- 8 -

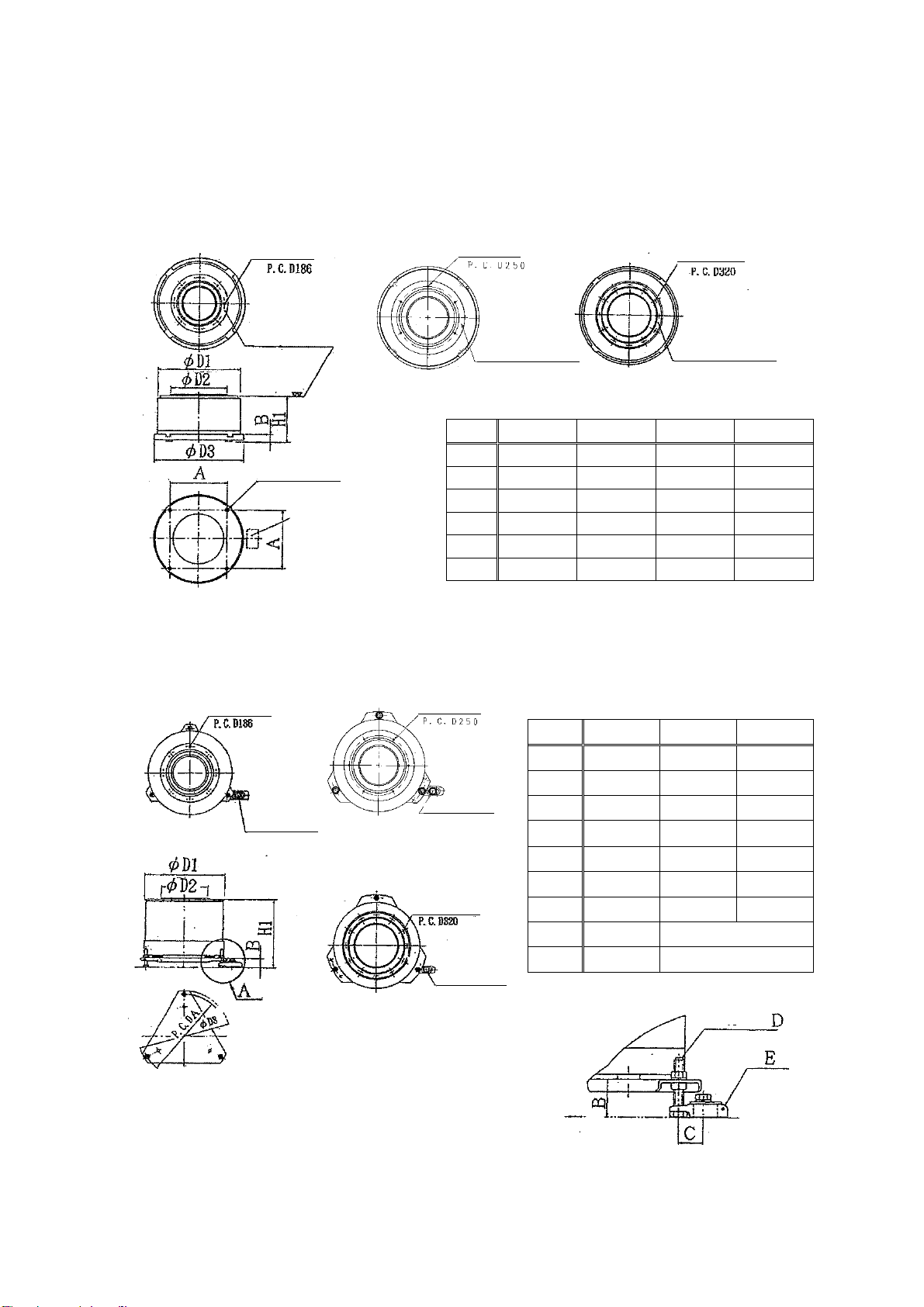

6. Transportation and Installation

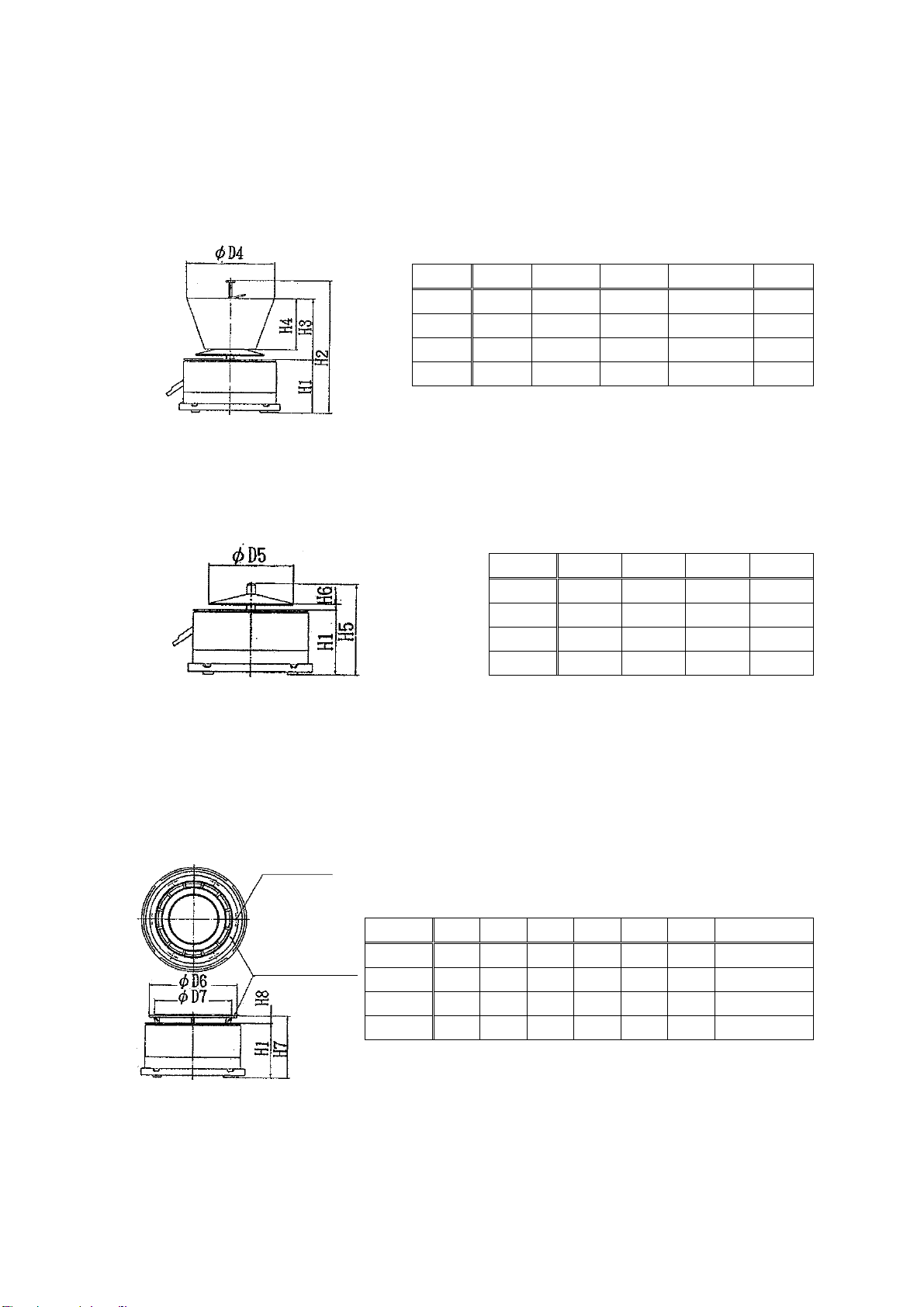

(1) Transportation

[1] When the machine is of a type with M12 nut provided at the bowl center,

relocate the machine with M12 hanging bolts mounted as shown below.

[2] When the machine is of a type with M12 nut not available for use at the

bowl center, relocate the machine with M12 hanging bolts mounted on

the M12 taps for transportation of the lower vibrator as shown.

(Note 1) Pull out the separation bottom, and mount hanging bolts on M12 taps.

(Note 2) Operate the machine with the hanging bolts removed during run.

Precautions for transportation

[1] Use a lifting device and a hoisting accessory of sufficient lifting capacity in considerations of

individual body masses (in the case of a type provided with a bowl, the bowl mass should be

added). For the body mass, refer to Section 10 “Specifications”.

[2] During transportation, be fully careful never to put your hands and feet under the machine body

suspended.

[3] Do not relocate the body while holding the bowl.

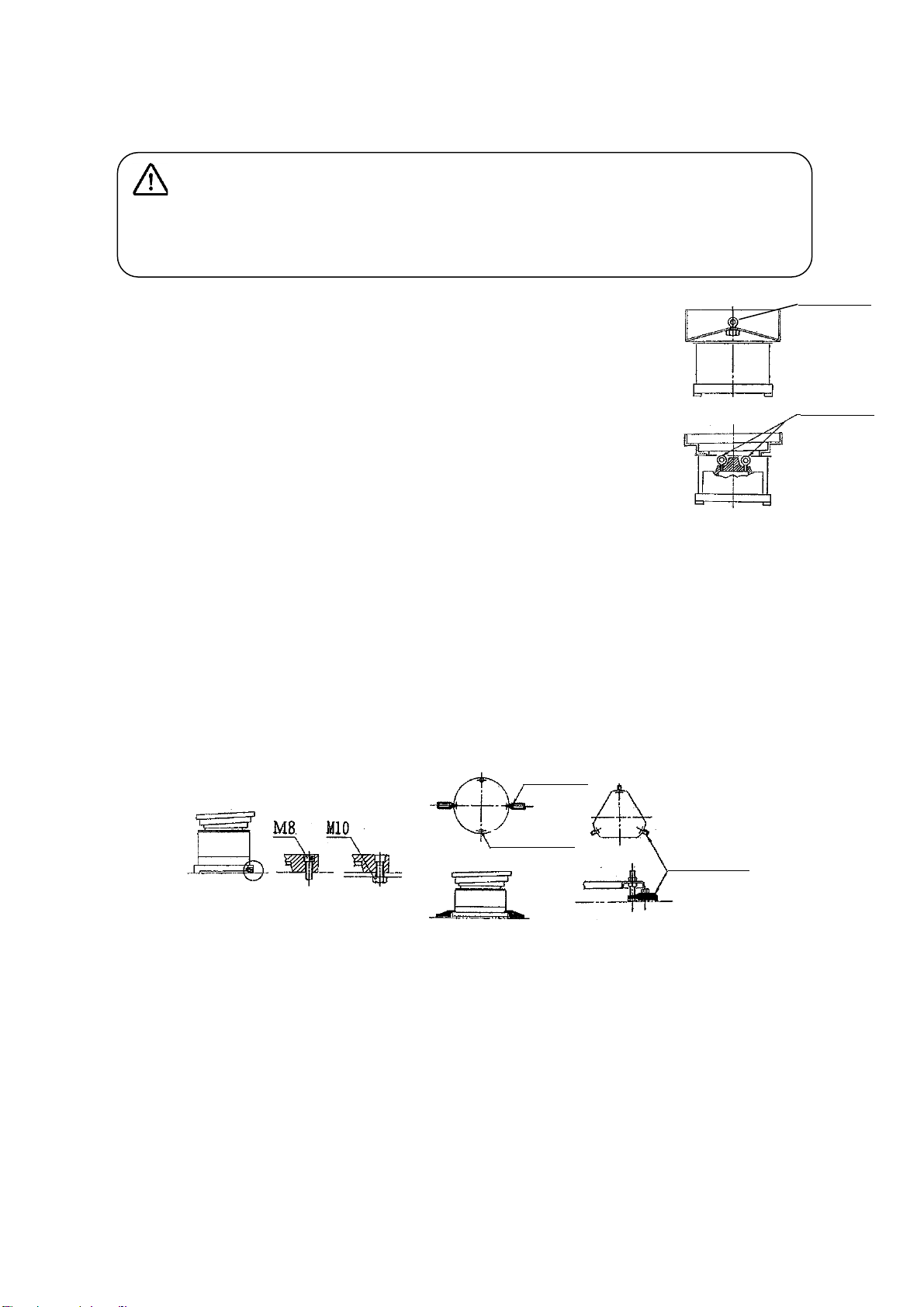

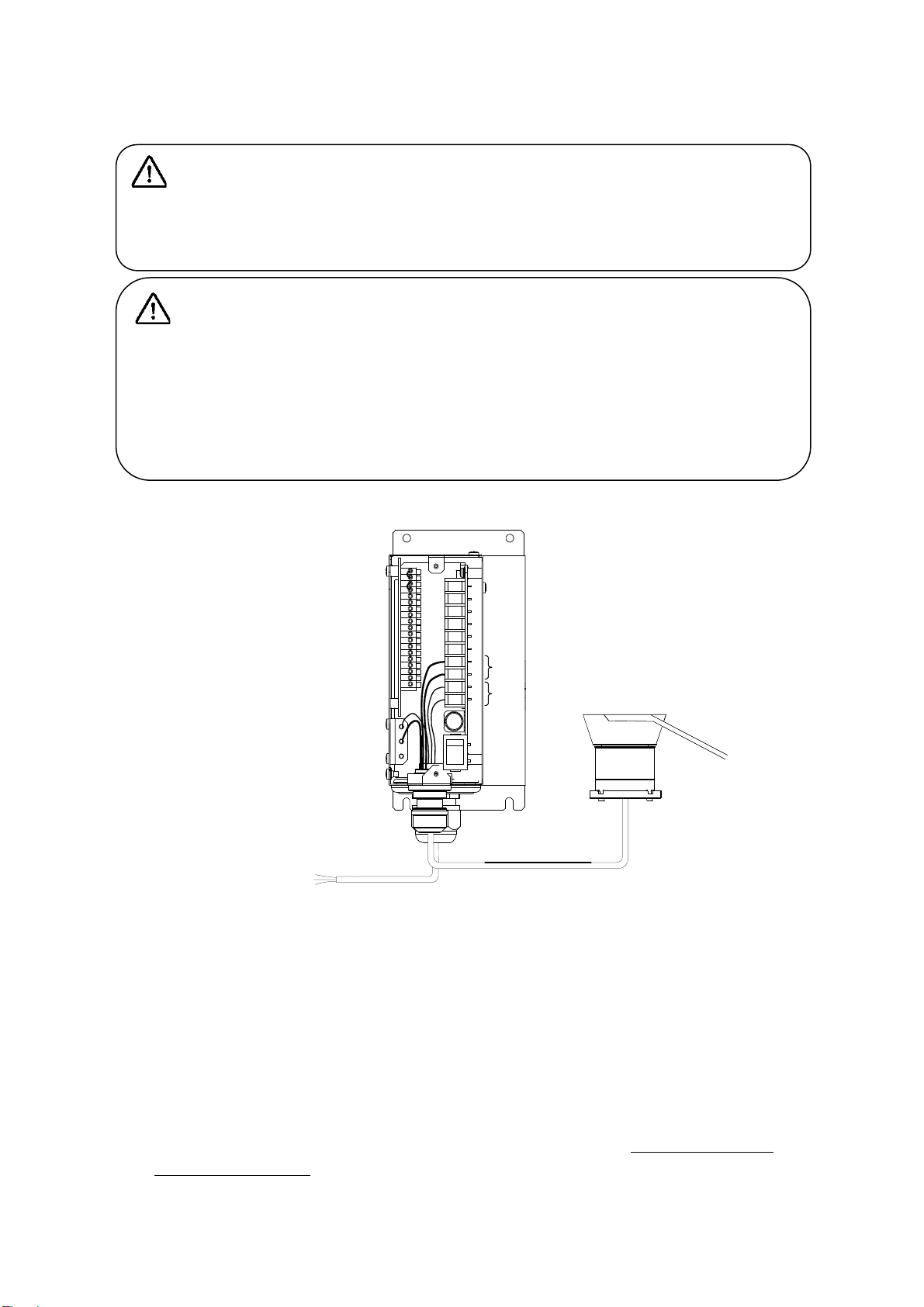

(2) Installation

[1] After installation, fix the product securely using base holes in 4 places (M8 or M10 bolts).

[2] When use of base clamps is intended, set base clamps and setscrews in 2 places each. In the

case of a free set base, set free set clamps in 3 places as shown below.

<Base mounting hole at 4 places>

Precautions for installation

[1] Assemble and set the machine with sufficient care paid to defects such as deformation of the

bowl and the alignment mechanism.

[2] Wear safety gloves to prevent bare hands from coming into contact with sharp edges of the

bowl and the alignment mechanism.

[3] Do not operate the machine on a base with insufficient strength or in an unstable place.

[4] Be careful not to fix the machine with its vibrating part (other than the base) in contact with

other parts.

[5] When the machine is inclined in installation, specified capability cannot be obtained. Be sure to

level the machine.

[6] When execution of welding work or grinding work is intended in vicinity of the bowl feeder, fit

a protective cover to the entire bowl feeder. Otherwise, infiltration of iron powder or the like

into the machine to spoil its performance.

CAUTION

machine is heavy. When required, transport

the machine carefully with a hoisting

accessory mounted as shown below. Note carefully that serious accident may result

when the machine is dropped.

P0801 (for N32 and