Version GR 2003-10-26

Type Basic Unit Module Cable Connection

Board

Remarks

P30R1 P30 30R1 A = 10 m

B = 25 m

A, B or C Max. 160 turns,

Spindle adapter type

30R1

P30R2 P30 30R2 A = 10 m

B = 25 m

A, B or C Max. 160 turns,

Spindle adapter type

30R2

P30L1 P30 30L1 A = 10 m

B = 25 m

A, B or C Linear actuator,

Standard stroke 40 mm

P30H P30 30H+30R2 A = 10 m

B = 25 m

A, B or C High torque

Max. angle 900

P30L2 P30 30L2 A = 10 m

B = 25 m

A, B or C Linear actuator,

Max. stroke 20 mm

D

OWNLOAD

FROM

:

WWW

.

ODENCONTROL

.

SE

PAGE 4

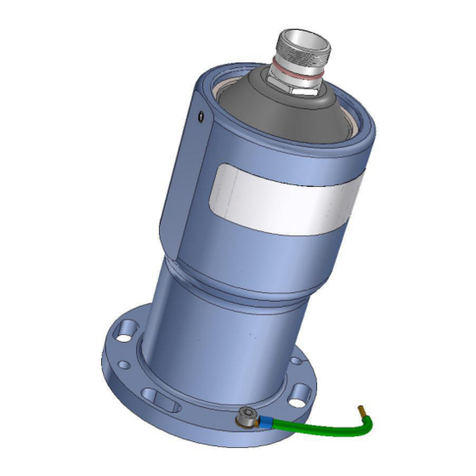

2.1 P30 Basic Unit

The unit consists of a sealed aluminium housing

which includes a brushless servomotor, a reduc-

tion gearbox, electronics and a connector

24 V DC feeds the servo system.

The control signal is normally the standard 4-20

mA , adigital signal or a field bus communication.

The electronics with all the power and logical

components are placed inside the unit, close to

the motor. A connector is fitted and grounded to

the rear end of the unit.

All parameters as torque, speed, working range

are programmed by a special software — the

OVP (Oden®Valve Program) Software (See App.

B).

NB

The parameter settings in the software are saved

in a permanent memory and cannot be lost even

during an extended power break.

The current position will be automatically saved in

a permanent memory during a power break. If the

valve has changed its position, the electronics will

detect the motion (if the break is less than 8 hrs).

After more than 8 hours power break an auto-

matic Power Calibration will be performed, as

soon as the power has returned (this function can

be disabled in the software).

To make sure that the valve is sealing tightly in

closed position, an automatic new Power Calibra-

tion will be performed every time the valve

reaches the closed position.

To avoid that a jamming of the valve occurs in

closed position depending on thermal expan-

sions, an automatic calibration will occur every 20

minutes. (This function can be disabled in the

software).

See also 5. The Calibration system PC/PC.

No batteries or potentiometers, limit switches

or other sensitive electro-mechanical compo-

nents are used.

If the valve is blocked and cannot reach its posi-

tion, Oden®P30 will make 10 starting efforts. The

Actuator will then stop, and a mA-error signal is

sent as return signal. (The level of the signal can

be set in the software).

Another 10 starting efforts can be performed by

changing the control signal more than 2.5 mA.

This starting sequence prevents the actuator

making several attempts for an extended time

and thus damaging the valve or the actuator itself.

Temperature sensors protect the motor and the

electronics.

The reduction gearbox is based on the patent

protected Oden®principle and has a reduction

ratio of 63:1.

2.2.1 Turning module 30R1

This module is normally used for a 900valve

movement but can also be used as a multi turn

actuator with max. 160 turns.

This module (see drawing) consists of:

Shaft unit

The shaft unit should be fitted to P30 Basic Unit

with the two M5 screws.

The Oden®P30 should be fitted by four M8

screws to the valve flange adapter. (Not included

in this module)

(A common valve flange adapter design is a bent

steel plate with its outer surface provided with

four holes for the M8 screws and nuts)

The shaft, going throw the flange plate with a little

clearance , has a bow gear coupling at one end

and two slots with different width at the other end.

Also a radial sealing is included.

Slitted cage

The slitted cage is made in different versions with

internal diameters fitting normal valve spindles.

Clamp collar

The clamp collar has two M10 stop screws which

create clamping forces to the valve spindle by the

shaft and the slitted cage. To this friction torque a

key can also be added. (See drawing).

.

At a power break a threaded pin can be put into

one of the two not used M10 threads in the clamp