Smart ‘S’ TWINFAN CONTROL Installation and Maintenance

3

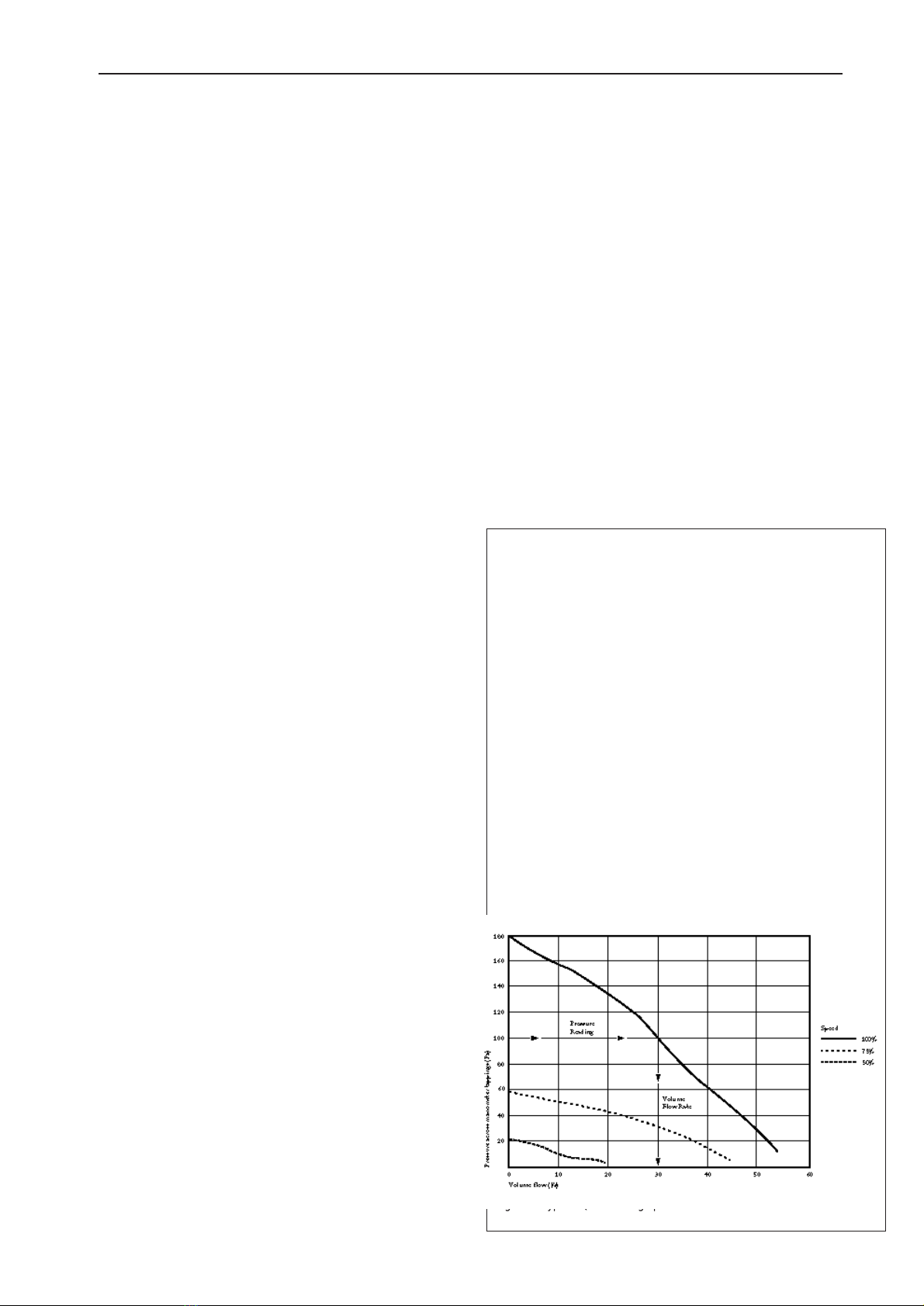

Fig. 4. A typical Quietwin graph

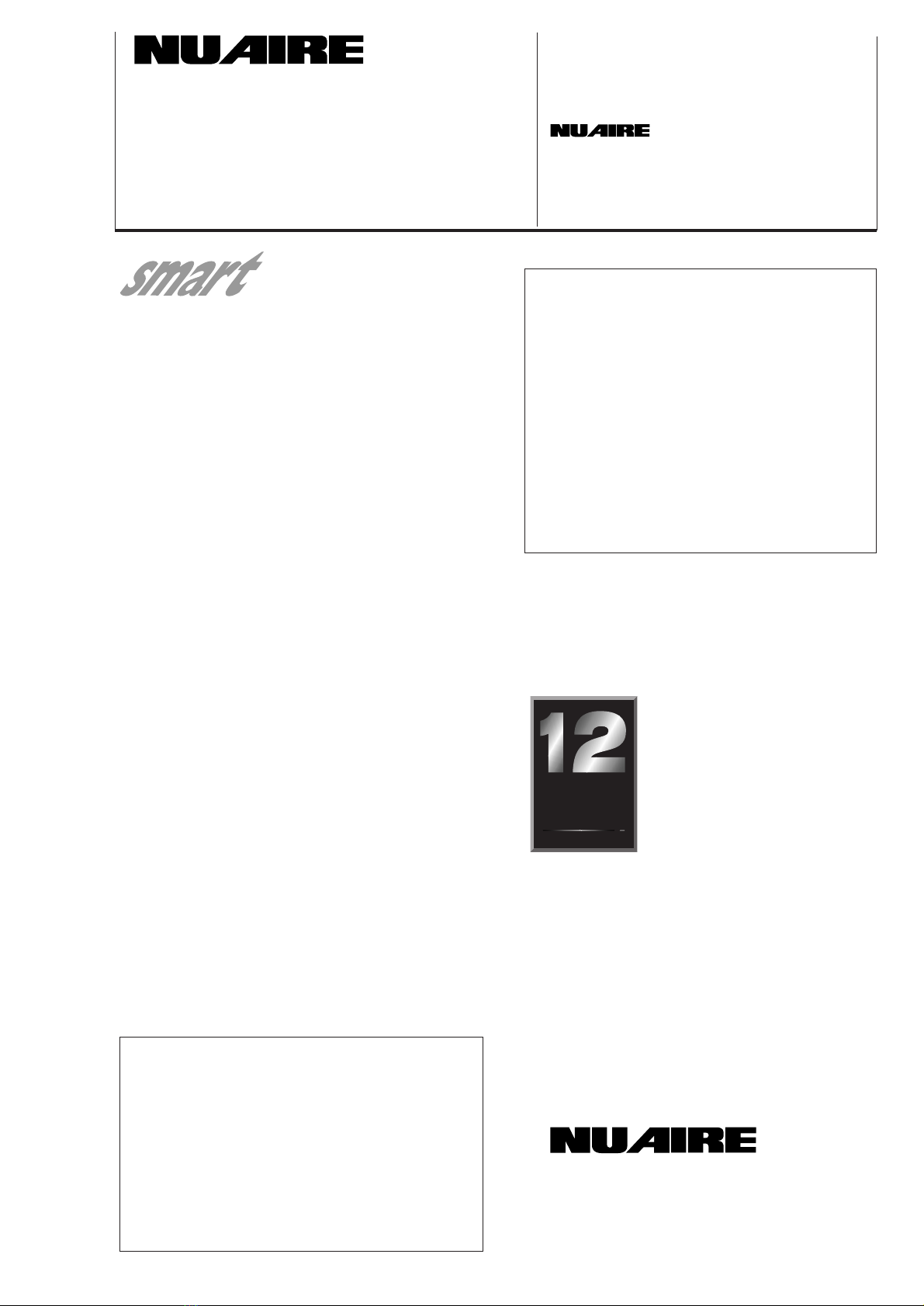

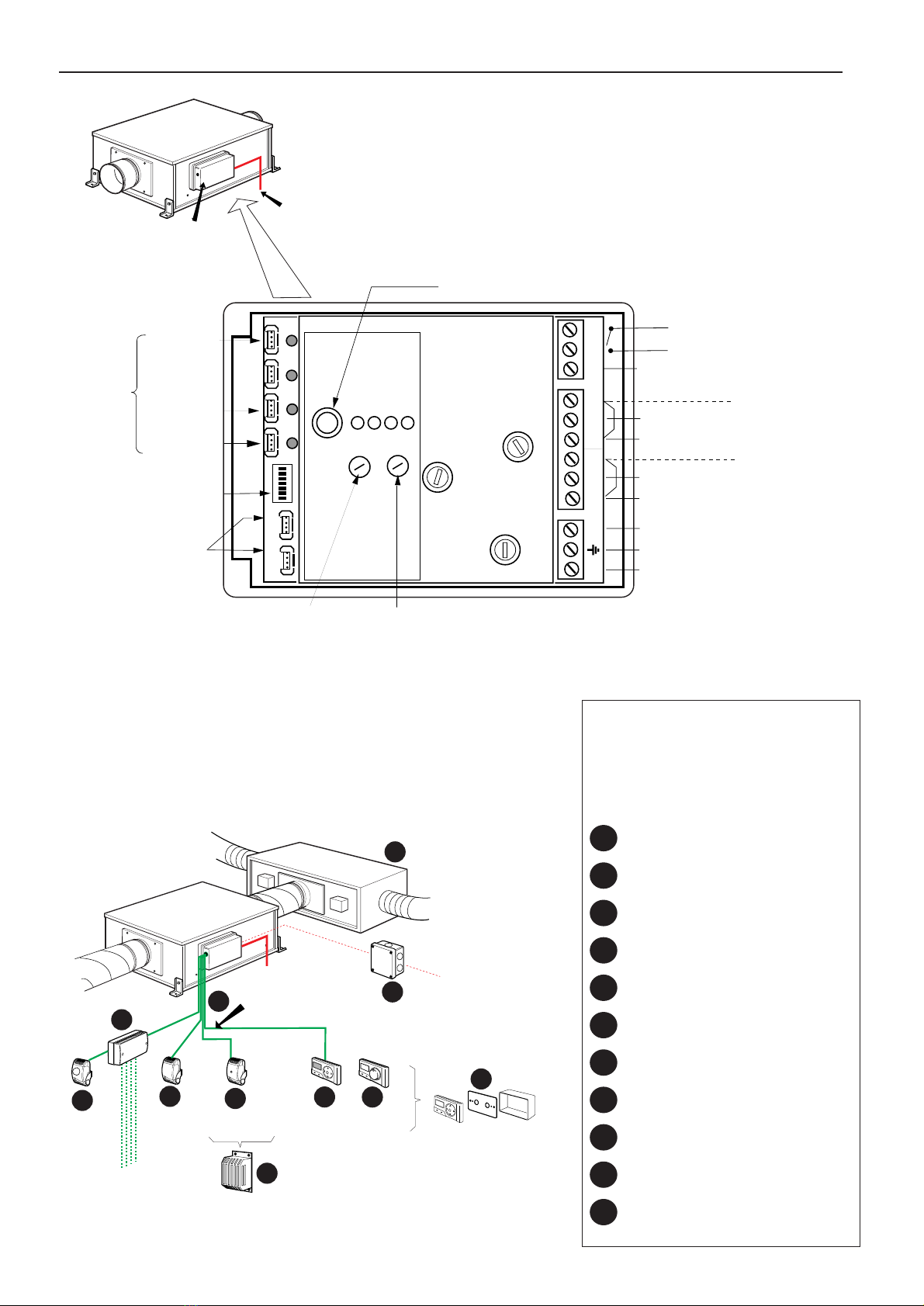

Commissioning Procedure (see fig. 2).

1. Switch on the supply to the QTI Quietwin fan.

2. Locate the control module panel Care must be taken if

the module has any covering panels removed as live

230v incoming supply terminals may be exposed.

Note covers MUST be properly replaced when commission

ing has been completed.

3. Wait approximately 60 seconds for the system to complete

its self test’

4. Press the step sequencing button several times until only

the ‘FAN 1’ light is illuminated and the ‘AUTO’ light is

off. (See detail of control panel Fig. 2).

5. Connect a manometer across the tappings provided on the

outside of the fan casing. Reading the manometer and using

the graph, determine the airflow. The fan is factory set at

full speed. Using the rotary graduated control,reduce the

speed to the desired setting (may require a screwdriver).

NOTE: allow 30 seconds for the fan to reach the set speed.

6. Set the Run on timer control. (Adjustable 5-60 min).

(See detail of control panel Fig. 2).

7. Press the step button through the sequence until ‘AUTO’

light shows.

COMMISSIONING IS NOW COMPLETE.

Using the graphs

(SPECIFIC GRAPHS FOR YOUR

QUIETWIN FAN ARE SHOWN IN THE

FAN INSTALLATION & MAINTENANCE

LEAFLET).

The graphs are designed to assist you in establishing an AIR

VOLUME FLOW RATE for your fan installation.

The curves shown indicate performance at 100%, 75% and 50%.

Assuming that the ventilation system is installed and the fan is

connected to all ductwork. Connect a manometer across the

tappings provided on the outside of the fan unit casing.

The fan is factory set for full speed. With the fan operating at this

full speed (100%) take a pressure reading in Pa from the

manometer. Refer to the relevant graph for your size of unit and

with your Pa figure, read across the graph to where the line

intersects the 100% curve.

Drop a line vertically down from this point and the air volume

flow is indicated on the base line of the graph.

See the fan Installation & Maintenance leaflet supplied.

Using the Step button (see fig 2).

Refer to the label on the controls inside cover for more guidance.

Pressing the step button will sequence through the options and

change the modes as follows:

1. FAN 1 in manual mode (used for commissioning)

2. FAN 2 in manual mode (used for commissioning)

3. SYSTEM OFF

4. SYSTEM IN AUTOMATIC (normal selection)

To clear a fail, press the STEP button until the fail has cleared.

IMPORTANT After commissioning, press the STEP but-

ton through until AUTO is illuminated.

System is now in automatic mode.

EXTERNAL USE QUIETWINS WITH THE SMART

CONTROL OPTION ARE PROVIDED WITH A COM-

MISSIONING BOX ON THE OUTSIDE OF THE CASE

The main control module is inside the fan (See fig 5).

Control Module Connections /Inputs and

their uses (see fig 2)

SENSOR INPUT 1:

This is the Master on/off control input and is usually ‘linked out’

with a special plug unless:

A Timeclock can be connected into this input e.g. ST-TC

During ON times the unit is allowed to operate.

During OFF times the unit is off- zero duty.

Note: The ST-TC Timeclock must always be plugged into the fan

mounted control module NOT into a ST-JB junction box.

SENSOR INPUTS 2, 3 & 4

Any sensor can be connected to these inputs to allow activation

of the unit. If any of these inputs is activated, the unit will run at

the maximum set duty. These sensors include ST-PIR,

ST-HUM, ST-TEMP.

Note: Additional sensors may be added by using an ST-JB Junction Box.

SWITCH LIVE terminals

This acts just like the sensor inputs 2,3,4. If 230v ac is detected

on the SW - Live terminals, the unit will run at the max. set duty

DAMPER terminals (2 sets)

When the fan is running at full duty, both these damper connec-

tions will be activated. i.e. power will be available on the OP

terminals of the damper connections. The fan will not go to full

duty until the RET terminals have 230v ac (Limit Switch).

FAILURE RELAY

This relay is normally closed when there are no faults. When

faults occur this relay will open and break the circuit. This

method of operation allows all types of failure to be detected for

example ‘Power failed’, ‘Fan/s fail.

This connection is a volt free switch. it can handle power up to

5A (230v) and is fused for protection.

NO FAULT: The volt free switch is closed i.e. the two

terminals are connected.

FAN FAULT: The volt free switch is opened. i.e. the two

terminals are disconnected.