Models NOL/NOR Modulating Revision 101199BPage 8

II

II

INTRODUCTIONNTRODUCTION

NTRODUCTIONNTRODUCTION

NTRODUCTION

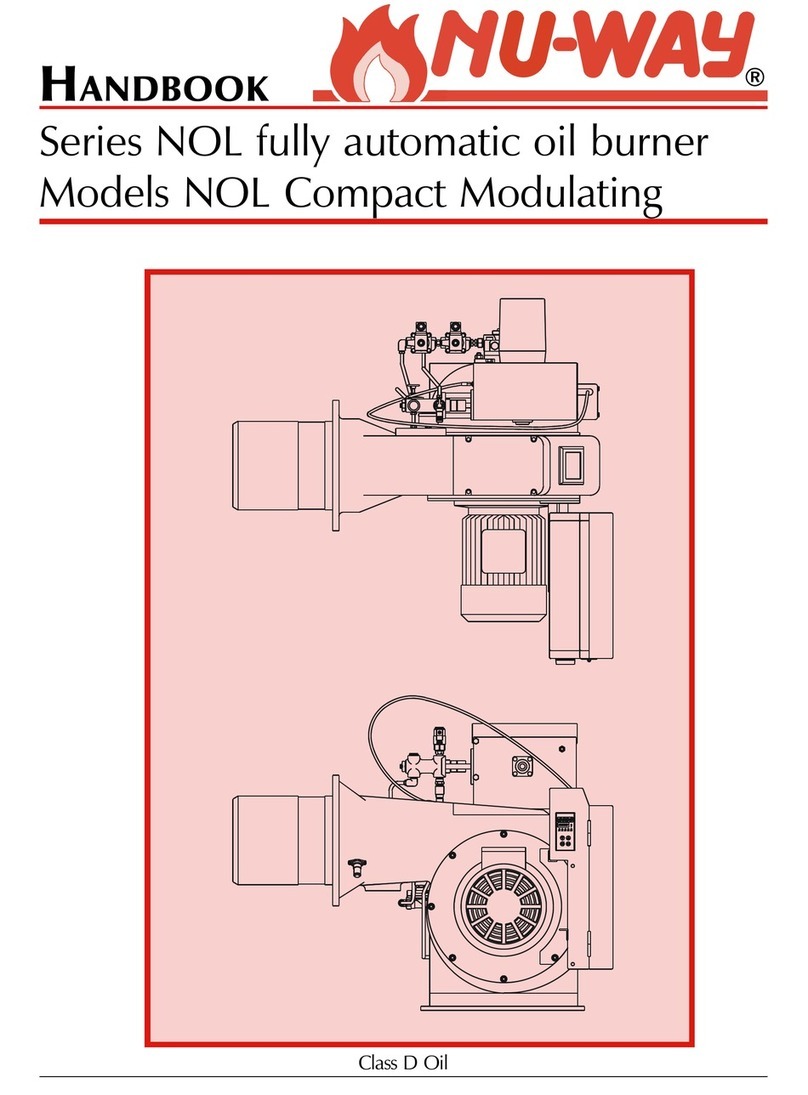

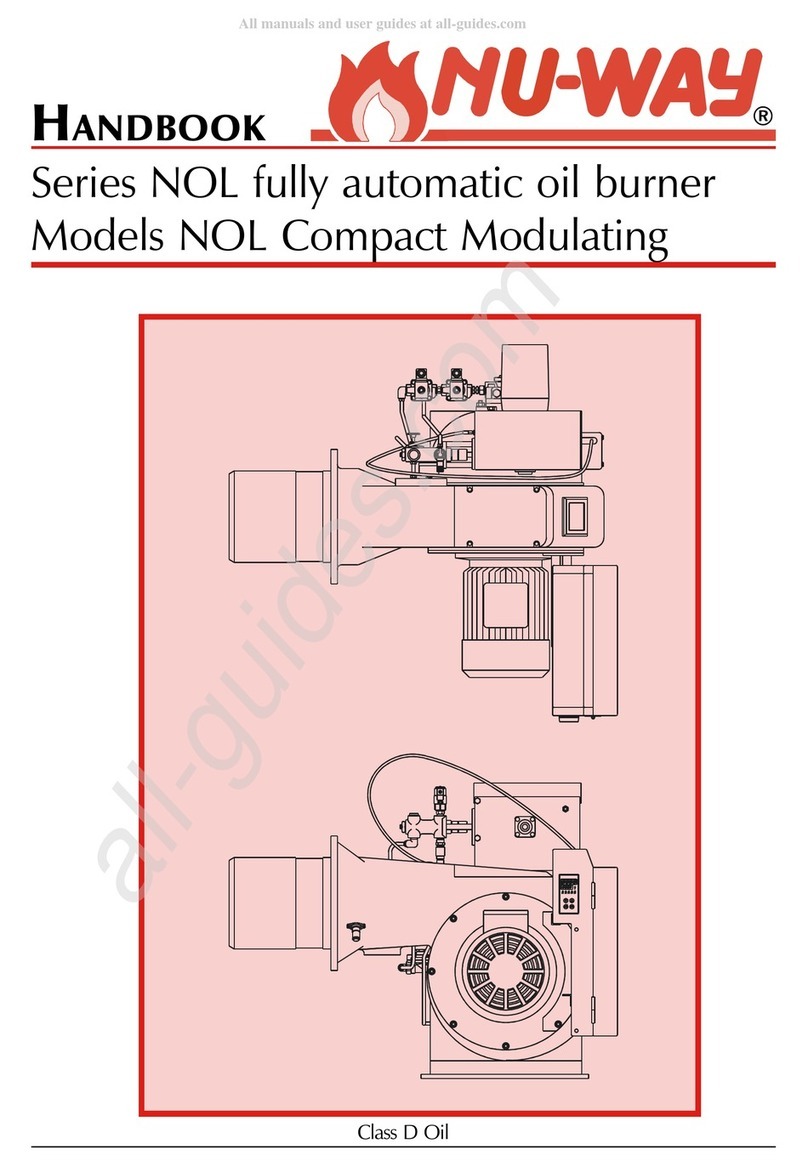

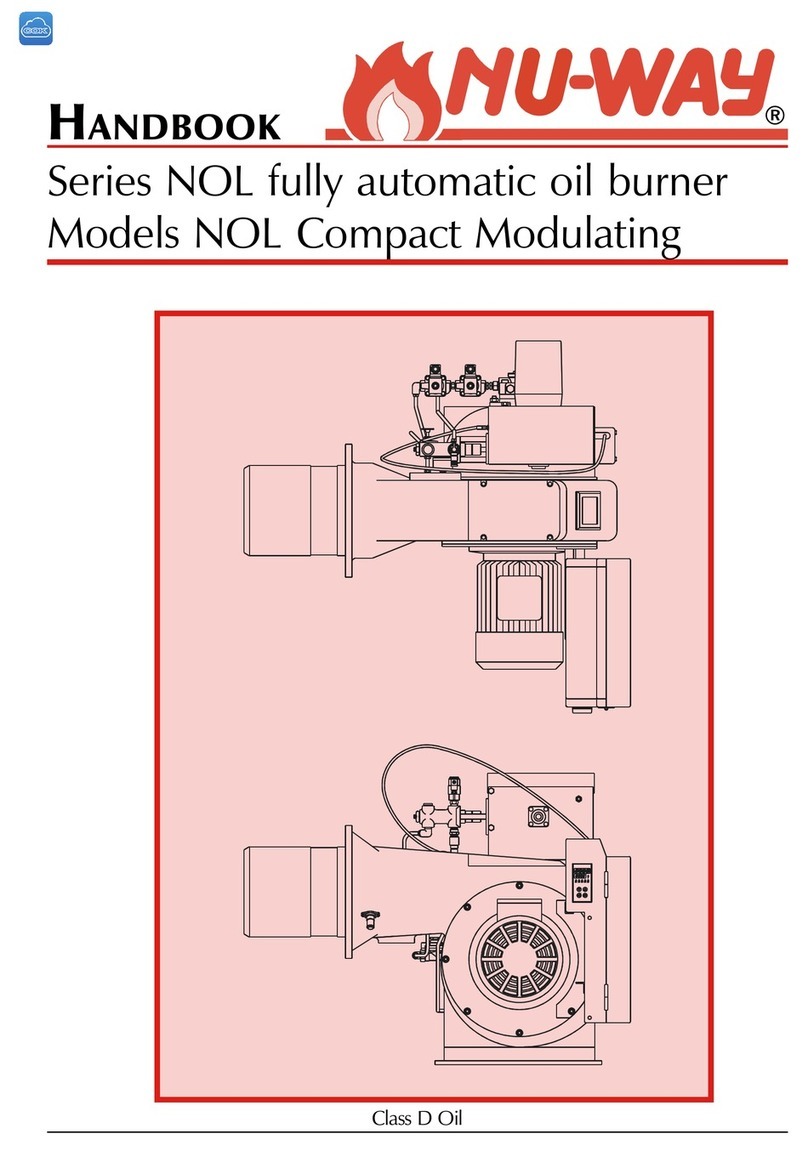

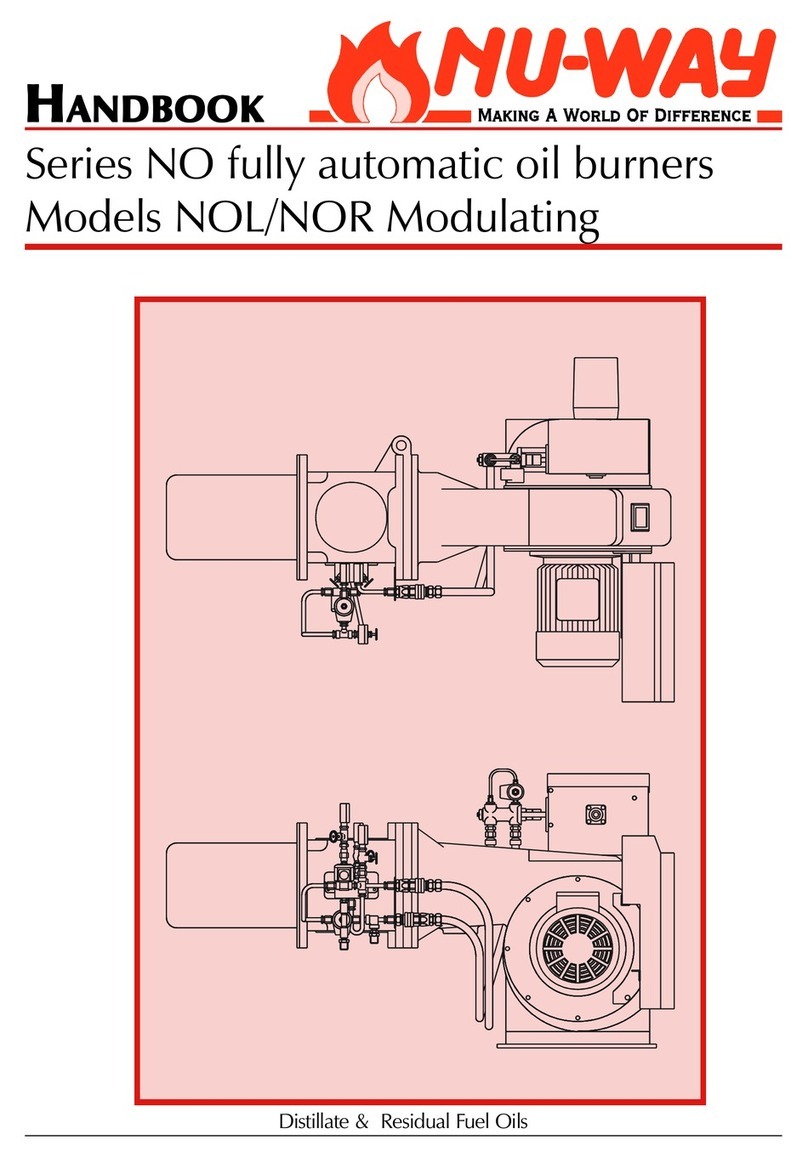

This manual has been produced to enable users

to install, commission and use NO Modulating

burners safely and efficiently. The manual covers

two types of burner: Models NOL distillate (Class

D fuel) oil burners and models NOR residual (Class

E, F & G) oil burners. At each stage the conditions

which should be met and the adjustments and

other actions which should be carried out are de-

tailed and the locations of the various components

and adjustment mechanisms are identified. Where

appropriate, this information is supported by ta-

bles and graphs. Literature on the proprietary com-

ponents used in NO Modulating systems is avail-

able on request.

FF

FF

FEAEA

EAEA

EATURESTURES

TURESTURES

TURES

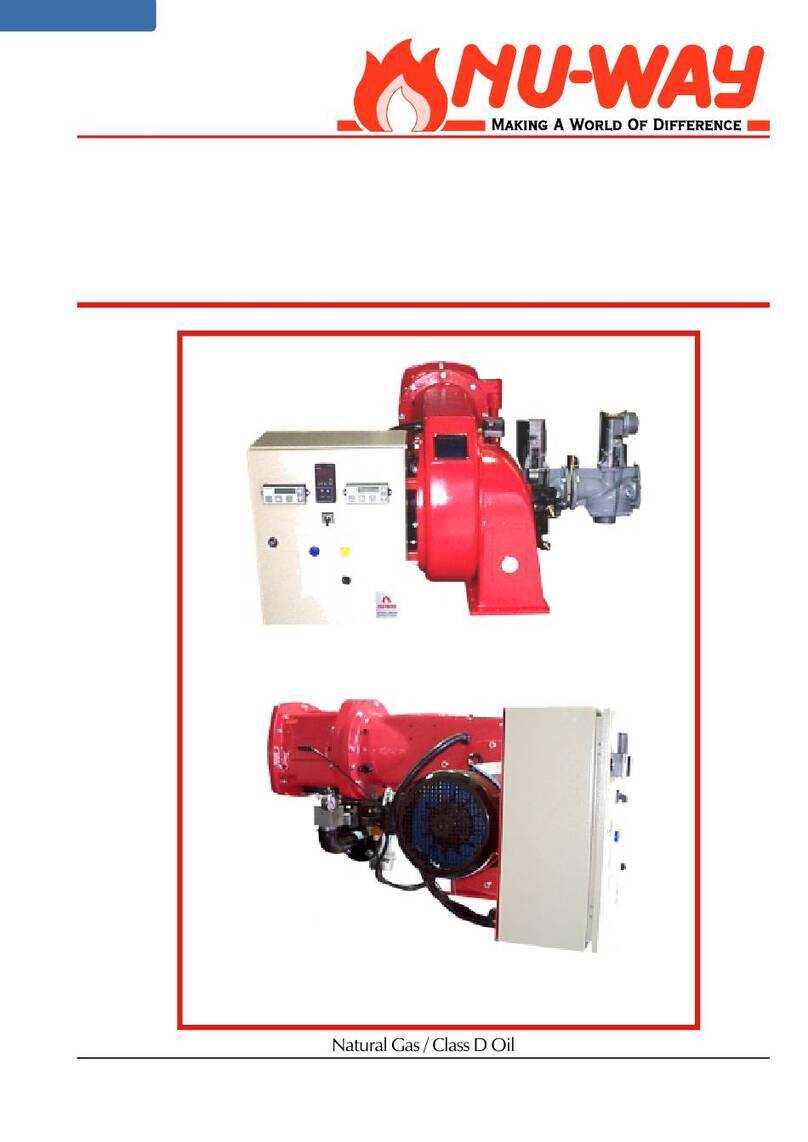

Developed through extensive field experience in

the UK and overseas markets, the NO Fully modu-

lating series meets the current known test author-

ity requirements in these markets and sets new

standards in efficient and reliable operation. NO

Modulating burners are designed for flange mount-

ing to the appliance front plate and they are deliv-

ered ready to install with a pre-wired packaged

control system and oil pumping or pumping & heat-

ing unit.

Burner Nominal Capacities

NO18 (2 Models) 530 kW 42.0 kg/h

NO35 (2 Models) 940 kW 74.0 kg/h

NO50 (3 Models) 1750 kW 138.0 kg/h

NO60 (3 Models) 2100 kW 165.5 kg/h

NO85 (1 Model) 2432 kW 192.0 kg/h

NO100 (2 Models) 2930 kW 231.5 kg/h

NO125 (3 Models) 3668 kW 290.0 kg/h

NO150 (3 Models) 4396 kW 347.0 kg/h

Controls and Safety Systems

NO Modulating burners are fitted with an auto-

matic sequence / flame failure control and photo-

electric cell for continuous flame supervision. A

combustion air flow control coupled to an oil noz-

zle pressure control system ensures smooth start-

ing and optimum operating effeciency.

Operating Mode

In standard form the NO Fully Modulating burner

can provide a turndown range of up to 3:1.

Fuels

NO burners covered in this manual are designed

to fire distillate and residual fuel oils, which com-

ply with the specifications given in the tables on

page 10. NO burners configured for firing other fuel

grades may be available on request.

SS

SS

SITEITE

ITEITE

ITE CC

CC

C

ONDITIONSONDITIONS

ONDITIONSONDITIONS

ONDITIONS

ANDAND

ANDAND

AND SS

SS

S

ERVICESERVICES

ERVICESERVICES

ERVICES

Flue and Chimney Requirements

It is important that:

The flue pipe from the appliance and the

joint between this flue and the chimney are

sealed to prevent leakage of combustion

products.

The flue pipe from the appliance does not

protrude into the chimney beyond the inside

wall.

The top of the flue or chimney shall be higher

than any roof within a radius of 10 metres.

Checks are made to ensure that the chim-

ney is suitable for oil fired appliances and that

the proposed installation complies with all

Local Authority and other regulations cover-

ing such installations.

If more than one appliance is connected to

a common flue or chimney the cross-section

of this flue or chimney should be adequate

for the total volume of combustion products

from the appliances. It is recommended that

each appliance should be exhausted into a

separate flue.

Plant Room Ventilation

The burner must be supplied with dust free air at

sufficient rates for all firing conditions, in accord-

ance with the appropriate standards.

Existing Appliances

The appliance should be prepared for installation

of the NO burner by thorough cleaning, including

the removal of all adhering tar, scale and dirt. An

inspection should also be carried out to ensure

that the appliance is in good condition. Any doubt

about the appliances suitability for oil firing shall

be referred to the appliance manufacturer.

Combustion Chamber Conditions

The combustion chamber conditions should not

exceed those shown on page 27 of this manual.