Page 4 of 15

1. General

While selecting the location for the balancer always consider the regulations and instructions of

the Accident Prevention & Insurance Assocation as well as the requirements of the national

working regulations.

The wheel balancer can be located on each flat ground. A fastening of the machine is not

compulsory. For balancing wheels with a weight of more than 40kg, everything is prepared to fix

the machine with dowels on the ground.

Because of logistical reasons the wheel balancing machines are fragmented in their main

components and packed in special cartons.

The main components are:

- Machine including mid centring device mounted

- Touch PC (for BM x5 – types only)

- Wheel cover/hood

- Weight tray (for BM x5 – types including monitor boom)

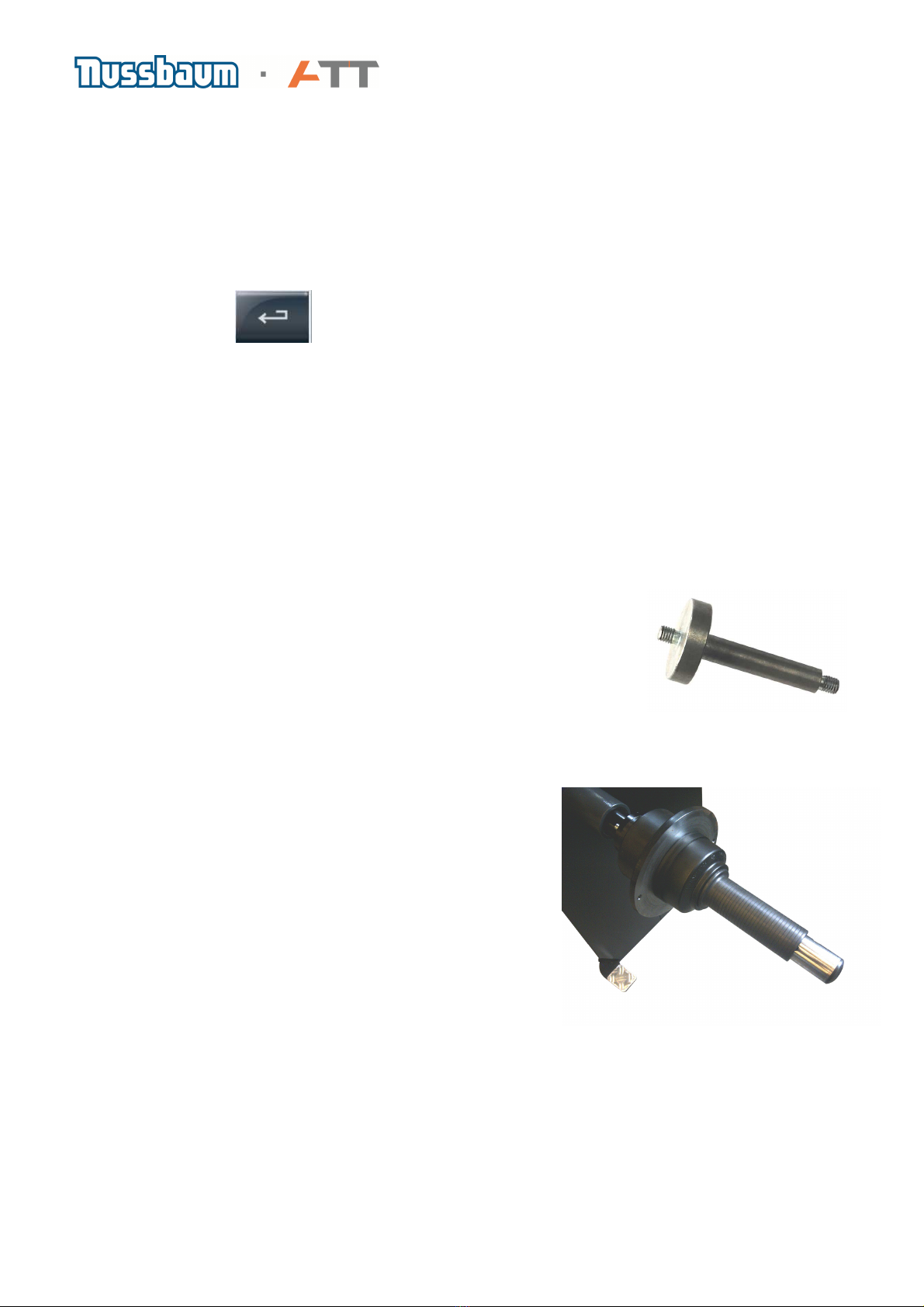

- Carton with documentation, Weight pliers, wheel weight removal tool, cones, quick nut (clamping

sleeve for QuickSpan

models), pressure cup for steel wheels, distance ring

2. Assembling the machine

The unpacking, built up and the mounting should be done practically by 2 persons.

After put up and fixing the machine, it has to be positioned on the 3 marked points. If this is not

the case, this has to be compensated with special parts which have to be lay underneath the

marked points (the machine has to be positioned on this points).

Lift up the machine on the pallet and turn it 180° around a corner. Then dump it on the ground.

Pull out the pallet underneath the machine and position the machine smoothly.

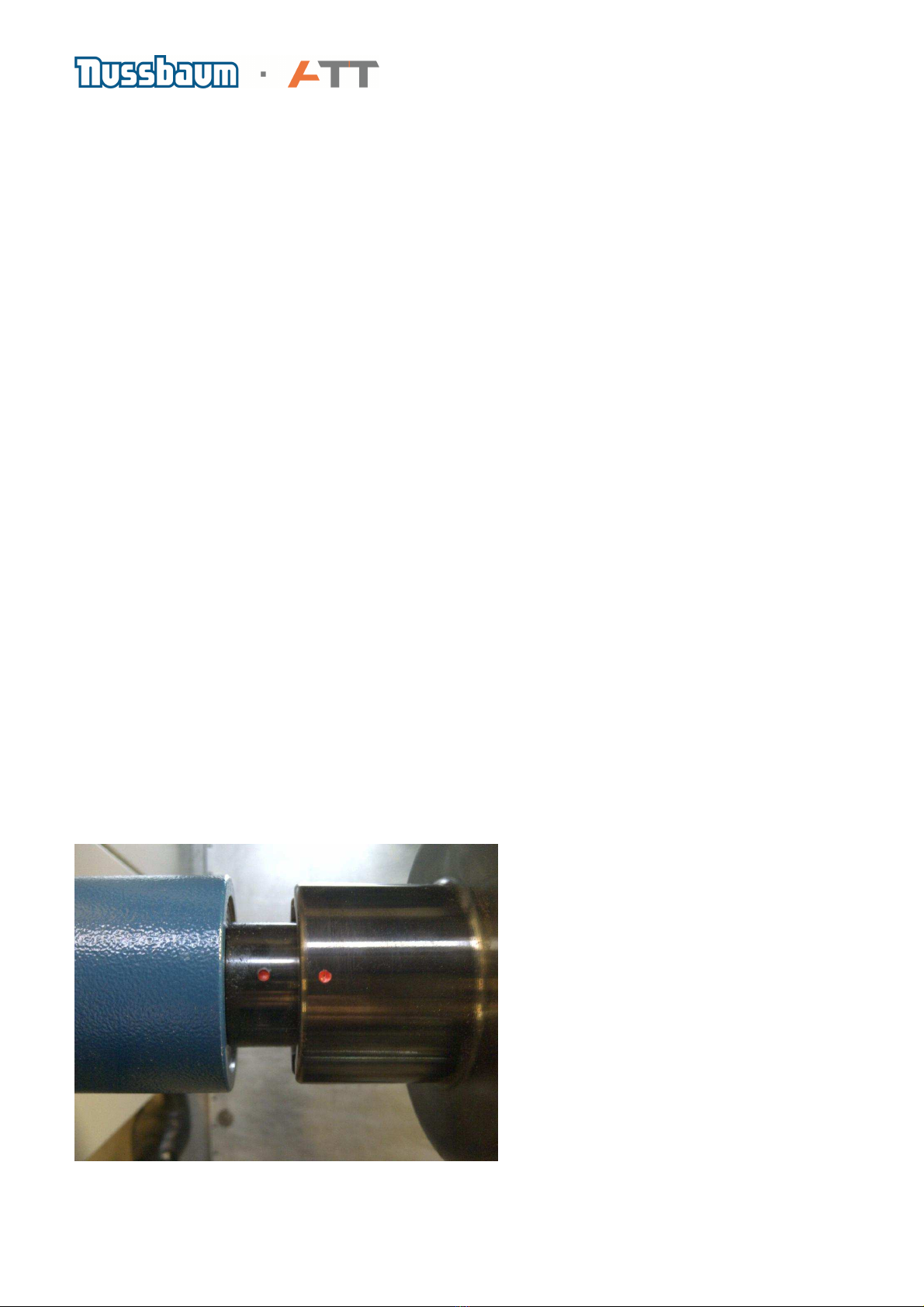

Make sure that the mid centring device is mounted correctly and the 2 red dots (1 on the shaft and

1 on the mid centring device) are in line to each other as shown in the picture below