SW22

9 User manual P1630830G

The third operation of Total that the terminal SW-22 provides the operator, is that of Total for

Item, ie the sum of all items divided by code.

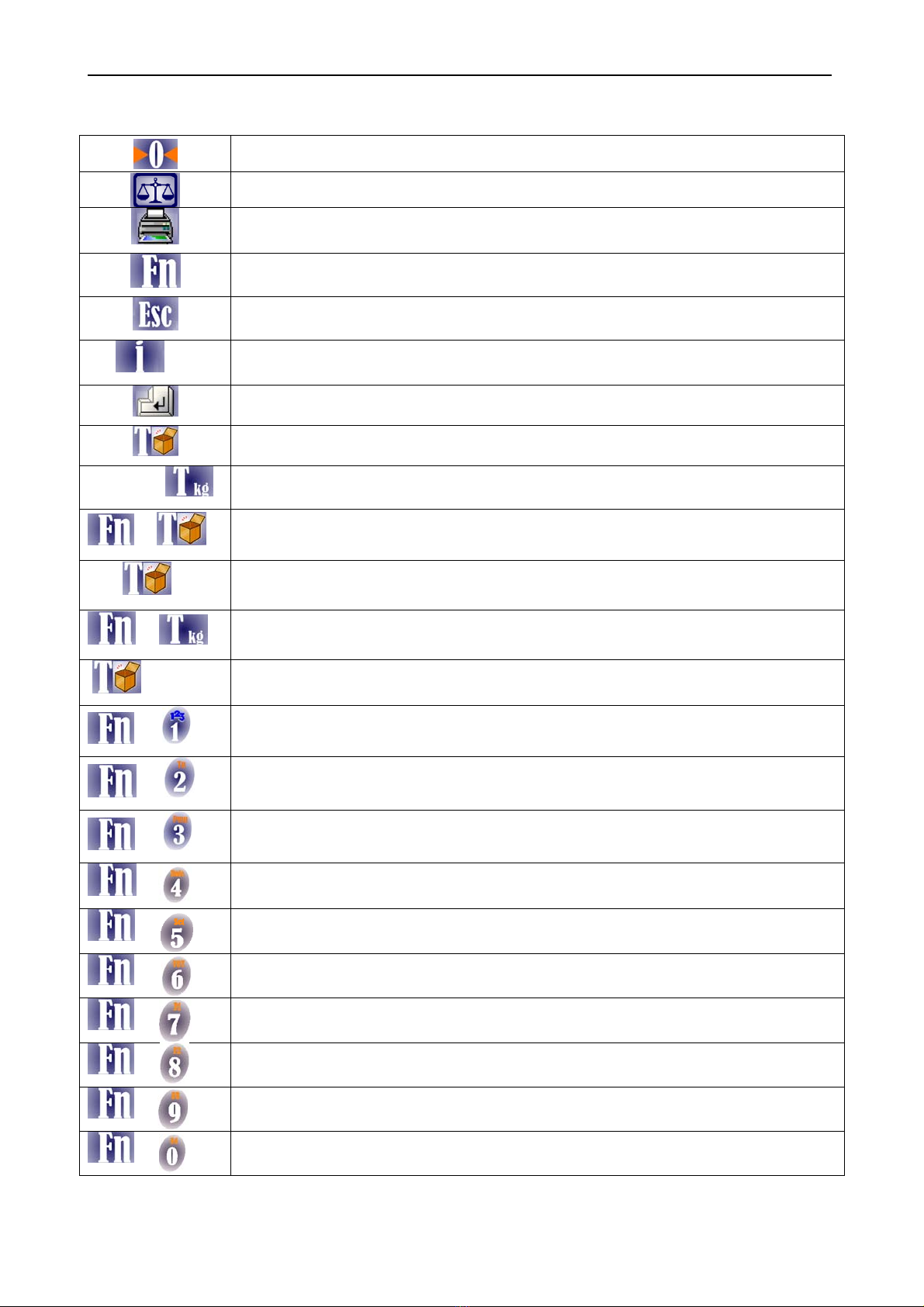

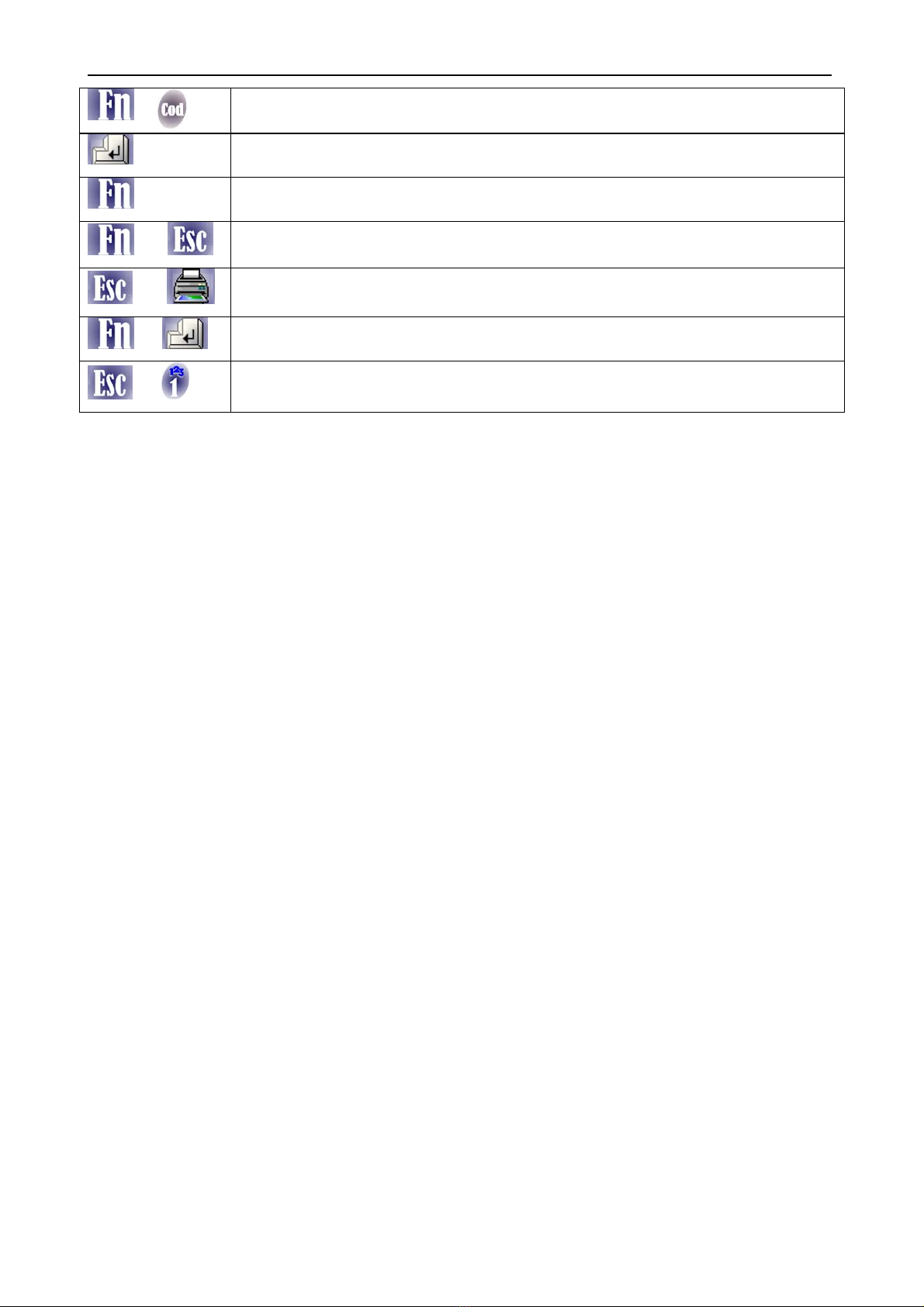

Press keys and in sequence and prints the total weight of all items with a value other

than 0; in this case, the reset request concerns the total of all codes (ENTER = YES; ESC =

NO).

3.1.6 - Display Subtotal

Press keys and TOT in sequence the value of subtotal currently achieved is displayed for 3

sec. after which the display automatically returns to normal operation

3.2 - Weighing with partial resets

By selecting this mode, all operations are made as in "Weighing with totalization", with the

difference that at each weighing, the weight value is automatically reset to zero, the balance is

now ready to receive another weighing.

To close the sequence of weighted and require the subtotal, press the button for 3 sec.

After printing the total, the display will show the actual gross weight on the scale.

3.3 - Animal Weighing

This mode of operation is selected to prevent the normal movement of the animal on the scale

may affect the oscillation of the weight on the display so as to make impossible an accurate

reading.

Once you reach the maximum weight is carried an average between the oscillations around a

default, and then the system will display, locking, this value on the display

3.4 – Counting Mode

By selecting this mode, you activate the typical functions of the counting operation and allow

the entry of number of samples, the average piece weight and the alternating display of

number of pieces, weight, average piece weight and net weight.

3.4.1 - Sampling

The first step to be carried out in an operation of counting is sampling.

This can be done in two modes:

Sampling charge: on the weighing plate is loaded a known number of details that will serve as

samples for the calculation of the Average Piece Weight.

Press keys and in sequence, and place the sample on the scale plate and enter their

number and confirm with ; the Average Piece Weight is displayed for 3 sec., and then the

calculated number of pieces; add at this point the total quantity of pieces to count the number

of which will be automatically updated on the display.

Download sampling: the download sampling operation is carried out starting from a container

full of pieces already placed on the scale plate, from which the samples are removed.

Press keys and in sequence and take the scale plate samples, enter their number and

confirm with ; is displayed for 3 sec. the Average Piece Weight calculated and then the

total number of pieces present in the scale.

In both cases it is very important to consider the value of Tara that, in order to avoid counting

errors, must be separated from the Gross Weight through the various features available.

To clear the stored value of the average piece weight, press keys and

in sequence.

3.4.2 - Setting manual PMU

In the case in which the Average Unit Weight of the details that you want to count is known, it

is possible to avoid the phase of sampling described above, by entering the value.

This operating mode is recommended when there is the certainty that the details are

homogeneous, ie that do not show even minor differences in weight with one another.

Type the numeric value corresponding to the Average Piece Weight grams to be used for