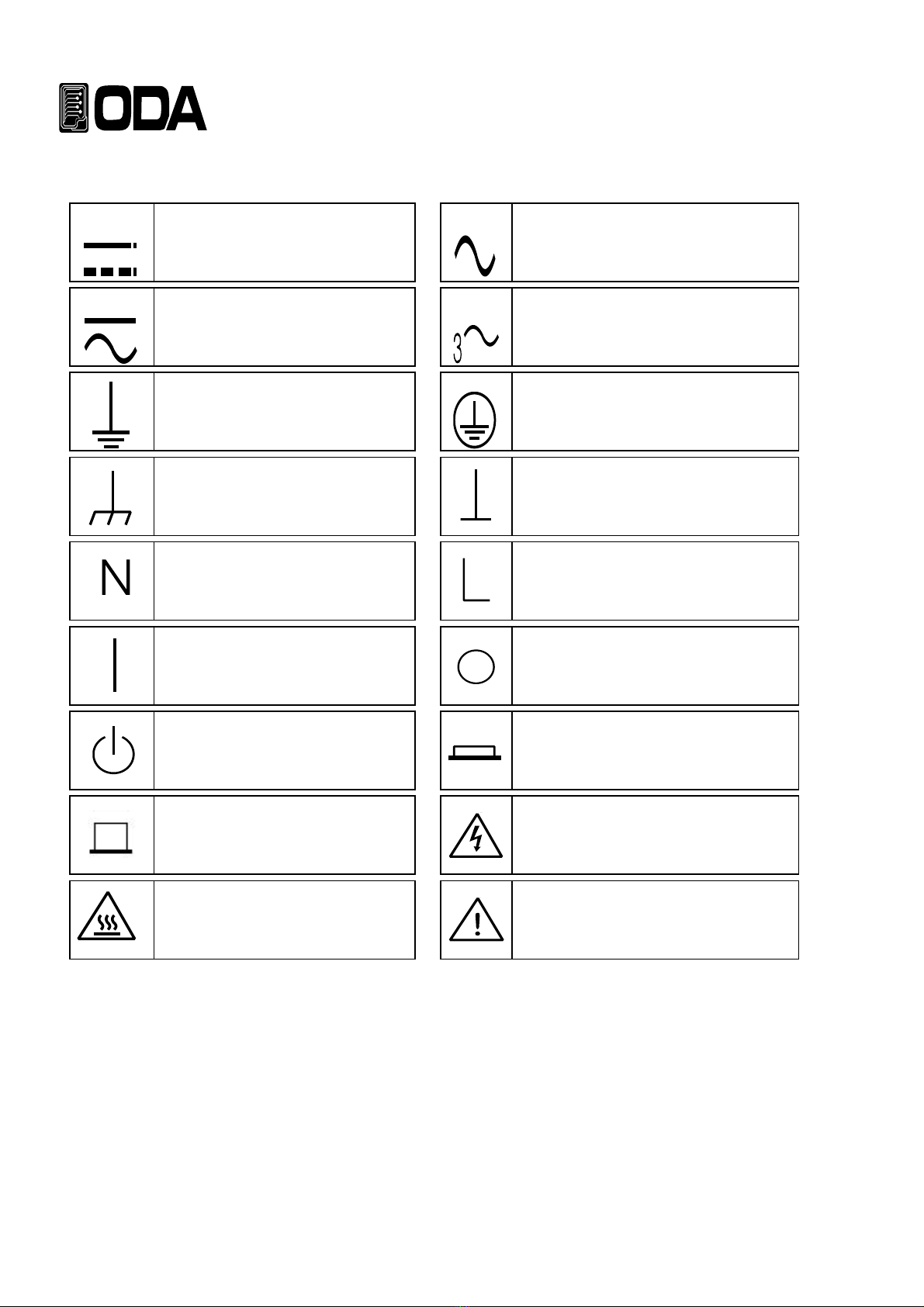

Safety Notices

The following general safety precautions must be observed during all phases of operation of this

instrument. Failure to comply with these precautions or with specific warnings or instructions elsewhere

in this manual violates safety standards of design, manufacture, and intended use of the instrument.

ODA Technologies assumes no liability for the customer's failure to comply with these requirements.

Instruments that appear damaged or defective

should be made inoperative and secured against

CAUTION

A CAUTION notice denotes a hazard. It calls

attention to an operating procedure, practice, or

Verify that all safety precautions are taken. the like that, if not correctly performed or adhere

Make all connections to the unit before

applying power. Note the instrument's of important data. Do not proceed beyond a

external markings described under "Safety Symbols"

CAUTION notice until the indicated conditions

are fully understood and met.

The instrument contains an internal fuse, which WARNING

is not customer accessible.

attention to an operating procedure, practice,

Do Not Operate in an Explosive Atmosphere or the like that, if not correctly performed or

Do not operate the instrument in the presence

of flammable gases or fumes.

death. Do not proceed beyond a WARNING

notice until the indicated conditions are fully

Do Not Remove the Instrument Cover

Only qualified, service-trained personnel who

are aware of the hazards involved should Location of parts

remove instrument covers. Always disconnect

Do not place power cord, equipment inlet,

the power cable and any external circuits before main switch, etc. to make it difficult to operate

removing the instrument cover. the equipment.

for service and repair to ensure that safety

(provided with a protective earth terminal).

features of this product may be impaired if it is

the product to an ODA Sales and Service Office

used in a manner not specified in the operation

Do Not Modify the Instrument

Do not use this product in any manner not

Do not install substitute parts or perform any

specified by the manufacturer. The protective

unauthorized modification to the product. Return

packaging, warranty may not be assured.

When returning, be sure to use the box that was

If there's any damage occurred from using other

This product is a Safety Class 1 instrument

To minimize shock hazard, the instrument

chassis and cover must be connected to an

electrical ground. The instrument must be

connected to the ac power mains through

A WARNING notice denotes a hazard. It calls

adhered to, could result in personal injury or

a grounded power cable, with the ground

interruption of the protective (grounding)

conductor or disconnection of the protective

wire firmly connected to an electrical ground

(safety ground) at the power outlet. Any

hazard that could result in personal injury.

earth terminal will cause a potential shock

qualified service personnel.

unintended operation until they can be repaired b

Keep the vents unobstructed.

to, could result in damage to the product or loss