NSK Ultimate XL User manual

OPERATION MANUAL

Micromotor for Laboratory Work

English

1

Thank you very much for purchasing ULTIMATE XL.

Please read this Operation Manual carefully regarding the instructions for use, handling method,

and maintenance and inspection prior to use and store it in a place where users can review it

anytime.

IMPORTANT INSTRUCTIONS AND WARNING

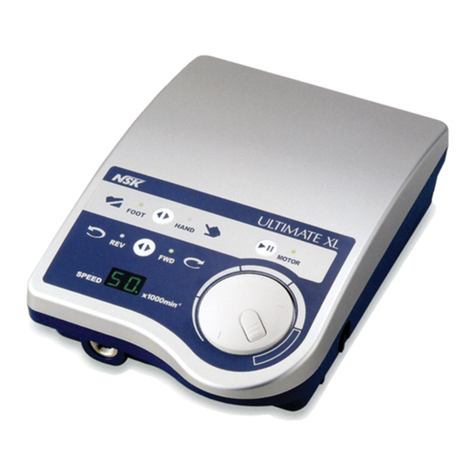

1. Component Names

2. Set up of Control Unit

3. Operation Procedure

4. Speed limit mechanism

5. Protective Circuit for Motor

6. Memory Function

7. Error Code

8. Replacement of Fuse

9. Maintenance Mode

10. Vacuum-coupled Mode

11. Handling of Motor and Handpiece

12. Handpiece Stand

13. Handpiece Holder

14. Specification

15. Troubleshooting

1

5

6

7

8

8

8

9

10

10

11

12

14

14

14

15

·············································

·························································································

·····················································································

······················································································

···················································································

·············································································

····························································································

······································································································

······················································································

·························································································

··················································································

··································································

····························································································

···························································································

···································································································

······························································································

Contents

WARNING!

When using electric tools, basic safety precautions should always be followed to reduce

the risk of fire, electrical shock and personal injury, including the following. Read all these

instructions before operating this product and save these instructions.

IMPORTANT INSTRUCTIONS AND WARNING -Electric Devices

English

2 3

A. GROUNDING INSTRUCTIONS

1. In the event of a malfunction or breakdown, grounding provides a path of least resistance for

electric current to reduce the risk of electric shock. This tool is equipped with an electric cord

having an equipment-grounding conductor and a grounding plug. The plug must be plugged

into a matching outlet that is properly installed and grounded in accordance with all local

codes and ordinances.

2. Do not modify the plug provided - if it will not fit the outlet, have the proper outlet installed by

a qualified electrician.

3. Improper connection of the equipment-grounding conductor can result in a risk of electric

shock. The conductor with insulation having an outer surface that is green with or without

yellow stripes is the equipment-grounding conductor. If repair or replacement of the electric

cord or plug is necessary, do not connect the equipment grounding conductor to a live

terminal.

4. Check with a qualified electrician or service personnel if the grounding instructions are not

completely understood, or if in doubt as to whether the tool is properly grounded.

5. Use only 3-wire extension cords that have 3-prong grounding plugs and 3-pole receptacles

that accept the tool's plug.

6. Repair or replace damaged or worn cord immediately.

7. This tool is intended for use on a circuit that has an outlet that looks like the one illustrated in

Sketch A in Figure (below) (120V). The tool has a grounding plug that looks like the plug

illustrated in Sketch A in Figure (below). A temporary adapter, which looks like the adapter

illustrated in Sketches B and C, may be used to connect this plug to a 2-pole receptacle as

shown in Sketch B if a properly grounded outlet is not available. The temporary adapter

should be used only until a properly grounded outlet can be installed by a qualified

electrician. The green-colored rigid ear, lug, and the like, extending from the adapter must be

connected to a permanent ground such as a properly grounded outlet box.

8. USE PROPER EXTENSION CORD. Make sure your extension cord is in good condition.

When using an extension cord, be sure to use one heavy enough to carry the current your

product will draw. An undersized cord will cause a drop in line voltage resulting in loss of

power and overheating. Table (below) shows the correct size to use depending on cord

length and nameplate ampere rating. If in doubt, use the next heavier gauge. The smaller the

gauge number, the heavier the cord.

9. Install equipment so that the power supply cord can be pulled out without hindrance in event

of emergency.

1. For your own safety read instruction manual before operating tool.

2. Wear eye protection.

3. Replace cracked wheel immediately.

4. Always use guards and eye shields.

5. Do not over tighten wheel nut.

6. Use only flanges furnished with the grinder.

7. REMOVE ADJUSTING KEYS AND WRENCHES. From habit of checking to see that keys and

adjusting wrenches are removed from tool before turning it on.

8. KEEP WORK AREA CLEAN. Cluttered areas and benches invite accidents.

9. DON'T USE IN DANGEROUS ENVIRONMENT. Don't use power tools in damp or wet

locations, or expose them to rain. Keep work area well lighted.

10. Risk of injury due accidental starting. Do not use in an area where children may be present.

11. DON'T FORCE TOOL. It will do the job better and safer at the rate for which it was designed.

12. USE RIGHT TOOL. Don't force tool or attachment to do a job for which it was not designed.

13. WEAR PROPER APPAREL. Do not wear loose clothing, gloves, neckties, rings, bracelets, or

other jewelry that might get caught in moving parts. Nonslip footwear is recommended. Wear

protective hair covering to contain long hair.

14. ALWAYS USE SAFETY GLASSES. Everyday eyeglasses only have impact resistant lenses,

they are NOT safety glasses. Also use face or dust mask if cutting operation is dusty.

15. SECURE WORK. Use clamps or a vise to hold work when practical. It's safer than using your

hand and it frees both hands to operate tool.

16. MAINTAIN TOOLS WITH CARE. Keep tools sharp and clean for best performance and to

reduce the risk of injury to persons. Follow instructions for lubricating and changing

accessories.

B. OTHER WARNING INSTRUCTIONS

Grounding Method

Minimum gauge for cord

Volts

120V

240V

Code Number

Total Length of cord

7.5m (25ft.) 15m (50ft.) 30m (100ft.) 45m (150ft.)

15m (50ft.) 30m (100ft.) 60m (200ft.) 90m (300ft.)Ampere Rating

More Than

0

6

10

12

Not More Than

6

10

12

16

#18

#18

#16

#14

#16

#16

#16

#12

#16

#14

#14

Not Recommended

#14

#12

#12

GROUNDING

PIN

METAL SCREW

GROUNDING MEANS

GROUNDING PIN

ADAPTER

COVER OF GRIUNDING

OUTLET BOX

English

4 5

C. Important Instructions and Warning on ULTIMATE XL.

17. DISCONNECT TOOLS before servicing; when changing accessories, such as blades, bits,

cutters, and like.

18. REDUCE THE RISK OF UNINTENTIONAL STARTING. Make sure switch is in off position

before plugging in.

19. USE RECOMMENDED ACCESSORIES. Consult the owner's manual for recommended

accessories. The use of improper accessories may cause risk of injury to persons.

20. NEVER LEAVE TOOL RUNNING UNATTENDED. TURN POWER OFF. Don't leave tool until it

comes to a complete stop.

21. For recommended operating speed for various applications, please follow the instructions of

bur manufacturers.

22. The system functions normally in the environment where the temperature is at 0-40°C,

humidity at 10-85% RH, atmospheric pressure at 500-1060hPa, and no moisture

condensation in the Unit. Use at outside of these limits may cause malfunction.

23. Store the system in the place where the temperature is at -10-60°C, humidity at 10-85% RH,

atmospheric pressure at 500-1060hPa, and the system is not subject to air with dust, sulfur,

or salinity.

24. Severe shock – Eg. Dropping Control Unit, or the Micromoto – may cause damage.

25. Do not turn the bur lock ring while the handpiece is rotating.

26. Do not rotate the motor when the bur lock ring is at OPEN position, or a bur is not mounted

in the chuck. It may cause the motor/handpiece disconnection or sudden heat generation.

27. Activation of Circuit Breaker means too much load is applied to the motor beyond the

capacity the motor takes. This circuit breaker is designed to protect the motor, but it is

desired to perform the grinding work without activating the circuit breaker.

28. Care should be taken not to drop micromotor handpiece on floor or hard work surface in

order to avoid damage caused by impact shock.

No lubrication is required to either motor or handpiece because ball bearings impregnated with

grease in both motor and handpiece.

Control Unit

Motor Handpiece

Foot Pedal (FC-64)

Power Switch

Motor Connector

Handpiece Stand

Forward/Reverse Selector Switch

Hand/Foot Selector Switch

Motor Switch

Motor LED

Indicator

Speed Control Knob

Speed Limit Release Button

Foot Pedal Connector

Fuse Box

Power supply cord

1. Component Names

1

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

4

10

8 9

7

11

12

13

3

2

6

14 15

16

5

English

6 7

1. Mounting of Motor

Insert the motor cord plug locator into Motor

Connector aligning it with the groove of the

connector, and tighten the motor cord plug nut

to fix. (Fig. 1)

2. Set up of Control Unit

Fig.1

2. Mounting of Foot Pedal

Insert the Foot Pedal cord plug locator into

Foot Pedal Connector aligning it with the

groove of the connector. (Fig. 2)

Fig.2

3. Connecting of Power Cord

Securely insert the plug of Power Cord into

connector at the back of the unit aligning it with

the configuration. (Fig. 3)

Fig.3

1. Connect Power Cord to a wall outlet.

2. Make sure that Speed Control Knob is at the lowest speed position.

3. Turn Power Switch ON (Green Power Lamp will light). The preset rotation speed will

appear on the Indicator.

4. Select the rotation direction with Forward/Reverse Selector Switch. Each time this switch

is pressed, the direction changes between FORWARD and REVERSE.

5. Select the control method with Hand/Foot Selector Switch. Each time this switch is

pressed, the method changes between the HAND and FOOT.

Operation - 1

HAND Operation

6. Select HAND with Hand/Foot Selector Switch.

7. Preset the rotation speed with Speed Control Knob with checking the speed on the

Speed Display.

8. Press Motor Switch, and the motor will run.

9. To stop the motor, press Motor Switch again.

Operation - 2

Operation by Foot Pedal

6. Select FOOT with Hand/Foot Selector Switch.

7. Preset the maximum rotation speed with Speed Control Knob with checking the speed

on the Speed Display.

8. Depress Foot Pedal, and the motor will run. The rotation speed can be variably

controlled within the preset maximum rotation speed range according to the amount of

depressing Foot Pedal.

Auto speed mechanism

To Fix the speed within the rotation speed range set by the volume, press Motor Switch

while the motor is running at the desired speed. The display lamp will flash and the rotation

speed can be maintained even if Foot Pedal is released. To cancel it, press Motor

Switch again or depress Foot Pedal again.

3. Operation Procedure

5

14

4

7

8

8

8

3

3

9

9

3

3

9

9

12

12

12

16

16

English

When the Power Switch is turned on, the rotation direction and HAND/FOOT selections made

when the main switch was last turned off are restored. Special attention should be given to the

rotation direction.

For the use of a small-diameter round bur or

fisher bur at 40,000min-1(rpm) or more, pressing

the Speed Limit Release Button, which is

equipped with the Speed Control Knob, and

turning the Speed Control Knob allows a

setting of up to 50,000min-1(rpm). (Fig.4)

When the motor is stopped due to some trouble such as a failure, overload, wire breakage or

misuse, Speed Display displays the error code for checking the status of the unit and

understanding the cause of the trouble easily.

How to reset the protective circuit

During manual operation, it can be reset by pressing Motor Switch again. During operation

by Foot Pedal, depress Foot Pedal back to stop, and the protective circuit will be reset.

8 9

12

12

13

9

3

Fig.4

Speed Limit Release Button

Speed Limit Release Button

Speed Limit Release Button

Fig.5

Indicator

Indicator

Indicator

4. Speed limit mechanism

When the motor is operated with a load

exceeding the limit or the handpiece is in an

unrotational condition, the circuit to protect the

motor and unit works to stop the power supply

to the motor, an error code appears on

Indicator. (Fig.5)

5. Protective Circuit for Motor

6. Memory Function

CAUTION

Use of 40,000min-1(rpm) or more is allowable only when the bur manufacturer or dealer

specifies that the bur's acceptable rotation speed is 40,000 min-1(rpm) or more. If the

use of more than the acceptable rotation speed is made, the bur may be broken.

For countermeasures against error displays, see the section on 15.Troubleshooting.

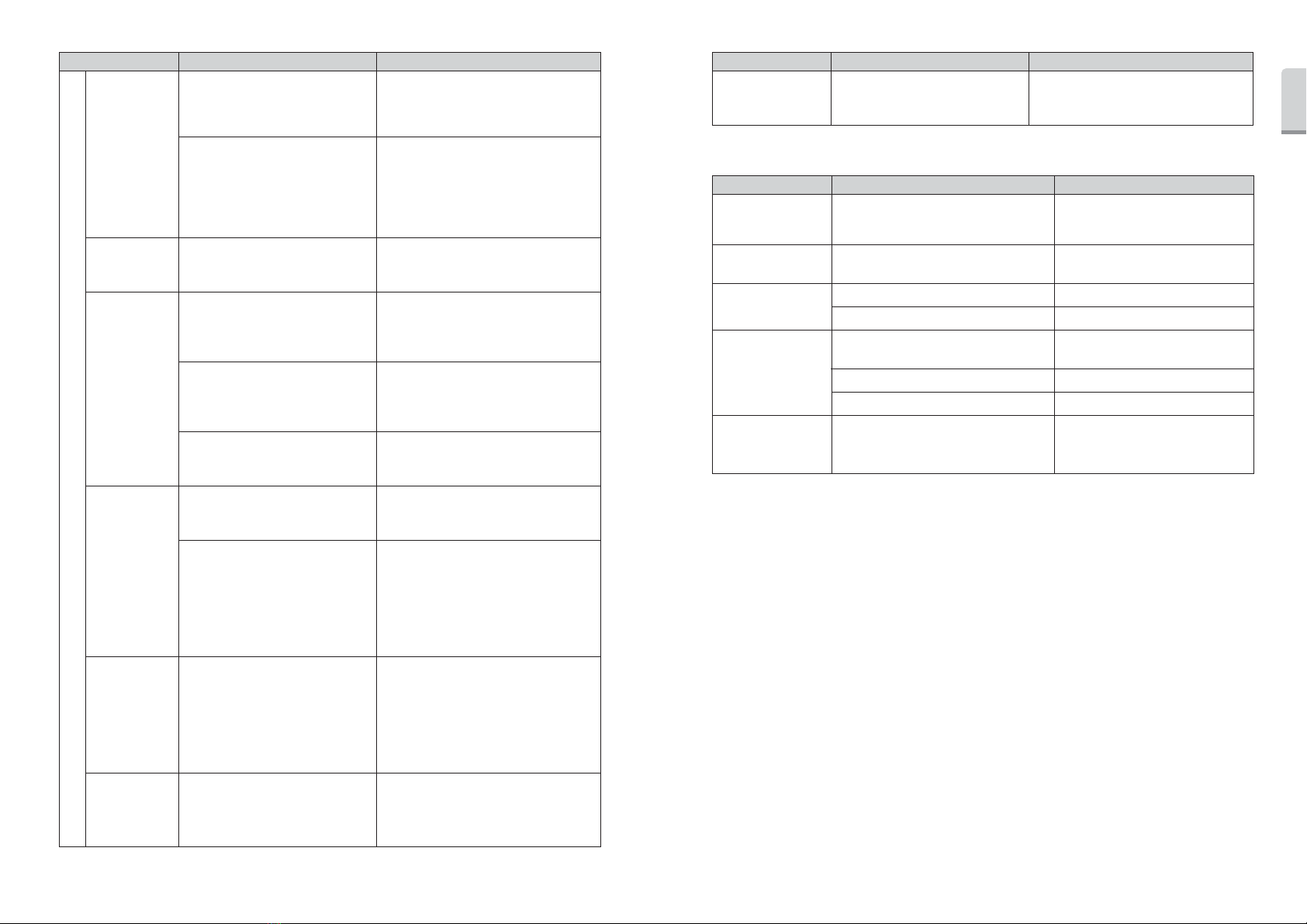

Error cord

E0

E1

E2

E3

E4

E5

E6

E8

E9

EF

Description

Self-check error

Overcurrent detection error

(Hard)

Overvoltage detection error

Motor sensor error

Unit overheat error

PAM circuit error

Rotor lock error

Overvoltage detection error

(Soft)

ITRIP error

Foot pedal error

7. Error Code

Cause

• Abnormal internal memory

• Broken internal memory

• Long-time use at a high load (overcorrect)

• Shorted cord (power line)

• Shorted motor winding

• Shorted cord (power line),damaged circuit

• Broken internal circuit

• Faulty sensor (Hall IC) in the motor

• Disconnected motor cord

• Severed cord (signal line)

• Temperature rise in the unit due to longtime

use at a high load

• Unit placed under high temperature

• Abnormal voltage generated in start / stop

circuit

• Faulty start / stop circuit from PAM(L Slide)

• Open chuck

• Faulty handpiece

• Motor Faulty

• Faulty sensor (Hall IC) in the motor

• Severed cord (signal, power line)

• Long-time use at a high load (overcorrect)

• Shorted cord (power line)

• Shortstop of the motor winding

Faulty motor and circuit

• Faulty Foot Pedal or Shorted Foot Pedal cord

• Broken internal circuit

11

English

(4) "Pd": Foot Pedal check

Press Forward/Reverse Selector Switch, and Indicator will change. During normal time,

Indicator changes in hexadecimals ( 0~9, A~F ) according to the amount of depressing

Foot Pedal . Also, depressing the pedal slightly lights Reset Lamp, and depressing it fully

extinguishes the lamp. If Indicator does not change smoothly or Reset Lamp does not

light properly, Foot Pedal may be faulty. To cancel this check, press Forward/Reverse

Selector Switch again.

(5) "in": Initializing function

Press Forward/Reverse Selector Switch, and beeps will be made and rotation direction,

HAND/FOOT and other settings will return to the factory set condition.

Rotation direction: FWD (forward)

HAND/FOOT: HAND

Vacuum-coupled mode: OFF

(3)

"HL": Motor signal check (Hall IC check)

Press Forward/Reverse Selector Switch, and Indicator will indicate one or two

horizontal lines. Turn the motor slowly by hand, and this display will change to one line, two

lines, one line, two lines, smoothly from the top to bottom or from the bottom to top. If any

one of the three lines does not light, the sensor (Hall IC) in the motor is faulty or the cord is

severed, therefore repair is needed. To cancel this check, press Forward/Reverse Selector

Switch again.

Eg.

Fuse is located in Fuse Box. Release ratchet

clamp located on the right-and-left top and

bottom of the Fuse Box and pull it out to

change the fuse (T3.15AL250V). (Fig. 6)

When the fuse come down, Insert new fuses

(T3.15AL250V)into the Fuse Box and then

push the Fuse Box into the original position

until hearing a sound click.(Fig.6)

- Fuse: Order No. (120V) : 12001-31510

- Fuse: Order No. (230V) : 12001-16010

The unit is provided with a maintenance mode to check the function of the switches, display,

Foot Pedal, motor, etc. While pressing Hand/Foot Selector Switch and Motor Switch at

the same time, turn on the Power Switch and keep pressing the button until beeps are made

(for about 2 seconds). At this time, turning the volume from the minimum position in order

displays "oP", "dP", "HL", "Pd" and "in", allowing the following checks. To release Maintenance

Mode, turn Power Switch off and switch on again.

(1) "oP": Switch check (operation check)

Press the switches on the panel, and the right and/or left lamps will light to check to see if

the switches operate normally.

(2) "dP": Display check

Press Forward/Reverse Selector Switch, and the lamps will light one by one to check to

see if they operate normally. To cancel this check, press Forward/Reverse Selector Switch

again.

10 11

11

11

11

15

15

15

15

9

8

7

7

Fig.6

8. Replacement of Fuse

9. Maintenance Mode

CAUTION

Fuse is burned out when a short circuit occurs or when over-voltage is flowed into the

primary current source. If the cause is uncertain, return the product to an authorized

NSK's service shop for inspection.

7

7

7

7

7

3

3

2 3 4 A b C d C b A 4 3 2

4

7

On some dental tables with vacuum dust collector, the motor may be used while being coupled

with a dust collector. When such a dust collector * is used, power consumption of ULTIMATE

XL can be regulated so that the vacuum-coupled function can work. If you need coupling with

a vacuum dust collector, select the mode as follows:

How to select the mode

While pressing Forward/Reverse Selector Switch, turn on Power Switch, and the mode

can be selected. A long beep indicates vacuum-coupled mode and 2 short beeps indicate

non-coupled (energy-saving) mode.

* Each time the switch selection is made, the mode changes between vacuum-coupled mode

and non-coupled mode.

* A currently known dust collector is KAVO EWL-560.

10. Vacuum-coupled Mode

English

12 13

Fig.8

(1) Insertion or Removal of Bur

The chuck is opened by turning the Bur Lock Ring

to an open position. The chuck is loosened and the

bur can be removed. By turning the ring in the

LOCK direction, the chuck is closed and the bur

can be mounted. At this time, turn the ring until it

clicks. (Fig.7)

(2)

Cleaning and Replacement of Chuck

(1) Removal of Chuck

To remove the chuck, open the ring and turn

the chuck counterclockwise with the provided

spanner wrench. (Fig.8)

11. Handling of Motor and Handpiece

Fig.7

CAUTION

• Do not turn the Ring during rotation.

• Do not turn a motor, when it has not attached bur or the Ring Open position. It may be

reasons for the failure or overheating of the handpiece.

CAUTION

Neglecting to clean the chuck for a long time is very dangerous because wax, gypsum,

etc., accumulate in the chuck and the bur is caught insecurely, causing runout.

OPEN

LOCK

Loosen

Loosen

Loosen

Fig.9

* If a bur having a large diameter of a cutting

part is used under a high torque, the chuck

may rotate in the close direction and the bur

may be stuck and cannot be removed. In

this case, align the nose's slit and spindle's

spanner position (flat part), and apply an L

spanner to fix the spindle. Open the ring and

turn the chuck counterclockwise with the

provided spanner wrench to remove it.

(Fig. 9)

(2) Cleaning of Chuck

Remove and clean the chuck as frequently as possible in the ultrasonic cleaner. Clean at

least once a week.

Loosen

Loosen

Loosen

(3) Insertion of Chuck

Thinly apply oil before insertion. Open the ring,

insert the dummy bur or the bur in use into

the chuck, and turn the chuck clockwise by

hand until it stops. Then, lock the ring, and

the chuck could hold the bur securely.

(Fig. 10)

Fig.10

CAUTION

Before using the handpiece, make sure to pull the rotating instrument (bur, etc.) to check

that it is securely mounted.

Turn until finger-tight

Turn until finger-tight

Turn until finger-tight

Fig.11

Fig.12

3. Disconnecting and Connecting of Motor Cord to Motor

Remove the cord nut at the rear end of the motor, and the motor cord connector can be

pulled out. For connection, align the connector pin and the hole in the motor cord connector,

and insert the connector straight until it stops. Then, tighten the cord nut.

* When inserting the connector, do not turn or twist it.

4.

Disconnecting Handpiece from Motor

The handpiece and motor are screwed at the

midpoint. Firmly grasp the motor outer case

and the handpiece outer case and turn it

counterclockwise to disconnect. (Fig. 12)

Fig.13

Torque Type/Compact Type

CAUTION for Handpiece connection

When connecting the handpiece to the motor, turn

the handpiece clockwise and tighten firmly. If the

clutch is not engaged properly, the handpiece cannot

be tightened completely. In such case, Do Not Force.

Loosen the handpiece and turn the bur briefly to

re-position the drive dog. Reconnect the handpiece and tighten securely. (Fig. 13).

English

14 15

Please check the following points before sending back instruments for repair.

<Unit / Motor>

15. Troubleshooting

Fig.15

Handpiece Holder

At the bottom of the handpiece stand, tools

necessary for handpiece maintenance and a

spare chuck (optional) can be mounted.

(Fig. 14)

12. Handpiece Stand

The handpiece holder that can be mounted on

the right side of the control unit will widen a your

effective work area. Insert the holder into the slot

and fasten the screw. Adjust the holder angle to

your best position. (Fig. 15)

13. Handpiece Holder

Control Unit

Model

Power supply

Weight

Dimensions

NE213-G (Gray)

NE213-W (White)

AC120V 50/60 Hz 46VA

AC230V 50/60 Hz 46VA

2.8kg

W167 x D247 x H77mm

14. Specification

Fig.14

Motor Handpiece

1 ) Torque Type

Model

Speed

Max. Torque

Weight

Dimensions

Code Length

UMXL-TP / UMXL-TP 2M

1,000~50,000 min-1

8.7N · cm

215g ( exclude the code)

L151 x ø 29mm

1.2m / 2.0m

2 ) Compact Type

Model

Speed

Max. Torque

Weight

Dimensions

Code Length

UMXL-C/ UMXL-C 2M

1,000~50,000 min-1

6 N · cm

181g ( exclude the code)

L144 x ø 27mm

1.2m / 2.0m

Food Pedal

Model

Weight

FC-64

460g

Handpiece

Model

Weight

Handpiece Stand

120g

Trouble Cause / Check Remedy

Pilot Lamp does not

light

Foot Pedal

dose not work.

Error code E0

appears.

Error code E1

appears.

Error code E2

appears.

Error code E3

appears.

The power plug is disconnected.

The fuse is blown.

Power Switch is faulty.

The connection of the foot control

cord plug is loose.

Hand/Foot Selector Switch is set

by HAND.

Maintenance mode (4) “Pd”:

Check to see if the foot control

operates normally.

Turn on the power again.

Turn on the power again.

If you have two or more units,

replace the motor and the motor

cord and check the operation.

The motor cord is disconnected.

If you have two or more units,

replace the motor and the motor

cord and check the operation.

The motor cord is disconnected.

Maintenance mode (3) “HL”:

Confirm whether you work by a

motor signal check normally.

Insert the power plug correctly.

Replace it with a specified fuse. If the

reason the fuse has blown is unknown,

ask for an inspection.

Ask for repair.

Connect the foot control cord plug

correctly.

Set Hand/Foot Selector Switch to

FOOT.

If the foot control dose not operates

normally, ask for repair of the foot

control or replace it with a new one.

If the same error code appears, ask for

repair of the unit.

If it operates normally, the error display

is temporarily due to overload, which is

not a problem.

If it operates normally after replacing

the motor and the motor cord, the

motor and/or the motor cord may be

shorted. Ask for repair of the motor

and/or the motor cord. If the same

error code still appears after replacing,

ask for repair of the unit.

Connect the motor cord correctly.

If it operates normally after replacing

the motor and the motor cord, the

motor and/or the motor cord may be

severed. Ask for repair of the motor

and/or the motor cord. If the same

error code still appears after replacing,

ask for repair of the unit.

Connect the motor cord correctly.

If any problem is found during a check,

the motor cord may be severed or the

sensor in the motor may be faulty. Ask

for repair.

The motor and handpiece do not run, or Reset Lamp lights.

English

16 17

Trouble Cause / Check Remedy

Error code E4

appears.

Error code E5

appears.

Error code E6

appears.

Error code E8

appears.

Error code E9

appears.

Error code EF

appears.

Vacuum-coupled Mode is on,

while the dust collector is not

used.

After stopping to cool it down

place for about 10 minutes,

check the operation again.

Turn on the power again, and

repeat starting and stopping

several times.

The chuck is open.

Maintenance mode (3) “HL”:

Confirm whether you work by a

motor signal check normally.

Check turning a tip with a finger

lightly and turning around it

lightly.

Turn on the power again.

If you have two or more units,

replace the motor cord and

check the operation.

If you have two or more units,

replace the motor cord and

check the operation.

Maintenance Mode (4) “Pd”:

Check whether Foot Pedal

operates normally by Foot Pedal

Chuck.

Make the Vacuum-coupled Mode to

be off. See Vacuum-coupled Mode

section in the manual. (See *

Vacuum-coupled Mode)

If it operates normally, there is no

problem. Check the operating

environment, storage location, etc., for

high temperature. If the same error

code appears frequently, ask for repair

of the unit.

If it operates normally, there is no

problem. If the same error code

appears, ask for repair of the unit.

Lock the chuck. If any problem is

found during a check, the motor cord

may be severed or the sensor in the

motor may be faulty. Ask for repair.

If any problem is found during a check,

the motor cord may be severed or the

sensor in the motor may be faulty. Ask

for repair.

If the rotation is abnormal, ask for

repair of the motor and handpiece.

Error indication is a temporary thing by

the overload if I work normally. There is

not it abnormally.

If it operates normally after replacing

the motor cord, the motor and/or the

motor cord may be shorted. Ask for

repair of the motor and/or the motor

cord. If the same error code still

appears after replacing the motor

cord, ask for repair of the unit.

If it operates normally after replacing

the motor cord, the motor and/or the

motor cord may be shorted. Ask for

repair of the motor and/or the motor

cord. If the same error code still

appears after replacing the motor

cord, ask for repair of the unit.

If it does not operate normally, change

the Foot Pedal for new or ask for

repair.

The motor and handpiece do not run, or Reset Lamp lights.

<Handpiece>

Trouble Cause / Check Remedy

The handpiece does

not run with the

chuck tightened.

Heat is generated

during rotation.

Vibration or noise

occurs during rotation.

Run out of the bur

is heavy.

The bur comes out

Entry of foreign matter in the ball

bearings or seizure.

Entry of foreign matter in the ball

bearings, causing wear of the bearings.

Same as the above.

A bent bur is used.

Dust may be stuck in the chuck or

spindle.

The chuck is worn.

The ball bearings are worn.

The chuck is loose.

Send it to your dealer. Ask for

repair.

Same as the above.

Same as the above.

Replace the bur

Clean the inside of the chuck and

spindle.

Replace the chuck.

Send it to your dealer.

Tighten the chuck securely. (See

*Handling of Motor and

Handpiece.)

Trouble Cause / Check Remedy

The rotation speed

does not rise.

The maximum rotation speed for

operation by foot pedal should be

set with the Speed Control Knob.

Set the maximum rotation speed with

the Speed Control Knob.

English

Other manuals for Ultimate XL

1

Table of contents

Other NSK Laboratory Equipment manuals