SIMPLY PRECISE

Index

1. Features and Applications .................................................................................................... 4

2. Safety ...................................................................................................................................... 5

2.1 General Information ..................................................................................................... 5

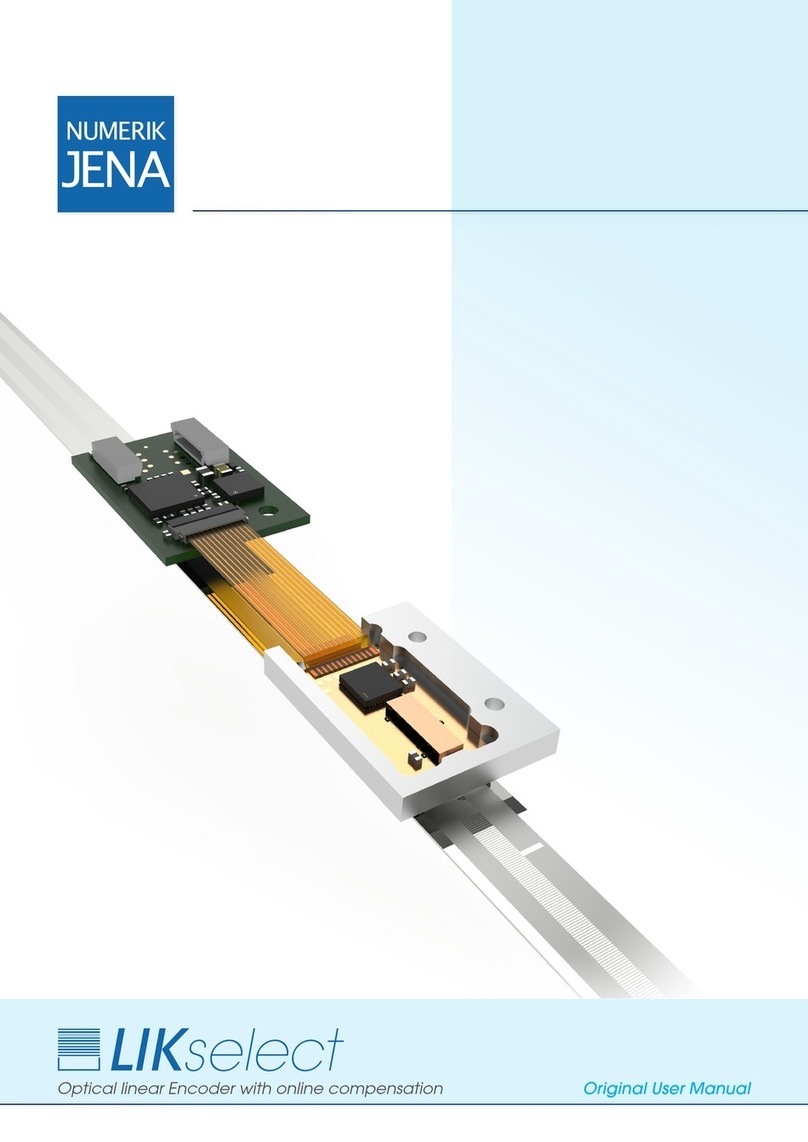

2.2 Notes on Legal Requirements ..................................................................................... 6

2.3 Notes on Transport, Storage and Handling .................................................................. 7

2.4 Notes on Operation ...................................................................................................... 8

2.5 Notes on Maintenance ................................................................................................. 8

3. Setup of the Vacuum Encoder .............................................................................................. 9

4. Grating Disks ....................................................................................................................... 10

4.1 Grating Disks - Types ................................................................................................. 11

5. Scanning Head ..................................................................................................................... 12

6. Technical Data ...................................................................................................................... 13

6.1 ResolutionandAccuracy(Denition) ......................................................................... 13

6.2 Resolution .................................................................................................................. 13

6.3 Accuracy .................................................................................................................... 13

6.4 Mechanical Data ........................................................................................................ 14

6.5 Calculation of the Attainable Speed of Rotation ......................................................... 14

6.6 Electrical Data ............................................................................................................ 15

6.7 Switch-On Behaviour ................................................................................................. 15

6.8 Ambient Conditions .................................................................................................... 16

6.9 Cable .......................................................................................................................... 16

6.10 Connector .................................................................................................................. 16

6.11 Pin Assignment .......................................................................................................... 17

6.12 ElectromagneticCompatibility(EMC) ........................................................................ 18

6.13 Shielding Concepts .................................................................................................... 19

6.14 Voltage Output 1 VPP .............................................................................................................................................................................. 20

6.15 Square-Wave Output RS 422 .................................................................................... 21

6.16 OnlineCompensation(OffsetandAmplitudeControl) ............................................... 22

7. General Mounting Instructions ........................................................................................... 23

7.1 Delivery Contents ....................................................................................................... 23

7.2 Encoder Mounting Position ........................................................................................ 23

7.3 Mounting of the Encoder System ............................................................................... 24

7.4 Dimensions and Mounting Tolerances ....................................................................... 25

7.5 Mounting of the Grating Disk ..................................................................................... 27

7.6 Mounting of the Scanning Head ................................................................................. 31

2