NTI 84713 User manual

#

Installation Instructions 84713 │Gas Valve EBM 120VDC

Revision Date: 2019-06-19

S:\NTI2001_N_Drive (1-20-09)\R&D\PARTS - ENGINEERING\Parts Department Stickers and Instructions\Current Parts Instructions (doc)\Parts

instructions word docs\84713 instructions - Gas Valve EBM 120VDC R1.doc

NTI Boilers Inc.

Tel: (506) 657-6000

Toll Free: 1-800-688-2575

Fax: 1-506-432-1135

Web: www.ntiboilers.com

Email: info@ntiboilers.com

84713

Gas Valve EBM 120VDC

Applicable Appliance Models

Tx51, Tx81, Tx101, Tx151, Tx151C

VM110, VM110P, VM153, VM153P

TV110, FTV110C, FTV150, FTV150C, FTV190, FTV190C

Kit Contents

84713 –Gas Valve

Tools Required

Pipe Wrench (for gas line)

Adjustable Wrench (for gas line union)

1/4” and 5/16” Nut Drivers

3 mm Allen wrench

2 mm Allen wrench

Flat Screwdriver

Torx T25 Screwdriver

Combustion Analyzer

The installation of this gas valve must be performed by a qualified gas technician in accordance

with these instructions. Installing this valve without the proper background and training is

hazardous and may result in property damage serious injury or death.

Replacement Instructions

1) Shut off the power and gas supply to the boiler.

2) Remove the gas line from the gas valve.

3) Remove the gas valve harness and feedback tube from the gas valve.

4) Remove the screws securing the gas valve to the Venturi and remove the gas valve from the boiler.

5) Transfer gas line inlet adapter to the new valve. Use care to ensure that the O-ring gasket does not fall out.

6) Transfer gas valve outlet gasket to the replacement gas valve (see Figure 3). Propane (LP): if equipped with an LP

orifice, ensure it remains inside the groove in the middle of the gas valve outlet gasket.

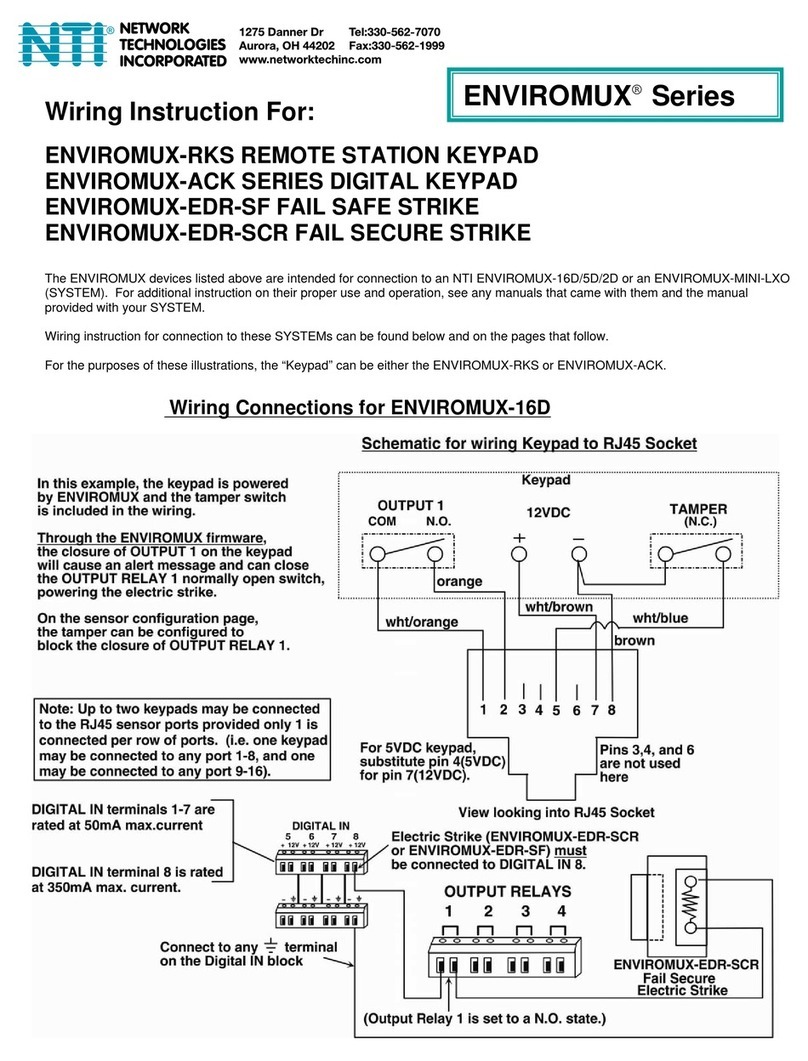

Figure 2

Figure 1 Gas Valve

Gas valve outlet gasket

(location for LP orifice –if

applicable)

Installation Instructions 84713 │Gas Valve EBM 120VDC

| 2

7) For Tx models, drill 1/8” hole in the bottom of the air-inlet pipe assembly in accordance with the Trinity Tx Air-inlet

Pipe –Drain Hole Addition instructions (see last page).

8) Reinstall the new valve in the reverse order it was removed

Feedback Tube –Reconnect the tubing from the air-inlet to the gas valve feedback port.

Failure to properly reconnect the feedback tube will negate the boiler’s blocked vent safety

shutoff mechanizm, and could lead to incorrect combustion resulting in property damage,

serious injury or death.

9) The valve is not set when received, turn the Throttle Screw (see Figure 4) clockwise until it stops, then

counterclockwise the number of turns indicated in Table 1. Then proceed with the Combustion Calibration

Procedure detailed on the following pages.

Combustion Calibration Procedure

To calibrate burner combustion, perform the following procedure using a calibrated combustion analyzer capable of

measuring CO2and CO from a Natural Gas or Propane burning appliance:

1. Set analyzer to the appropriate fuel (Natural Gas or Propane).

2. Gas Line Pressure Test –monitor gas line pressure throughout all combustion tests and verify it is maintained

within tolerance. See Gas Line Pressure Test below.

3. Set Throttle Screw –operate burner to the maximum modulation rate (see Table 3); set combustion according to

Table 2 using the Throttle Screw; allow time for the analyzer readings to stabilize between adjustments –record

CO2value. See Throttle Screw Adjustment below.

4. Set Offset Screw –operate burner to the minimum modulation rate (see Table 3); using the Offset Screw, set the

CO2to 0.4-0.8% lower than the value obtained during the maximum modulation rate test (e.g. if CO2at Max =

9.5%, then CO2at Min must = 8.8-9.1%). See Offset Screw Adjustment below.

Combustion Calibration is mandatory upon installation and during each annual service.

Failure to perform the Combustion Calibration in accordance with these instructions may result

in incorrect combustion leading to burner damage or excessive Carbon Monoxide concentrations

causing property damage, personal injury or death.

Carbon Monoxide - Never leave the unit operating while producing Carbon Monoxide (CO)

concentrations in excess of 175 ppm. Failure to follow this warning may result in serious injury

or death.

Table 1 –Throttle Screw Preset

Boiler model

# of Turns Out (ccw) from Fully Closed

Natural Gas

Propane (LP)

Tx51

4

4

Tx81

4

4

Tx101

4

4

Tx151, Tx151C

4

4

VM110, VM110P

4

4

VM153, VM153P, FTV150, FTV150C

10

7

FTV110, FTV110C

10

6

FTV190, FTV190C

16

11

Note- these are starting points, Throttle screw may need as many as 4 more full turns

before lighting

Installation Instructions 84713 │Gas Valve EBM 120VDC

| 3

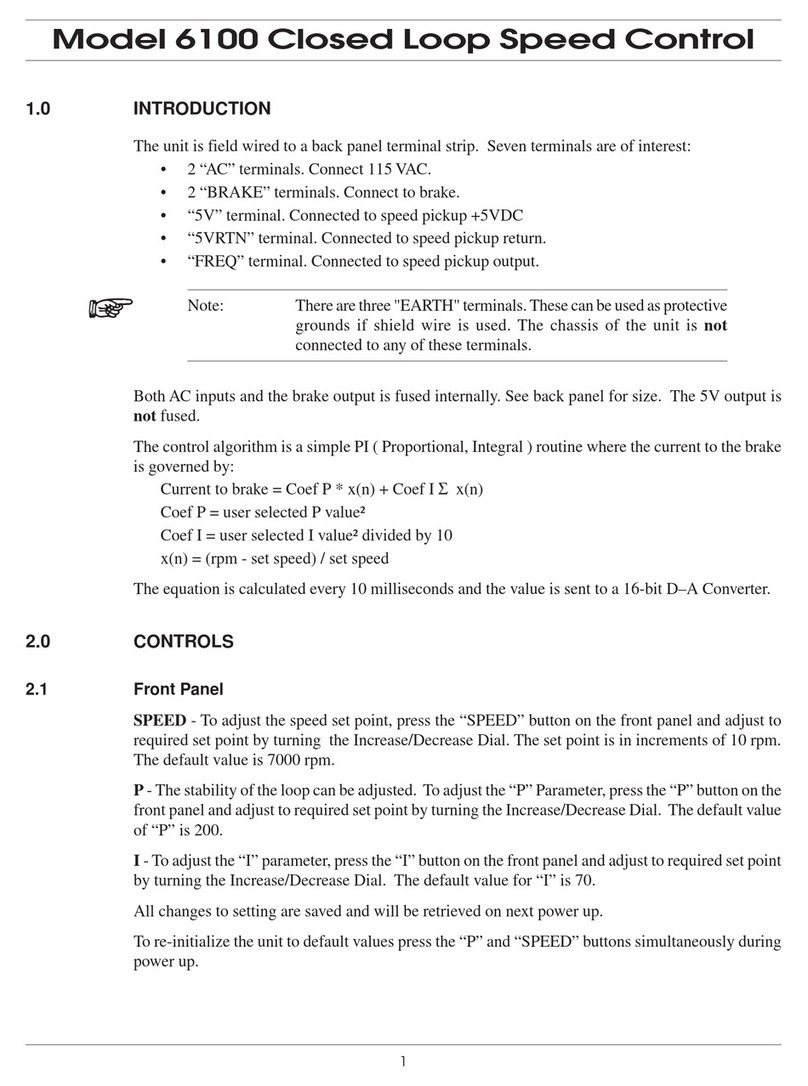

Throttle Screw Adjustment

The gas valve Throttle Screw (see Figure 4) is used to calibrate the CO2concentration with the burner operating at or

near the maximum modulation rate (see Table 3). Turning the Throttle Screw in (clockwise) decreases the CO2

concentration. Turning the Throttle Screw out (counterclockwise) increases the CO2 concentration. Typical adjustment

required is 0 –1/2of a turn in or out from the factory setting.

NOTE: Calibration of the Throttle Screw should only be performed with the burner operating at or near the

maximum modulation rate (see Table 3).

Adjustments to the Throttle Screw may only be made by a qualified gas technician using a

calibrated combustion analyzer capable of measuring CO2and CO. Adjustments may only be

performed if the gas line pressure is maintained above minimum levels throughout the duration

of the test (see Table 2). Failure to follow these instructions may result in serious injury or death.

Offset Screw Adjustment

The gas valve Offset Screw (see Figure 4) is used to calibrate the CO2offset at minimum modulation vs. maximum

modulation. Turning the Offset Screw in (clockwise) increases the CO2 concentration at minimum modulation rate.

Turning the Offset Screw out (counterclockwise) decreases the CO2 concentration at minimum modulation rate. Typical

adjustment required is 0 - 1/8th of a turn in or out from the factory setting.

NOTE: Calibration of the Offset Screw must only be performed with the burner operating at the minimum

modulation rate (see Table 3).

Adjustments to the Offset Screw may only be made by a qualified gas technician using a

calibrated combustion analyzer capable of measuring CO2and CO, and only with the burner at

the minimum modulation rate (see Table 3). Attempting to set the Offset Screw while the burner

is operating at a modulation rate other than the minimum will result in incorrect combustion and

may lead to burner damage or excessive CO.

Gas Line Pressure Test

The boiler gas valve is equipped with a line pressure test port; see Figure 4. Use the following procedure to measure the

gas line pressure to the boiler to ensure it falls within the range given in Table 2:

1. Turn the supply of gas to the boiler off.

2. Open the bleed screw of the line pressure test port approximately 1-1/2 turns. This port is directly connected to the

gas line feeding the boiler. See Figure 4.

3. Force 1/4ID tubing over the housing of the line pressure test port; install the other end of the tubing to an

appropriate line pressure test gauge or manometer. Ensure both ends of the tubing make a tight connection.

4. Open the supply of gas to the boiler and check for gas leaks.

5. Observe the line pressure under static conditions and compare it to Table 2. The pressure will be greatest under

static conditions.

6. With all other gas appliances in the application running, operate the burner to the maximum firing rate (See Table 3)

and compare the observed line pressure with Table 2. The pressure will be lowest during the maximum flow of gas.

7. Adjust the gas line pressure to ensure the parameters in Table 2 are attained under all conditions. If possible adjust

the line pressure to the "Nominal/Desired" value listed in Table 2, while the unit is operating at the maximum

modulation rate, see Table 3.

8. Continue observing the gas line pressure until the completion of the combustion analyses, in case adjustments need

to be made.

9. Complete pressure testing, and then return the bleed screw of the Line Pressure Test Port to the closed position.

The line pressure is a function of the gas supply and is affected solely by field provided

parameters such as line size and regulator settings. Under no circumstances can the boiler gas

valve influence or be used to adjust the gas line pressure.

Installation Instructions 84713 │Gas Valve EBM 120VDC

| 4

Failure to close the bleed screw of the Line Pressure Test Port will cause a severe leakage of gas,

resulting in a fire or explosion causing property damage, serious injury or death.

Table 2 Line Pressure and Combustion Parameters

Gas

Line Pressure (inches w.c.)

CO2(%)

CO (ppm)

Max.

Nominal/Desired

Min.

Max.

Min.

Max.

Natural

7

4

10.5

9.0

9.5

175

Propane

11

8

13

10.0

10.8

175

Notes:

1Combustion calibration must only be performed with the burner operating at maximum modulation rate; when tested at

minimum modulation rate the CO2must be 0.4-0.8% lower than CO2at maximum modulation rate.

Table 3 Minimum and Maximum Modulation Rates

Model

Gas

Type

Min.

Modulation

Rate (RPM)

Max.

Modulation

Rate (RPM)

Model

Gas

Type

Min.

Modulation

Rate (RPM)

Max.

Modulation Rate

(RPM)

Tx51

N/A

1380

5460

FTV110/C

NG

1620

7620

Tx81

1260

5700

LP

1860

8040

Tx101

5820

FTV150/C

N/A

1740

8220

Tx151/C

1380

6420

FTV190/C

1620

8280

Tx200/C

1020

5280

VM153/P

NG

1740

7980

VM110/P

NG

1680

7800

LP

7500

LP

7680

Notes:

1Use Installer Menu setting 2-15 to force the burner to operate at the max. (2-15 = 3) and min. (2-15 = 1) modulation rates;

see Section 17.0 DISPLAY MENU GUIDE.

Figure 4 Gas Valve and Venturi Assembly (Tx Illustrated)

Venturi

Gas Valve

Offset Screw –used to set

combustion at min. modulation rate

(use 2 mm hex wrench)

Throttle Screw –used to calibrate

combustion at max. modulation rate

Line Pressure

Test Port

Installation Instructions 84713 │Gas Valve EBM 120VDC

| 5

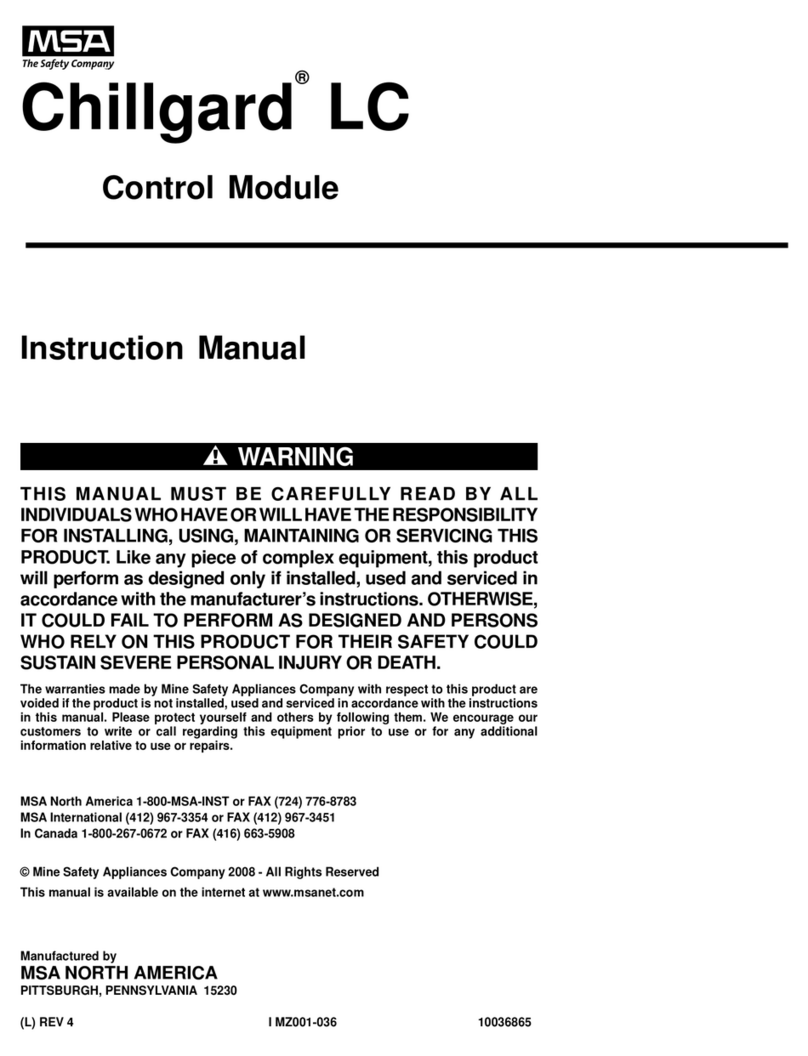

Trinity Tx Air-inlet Pipe –Drain Hole Addition

(factory equipped post s/n 116575)

Instructions:

Working with the boiler turned off, drill a 1/8” diameter hole in bottom of air-inlet pipe as close to the clamp as

possible. (Figure 5)

Figure 5

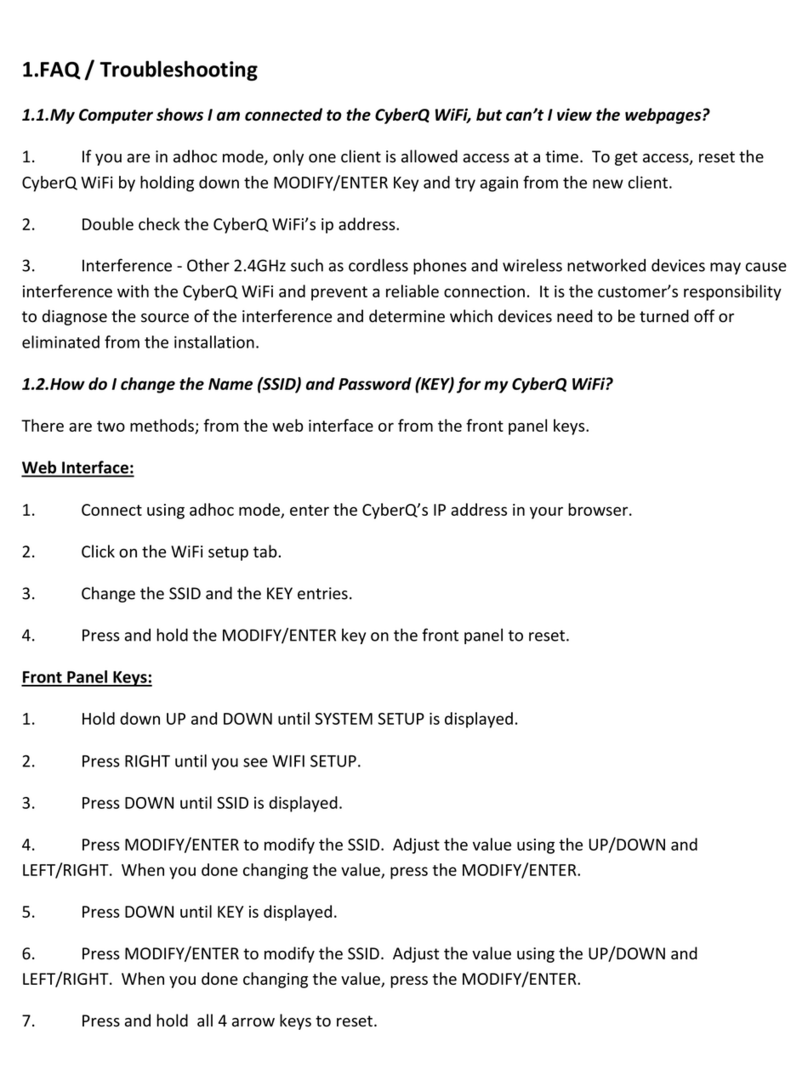

Remove the air-inlet pipe assembly from the boiler to clean out any filings created by drilling the hole.

Reinstall air-inlet pipe –make sure the feedback tube is reconnected to both the gas valve and the air-inlet pipe.

Figure 6 shows how the finished product should look.

Figure 6

Carbon Monoxide Poisoning –adding a hole to the air-inlet assembly of a Trinity Tx

boiler, in any location other than the one illustrated, or of a larger diameter, may defeat

the boiler’s blocked vent safety shutoff mechanism, which protects against extremely

high Carbon Monoxide (CO) concentration in the event the air-inlet pipe is blocked.

Failure to correctly follow these instructions may result in serious injury or death.

Feedback tube –RECONNECT

TO BOTH GAS VALVE AND

AIR-INLET PIPE

1/8 in. diameter hole

NOTICE: Hole cannot be larger than 1/8

in.

Table of contents

Other NTI Control Unit manuals

Popular Control Unit manuals by other brands

Lenze

Lenze E94AYCIB Mounting instructions

Digitrax

Digitrax UT1 manual

Emerson

Emerson EX4-6-...FLR Series operating instructions

ARI

ARI D-060 Installation, operation and maintenance

Porsche

Porsche 9Y0.915.686 operating manual

Telit Wireless Solutions

Telit Wireless Solutions LE910C series Thermal Design Guide

NI

NI DAQPad-6016 OEM user guide

Hansen

Hansen MCV Installation, service instructions & parts

GEM

GEM 620 Series Installation, operating and maintenance instructions

ZIEHL-ABEGG

ZIEHL-ABEGG UNIcon CPG AVC Series operating instructions

JS Automation

JS Automation MPC3034A user manual

Etherma

Etherma eNEXHO-IL Assembly and operating instructions