Construction Manual www.oldschoolmodels.com Page 3

• 6 and 30 minute epoxy

• Epoxy brushes and mixing sticks

• Threadlocking compound

• Canopy glue

Before Starting Assembly

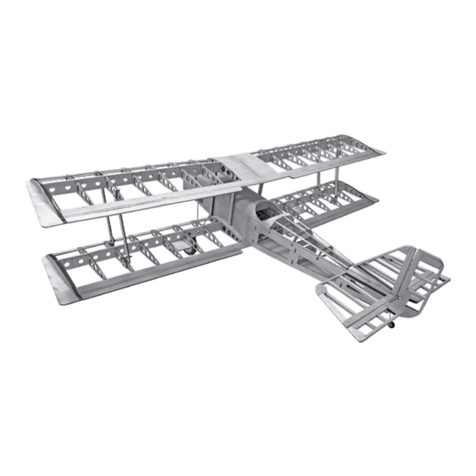

The Comet should only be built by an experienced builder. If

you’ve never built a kit before it’s quite possible you will have a

great deal of difficulty building this kit successfully.

Closely inspect the supplied laser cut parts for damage. If you find

any damaged or missing parts, contact us immediately.

When removing the laser cut parts from their sheets, you’ll notice

the parts are held in place by several very small “tabs”. These tabs

are uncut pieces of wood and can sometimes make it difficult to

remove a part. Rather than breaking and/or splintering the wood

by forcing out the part, we recommend removing any laser cut

parts from their sheets by using a hobby knife with a new, sharp

blade. A quick cut of the tab will allow the piece to be removed

with no damage. Sand any remainders flush with the part so there

will be no problem aligning them later.

THE COMET USES RIBS THAT HAVE LARGER ALIGNMENT

TABS. IT IS IMPORTANT THAT THESE TABS REMAIN ON

THE PIECES TO AID IN BUILDING A STRAIGHT AND TRUE

MODEL. IF YOU DO BREAK OFF A TAB, IMMEDIATELY

TACK-GLUE IT BACK TO THE PIECE.

It’s best to not remove parts from their sheets until they are needed.

Refer to Appendix A of this manual as a reference to what all the

laser cut parts look like and are called.

For each step, we highly recommend that you dry fit the parts in

each step first. Lightly sand as needed to ensure a good fit. Once

you’re satisfied with the fit, then and only then, glue the parts in

position.

IT IS VERY IMPORTANT THAT YOU ASSEMBLE THIS KIT

IN THE ORDER DESCRIBED. SKIPPING FORWARD IN

THE STEPS COULD LEAVE YOU WITHOUT THE PROPER

LENGTHS OF WOOD TO FINISH THE KIT.

WE’VE INCLUDED ENOUGH WOOD TO EASILY COMPLETE

THIS KIT, BUT YOU MUST TAKE CARE TO PROPERLY

MEASURE AND NOT WASTE WOOD WHEN CUTTING.

All photos shown in this manual were of the prototype Comet.

Several pieces have changed slightly with improvements we’ve

made so they might look a little different in some steps.

Online Supplementary Photos

We realize that the smaller black-and-

white photos in this manual might not

show some of the steps as clearly as

you might want. So we’ve anticipated

this and made these photos available

on our website. You can either scan the

QR code or type this address into your

browser:

www.oldschoolmodels.com/mpics/comet

Let’s begin construction by working on the center section of

the Comet.

Prepare your work area

You’ll need a flat building surface that is a minimum of 40” wide as

the Comet is built as a one-piece airframe.

Cut out the nose section of the plans along the dotted line, then

tape this section in place on the plans to form a 1-piece plan with

the nose section attached.

Position plan over your building surface and tape into position.

Tear off a few lengths of waxed paper to cover plan, then tape

them into position, covering the plan.

Step 1 - Alignment triangle

Pre-cut into LP3 is a triangle, that

can be used to vertically align any of

the parts in the construction of your

Comet. LP3 also includes a foot piece

that can be used with the triangle,

holding the triangle vertical hands-

free.

Step 2 - Center Section (nose gear mount)

Locate both F5 pieces from the LP2

sheets. Glue both of these pieces

together to form a thicker F5. This

will be the mount for the nose gear.

Note that the shape of this piece

has changed from what’s shown

here to include a cutout to allow air

and tubing to pass through.

Step 3 - Center Section (mount nose gear block)

In your Comet kit, there is a separate

hardware bag which contains all the

pieces to assemble the nose gear.

From this bag, locate the nose gear

mounting block, the 4 mounting

screws and the 4 t-nuts from this

package. Use these pieces to

mount the nose gear block to the

assembled F5 as shown here.

You may need to use a cutoff wheel to trim the screws length after

they are installed.

Step 4 - Center Section (R1As)

Locate both R1A and R1B pieces from

the LP1 sheets. Align the curvy cuts

in R1A and R1B to create a finished

R1. Pay attention when joining so you

align the engraved circles next to each

other. Make two finished R1 pieces.

Step 5 - Center Section (attach

nose gear block)

Take one of the completed R1 pieces

and glue the F5 assembly to it. Make

sure it is 90° from the side and the nose

gear block is positioned as shown here.