ARTWORK/PRODUCT ART/

DWGS/START HERE ARROW

START HERE

ARTWORK/PRODUCT ART/

DWGS/START HERE ARROW

ARTWORK/PRODUCT ART/

DWGS/START HERE ARROW

ARTWORK/PRODUCT ART/

DWGS/START HERE ARROW

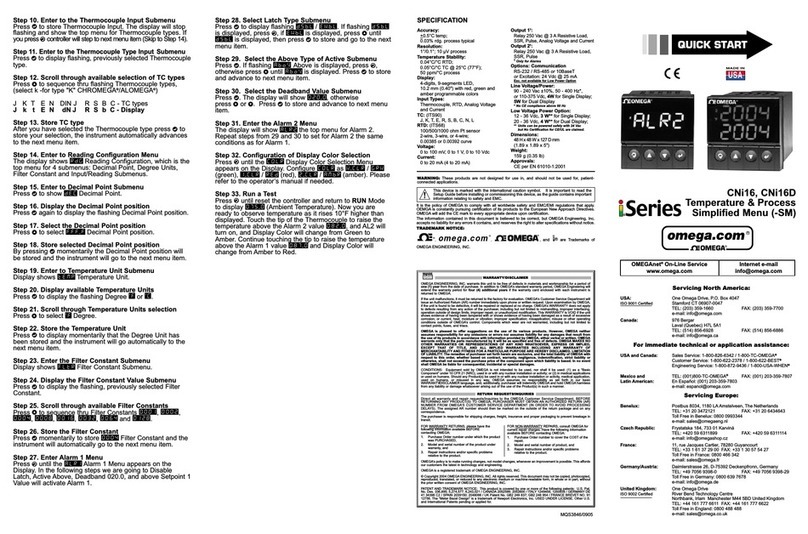

CND3 Series Temperature Controller

Warning

DANGER! Caution! Electric Shock! When the power is on, DO NOT touch the AC terminals in case

an electric shock may occur. Make sure the power is disconnected when you check the input power

supply.

1. Prevent dust or metallic debris from falling into the controller and cause malfunctions. DO NOT modify or uninstall

the controller.

2. CND3 controller is an open-type device. Make sure it is installed in an enclosure free of dust and humidity in case of

an electric shock.

3. Wait for one minute after the power is switched off to allow the capacitor to discharge. DO NOT touch the internal

wiring within this period of time.

Display, LED & Keys

Ordering Information

Series Omega CND3 series temperature controller

Panel size

04: 1/4 DIN

08: 1/8 DIN

16: 1/16 DIN

Output 1 R: Relay M: Linear mA

S: Voltage Pulse L: Linear voltage

Output 2 R: Relay M: Linear mA blank: none

S: Voltage Pulse L: Linear voltage

Option 1

1U: 1 User input

2U: 2 User inputs

1C: 1 CT input

2C: 2 CT inputs

RT: Retransmission output

RS: Remote Setup Input

UC: User input + CT input

RR: Retrainsmission + Remote

Setup input

UR: User input + Retransmission

output

US: User input + Remote Setup

input

CR: CT input + Retrainsmission

output

CS: CT input + Remote Setup input

blank: none

Option 2 CM: RS-485 Communication blank: none

Power AC: AC 100 to 240V DC: DC 24V

Specifications

Input power supply AC 100 to 240 V, 50/60Hz, DC 24 V ±10%

Display method LCD. Present temperature: yellow, Set temperature: green

Input sensors

Thermocouple: K, J, T, E, N, R, S, B, L, U, TXK

Platinum RTD: Pt100, JPt100

Resistance: Cu50, Ni120

Analog input: 0 to 5 V, 0 to 10 V, 0 to 20 mA, 4 to 20 mA, 0 to 50 mV

Control modes PID, PID programmable, Fuzzy, Self-tuning, manual, ON/OFF

Display accuracy 0 or 1 digit to the right of the decimal point

Sampling rate Analog input: 0.1s, Thermocouple or platinum RTD: 0.1s

Ambient temperature 0 to +50°C

Ambient humidity 35 to 80% RH (non-condensing)

Parameters Operation

Regulation Mode Operation Mode Initial Setting Mode

Auto-tuning (Set in PID

control and RUN mode)

Press

Use to set up target

temperature Press

Set up input type

Press

Self-tuning switch (set

when in PID control and the

TUNE parameter = ST)

Control loop RUN or

STOP Set up temperature unit

(not displayed when in analog

input)

Regulation Mode Operation Mode Initial Setting Mode

Select the nth (n = 0 ~ 5)

PID. When n = AUTO, PID is

auto-selected.

Set up start pattern (when in

PID programmable control and

)

Set up upper temperature

limit

Set up PID control offset Set up start step (when in

programmable control) Set up lower temperature

limit

Set up Fuzzy gain value Set up the position of

decimal point Select control modes

Set up Fuzzy Deadband Lock the keys Select SV control modes

Adjust Output 1 hysteresis

(when in ON/OFF control) Set up upper limit of Alarm 1 Set up waiting

temperature (when in

programmable control)

Adjust Output 2 hysteresis

(when in ON/OFF control) Set up lower limit of Alarm 1 Set up waiting time (when

in programmable control)

Control cycle for

Output 1 (except in ON/OFF

control)

Set up upper limit of Alarm 2 Set up start slope (when

in programmable control)

Control cycle for

Output 2

(except in ON/OFF control)

Set up lower limit of Alarm 2 Select pattern to be edited

Ratio of Output 1 against

Output 2 when in dual output

control (set when in PID and dual

output control)

Set up upper limit of Alarm 3 Select AT or ST

Set up deadband

(when in dual output) Set up lower limit of Alarm 3 Select heating, cooling or

dual output heating and cooling

Set up input filter factor Record highest

temperature of Alarm 1 Set up Alarm

1 mode

Set up input filter range Record lowest

temperature of Alarm 1 Set up Alarm

1 options

Adjust input compensation Record highest

temperature of Alarm 2 Set up Alarm

1 delay

Adjust input gain Record lowest

temperature of Alarm 2 PV color change

Set up rising slope (when

CRTS = SLOP) Record highest

temperature of Alarm 3 2PID Switch temperature

Adjust upper limit

compensation for analog Output

1*

Record lowest

temperature of Alarm 3 2PID Reset temperature

Adjust lower limit

compensation for analog Output

1*

Display and adjust Output 1

volume Set up Remote type

Adjust upper limit

compensation for analog Output

2*

Display and adjust Output 2

volume Select auxiliary function 1

Adjust lower limit

compensation for analog Output

2*

Set up percentage of upper

limit for Output 1 Select auxiliary function 2

Adjust upper limit

compensation for Retransmission* Set up percentage of lower

limit for Output 1 Enable/disable

communication write-in

Adjust lower limit

compensation for Retransmission* Set up percentage of upper

limit for Output 2 Select ASCII or RTU

format

Adjust Remote gain Set up percentage of lower

limit for Output 2 Set up communication

address

Adjust Remote

compensation Display current measured at

CT1 Set up baudrate

Remote lower limit

adjustment Display current measured at

CT2

Press to return to set up

target

temperature

Set up data length

Remote higher limit

adjustment Set up stop bit

Set up EVENT1 function Set up parity bit

Press to return to set up

input type

Set up EVENT2 function

Set up EVENT3 function

Press to return to auto-tuning

*1 scale = 2μA; 1scale = 1mV

PID mode: Any of the 6 PID groups can be selected. When n = AUTO, the program will automatically select

the PID group that is the closest to the target temperature.

Select the nth PID (n = 0 ~

5)

Press 0 ~ 5th PID

Set up the 0th PID

temperature value

Press

Set up the 5th PID

temperature value

Press

Set up the 0th proportional

band value Set up the 5th proportional

band value

Set up the 0th Ti value Set up the 5th Ti value

Set up the 0th Td value Set up the 5th Td value

Set up the 0th PID integral

deviation

Press to return to PID

deviation

Set up the 5th PID integral

deviation

Press to return to PID

deviation

Alarm Outputs

CND3 offers 3 alarm outputs, and each alarm output has 20 alarm modes to choose from in the initial setting mode.

When the target temperature exceeds or falls below the set point, the alarm output will be enabled.

SV Alarm mode Alarm output operation

0No alarm

1Alarm output will be enabled when the temperature reaches upper or

lower limit: The alarm will be enable when the PV exceeds SV + AL-H

or falls below SV – AL-L.

2Alarm output will be enabled when the temperature reaches the upper

limit: The alarm will be enabled when the PV exceeds SV + AL-H.

ON

OFF SV SV+(AL-H)

3Alarm output will be enabled when the temperature reaches the lower

limit: The alarm will be enabled when the PV falls below SV – AL-L.

ON

OFF SV-(AL-L) SV

4Alarm output will be enabled when the temperature reaches the

absolute value of the upper or lower limit: The alarm will be enabled

when the PV exceeds AL-H or falls below AL-L.

ON

OFF AL-L AL-H

5Alarm output will be enabled when the temperature reaches the

absolute value of the upper limit: The alarm will be enabled when the

PV exceeds AL-H.

ON

OFF AL-H

6Alarm output will be enabled when the temperature reaches the

absolute value of the lower limit: The alarm will be enabled when the

PV falls below AL-L.

ON

OFF AL-L

7Upper limit hysteresis alarm: The alarm will be enabled when the PV

exceeds SV + AL-H. The alarm will be disabled when the PV falls

below SV + AL-L.

8Lower limit hysteresis alarm: The alarm will be enabled when the PV

falls below SV – AL-H. The alarm will be disabled when the PV

exceeds SV – AL-L.

9Offline alarm: The alarm will be enabled when the input sensor is not

correct or offline.

10 Timing alarm

11 CT1 alarm: The alarm will be enabled when the CT1 value falls below

AL-L or exceeds AL-H. ON

OFF AL-L AL-H

12 CT2 alarm: The alarm will be enabled when the CT2 value falls below

AL-L or exceeds AL-H.

¾RS485 Communication

CND3 supports baudrate 2,400 to 38,400 bps, Modbus ASCII/RTU protocol, function code 03H and reads

maximum 8 words from the register.

Address Content Definition

1000H Present value (PV)

Measuring unit: 0.1 scale. The following values read mean

error occurs.

8002H: Temperature not yet acquired

8003H: Not connected to sensor

8004H: Incorrect sensor

1001H Set value (SV) Measuring unit: 0.1 scale.

1002H Upper limit of temp.

range Cannot exceed the default value

1003H Lower limit of temp.

range Cannot fall below the default value

1005H Control mode 0: PID, 1: ON/OFF, 2: Manual, 3: FUZZY

1006H Heating/cooling control 0: Heating/ Heating, 1: Cooling/ Heating, 2: Heating/cooling, 3:

Cooling/ Cooling

1007H 1st heating/cooling control

cycle 0.1 ~ 99.0 sec.

1008H 2nd heating/cooling control

cycle 0.1 ~ 99.0 sec.

1009H Proportional band (PB) 0.1 ~ 999.9

100AH Ti value 0 ~ 9,999

100BH Td value 0 ~ 9,999

1012H Read/write Output 1

volume Unit: 0.1%, only valid in manual control mode

1013H Read/write Output 2

volume Unit: 0.1%, only valid in manual control mode

1016H Regulated temp. value -99.9 ~ +99.9, Unit: 0.1

102AH Read/write LED status b0: ALM3, b1: ALM2, b2: °F, b3: °C, b4: ALM1, b5: OUT2, b6:

OUT1, b7: AT

102BH Read/write key status b0: Set, b1: Select, b2: Up, b3: Down, 0: Press it

102CH Panel lockup status 0: Normal, 1: Fully locked, 2: SV adjustable

102DH CT value Unit: 0.1A

103BHAT setting 0:OFF(default), 1:ON

103CHControl RUN/STOP

setting 0 : STOP, 1:RUN (default), 2 : END (program), 3 : HOLD

(program)

Panel Cutout

Model Panel cutout ( W × H )

1/16 DIN 45mm × 45mm

1/8 DIN 44.5mm × 91.5mm

1/4 DIN 91mm × 91mm

ON

OFF

SV SV+(AL-L) SV+(AL-H)

ON

OFF

SV-(AL-H) SV-(AL-L) SV

ON

OFF

SV-(AL-L) SV SV+(AL-H)