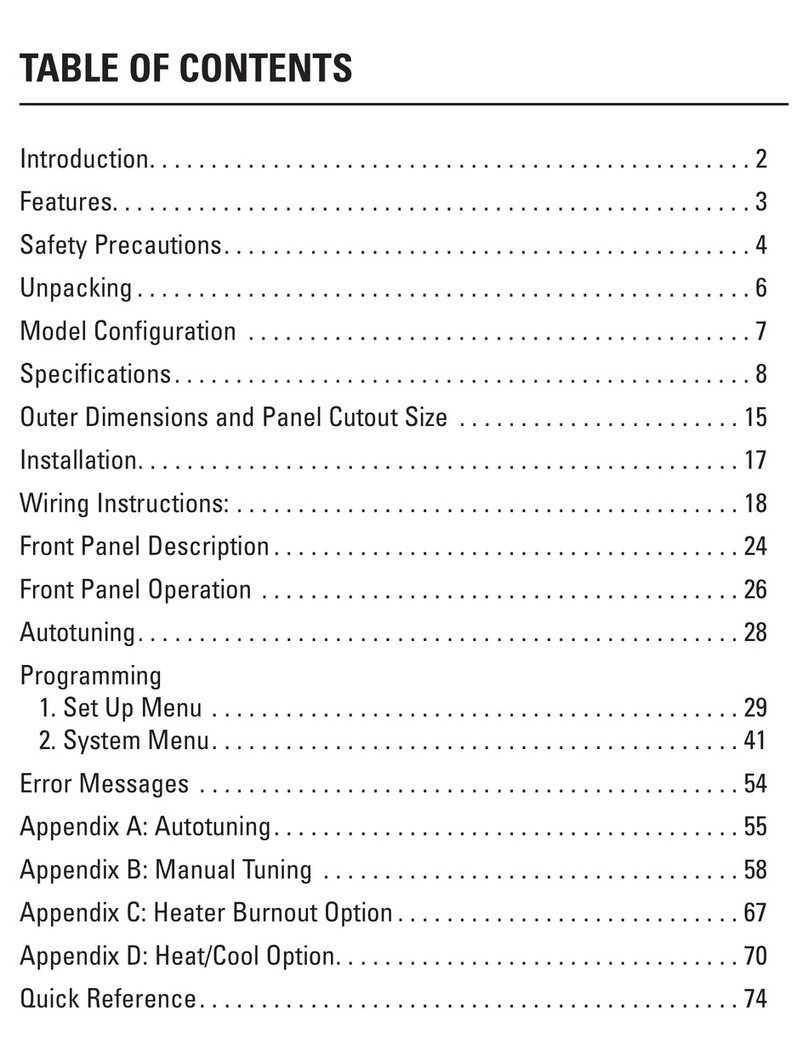

LIST OF FIGURES:

Figure 2.1 Front Panel Display .....................................................................5

Figure 2.2 Rear Panel Power and Output Connections .............................5

Figure 2.3 Rear Panel Input Connections ...................................................6

Figure 2.4 Main Power Connections............................................................7

Figure 2.5 Process Current Wiring Hookup ................................................8

Process Voltage

Figure 2.6 a) Process Voltage with Sensor xcitation ...........................8

b) Process Voltage without Sensor xcitation .....................8

Strain Gauge

Figure 2.7 a) 4-Wire Voltage Input with Internal xcitation....................9

b) 4-Wire Bridge Input with xternal xcitation....................9

Figure 2.8 a) 6-Wire Voltage Input with Internal xcitation....................9

b) 6-Wire Bridge Input with xternal xcitation....................9

Figure 2.9 4-Wire Voltage Input with Internal xcitation..........................10

Wiring Outputs

Figure 2.10 a) Mechanical Relay and SSR Outputs Wiring Hookup .....10

b) Pulse and Analog Outputs Wiring Hookup .....................10

Figure 2.11 Snubber Circuits Wiring Hookup .............................................10

Figure 2.12 a) RS-232 Output Wiring Hookup .........................................11

b) RS-485 Outputs Wiring Hookup .......................................11

Figure 2.13 Typical Applications ..................................................................12

Figure 2.14 a) xcitation Outputs ............................................................12

b) Top View Location of S2 ...................................................12

c) Top View Location of S2 on 1/8DIN Compact Unit ...........12

Figure 3.1 Flow Chart for ID and Setpoints Menu ....................................14

Figure 3.2 Flow Chart for Configuration Menu .........................................17

Figure 3.3 Flow Chart for Input Type Menu...............................................17

Figure 3.4 Flow Chart for Reading Configuration Menu ..........................19

Figure 3.5 Flow Chart for Alarm 1 Menu....................................................26

Figure 3.6 Flow Chart for Analog Output (Retransmission) Menu..........30

Figure 3.7 Flow Chart for Alarm 2 Menu....................................................33

Figure 3.8 Flow Chart for Loop Break Time Menu....................................34

Figure 3.9 Flow Chart for Output 1 Menu ..................................................36

Figure 3.10 Flow Chart for Output 2 Menu ..................................................43

Figure 3.11 Flow Chart for Ramp and Soak Menu......................................46

Figure 3.12 Flow Chart for ID Code Menu ...................................................48

Figure 3.13 Flow Chart for Communication Option Menu .........................50

Figure 3.14 Flow Chart for Display Color Selection Menu.........................56

LIST OF TABLES:

Table 2.1 Front Panel Display .....................................................................5

Table 2.2 Rear Panel Connector .................................................................6

Table 2.3 Fuse Requirements .....................................................................7

Table 2.4 Jumper Connections.................................................................12

Table 3.1 Button Function in Configuration Mode..................................13

Table 3.2 Conversion Table.......................................................................23

Table 3.3 Input Resolution Multiplier .......................................................23

Table 5.1 Factory Preset Values ...............................................................62

ii