature before being able to

run the motor safely.

The Xcalibur will not exit this screen until the heater

bands are at the set tempaerature, or the user aborts

the heating process. This is a safety measure as it can

be dangerous to begin extruding before the barrel

has heated up suciently.

4