4. Check that the spindle length above the valve flange adapter is

within A max and A min, see table on the right. Type A max

(mm) A min

(mm)

P50R 52 20

P200R 79 30

P500R 114 50

5. Move the valve to closed position.

NOTE: Some valve shafts change the axial position in the

closed valve position.

6. Attach the protection plate to the valve flange adapter and then fit

the turning module. Use a hand press or a similar tool to push it in

position. The indicator pins should now be in 45° to the valve.

The correct axial position of the turning module is important. The bottom surface of the turning module must be

at the same level as the top surface of the protection plate when it is placed at the valve flange adapter. The

tolerance should be 0 - +1.5 mm (above the protection plate surface).

NOTE: It is important to have a tight fit to the spindle and keyway in order to benefit from the accuracy

of the actuator. Do not use a hammer, this can damage the valve spindle.

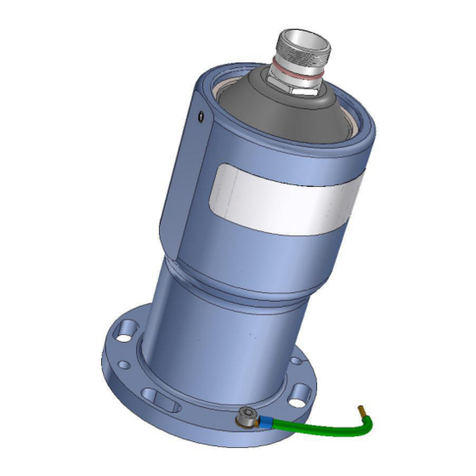

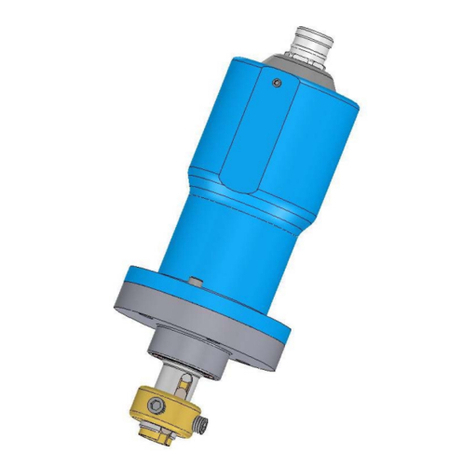

Fitting of the actuator

This instruction is written for the type of valve flange adapter shown above (two cylindrical bars with holes).

1. Remove the protection tape around the gear teeth of the turning module. Put the two long screws in

the flange of the actuator, through the protection plate and the bars.

2. Put the actuator carefully in position by slightly turning it in both directions to get the gears in the

spindle coupling in correct position to each other. An air cushion effect might prevent the mounting,

but the air disappears after a while.

3. Use the hand-wheel smoothly to turn the actuator to the right position for the screws in relation to

the valve flange threads.

4. When the valve is closed, check that there is a clearance of minimum 2 mm between the indicator

pins and the mechanical stops in the Oden actuator. For ball valves with no mechanical stops in the

valve, the closed position will of course be when the indicator pins hit the mechanical stops in the

actuator.

Some models have threads in the mechanical stops in the actuator. If necessary, stop screws can be used as

adjustable stops. It is important that these stop screws will hit the indicator pins at the same time. One stop pin

cannot take the full load and a dangerous tilting load can harm the reduction gear in the actuator.

If you are using stop screws you will reduce the free workingangle. There is a risk that the pins will hit the

mechanical stops before the actuator has reached the maximum opened position (normally 20 mA). This must be

avoided by reducing the programmed working range in OVP.

Mechanical control

The hand-wheel is engaged by pulling it out. Notice the warning label at the hand-wheel. Careless handling will

damage the valve or the actuator. The hand-wheel must not be used when the power is on.

NOTE: The hand-wheel moves in the opposite direction to the valve.

Please, check that the actuator can be operated easily by hand within the whole working range. The valve must

be closing completely. It should be running smoothly. If not: loose the adapter screws and let the unit centre

itself, then tighten alternately the screws. If the actuator is horizontal, relieve the weight of the actuator manually

during alternately tightening of the screws.

It is not necessary to align the Oden actuators to the valve by using shims. For other types of actuators this

alignment process is difficult and you easily get an uncontrolled loading to the valve spindle bushings and the

gland sealing. Hence the Oden actuator significantly improves the lifetime of the valve.

4.4 Installation of linear actuators

1. Check that the spindle adapter has the same thread as the valve spindle.

2. Fit the linear module with its rods and adapter flange to the valve flange.

8