AV44 Solid Shaft Incremental Encoder 2Rev: 003

With a direct drive, use a flexible disc coupling and align the shafts as

accurately as possible. For motors with a pre-aligned flange, it is also

acceptable to use a “spider” or “jaw” coupling type. If a rubber slinger

disc is used, position it on the shaft so it will rotate freely.

CAUTION

Do not force or drive the coupling onto the shaft, or damage

to the bearings may result. The coupling should slide easily

on the shaft. Remove nicks and burrs if necessary. Consider

driving shaft endplay & axial movement when positioning

coupling.

NOTE

Care must be taken to eliminate the potential for coupling

failures due to motor/encoder shaft misalignment. In

addition to coupling failures, misalignment can cause

excessive axial pressure &/or vibration which can result

in bearing damage. A typical installation should have max

0.001” [0.025mm] motor shaft/stub shaft Total Indicated

Runout (TIR). Alignment of motor and encoder shaft should

be ensured by precise fitment between mounting flange

and motor face, and between mounting flange and encoder

flange.

NOTE

Follow coupling manufacturer’s instructions for Max RPM,

Misalignment Tolerance, Installation Instructions, and other

pertinent guidance.

ENCODER MOUNTING INSTRUCTIONS

(When used with“flowerpot”/”coupling guard” type mounting flange)

1) Disconnect power from equipment and encoder cable.

2) Use dial indicator gauge to verify the motor shaft Total Indicated

Runout (TIR) 0.001” [0.025mm]

3) Place coupling on motor shaft, inserting to depth and affixing per

manufacturer’s instructions.

4) Attach/Affix coupling to motor shaft using set screws per

manufacturer’s instructions.

5) Slide encoder shaft into other side of coupling. DO NOT FORCE.

6) B10 flange with 11mm shaft with keyway: Align and affix per

coupling manufacturer instructions.

6.a) PY flange with 10mm shaft with flat: If coupling utilizes set

screw, ensure coupling set screw aligns with the flat on the shaft.

Affix per coupling manufacturer instructions.

7) Ensure C-Face on mounting flange matches and aligns with

encoder C-Face precisely.

8) Apply thread locker to socket head cap screws (supplied).

9) Align bolt holes of encoder flange and the mounting flange

(“flowerpot”), thread in socket head cap screws.

Torque to 5 ft-lb [7 N-m].

10) Tighten fasteners on encoder side of coupling per manufacturer’s

instructions.

NOTE

Both PY and B10 versions can be adapted for foot-mount

mounting. Contact factory for options.

WIRING INSTRUCTIONS

CAUTION

Disconnect power before wiring the encoder

12.a) For units with factory-installed connector(s) (such as M23/12-pin

& M12-8 10 Pin MS) connect cable as shown in wiring diagram.

12.b) For units with factory-installed cable, terminate as required per

local installation.

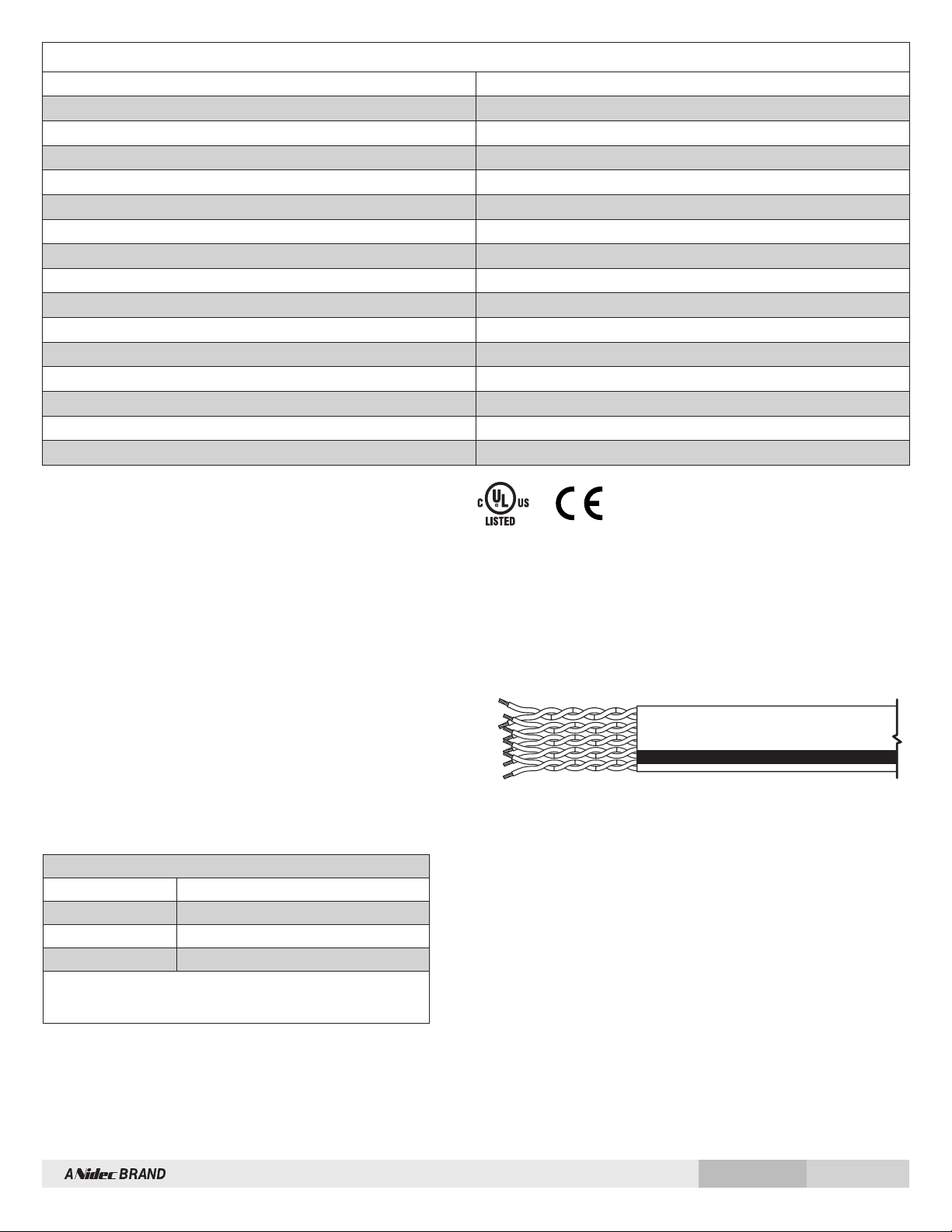

12.c) For unwired units remove encoder cover, and:

12.c-i) Strip cable and wires per illustration.

12.c-ii) Fold cable shield back over the claw.

12.c-iii) Remove the sealing nut, claw, and seal from the cable gland

and pass cable through the nut, claw and seal in the order in

which they were assembled on the encoder housing.

12.c-iv) Slide seal inside claw and pass wires through cable gland.

12.c-v) Connect wires according to pinout diagram on encoder label.

12.c-vi) Re-tighten sealing nut onto cable gland.

12.c-vii) Replace rear cover onto the encoder.

NOTE

The internal Terminal Strip is a Push-In type with 45° wire

entry. Wires can be removed from the Terminal Strip by

depressing the tab at each connection.

CAUTION

Trim wires to minimize excess length, as space inside the

encoder is limited.

13) Apply power to the encoder.

The AV44 encoder can be wired for single phase or two-phase

operation, either with or without complements, with or without markers.

See connector options and wiring diagrams.

CAUTION

When wiring for differential applications (A, /A, B, /B, Z, /Z),

A and /A should be wired using one twisted, shielded pair;

B and /B should be in a second pair, etc. Failure to use

complementary pairs (say, using A and B in a twisted pair)

will reduce noise immunity significantly.

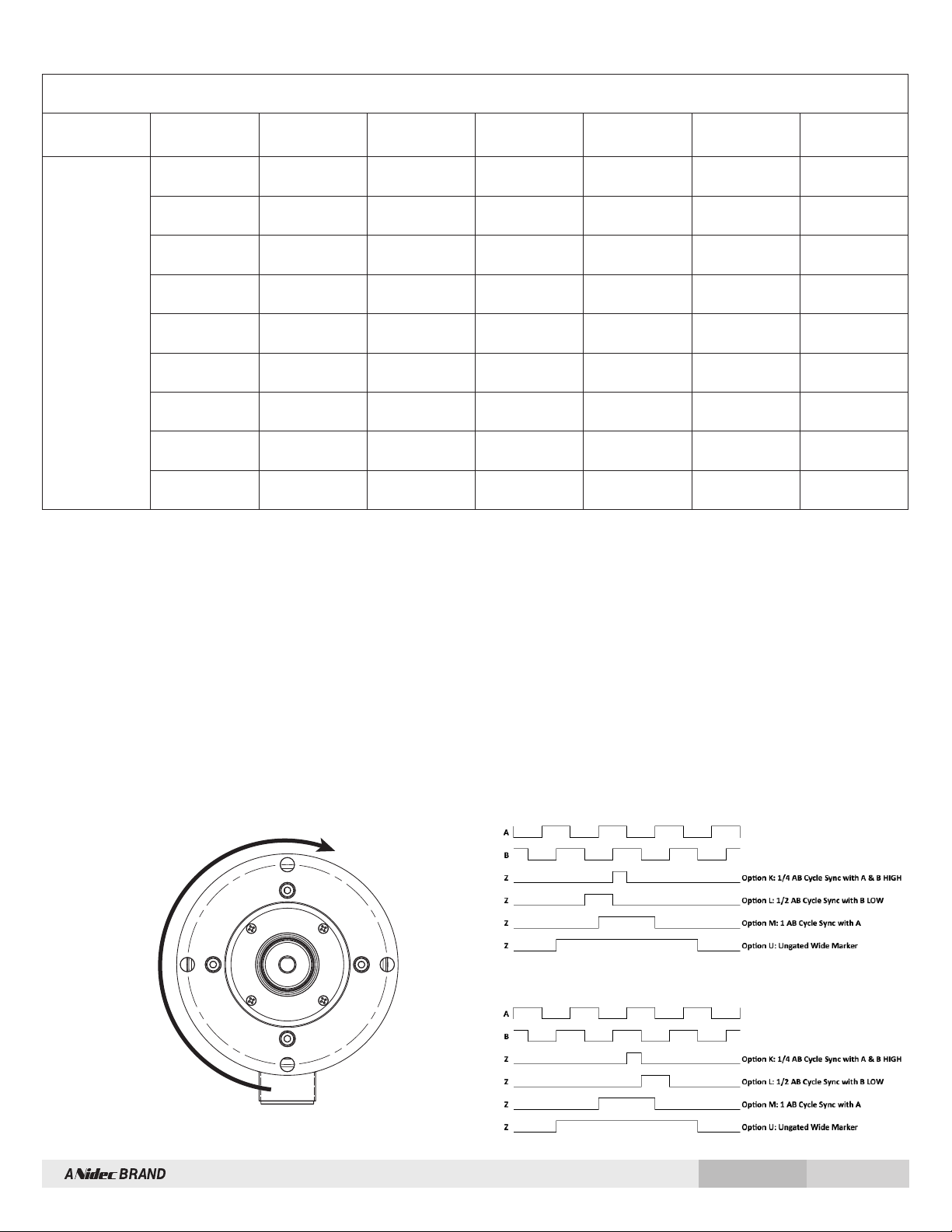

For encoder output that correctly reflects the direction of rotation, proper

phasing of the two output channels is important. Phase A channel leads

phase B channel for clockwise shaft rotation as viewed from the load

side of motor for standard phasing options. Follow instructions under

corrective installation as needed to reverse the direction of output or

purchase AV44 with reverse phasing (Connector options “B”, “3”).