77

2

CHAPTER

TWO

Chapter 2: Installation

Note: OceanLED makes every eort to protect our marine and fresh water

environment as well as our natural resources. Please take care to keep packaging away from

and out of the water by ensuring loose packaging materials are secured and not susceptible

to being blown into the water. Please recycle all packaging materials as the sustainability of our

environmentiseveryone'sresponsibility.

WARNING: Ensure mounting location is flat and check internally for ease of access or if there is a rib, strut,

stringer or other hull

irregularity

that may interfere with the installation.

WARNING: Never use power tools to secure your lights; hand tighten only.

WARNING: we recommend you use screws provided. If alternative screws are used, do not use counter sunk or

non flat shoulder screws to secure your lights to the hull.

WARNING: OceanLED recommends dry fitting all products. When installing, be sure that the light fits the area

and secures to the hull using the appropriate hardware before applying any sealant.

WARNING: Do not fit screw covers until the light has been fitted and tested.

WARNING: Light is for thru-hull mounting only. Cable and connections exposed to underwater submersion will

not be covered by warranty!

WARNING:Thereareseveraldierenthulltypes.MostareeithersolidGRPorcored.Besureyoufollowthe

correct procedures for the hull you are preparing since all require dierent preparation methods. We will

cover the most common type below. If in doubt please contact your local OceanLED representative or the

boat manufacturer for assistance.

WARNING:Please check all components prior to installation. If there is any damage to connectors, cables,

and/or any other component, please notify OceanLED BEFORE installation. Failure to notify OceanLED of

damage in transit prior to installation will lead to violation of warranty.

WARNING:Light is for mounting directly to a flat surface on the hull, with the cable passing through a

1/2 – 5/8" (12 - 15mm) hole in the hull. Do not submerse your cable in water; cable and connections ex-

posed to underwater submersion will not be covered by warranty. Mounting the light in any other configu-

ration, other than those described in this guide, will invalidate its warranty.

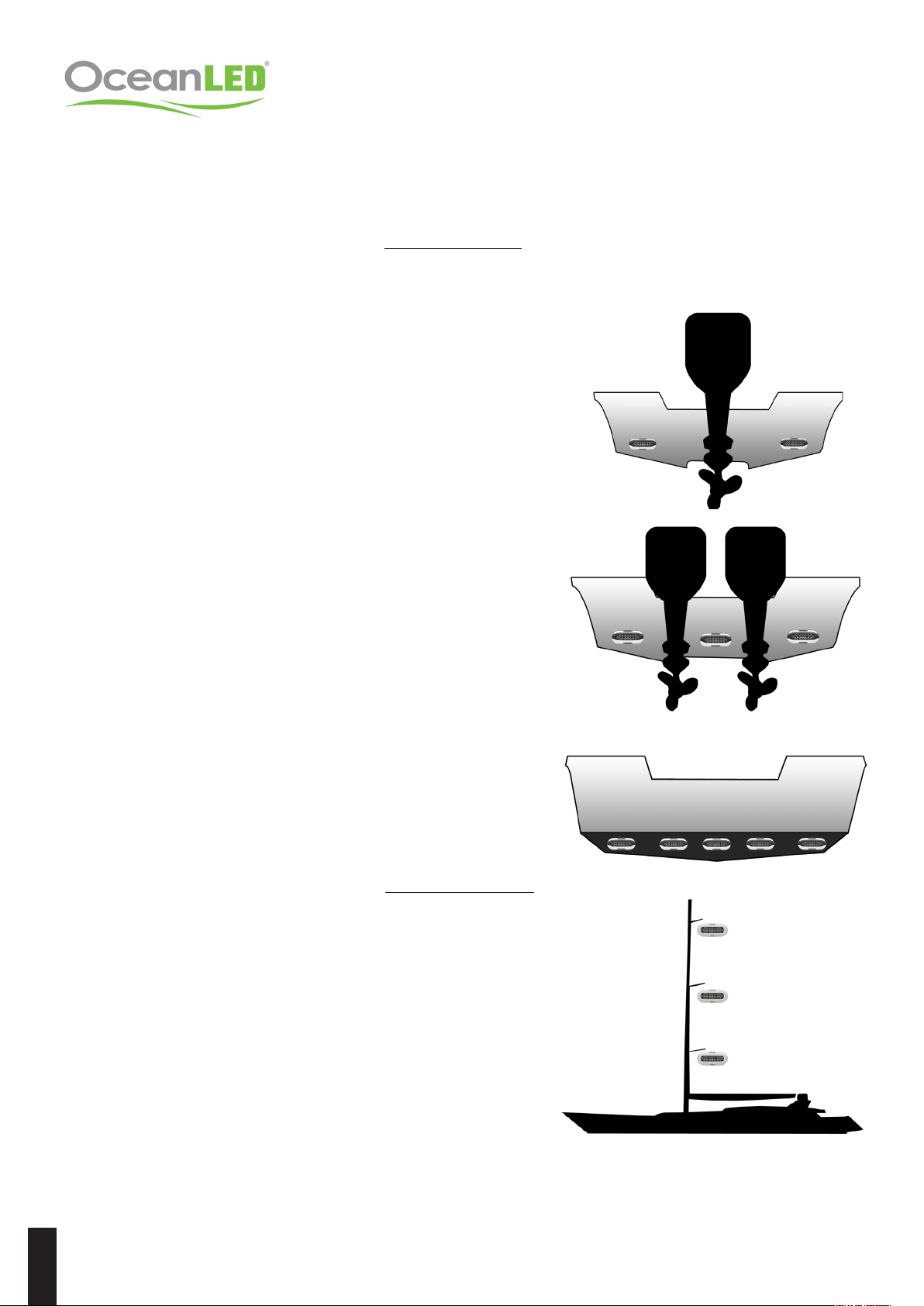

2.1 Preparing a fiberglass hull

TIP:Always wear safety goggles and a dust mask.

1. Drilla3mm/1/8"pilotholesquaretomountingsurfacefrominsidethehullifpossible.Ifthereis

a rib, strut, or other hull irregularity near the selected mounting location, this will need to be taken

into account in the planning phase and the location adjusted accordingly, or the obstruction safely

removed or modified. If the pilot hole is found to be drilled in the wrong location, drill a second hole

in a better location and repair first pilot hole.

2. Usingasuitabledrill,makea1/2"–5/8"(12-15mm)hole.Ensurethelightwilltushandwillbe

square to the mounting surface.

3. Sand the area around the hole using a heavy grit sandpaper to remove the previous bottom paint

and to ensure that the sealant will adhere properly to the hull. If there is any petroleum residue

inside the hull, remove it with acetone before sanding.

4. Place light fixture into position or use mounting template provided. Mark the screw hole position

and pilot drill using correct sized drill bit for included screws.

5. Always dry fit units before applying any sealant.