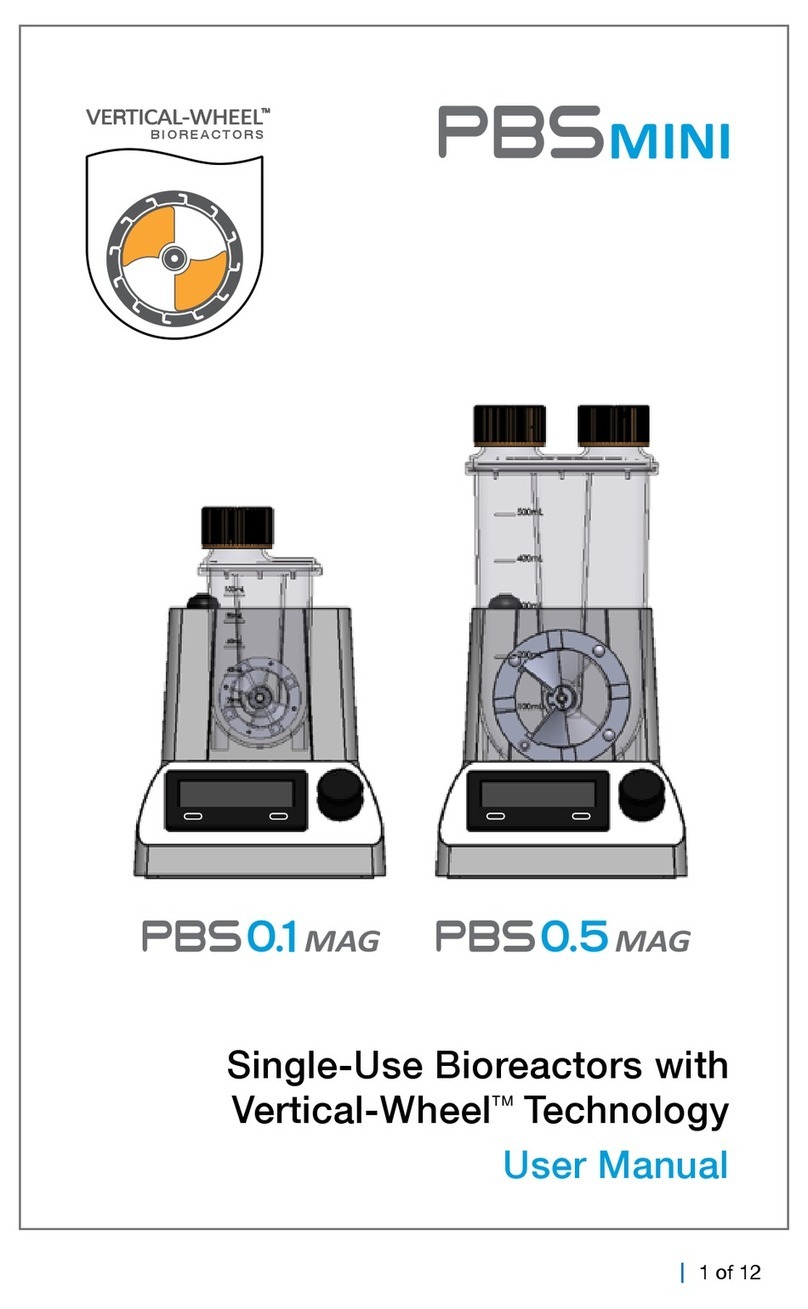

NSK VR-EB User manual

001

1

EN DE FR ES IT PT

1. User and Indications for Use

Users: Dental Technicians and Dentists

Indications for Use: For use in Dental Laboratories for cutting and polishing

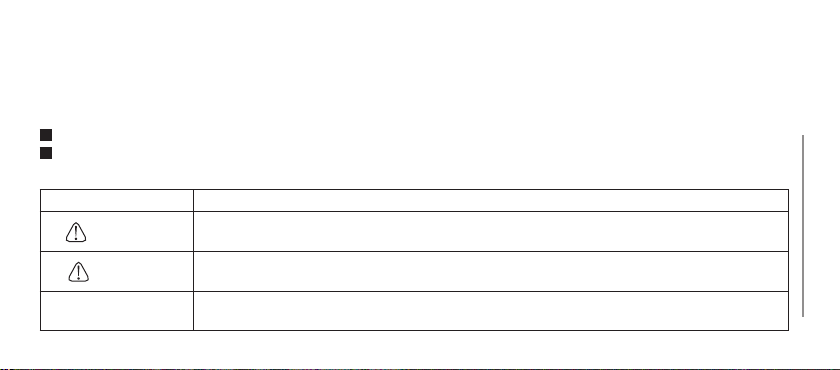

2. Precautions for handling and operation

Please read these precautions carefully and use only as intended or instructed.

Safety instructions are intended to avoid potential hazards that could result in personal injury or damage to the device.

Safety instructions are classified as follows in accordance with the seriousness of the risk.

Class Degree of Risk

WARNING Hazard that could result in serious injury or damage to the device if the safety instructions are not

correctly followed.

CAUTION Hazard that could result in light or moderate injury or damage to the device if the safety instructions

are not correctly followed.

NOTICE General product specification information highlighted to avoid product malfunction and performance

reduction.

ENGLISH

2

WARNING

Ř7KLVSURGXFWLVRQO\IRUXVHLQGHQWLVWU\'RQRWXVHLWIRUPHGLFDOWUHDWPHQW

Ř&RQIRUPWRWKHDOORZHGURWDWLRQVSHHGVSHFLILHGE\WKHPDQXIDFWXUHUGLVWULEXWRURIWKHEXU)DLOXUHWR'RVRPD\OHDGWR

LQMXU\GXHWRWKHEXUEUHDNLQJDQGVFDWWHULQJRUWKH0RWRU+DQGSLHFHPRYLQJYLROHQWO\

Ř'RQRWXVHEXUVZLWKLQVWDELOLW\FXUYLQJGDPDJHRUZHDURQWKHVKDQNDUHD'RLQJVRPD\OHDGWRLQMXU\GXHWRWKHEXU

EUHDNLQJRUIO\LQJRXWHWF

Ř:KHQXVLQJDGLVNXVHLWDWDVORZDURWDWLRQVSHHGDVSRVVLEOHWRSUHYHQWLWIURPVFDWWHULQJGXHWREUHDNLQJHWF

Ř6LQFHDJULQGVWRQHPD\EHXQEDODQFHGHYHQLILWLVQHZPDNHVXUHWRSHUIRUPGUHVVLQJEHIRUHXVLQJLW8VLQJDQ

XQEDODQFHGJULQGVWRQHPD\OHDGWRLQMXU\GXHWRLWEUHDNLQJDQGVFDWWHULQJ

CAUTION

ŘThe product must be used by a person who has received professional instruction as a health care provider, such as a dental

technician or dental physician, in a dental clinic, hospital or other medical institution.

ŘUsers are responsible for the operational control, maintenance and continual inspection of this product.

3

EN DE FR ES IT PT

CAUTION

ŘRotate the bur to check for vibrations, noise, or temperature (heat) being emitted. Should the Handpiece function abnormally

at this time, stop using it immediately and contact your Authorized NSK Dealer. (Refer to “6. Checking the Handpiece Before

Each Use”)

ŘDo not disassemble or alter the handpiece except as recommended by NSK in this Operation Manual.

ŘDo not allow any impact on to the product. Do not drop the product.

ŘOperators and all others in the area must wear eye protection, a mask, and gloves when operating the Handpiece.

ŘOperate the Handpiece at speeds under the maximum rotation speed of 35,000min–1.

ŘWhen using a bur with a large cutting blade (4mm or larger in diameter), use it at as low a rotation speed as possible.

ŘDo not use burs with problems listed below as the bur may break, seize up or disengage from the chuck.

– Bent, deformed, worn, rusted, broken, deficient bur.

– Bur which is cracked on the edge or axis.

– Non-ISO (EN ISO) standard, or tampered bur.

ŘAlways keep the bur shank clean. Debris in the chuck could cause poor bur concentricity or low chuck retention force.

ŘAlways insert the bur all the way into the chuck. If insertion is insufficient, premature failure of the handpiece head bearings,

or accidental release of the bur, may occur.

4

CAUTION

ŘAlways follow the instructions provided by the bur manufacturer.

ŘWhen a bur is rotating, do not turn the bur lock ring in the direction. Doing so will cause the Handpiece to break.

Particularly when replacing a bur, do so after rotation has completely stopped.

ŘShould the handpiece function abnormally during use, stop using the handpiece immediately and contact your Authorized NSK

Dealer.

ŘClean the Handpiece on a timely basis. Follow the procedure in “7. Post-use Maintenance” in the Operation Manual to perform

cleaning.

ŘDo not use the following fluids to wipe, immerse or clean the product; strong / super acid water, strong acid / alkaline

chemicals, chlorine-containing solutions, solvents such as benzine or thinner.

ŘDo not lubricate the Motor Handpiece with oil. Doing so might cause it to generate heat or malfunction.

ŘPerform regular function and maintenance checks. (Refer to “8. Periodical Maintenance Checks”)

ŘIf the handpiece has not been used for a long period, rotate the handpiece and check for noise, vibration and overheating

before use.

ŘTo avoid clinical downtime it is recommended that a spare be kept on hand in case of a breakdown during treatment.

5

EN DE FR ES IT PT

NOTICE

ŘKeep a cutting bur or test bur attached even when the product is not in use.

ŘContact your Authorized NSK Dealer if the product fails.

3. Accessory List

No. Name Quantity

1 Wrench for Adjusting Chuck 1

6

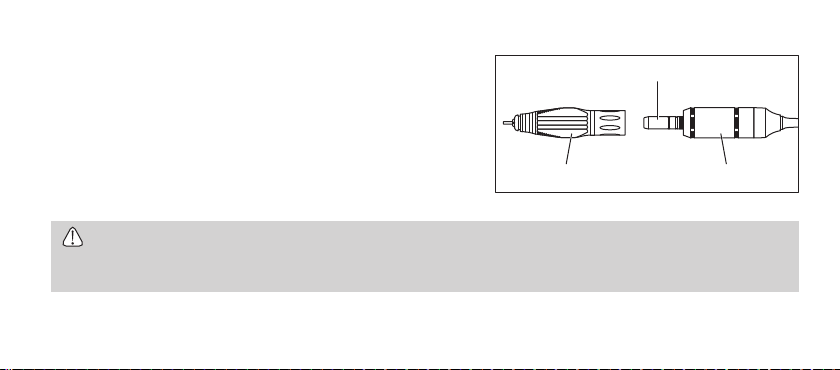

4. Connecting and Disconnecting the Handpiece from the Motor

4-1 Connecting

1) Insert the handpiece direct into the motor (Fig. 1). When

connecting an optic handpiece, turn the handpiece until it clicks

and locks into position.

2) Confirm that the handpiece is securely connected to the motor.

4-2 Disconnecting

Hold the motor and the handpiece, then pull apart.

Insertion Area

Handpiece Motor

Fig. 1

CAUTION

ŘDo not connect or disconnect the handpiece until the motor has completely stopped.

ŘConnect ONLY to E type motors (ISO 3964 (EN ISO 3964)).

7

EN DE FR ES IT PT

5. Inserting and Removing the Bur

5-1 Removing the Bur

1) Turn the bur lock ring in the direction until it clicks to loosen the chuck.

2) Pull out the bur.

5-2 Inserting the Bur

1) Insert the bur in all the way.

2) Turn the bur lock ring in the direction until it clicks to tighten the chuck.

After attaching the bur, pull it back and forth to confirm that it is connected

securely.

Bur Lock RingChuck Open

Open

Closed

Closed

Fig. 2

8

WARNING

Ř&RQIRUPWRWKHDOORZHGURWDWLRQVSHHGVSHFLILHGE\WKHPDQXIDFWXUHUGLVWULEXWRURIWKHEXU)DLOXUHWR'RVRPD\OHDGWR

LQMXU\GXHWRWKHEXUEUHDNLQJDQGVFDWWHULQJRUWKH0RWRU+DQGSLHFHPRYLQJYLROHQWO\

Ř'RQRWXVHEXUVZLWKLQVWDELOLW\FXUYLQJGDPDJHRUZHDURQWKHVKDQNDUHD'RLQJVRPD\OHDGWRLQMXU\GXHWRWKHEXU

EUHDNLQJRUIO\LQJRXWHWF

Ř:KHQXVLQJDGLVNXVHLWDWDVORZDURWDWLRQVSHHGDVSRVVLEOHWRSUHYHQWLWIURPVFDWWHULQJGXHWREUHDNLQJHWF

Ř6LQFHDJULQGVWRQHPD\EHXQEDODQFHGHYHQLILWLVQHZPDNHVXUHWRSHUIRUPGUHVVLQJEHIRUHXVLQJLW8VLQJDQ

XQEDODQFHGJULQGVWRQHPD\OHDGWRLQMXU\GXHWRLWEUHDNLQJDQGVFDWWHULQJ

9

EN DE FR ES IT PT

CAUTION

ŘWhen using a bur with a large cutting blade (4 mm or larger in diameter), use it at as low a rotation speed as possible.

ŘAlways keep the bur shank clean. Debris in the chuck could cause poor bur concentricity or low chuck retention force.

ŘAlways insert the bur all the way into the chuck. If insertion is insufficient, premature failure of the handpiece head bearings,

or accidental release of the bur, may occur.

ŘAlways follow the instructions provided by the bur manufacturer.

ŘWhen a bur is rotating, do not turn the bur lock ring in the OPEN direction. Doing so will cause the Handpiece to break.

Particularly when replacing a bur, do so after rotation has completely stopped.

6. Checking the Handpiece Before Each Use

Before using the product, rotate the bur to perform an inspection. If you notice a problem such as bur instability, vibrations,

generation of heat, or abnormal sounds during an inspection or use of the product, cease operation immediately and contact your

Authorized NSK Dealer.

10

7. Post-use Maintenance

Perform the following maintenance after use.

7-1 Preparation

1) Remove the bur.

2) Disconnect the handpiece from the motor.

3) Wipe the surface of the Handpiece with a damp cloth, and then wipe it with a cloth

dampened with rubbing alcohol, etc.

7-2 Cleaning and Replacing the Chuck

7-2-1 Removing the Chuck

1) Turn the bur lock ring to the OPEN position.

2) Turn the chuck counterclockwise with the included wrench for adjusting chuck

(Fig. 3).

Loosen

Fig. 3

11

EN DE FR ES IT PT

3) Remove the chuck (Fig. 4).

7-2-2 Cleaning the Chuck

In order to maintain the precision of the chuck, remove it regularly for cleaning with

an ultrasonic cleaner, etc. It is recommended that you clean it at least once a week

to ensure the product can be used safely. Chuck

Fig. 4

CAUTION

ŘNeglecting to clean the chuck for a long time is very dangerous because wax, gypsum, etc., will accumulate in the chuck,

causing the bur to be insecure and causing runout.

12

7-2-3 Attaching the Chuck

1) Turn the bur lock ring to the OPEN position.

2) Push the chuck in all the way with a bur inserted.

3) Turn the chuck clockwise with your finger until it stops (Fig. 5).

Then lock the bur lock ring to hold the bur securely.

Fig. 5

Until it stops

CAUTION

ŘAfter attaching the chuck, pull it back and forth to confirm that it is connected securely.

NOTICE

ŘApply a thin layer of oil to the chuck before insertion.

13

EN DE FR ES IT PT

8. Periodical Maintenance Checks

Every 3 months perform periodical maintenance checks, referring to the check sheet below. If any abnormalities are found, contact

your Authorized NSK Dealer.

Points to check Details

Rotation Rotate the handpiece and check for abnormalities such as abnormal rotation, vibration,

noise, and overheating.

14

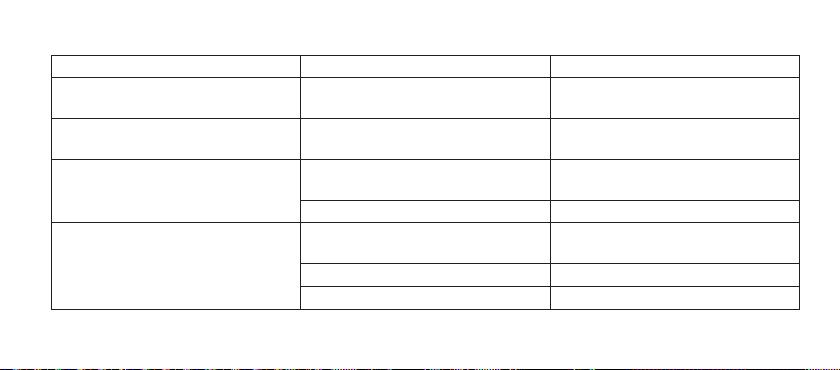

9. Problems and Solutions

Problem Cause Solution

The bur does not rotate with the bur lock

ring closed.

The ball bearings have burned out or

have foreign material inside them.

Contact your Authorized NSK Dealer.*

Heat is emitted during rotation. There is wear on the ball bearings due to

foreign material inside them.

Contact your Authorized NSK Dealer.*

Vibrations/noise is emitted during

rotation.

There is wear on the ball bearings due to

foreign material inside them.

Contact your Authorized NSK Dealer.*

A curved bur was used. Replace the bur.

The bur has poor concentricity. Foreign material may be attached to the

inside of the chuck.

Clean the inside of the chuck.

The chuck is worn. Replace the chuck.

The ball bearings are worn. Contact your Authorized NSK Dealer.*

15

EN DE FR ES IT PT

Problem Cause Solution

The bur disconnects. The chuck is loose. Tighten the chuck.

*The product cannot be repaired at a dental clinic, etc.

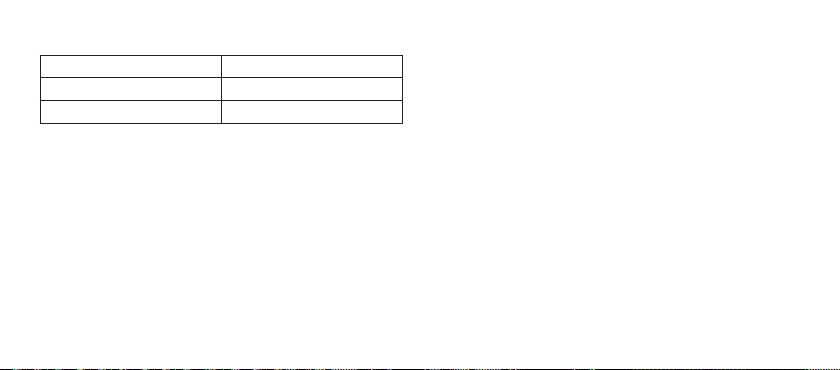

10. Specifications

Model VR-EB

Max. Rotation Speed (Motor) 35,000min–1

Max. Rotation Speed (Handpiece) 35,000min–1

Bur Type ISO 1797-1 (EN ISO 1797-1) Type2 ø2.35mm HP Bur

Use Environment Temperature: 10 - 40°C, Humidity: 30 - 75% (No Condensation)

Transportation and Store Environment Temperature -10 - 50°C, Humidity: 10 - 85%, Pressure: 500 - 1,060hPa

16

11. Symbol

Conforms to CE European Directive.

Manufacturer.

Authorized representative in the European community.

12. Warranty

NSK products are warranted against manufacturing errors and defects in materials. NSK reserves the right to analyze and determine

the cause of any problem. Warranty is voided should the product be not used correctly or for the intended purpose or has been

tampered with by unqualified personnel or has had non NSK parts installed. Replacement parts are available for seven years beyond

discontinuation of the model.

17

EN DE FR ES IT PT

13. Spare Parts List

Model Order Code

Chuck-2.35A H203A180A

Wrench for Adjusting Chuck K015751

14. Disposing product

In order to avoid the health risks of operators handling the disposal of medical equipment, as well as the risks of environmental

contamination caused thereof, a surgeon or a dentist is required to confirm the equipment is sterile. Ask specialist firms who are

licensed to dispose of specially controlled industrial wastes, to dispose the product for you.

18

19

EN DE FR ES IT PT

1. Benutzer und Verwendungszweck

Benutzer: Zahntechnikern und Zahnärzten

Anwendungshinweise:

Diese Vorrichtung dient der Übertragung von Rotation, die aus einer Energiequelle stammt, wodurch ein Instrument wie zum

Beipiel ein Fräser angetrieben wird, um ein einem Dentallabor künstliche Zähne (Zahnersatz) zu Schneiden und zu Polieren.

2. Sicherheitsanweisungen für die Handhabung und Bedienung

Lesen Sie bitte diese Sicherheitsanweisungen aufmerksam durch und benutzen Sie das Gerät ausschließlich gemäß seines

bestimmungsgemäßen Gebrauchs und entsprechend der Anweisungen.

Die Sicherheitsanweisungen sind dafür vorgesehen, mögliche Gefahren zu verhindern, die Körperverletzungen oder

Beschädigungen am Gerät verursachen können.

Die Sicherheitsanweisungen werden gemäß der Schwere des Risikos wie folgt klassifiziert.

KLASSE Ausmaß und Schwere der Gefährdung oder Schädigung

ACHTUNG Risiko, das zu schweren Verletzungen oder Schäden am Gerät führen kann, wenn die

Sicherheitshinweise nicht beachtet werden.

VORSICHT Ein mögliches Risiko, das zu leichten bis mittleren Personen- oder Sachschäden führen kann, wenn die

Sicherheitshinweise nicht beachtet werden.

HINWEIS Allgemeine Produktinformationen, die besonders hervorgehoben werden, um Störungen oder

Leistungsminderungen zu vermeiden.

DEUTSCH

Table of contents

Languages:

Other NSK Laboratory Equipment manuals

Popular Laboratory Equipment manuals by other brands

Guth Laboratories

Guth Laboratories 12V500 DUPLEX Operator's manual

Showa Denko

Showa Denko Shodex Asahipak GS-HQ Series Operation manual

MRC

MRC ROVA-100S Operation instructions

GOLDENSEA UV

GOLDENSEA UV UVM216 user manual

Axygen

Axygen AxySpin R C2500-R-AXY manual

MIHM-VOGT

MIHM-VOGT KM operating instructions

Thermo Scientific

Thermo Scientific STP420D instruction manual

Stuart

Stuart SBH CONC/1 Instructions for use

Witeg

Witeg TITREX 2000 operating manual

Thermo Scientific

Thermo Scientific TGA-IR user guide

Parker Research Corp

Parker Research Corp DA750-115 operating instructions

Agilent Technologies

Agilent Technologies G2916A manual