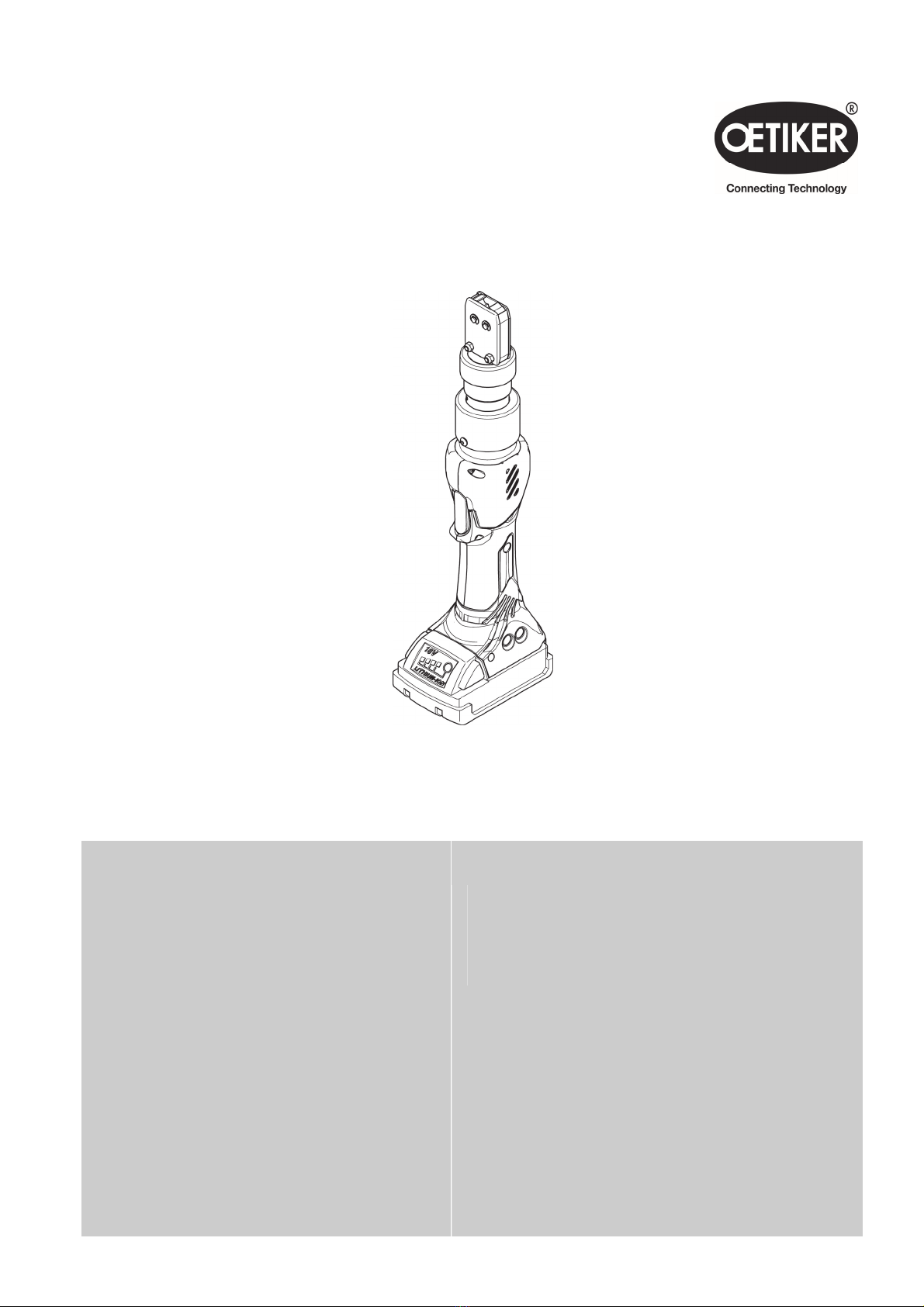

Clamp pincer CP 10 / CP 20 / CC 20 Contents

Issue 11.15 08902961 1-3

5.2.1 Battery charge level display.................................................................................................5-23

5.2.2 Charging battery ..................................................................................................................5-24

5.2.3 Inserting battery ...................................................................................................................5-24

5.2.4 Aligning the pincer head ......................................................................................................5-25

5.2.5 Performing closure...............................................................................................................5-26

5.2.6 Decommissioning clamp pincer CP 10 / CP 20 / CC 20......................................................5-28

5.3 Output of closing data parameters............................................................................................5-29

5.3.1 Creating single closure report..............................................................................................5-29

5.3.2 Creating multiple closure report...........................................................................................5-30

6Maintenance and repair .........................................................................................................................6-31

6.1 General safety instructions on maintenance and repair work...................................................6-31

6.2 Maintenance..............................................................................................................................6-32

6.2.1 Before starting maintenance work .......................................................................................6-32

6.2.2 After completion of maintenance work.................................................................................6-32

6.2.3 Weekly maintenance work...................................................................................................6-32

6.2.4 Preventative maintenance work...........................................................................................6-33

6.3 Repair........................................................................................................................................6-33

6.3.1 Pincer jaw replacement .......................................................................................................6-33

6.3.2 Pincer head replacement.....................................................................................................6-36

7Description of PC software ...................................................................................................................7-37

7.1 Structure of the PC software.....................................................................................................7-37

7.2 Status menu..............................................................................................................................7-38

7.3 Closing data menu ....................................................................................................................7-40

7.4 Calibration menu.......................................................................................................................7-42

7.5 Firmware menu .........................................................................................................................7-43

7.6 Service log menu ......................................................................................................................7-44

7.7 Additional information menu .....................................................................................................7-45

8Attachment..............................................................................................................................................8-46

8.1 General information in event of faults .......................................................................................8-46

8.2 Clearing faults ...........................................................................................................................8-46

8.3 Error messages and troubleshooting measures.......................................................................8-46

8.4 Decommissioning and storage..................................................................................................8-48

8.5 Recommissioning......................................................................................................................8-48

8.6 Disposal ....................................................................................................................................8-48