GROUNDING

PIN (A) (B)

(C)

(D)

ADAPTER

GROUNDING

MEANS

METAL SCREW

COVER OF GROUND

OUTLET BOX GROUNDING

PIN

WARNING !

When using electric tools, basic safety precautions should always be followed to reduce the risk of fire, electrical

shock and personal injury, including the following.

Read all these instructions before operating this product and save these instructions.

A. GROUNDING INSTRUCTIONS

1. In the event of a malfunction or breakdown, grounding provides a path of least resistance for electric current

to reduce the risk of electric shock. This tool is equipped with an electric cord with a grounding conductor

and a grounding plug. The plug must be plugged into a matching outlet that is properly installed and

grounded in accordance with all local codes and ordinances.

2. Do not modify the plug provided - if it will not fit the outlet, have the proper outlet installed by a qualified

electrician.

3. Improper connection of the grounding conductor can result in electric shock. The conductor with insulation

having an outer surface that is green with or without yellow stripes is the grounding conductor. If repair or

replacement of the electric cord or plug is necessary, do not connect the grounding conductor to a live

terminal.

4. Check with a qualified electrician or service person if the grounding instructions are not completely

understood, or if in doubt as to whether the tool is properly grounded.

5. Use only 3-wire extension cords that have 3-prong grounding plugs and 3-pole receptacles that accept the

tool's plug.

6. Repair or replace damaged or worn cord immediately.

7. This tool is intended for use on a circuit that has an outlet that looks like the one illustrated in Sketch A in

Figure(below)(115V). The tool has a grounding plug that looks like the plug illustrated in Sketch A in Figure

(below). A temporary adapter, which looks like the adapter illustrated in Sketches B and C, may be used to

connect this plug to a 2-pole receptacle as shown in Sketch B if a properly grounded outlet is not available.

The temporary adapter should be used only until a properly grounded outlet can be installed by a qualified

electrician. The green-colored rigid ear, lug, and the like, extending from the adapter must be connected to a

permanent ground such as a properly grounded outlet box.

Grounding Method

Minimum gage for cord

Ampere Rating

Volts Total length of cord

120V

240V

More

Than

Not

More

Than

Only the applicable parts of the Table need to be included. For instance,

a 120-volt product need include the 240-volt heading.

IMPORTANT INSTRUCTIONS AND WARNING - Electric Devices

8. USE PROPER EXTENSION CORD. Make sure your extension cord is in good condition. When using an

extension cord, be sure to use one heavy enough to carry the current your product will draw.

An undersized cord will cause a drop the line voltage resulting in loss of power and overheating.

Table(below)shows the correct size to use depending on cord length and nameplate ampere rating.

If in doubt, use the next heavier gage. The smaller the gage number, the heavier the cord.

0

6

10

12

6

10

12

16

18

18

16

14

16

16

16

12

16

14

14

14

12

12

Not Recommended

P.1

7.5m(25ft.)15m(50ft.)30m(100 ft.)45m(150 ft.)

15m(50ft.)30m(100ft.)60m(200 ft.)90m(300 ft.)

B. OTHER WARNING INSTRUCTIONS

1. For your own safety read instruction manual before operating tool.

2. Wear eye protection.

3. Replace cracked wheel immediately.

4. Always use guards and eye shields.

5. Do not overtighten wheel nut.

6. Use only flanges furnished with the grinder.

7. REMOVE ADJUSTING KEYS AND WRENCHES. Get in the habit of checking to see that keys and adjusting

wrenches are removed from tool before turning it on.

8. KEEP WORK AREA CLEAN. Cluttered areas and benches invite accidents.

9. DON'T USE IN DANGEROUS ENVIRONMENT. Don't use power tools in damp or wet locations, or expose

them to rain. Keep work area well lighted.

10. Risk of injury due accidental starting. Do not use in an area where children may be present.

11. DON'T FORCE TOOL. It will do the job better and safer at the rate for which it was designed.

12. USE RIGHT TOOL. Don't force tool or attachment to do a job for which it was not designed.

13. WEAR PROPER APPAREL. Do not wear loose clothing, gloves, neckties, rings, bracelets, or other jewelry

that might get caught in moving parts. Nonslip footwear is recommended. Wear protective hair covering to

contain long hair.

14. ALWAYS USE SAFETY GLASSES. Everyday eyeglasses only have impact resistant lenses, they are NOT

safety glasses. Also use face or dust mask if cutting operation is dusty.

15. SECURE WORK. Use clamps or a vise to hold work when practical. It's safer than using your hand and it

frees both hands to operate tool.

16. MAINTAIN TOOLS WITH CARE. Keep tools sharp and clean for best performance and to reduce the risk of

injury to persons. Follow instructions for lubricating and changing accessories.

17. DISCONNECT TOOLS before servicing; when changing accessories, such as blades, bits, cutters, and like.

18. REDUCE THE RISK OR UNINTENTIONAL STARTING. Make sure switch is in off position before plugging in.

19. USE RECOMMENDED ACCESSORIES. Consult the owner's manual for recommended accessories. The use

of improper accessories may cause risk of injury to persons.

20. NEVER LEAVE TOOL RUNNING UNATTENDED. TURN POWER OFF. Don't leave tool until it comes to a

complete stop.

21. For recommended operating speed for various applications, please follow the instructions of bur

manufacturers.

22. Use Accessories suitable for Max. 40,000min-1

(ASTRO-E 400)and Max. 50,000min-1

(ASTRO-E 500).

C. Important Instructions and Warnings about ASTRO-E 400 / 500 SYSTEM

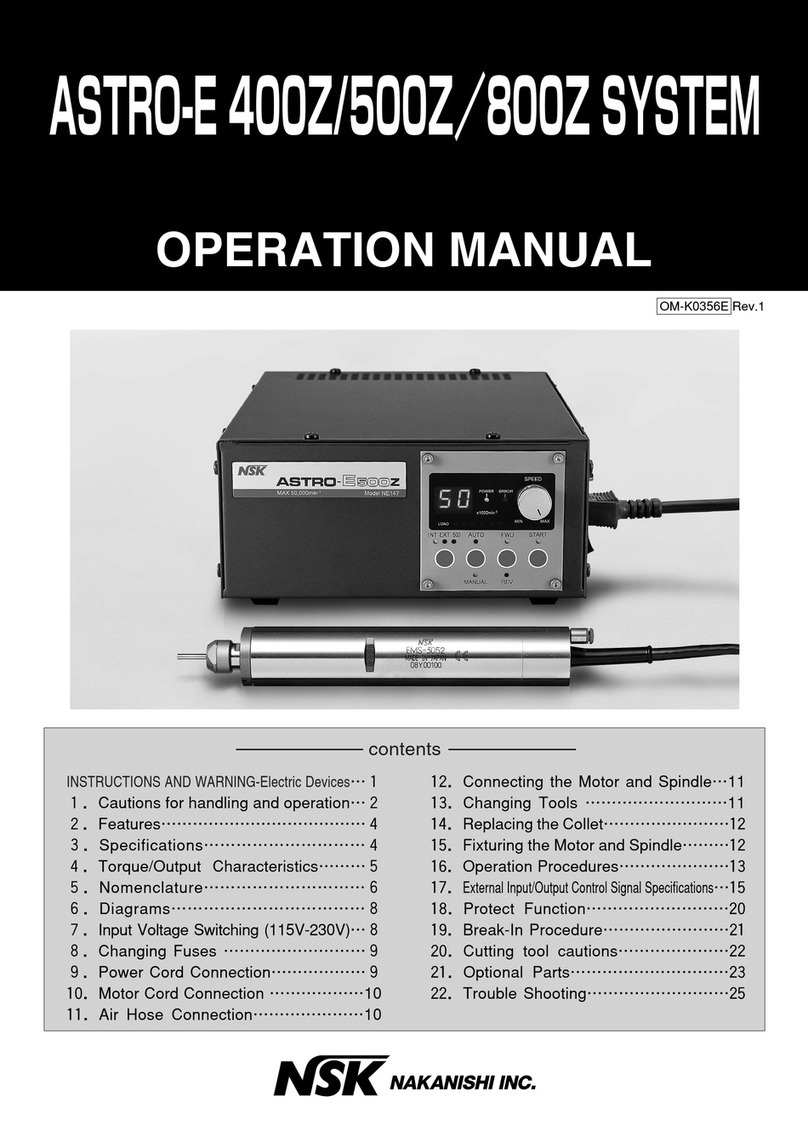

1. LOCATING CONTROL UNIT NE52

The control unit NE52, NE52-500 is equipped with vents and a cooling fan to prevent overheating of its

electronic circuitry. When choosing a mounting position, make sure that these vents at the rear of panel are

kept open and free of obstruction so that air may flow freely. Failure to do so will result in overheating and

failure of system.

2. RESET SWITCH

Continuous "KICK OFF" of reset switch is an indication that the ASTRO-E 400 / 500 system is being used

beyond its envelope of operation. Continuous use under such circumstances will only produce poor

product finish and system failure.

3. SPEED AND TORQUE

・If speed requirements are under 2,000 min-1, it is recommended that reduction gears ARG-01E or ARG-

02E be used to assure proper torque at low end speeds.

・

Do not exceed 1.5 cN・m(in.-oz.)load for prolonged periods of time as this will overheat the EM-401

,

EM-405

,

EM-

401A,EM-501,EM-505,EM-501A motor.

4. TOOLING

・When making a choice of tooling to be used with the ASTRO-E 400 / 500 system, make sure that such

tooling are rated to maximum speeds above 40,000 min-1 / 50,000 min-1.

・When using mounted stones, make sure that stones are properly dressed to assure good product finish.

An undressed stone will cause bearing stress, vibration and poor finish.

・Never use tooling that is bent chipped, or unrated as this will only result in a hazardous condition to

operator and create a malfunction of the ASTRO-E 400 / 500 system.

・Never extend tooling more than 13mm from base of collet cap as this will cause vibration on the tooling

and good finish of product will not be achieved.

P.2

ASTRO-E400/K0054E.3/e/02.0706.12.2211:24ページ3