Safety Messages and Electrical Safeguards ..............................1-2

Introduction .................................................................................2-3

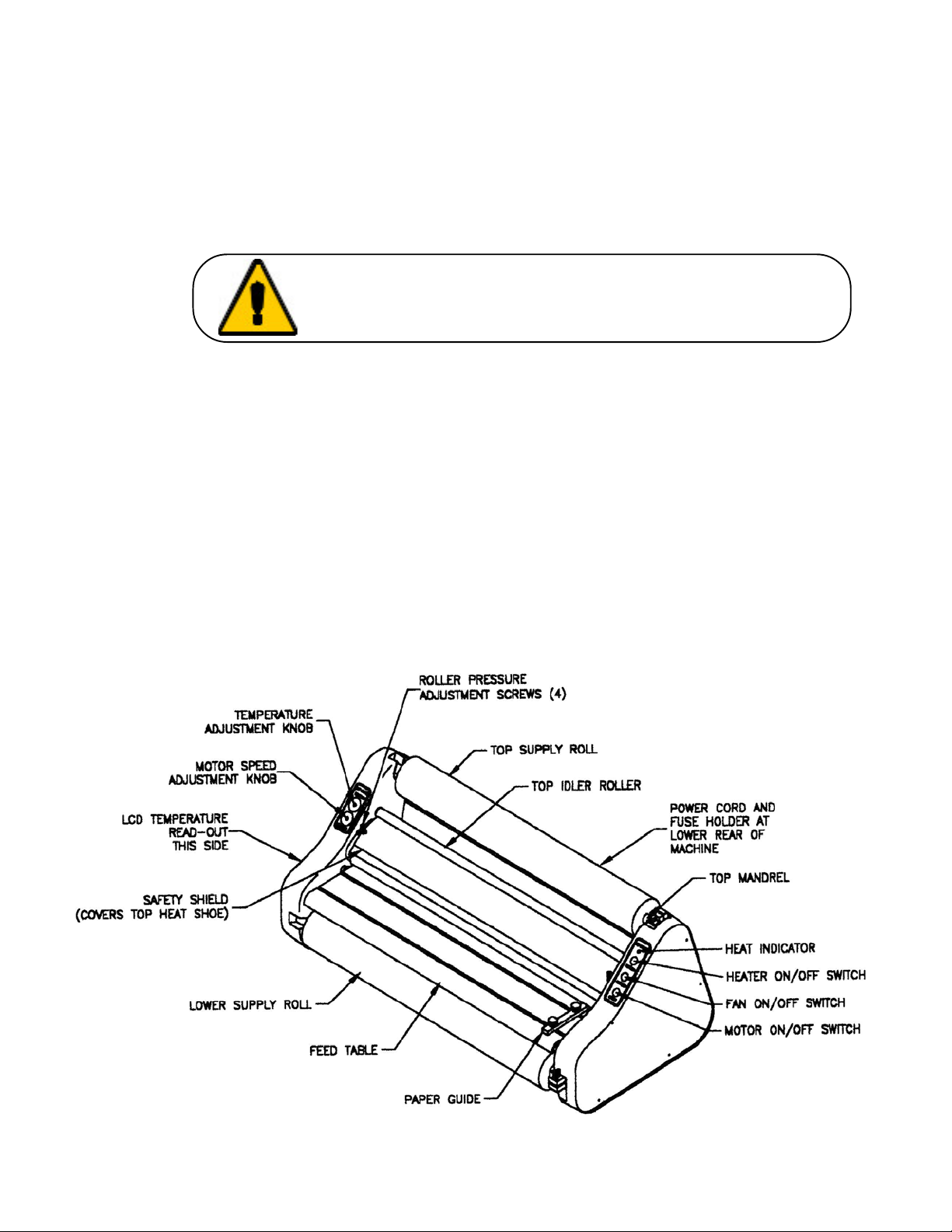

Laminator Features .................................................................3

Specifications ...................................................................................3

Intial Set-up ..................................................................................4-5

Unpacking ...............................................................................4

Components .........................................................................4-5

Operation ......................................................................................5-8

Loading Laminating Film .......................................................5

Threading Laminating Film ..................................................6-7

Adjusting Mandrel/Film Tension.............................................7

Heat Shoe Temperature ...........................................................8

Adjusting Slitter Blades ...............................................................8-9

Laminating ..................................................................................9-11

Coating Mount Board.............................................................10

Mounting & Laminating.........................................................11

Troubleshooting ........................................................................12-13

Maintenance ..............................................................................13-14

Cleaning Heat Shoes & Rollers .......................................13-14

Removing Wrap-Arounds......................................................14

Warranty & Return Policy ...........................................................14

Parts List ....................................................................................15-17

Parts Illustrations ......................................................................18-21

Exploded View .......................................................................18

Side Panels ........................................................................19-20

Wiring Diagram.......................................................................21

TABLE OF CONTENTS

1-800-543-5454 www.officezone.com