CANopen Interface

NTI AG / LinMot Usermanual CANopen Interface / 14.09.2005 Page 9/16

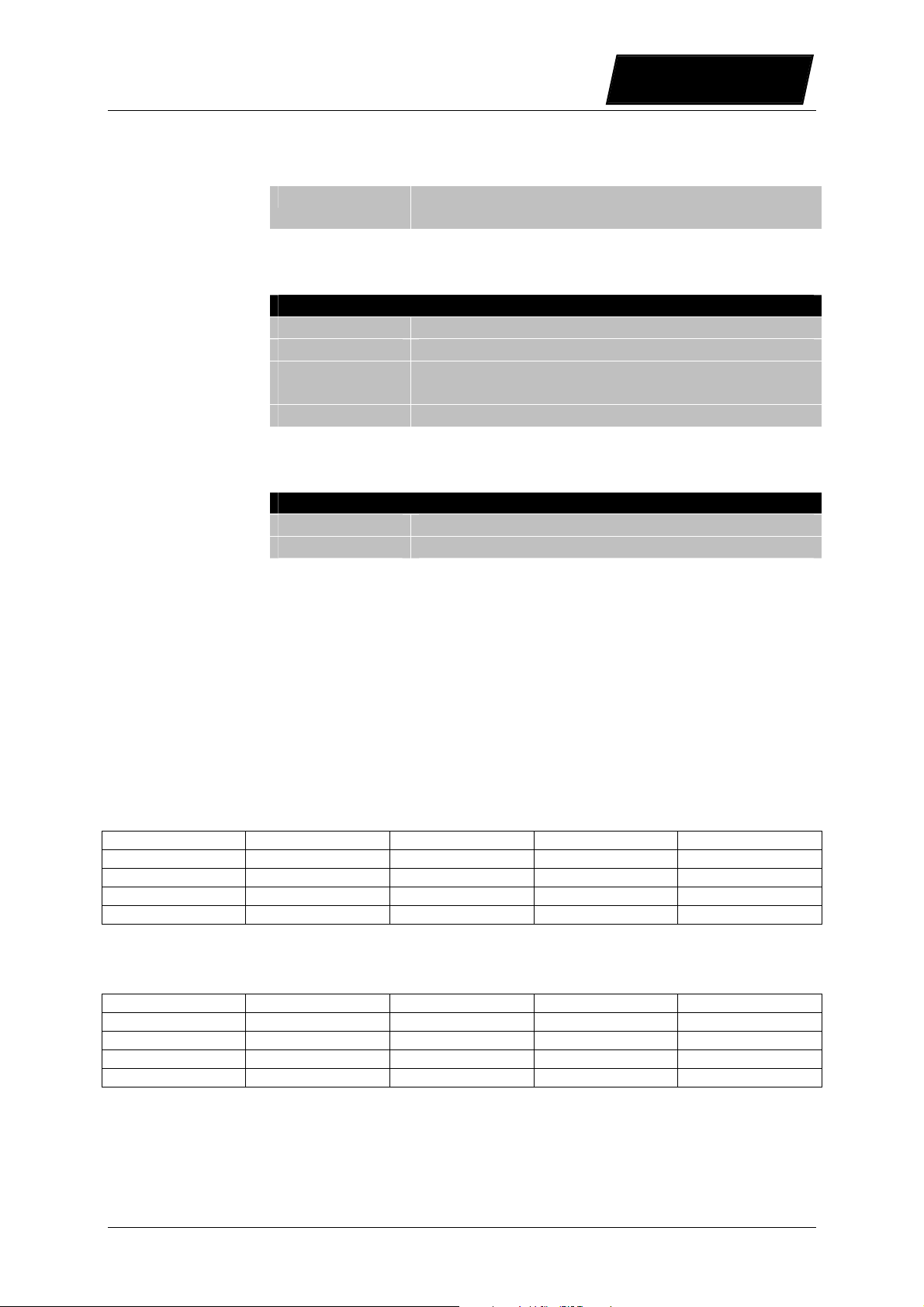

5. Motor Commands

The commands for the motors are defined as followed:

CMD Mot X:

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

Toggle MA MB MC MD Command ID

The Toggle Bit corresponds to the “CMD Toggle response Mot X”-flag in the status word.

With the Bits MA..MD the command selects the motor. The command can be used for 1 to 4 Motors.

The following Command ID’s are defined:

ID Description

0 No operation

1 Goto Position (Par 1 = Position)

2 Goto Position with max Speed (Par 1 = Position, Par 2 = max. Speed)

3 Goto Position with max Speed and Acceleration (Par 1 = Position, Par 2 = max Speed,

Par 3 = max. Acceleration)

4 Set Filter Parameter (Par 1 = max Speed, Par 2 = max. Acceleration, Par 3 = max.

Current)

5 Redefine Position (Par 1 = Position to redefine to)

6 Move Home Position (Par 1 = Position Difference)

7 PVA Mode (Par 1 = Position, Par 2 = Speed, Par 3 = Acceleration)

16 Run Curve (Par 1 = Curve Number)

17 Run Curve with curve speed (Par 1 = Curve Number, Par 2 = Curve Speed)

18 Run Curve with curve Speed and Amplitude (Par 1 = Curve Number, Par 2 = Curve

Speed, Par 3 = Curve Amplitude)

19 Run curve with auto Offset (Par 1 = Curve Number)

20 Run Curve with Auto Offset, curve Speed and Amplitude (Par 1 = Curve Number, Par 2 =

Curve Speed, Par 3 = Curve Amplitude)

21 Set Curve Parameter (Par 1 = Curve Speed, Par 2 = Curve Amplitude, Par 3 = Curve

Offset)

32 Set PID (Par 1 = P, Par 2 = I, Par 3 = D)

33 Set FF (Par 1 = FF acc, Par 2 = FF dec, Par 3 = FF frict)

34 Set Current Offset (Par 1 = Current Offset)

48 Run ME Curve (Par 1 = Curve Number)

49 Run ME Curve with Auto Offset (Par 1 = Curve Number)

50 Set ME Curve Parameter (Par 1 = Curve Amplitude, Par 2 = Offset)

64 Write Memory Word (Par 1 = Address Seg, Par 2 = Segment Offset, Par 3 = Value)

65 Read Memory Word (Par 1 = Address Seg, Par 2 = Segment Offset)