Bioer ThermoShaker MB-202 User manual

ThermoShaker Mixing Block

MB-202 Type

Oscillating Dry Bath

Operation Manual

H a n g z h o u B i o e r T e c h n o l o g y C o . , L t d .

Operation Manual for Oscillating Dry Bath Important Notes

—I—

Caution:

All rights reserved. Hangzhou Bioer Technology Co., Ltd. reserves the

right to modify this manual at any time without notice.

All rights reserved. Without prior written consent from Hangzhou Bioer Technology

Co., Ltd., any part of the manual shall not be duplicated, reproduced or translated into

any other languages.

Document No.: BYQ66140000000ESM

Document Version: March 2017, Version 1.0

Before the initial use of this instrument, please carefully

read this manual!

Operation Manual for Oscillating Dry Bath Important Notes

—II —

Important Notes

1. General Practice

Caution:

Important information is contained in any item and should be carefully read. Failure

to observe the instructions would result in damage to or malfunction of the

equipment.

Warning!

The warning message requires extremely careful operation of a certain step. Failure

to observe the instructions may result in serious personal injuries.

2. Safety

During operation, maintenance and repair of this instrument, the following basic safety measures

shall be observed. In case of failure to follow these measures or the warnings or notes indicated herein,

the basic protection provided by the instrument, its safety criteria of design and manufacture, and its

predicted use range would be impaired.

Hangzhou Bioer Technology Co., Ltd. would be irresponsible for any consequence resulted from

the user’s failure to observe the following requirements.

Caution:

This instrument is for indoor use.

a) The ground connection

To avoid the electric shock, the input power line must be reliably grounded. The instrument is

equipped with the three-pin plug that has the third pin (the pin connects the ground), therefore, the plug

shall be used with the grounded power socket only. This is a kind of safety device. If the plug cannot

be plugged into the power socket, please ask the electrician to install a correct power socket, so as to

make the grounded plug to work for safety.

b) Keeping apart from the live circuit

The operator shall not disassemble the instrument without permission. Only qualified

professionals are allowed to replace elements or adjust the machine inside. Replacement of elements

under energizing state is prohibited.

c) Be careful of the power supply

Before the instrument is connected with the AC power source, the voltage of the power source

shall be the same with the required voltage of the instrument (a deviation of 10% is allowed). The

rated load of the power socket shall not be lower than the requirements of the instrument.

d) Be careful of the power line

Usually, the instrument shall use the power line attached to it. If the power line is destroyed, it

Operation Manual for Oscillating Dry Bath Important Notes

—III —

must be replaced but not be repaired. The replacement shall be carried out with the power line of the

same type and same specification. No goods shall be put on the power line when the instrument is

working and please do not put it in a frequently-visited place.

e) The plugging in and removing of the power line

The user should hold the plug to remove the power line. When plugging in the plug, the user

should make sure that it has been fully plugged in; when removing the plug, do not pull the power line

forcefully.

f) Placement of the instrument

This instrument shall be fixed in a low RH and low dust place apart from water source (e.g. water

pool and water pipeline) and the room shall be well ventilated, and free of corrosive gas and

interference of strong magnetic field. The instrument shall not be placed in a wet or dusty location.

The openings on this instrument are for ventilation circulation and in order to avoid over-heat of

the instrument body, they shall not be blocked or covered. When a single set of instrument is used, the

interval between ventilation openings before and after the instrument and the nearest object shall not

be less than 25cm. Also, don’t use the instrument on loose or soft surface, or the air inlet at instrument

bottom might be blocked.

Excessive temperature would impair the test performance or result in fault of instrument. This

instrument shall not be used in location subjected to direct sunshine. The instrument shall be kept away

from hot gas, stove and all other heat sources.

If the instrument is to be set aside for a long time, the power plug shall be withdrawn and the

instrument covered with soft cloth or plastic film to avoid entrance of dust.

Caution:

In any of the following cases, immediately cut off the power supply, withdraw the

power plug from the power socket, and contact the supplier for treatment:

Liquid drops into the inside of the instrument;

The instrument is rained or watered;

The instrument works abnormally, especially generates abnormal sound or

odor;

The instrument is dropped or its casing is damaged;

The function of instrument obviously changes.

g) Warning sign

Warning!

There is a sign of “HOT SURFACE” on the instrument. The metal part (module)

near the sign shall not be touched with any part of the body when the instrument is

operating in a high temperature state or just finishes this operation to avoid scald!

3. Module Installation and Instrument Maintenance

The instrument module is not fixed by screws. At the time of installation, the bevel at the left

Operation Manual for Oscillating Dry Bath Important Notes

—IV —

bottom of the module should be tangent with the left bevel of the transition plate of the instrument;

press the right side down; if a buckle sound is heard, it means the module has been installed

successfully. At the time of disassembly, hold the module with the left hand and press the button on the

right of the module with the right hand, then the module will be separated from the mainframe.

The bore-hole of the instrument should be regularly cleaned with a wet swab to ensure the test

tube be well contacted with the wall of the bore-hole so as to have good heat conduction.

If the surface of the instrument is polluted, it can be cleaned with soft cloth which is soaked and

then squeezed.

Warning!

At the time of cleaning the surface of the instrument, the power supply must be

cut off;

The power supply must be cut off at the time of replacing the module;

Do not start the oscillating operation when the module is not installed;

The instrument surface shall not be cleaned with the corrosive cleaning agent.

4. After-sales Service

a) Warranty content

Hangzhou Bioer Technology Co., Ltd. is responsible for the replacement for failures caused

by material and manufacturing defects within 1 month after goods delivery.

Hangzhou Bioer Technology Co., Ltd. is responsible for maintenance of failures caused by

material and manufacturing defects within 12 months after goods delivery. Hangzhou Bioer

Technology Co., Ltd. is responsible for selectively repairing and replacing instruments with confirmed

defects within warranty period.

Maintained products shall be sent to maintenance department designated by Hangzhou Bioer

Technology Co., Ltd. by the user. The freight incurred thereof shall be borne by the user. Hangzhou

Bioer Technology Co., Ltd. will bear the freight incurred by returning instrument. (For domestic users

only)

For maintenance out of warranty period, Hangzhou Bioer Technology Co., Ltd. will charge for

certain maintenance cost.

b) Warranty scope

The abovementioned warranty does not apply to damages incurred by improper use and

maintenance, using under unqualified conditions, unauthorized maintenance or modification.

Hangzhou Bioer Technology Co., Ltd. does not provide any other warranty expressions

otherwise; and does not bear liabilities for business promotion under special circumstances.

Caution:

After unpacking, immediately check the goods against the packing list. In case of

damaged or missed goods, please immediately contact the supplier.

After qualification of acceptance, properly fill in the product acceptance sheet and

send (or fax) the copied sheet to the supplier for filing and maintenance.

After unpacking, the packing box and packing materials shall be well kept for future

repair. For the damage of instrument occurring during transporting to the repair

department due to improper package, Hangzhou Bioer Technology Co., Ltd. shall

bear no liabilities.

Operation Manual for Oscillating Dry Bath Contents

Contents

CHAPTER I INTRODUCTION--------------------------------------------------------------------------------------1

CHAPTER II FEATURES---------------------------------------------------------------------------------------------2

1 NORMALWORKING CONDITIONS ---------------------------------------------------------------------------2

2 TRANSPORTATION AND STORAGE CONDITIONS-------------------------------------------------------2

3 BASIC PARAMETERS AND PERFORMANCE---------------------------------------------------------------2

CHAPTER III PREPARATORY WORK---------------------------------------------------------------------------4

1 STRUCTURE DIAGRAM-------------------------------------------------------------------------------------------4

CHAPTER IV OPERATION GUIDE -------------------------------------------------------------------------------5

EXAMINATION BEFORE STARTUP------------------------------------------------------------------------------5

CHAPTER V FAULT ANALYSIS AND TROUBLESHOOTING ------------------------------------------- 13

FAULTANALYSIS AND TROUBLESHOOTING ------------------------------------------------------------- 13

2 DISPLAY FAULTALARM MESSAGE PROMPT COMPARISON TABLE --------------------------- 14

APPENDIX 1: MB-202 WIRING DIAGRAM------------------------------------------------------------------- 15

Operation Manual for Oscillating Dry Bath Chapter I Introduction

—1—

Chapter I Introduction

This product is a dry bath adopting advanced microcomputer control, which can choose a

variety of metal modules applicable to a variety of test tubes. It can be widely used in the

preservation of samples, preservation and reaction of all kinds of enzymes, electrophoresis

pre-degeneration, serum coagulation, incubation and culture of all kinds of molecular biological

experiments with oscillation requirements, etc. This product has the following characteristics:

LCD true color high brightness display;

Simultaneous display of set temperature and instant temperature;

Simultaneous display of set time and run time;

The use of metal modules, so that the samples can be free of pollution;

The metal modules can be easily replaced, cleaned and disinfected, and can apply to a variety of

test tubes;

The built-in over-temperature protection device makes it more reliable for use;

Run end reminder function;

Temperature deviation calibration.

Operation Manual for Oscillating Dry Bath Chapter II Features

—2—

Chapter II Features

This chapter mainly introduces the usage, transportation and storage conditions of the instrument, as

well as its basic parameters, performance and functions.

1 Normal Working Conditions

Ambient temperature: 10C ~ 30C

Relative humidity: ≤70%

Power supply: AC220V22V 1.5A 50Hz1Hz

Surface for placement: Horizontal, stable

Caution:

Before using the instrument, please confirm whether the working conditions meet the

above requirements. Pay special attention to whether the power line is reliably

grounded, and whether the work surface is stable.

2 Transportation and Storage Conditions

Ambient temperature: -20C ~ +55C

Relative humidity: ≤80%

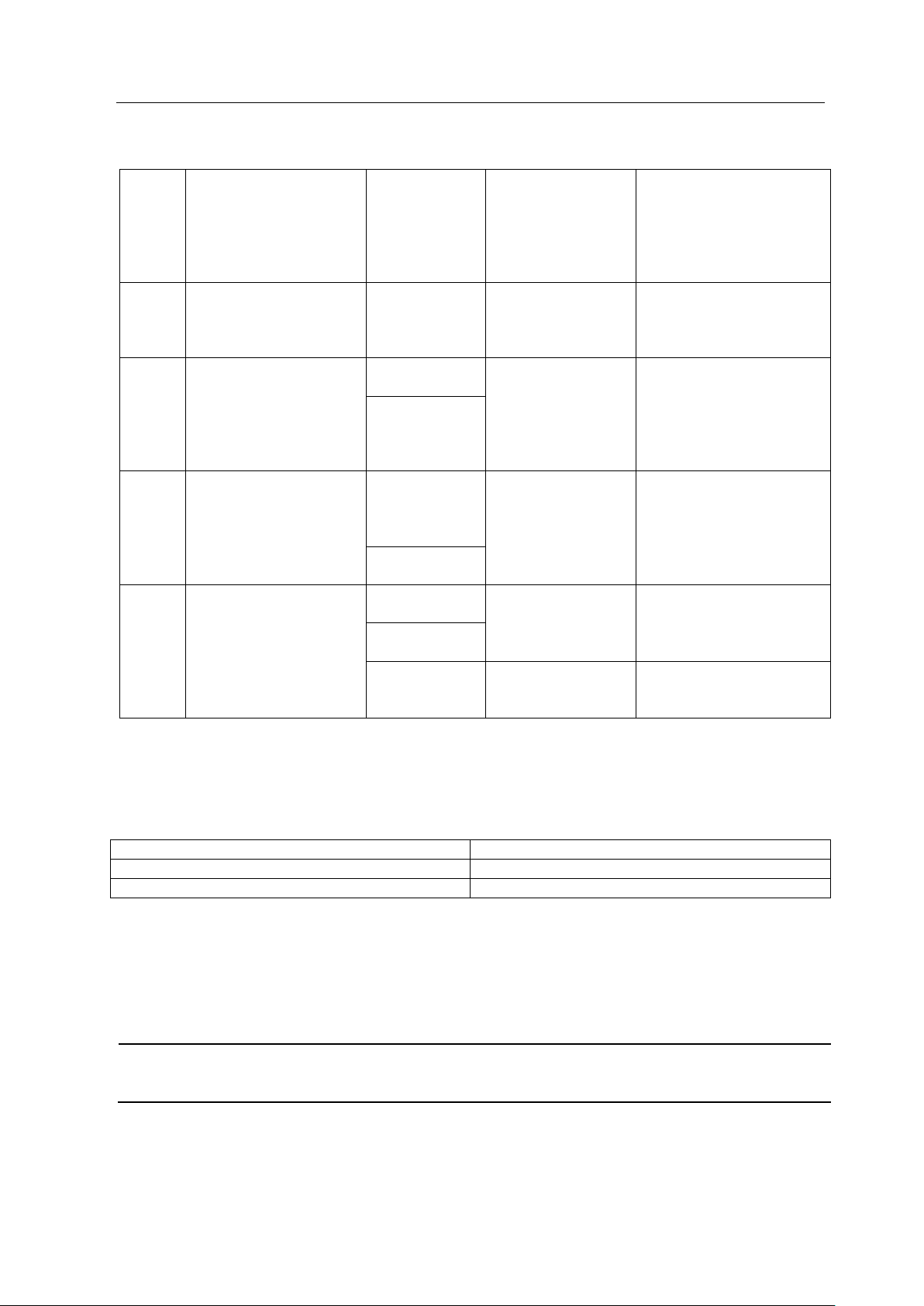

3 Basic Parameters and Performance

Operation Manual for Oscillating Dry Bath Chapter II Features

—3—

Model

MB-202

Temperature setting

range

0~100℃

Temperature control

range

Room temperature -15°C to 100°C (minimum temperature 0°C)

Time setting

1min~99h59min

Temperature

fluctuation

20℃-45℃≤±0.5℃;<20°C 或>45°C≤±0.8℃

Temperature control

accuracy

≤0.5℃(15℃~100℃)

Module temperature

uniformity

20℃-45℃≤±0.5℃;<20°C 或>45°C≤±0.8℃

Ambient temperature20℃~25℃

Humidity:≤70%

Number

Module

Heating time

Cooling time

Oscillation

frequency

weight

(kg)

Module

lid

included

Rise from

25℃to 95℃

Drop 10℃

from the

room

temperature

Drop from

95℃to

25℃

A

384

≤12min

≤12min

≤12min

3000rpm

0.36

Yes

B

96×0.2mL

≤12min

≤12min

≤12min

2000rpm

0.33

Yes

C

54×0.5 mL

≤12min

≤12min

≤12min

2000rpm

0.43

None

D

35×1.5 mL

≤12min

≤12min

≤14min

2000rpm

0.45

None

E

35×2.0 mL

≤12min

≤12min

≤14min

2000rpm

0.45

None

F

12×5.0 mL

≤18min

≤18min

≤18min

1000rpm

0.62

None

G

12×15 mL

≤21min

≤18min

≤21min

1000rpm

0.91

None

H

4×50mL

≤21min

≤18min

≤21min

1000rpm

0.98

None

J

20×1.5 mL

+32×0.2

mL

≤12min

≤12min

≤14min

2000rpm

0.5

None

Dimensions (mm)

311×210×145

Net weight

5.9kg(without module)

Power supply

AC110V-240V,50-60Hz,180W

Caution:

The metal module can be custom-made. If the custom-made module is needed, please

contact with the supplier.

Operation Manual for Oscillating Dry Bath Chapter III Preparatory Work

—4—

Chapter III Preparatory Work

This chapter mainly describes the structure, operating keyboard and function of each button of the

instrument, as well as the preparatory work before the startup. When using this instrument for the first time,

familiarize yourself with the content of this chapter before starting up.

1 Structure Diagram

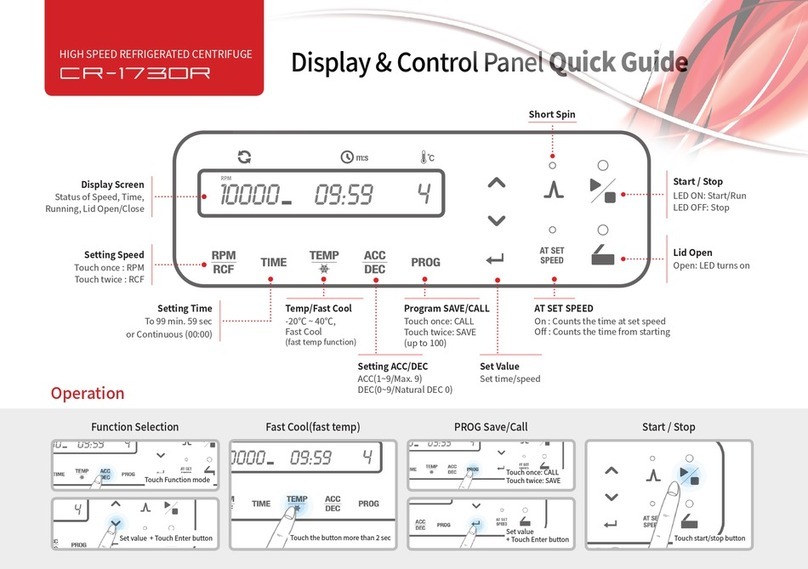

①Lid ②Housing ③Display window

④Module ⑤Power outlet, fuse wire, switch ⑥Nameplate

①

②

③

④

⑤

⑥

Operation Manual for Oscillating Dry Bath Chapter IV Operation Guide

—5—

Chapter IV Operation Guide

This chapter describes in detail the method of temperature setting, oscillation time setting and

oscillation speed setting of the oscillating dry bath, as well as how to correct the error between the actual

temperature and the display temperature, and the setting of the buzzer.

Assemble And Disassemble The Module

The module can be replaced according to requirements. To assemble the module, attach the module

chute to the host chute, then fix the module. To disassemble the module, press the module button, the

module will be set up and separated from the host.

Examination Before Startup

Please confirm the following content before plugging the plug into the power socket.

1 Whether the surface for placement of the instrument is horizontal and stable;

2 Whether the power supply is in line with the voltage required for the instrument; (refer to Chapter II

of this file for the power supply requirements)

3 Whether the power line plug has been securely plugged into the power outlet;

4 Whether the power line is reliably grounded;

5 Whether the module and the mainframe are securely fixed.

Warning!

If the display of the instrument is abnormal after startup, please turn off the power source

immediately and contact with the supplier.

Are you ready? Let's start!

Button

Chut

Operation Manual for Oscillating Dry Bath Chapter IV Operation Guide

—6—

1. Main interface

After the instrument is powered on, turn on the power switch and the display will enter the main

interface. The main interface includes Program, Single Point Set, System, Inching these four option

buttons.

Main Interface

2. Program editing

Click the "Program" option in the main

interface to enter the file list interface. The

maximum number of files that can be saved is

10. Click the "Back" button to return to the

main interface.

File List Interface

Operation Manual for Oscillating Dry Bath Chapter IV Operation Guide

—7—

Click "Delete" in the file list interface,

and the deletion confirmation box will pop up;

click "Yes" to confirm the deletion of the file

and click "No" to cancel the deletion. After the

operation is done, go back to the file list

interface.

删

D

Deletion Confirmation Box

In the file list interface, click "Add" or

select a certain file and click on the file to

enter the file editing interface. In the file

editing interface, operate on the file program.

The 1-5 in the first line of the interface

represent the number of sections, and a file can

be set up to 5 sections. Click "Back" to return

to the file list interface. When the number of

sections of a file is greater than or equal to 2,

click "Delete" to delete the selected section.

File Editing Interface

In the file editing interface, click "Add" to add a section after the selected section and enter the section

information editing interface. The section information includes temperature, time and speed. Click on the

white edit box to select the corresponding information and set the selected information with the 12 keys on

the right. After the setting is done, click "OK" to add the section successfully, click "Cancel" to give up

adding, and then return to the file editing

interface.

In the file editing interface, click on the

selected section to enter the section

information editing interface and modify the

information of the selected section as needed.

After the modification is done, click "OK" to

modify it successfully, click "Cancel" to give

up the modification, and then return to the file

editing interface.

Section Information Editing Interface

Operation Manual for Oscillating Dry Bath Chapter IV Operation Guide

—8—

In the section information editing interface,

click on the option box behind the

temperature to enter the temperature rise / drop

and speed setting interface. Set the temperature

rise / drop and speed with the 12 keys on the right.

Click "OK" to set the speed successfully, click

"Cancel" to abandon the setting, and then return to

the section information editing interface.

Temperature Rise / Drop and Speed Setting Interface

In the section information editing

interface, click on the option box behind the

speed to enter the oscillation setting interface. The

oscillation modes include Forward, Reversal,

Interval, Alternate.The oscillation time and pause

time are required to be set when the intermittent

oscillation is selected. Select the corresponding

time and set the time with the 12 keys on the right.

Click "OK" to set successfully, click "Cancel" to

abandon the setting, and then return to the section

information editing interface.

Oscillation Setting Interface

Forward: Clockwise

Reversal: Counterclockwise

Interval: Intermittent clockwise or intermittent counterclockwise

Alternate: Intermittent clockwise and counterclockwise, that is clockwise, intermittent, then

counterclockwise, with this cycle.

In the file editing interface, click "Save" to

enter the file saving interface. Use the 12 keys on

the right to set the file name. The file name is up

to 8 digits. Click "Back" to return to the file

editing interface.

文

件

保

File Saving Interface

Click "Save" in the file saving and editing interface, if the file name already exists, then a warning box

Operation Manual for Oscillating Dry Bath Chapter IV Operation Guide

—9—

will pop up. Select "Yes" to overwrite the

existing file, select "No" to go back to the file

saving interface, and finally save the file after

modifying the file name.

After the file is saved successfully, a

prompt box saying “The file has been

saved!”will pop up.

Operation Manual for Oscillating Dry Bath Chapter IV Operation Guide

—10 —

3. Single point set

Different from a file, a single point has only one

section. In the main interface, click "Single Point Set"

to enter the single point setting interface. The

operation is similar to that of the section information

editing interface, and the difference is that because it

has only one section, you can click "Run" to run

directly after the section information editing is done.

Click "Back" to return to the main interface.

4. Run

Click "Run" in the interface with a "Run"

button to enter the running interface. The running

interface displays the information of the running

section, including which section is currently

running, the current temperature, the remaining

constant-temperature time of the section, the

oscillation speed and mode.

Running Interface

Click "Pause" in the running interface, the run

time will be suspended and a prompt box will pop up.

Click "Continue" to continue the current section.

Click "Next" in the running interface to skip

the current section and go on to the next section. If the

current section is the last section, a “Stop Running”

prompt box will pop up. Click "Stop" to stop running

and a “Stop Running”prompt box will pop up. Select

"Yes" to stop running, or select "No" to return to the

current running section to continue running.

Stop Running

Pause Running

Operation Manual for Oscillating Dry Bath Chapter IV Operation Guide

—11 —

Click "Details" in the running interface to enter

the running details interface. The details interface

includes not only the running information of the

current section, but also the entire running file

information and the total run time. Click "Back" to

return to the running interface. Other operations are

the same as that of the running interface except

"Back".

Running Details Interface

When the running is finished, an “End of Run”

prompt box will pop up. If a prompt tone for the End

of Run has been set in the system settings, the

instrument will send out the prompt tone to indicate

that the program running has finished. Click "OK" in

the “End of Run”prompt box to return to the main

interface.

5. System settings

In the main interface, click "System" to enter

the system settings interface. The system settings

include language and sound settings. The languages

include Chinese and English; the prompt tones

include button, alarm and end of run. After

modifying the settings, click "OK" to save the

settings, click "Cancel" to give up the modification,

and return to the main interface.

6. Inching

In the main interface, hold “Inching”, and the instrument will oscillate. The oscillation speed is a

single point set speed, and the oscillation mode is forward. Release "Inching" and the instrument will stop

the oscillation.

7. Alarm interface

When the instrument is running, if the sensor breaks down, an alarm box will pop up. The error

System Settings Interface

Operation Manual for Oscillating Dry Bath Chapter IV Operation Guide

—12 —

code 0x1 means short-circuit of the sensor; 0x2 means open-circuit of the sensor. If an alarm prompt tone is

set in the system settings, the instrument will make a sound to indicate it when a fault occurs.

Alarm Interface

8. Firmware upgrade

The oscillating dry bath adopts a U disk for firmware upgrade. First create a firmware directory in the

U disk, and then copy the upgrade program BYQ6614_cpu _****.bin to the directory, and rename

BYQ6614_cpu _****.bin as Firmware.bin. After the above operation, a firmware upgrade U disk for the

oscillating dry bath is made successfully.

Insert the firmware upgrade U disk into the USB interface of the instrument, press and hold the display,

and turn on the power to enter the upgrade mode. After clicking UPGRADE, the upgrade program in the U

disk will be read and the upgrade will start. When Upgrade Finish is displayed, it indicates the upgrade is a

success. Restart the instrument and the upgrade is completed.

When reading the upgrade file, if “Read file error”is displayed, it indicates that the file reading is

unsuccessful, then you can click UPGRADE to reread it. If the error persists, it means that Firmware.bin

does not exist or is damaged.

Operation Manual for Oscillating Dry Bath Chapter V Fault Analysis and Troubleshooting

—13 —

Chapter V Fault Analysis and Troubleshooting

This chapter mainly introduces the possible fault phenomena, causes analysis and troubleshooting of

this instrument.

1

Fault Analysis and Troubleshooting

Serial

No.

Fault Phenomenon

Cause

Solution

Remarks

1

The display window is

not bright after the

power switch is turned

on.

The power is

not connected

Check the power

and turn it on

The fuse is

burned out

Replace the fuse

(250V 1.5A

Ф5x20mm)

The customer can replace

it according to the

specifications.

The switch is

damaged

Replace the switch

Other

Contact the supplier

or manufacturer

2

At the time of oscillating

operation, the instrument

body vibration is very

large accompanied by

abnormal sound.

The wrong

module parts

are applied

Replace the module

parts

Contact the supplier or

manufacturer to confirm

whether the module part of

this model is available for

this instrument.

The surface for

placement is

uneven or

unstable

Replace the

workplace, and

place the instrument

on a horizontal and

stable work surface

The spherical

foot wears

seriously or has

other defects

Replace the foot

Other

Contact the supplier

or manufacturer

3

The module temperature

uniformity is not good

The module is

not installed

correctly

Reinstall the

module

Before installing the

module, first clean the

contact surface with

alcohol; at the time of

installation, note that the

four screws should be

tightened with uniform

force.

Poor cooling

parts

Contact the supplier

or manufacturer

Operation Manual for Oscillating Dry Bath Chapter V Fault Analysis and Troubleshooting

—14 —

4

Crash phenomenon

occurs at the time of

replacing the module

parts

Poor grounding

of the

instrument

Check the power

line to ensure good

grounding; replace

the module when

the power is turned

off.

5

The temperature is

seriously inconsistent

with the actual

temperature

The sensor is

damaged or the

contact is not

good

Contact the supplier

or manufacturer

6

The cooling rate of the

module significantly

becomes slower or the

temperature cannot drop

below the room

temperature

The cooler is

damaged

Contact the supplier

or manufacturer

The fan is

damaged or not

running

7

The module is neither

heated nor cooled

The

temperature

sensor is

damaged

Contact the supplier

or manufacturer

The cooler is

damaged

8

The vibration stops

The driver is

damaged

Contact the supplier

or manufacturer

The motor is

damaged

The fuse is

burned out

Replace the fuse

(250V 1.5A Ф5 ×

20mm)

The customer can replace

it according to the

specifications.

2

Display Fault Alarm Message Prompt Comparison Table

Alarm Message Prompt

Cause of Fault

0x1

Short-circuit of the sensor

0x2

Open-circuit of the sensor

Caution:

The user is not allowed to open the housing of the instrument for inspection by

himself during the warranty period. If any failures that require opening of the housing

for inspection occur, the supplier or manufacturer should be contacted timely.

Table of contents

Other Bioer Laboratory Equipment manuals

Popular Laboratory Equipment manuals by other brands

CBM

CBM SST 1700B instruction manual

Endress+Hauser

Endress+Hauser Analytik Jena TOPwave operating manual

Raven

Raven Sidekick Pro Installation and operation manual

Zeiss

Zeiss HBO 50 operating manual

M&C

M&C SP Series instruction manual

Weinmann

Weinmann ACCUVAC WM 15261 Description of the equipment and instructions for use