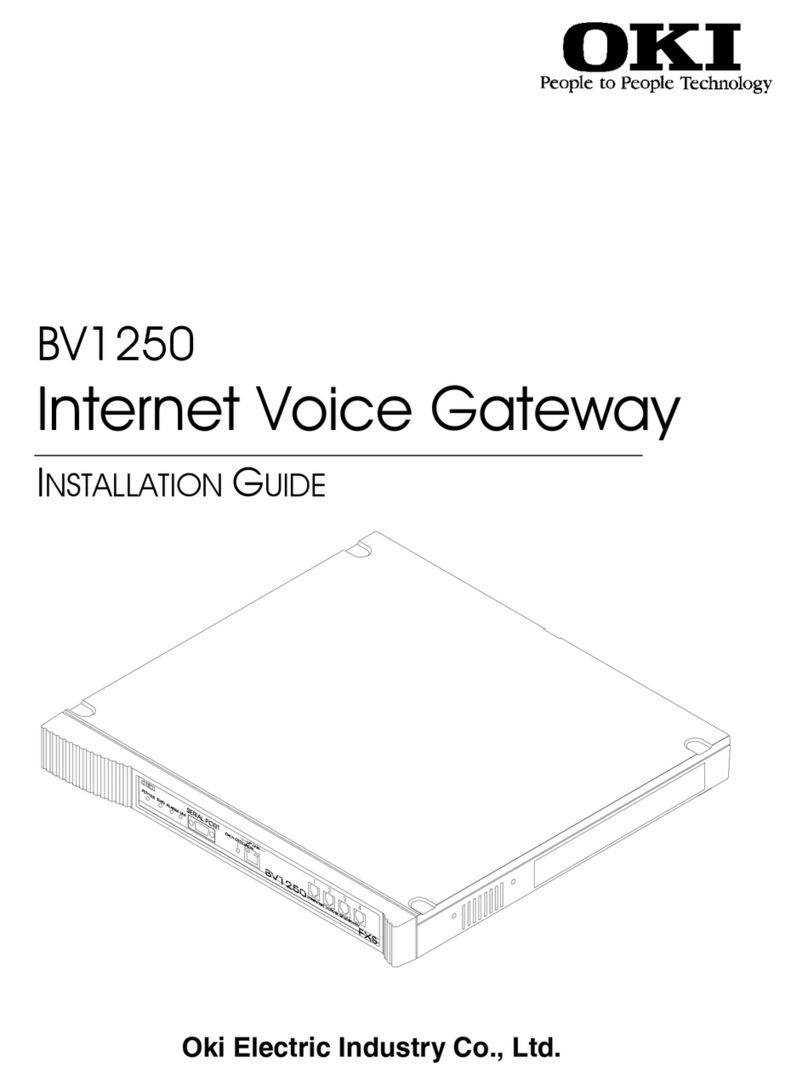

BV1250 Technical Reference

Rev. 1.0 Page iii

Limited Warranty

Oki Electric Industry Co., Ltd. warrants that these products (BV1250 and

Maintenance Console Software) are free of manufacturing defects during the

warranty period and while operating under normal conditions. In the event of

failure, a replacement unit and/or software will be provided free of charge.

This warranty covers this product only and is subject to the following conditions:

1. Oki Electric warrants the media upon which the Maintenance Console

Software is recorded to be free from defects in materials and workmanship

under normal use for a period of ninety (90) days from the date of purchase.

In the event any media prove to be defective during the warranty period,

user’s remedy shall be to return media to Oki Electric for replacement.

2. Oki Electric does not accept liability for loss or damage caused by the user's

mishandling, misoperation, or damages occurring as a consequence of

unusual events such as fire, earthquake, or flood.

3. Regarding the quality and functionality of the Maintenance Console Software

and this Installation Guide, Oki Electric holds no liability for the conformity of

the equipment to the purpose of use by the user and the marketability. Oki

Electric does not accept liability for any loss or damage occurring directly or

indirectly thereof.

4. No responsibility will be taken regarding the results obtained by the use of the

BV1250 and/or the Maintenance Console Software and/or this Installation

Guide.

5. Media such as this Installation Guide, floppy disks, CDs, etc., are supplied

with the Maintenance Console Software as a package and shall be used for

the Maintenance Console Software only. It is strictly forbidden to make a

copy of the Maintenance Console Software other than a back-up copy. Oki

Electric holds no liability for consequences incurred by the use of the copied

media.

Others

1. It is strictly forbidden to offer the MCS program to a third party as such or

after adding modifications. If this program is used by a third party, that use

infringes upon the copyright of the author and it becomes the author's right to

demand compensation.

2. Customer services are available at our company's head office and at our

service locations.