1Parker Hannifin Corporation

Tube Fittings Division

Columbus, OH

Bulletin 4391-B26 Hydraulic Tube Bender

FluidConnectors

Introduction

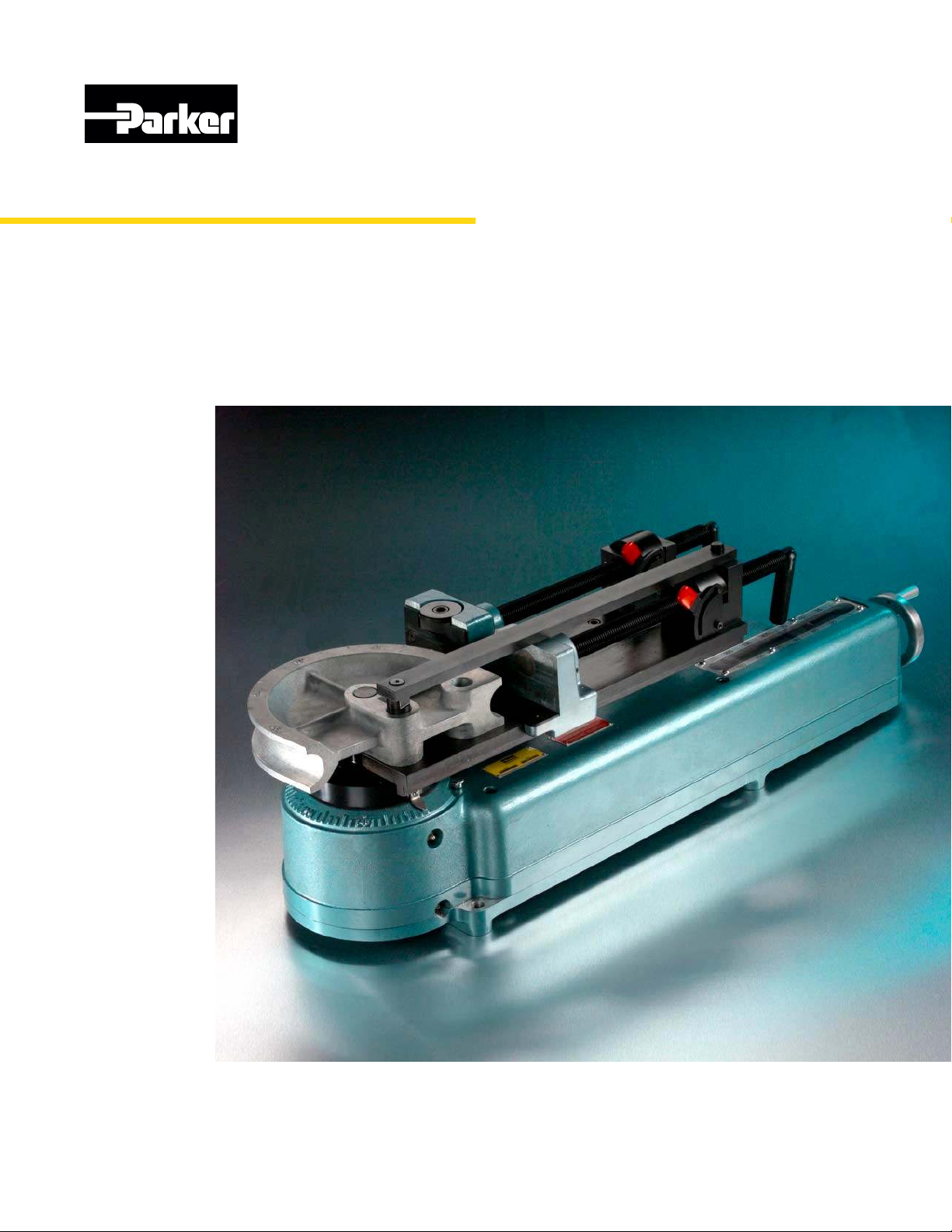

Parker Hydraulic Tube Bender

Model HB632

For 3/8" - 2" (10-50mm) tubing and 3/8 to

1 1/2 IPS

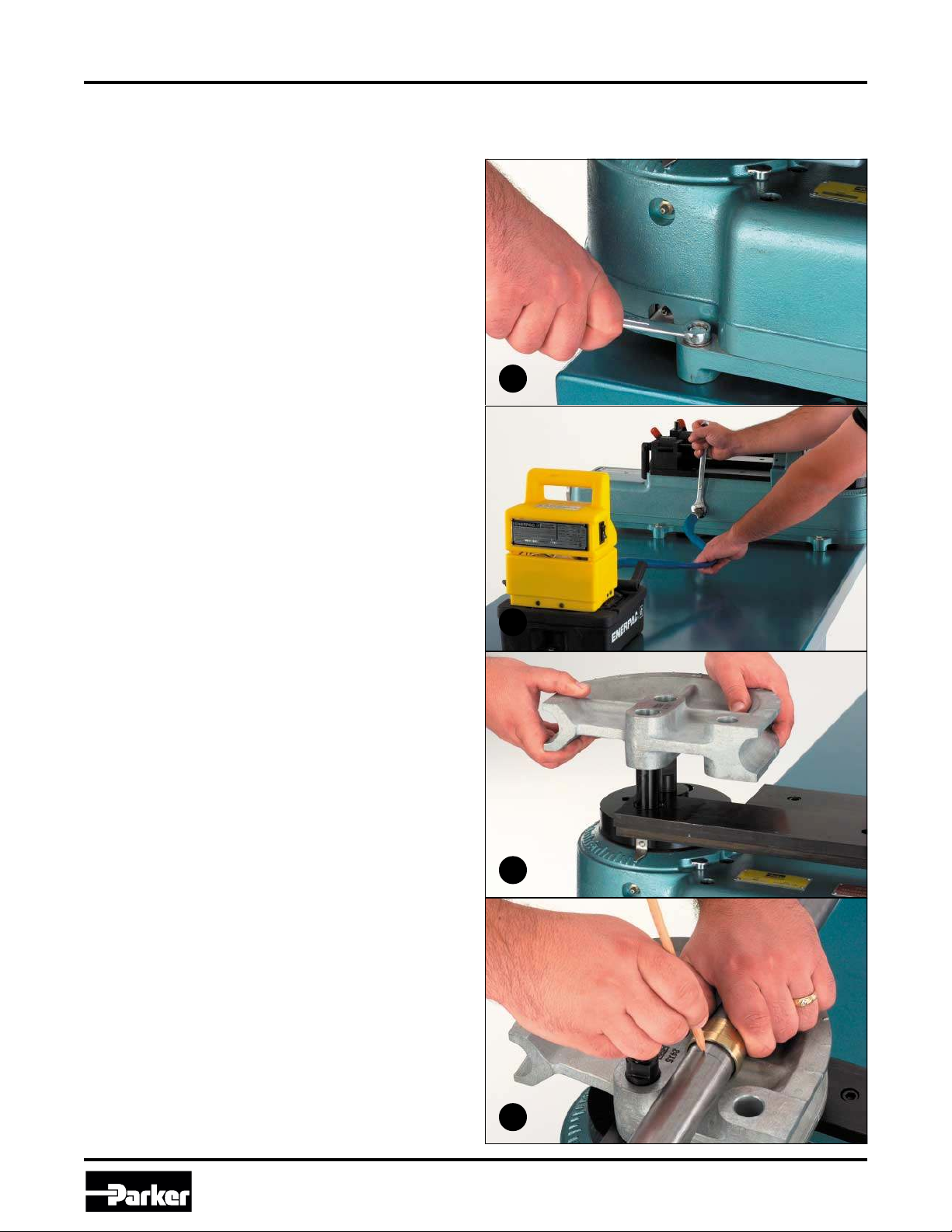

The Parker Model HB632 Tube Bender is a hydrauli-

cally operated bender for bending annealed steel and

stainless steel tubing from 3/8" O.D. through 2" O.D.

It is operated by means of a separate power source

producing 10,000 psi hydraulic pressure. It can be

operated without bolting to a table or bench if no man-

drels are required, making it an excellent unit to move

about and use at the point where the tubing installation

is being made. It can also be attached to a table and

used with mandrels. Part No.: 631050

Bender Construction

The bender consists of a cast aluminum housing, with a

hydraulically actuated drive mechanism which enables an

operator to make bends up to 180° in one continuous smooth

operation on tubing up to 2" in diameter.

Capacity

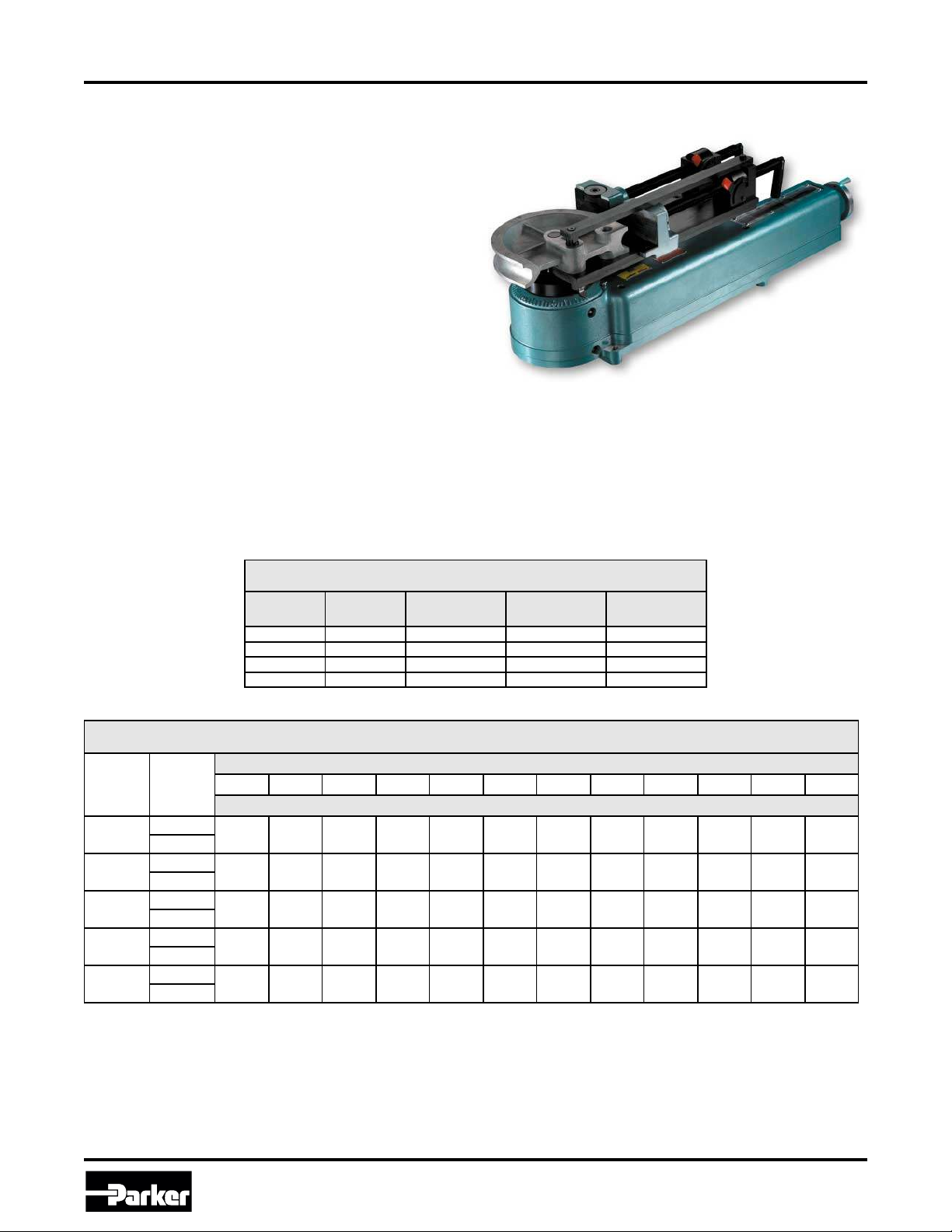

Table 1 below assigns a Model Code for each model of

Parker tube benders. Table 2 gives the capacity for all

Parker benders. The Model HB632 is represented by

model code C so you can easily check for its capabilities.

Table 1 –Tube Bender Model Codes

Table 2 –Tube Benders Maximum Capacity Guide

* See page 3 for pipe bending capabilities

Specifications:

1) Min. tube size 3/8"

2) Max. tube size 2"

3) Min. bend radius 1 1/8"

4) Max. bend radius 12" (special order)

5) Max. tube bend 180°

6) Weight —170 lbs. (77.1 kg) without accessories

7) Minimum tube wall thickness (% of O.D.) 4% with mandrel, 7% without mandrel

8) The HB632 is capable of bending 1/2" O.D. and under fully annealed steel and

stainless steel tubing with no limit on tube wall thickness

9) The HB632 is capable of bending SOFT aluminum and copper tubing with no

limit on wall thickness.

10) For HARD copper, ALLOY STEEL, and HIGH STRENGTH aluminum, use the

tabulations shown for stainless steel.

Model

Code

Model

No.

Tubing O.D.

Capacity Bender Type

Rated Torque

(in./lbs.)

A 412 1/4" –3/4" Worm & Gear 2,700

B 424 1/4" –1-1/4" Worm & Gear 11,000

C HB632 1/4" –2" Hydraulic 52,000

D CP432 3/8" –2" Hydraulic N/A

Tube Bender Model Codes

0.035 0.049 0.058 0.065 0.072 0.083 0.095 0.109 0.120 0.134 0.156 0.188

S ABCD ABCD ABCD ABCD BCD BCD BCD BCD BCD BCD BCD BCD

SS BCD BCD BCD BCD BCD BCD BCD BCD BCD BCD BCD BCD

S BCD BCD BCD BCD BCD BCD BCD BCD BCD BCD BCD BCD

SS BCD BCD BCD BCD BCD BCD BCD BCD BCD BCD CD CD

S BCD BCD BCD BCD BCD BCD CD CD CD CD CD CD

SS BCD BCD BCD BCD BCD CD CD CD CD CD C C

S BCD BCD BCD BCD BCD CD CD CD CD CD CD CD

SS BCD BCD CD CD CD CD CD CD CD CD C C

S CDCDCDCDCDCDCDCDCDCDCDCD

SS CD CD CD CD CD CD CD CD CD CD ——

2"

Material

3/4"

1"

1-1/4"

1-1/2"

Tube Benders Maximum Capacity Guide*

Tube

O.D.

Tube Wall Thickness (inches)

Tube Bender Model Codes