ASSEMBLY

1. Install hydraulic unit into receiver and secure with

provided 7.5mm X 22mm bolt.

2. Install lift foot pedal into sleeve.

3. Install handle into frame and secure using the

provided pins (2).

4. Ensure assembly rolls freely, lifts, locks, and lowers

easily. Get to know how the release pedal, lift pedal,

and the height locking and unlocking mechanism

work prior to loading the Lift.

3OIPM#49154-ATV2

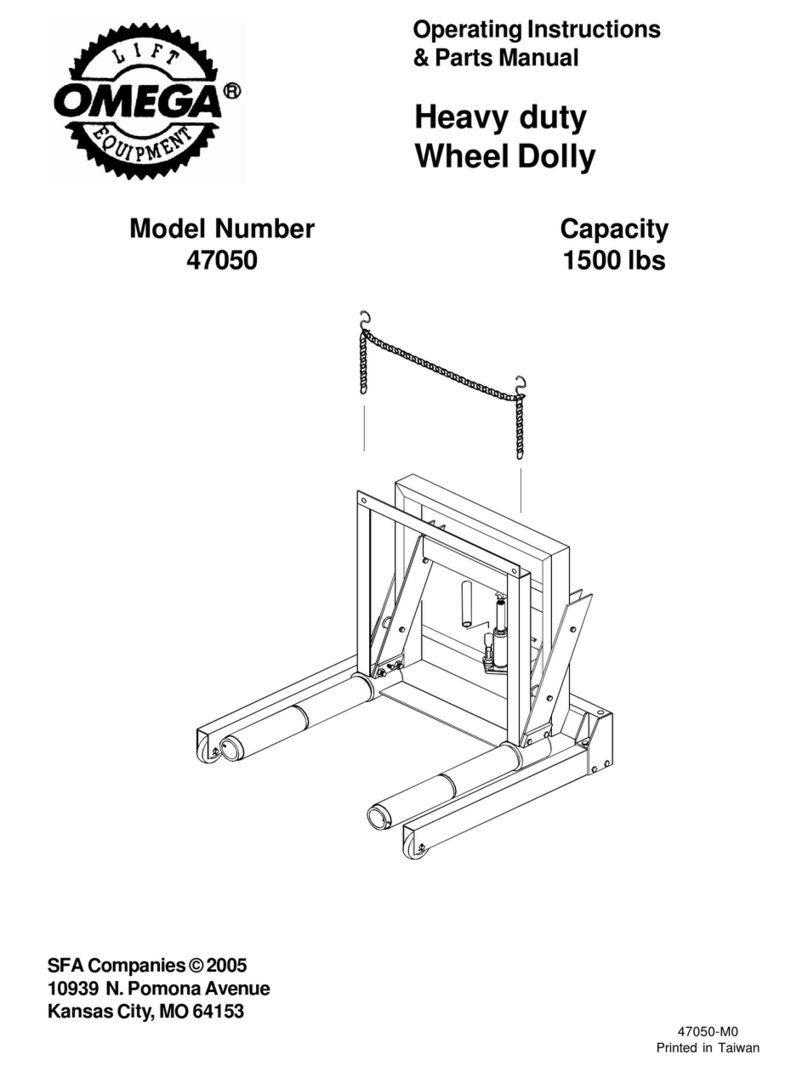

BEFORE USE (see Fig. 1)

1. Verify that the product and the application are

compatible, if in doubt call Omega Technical

Service (888) 332-6419.

2. Before assembling this product, read this operating

manual completely and familiarize yourself

thoroughly with the product, its components and

recognize the hazards associated with its use.

3. Before assembly, place hydraulic unit in an upright,

level position. Press release valve lever to ensure

ram is fully retracted. Locate and remove the oil filler

plug. As you remove the oil filler plug you may hear

pressurized air escaping from the reservoir. This

means you have successfully purged trapped air

from the system. Ensure the oil level is just below

the oil filler plug hole. Reinstall the oil filler plug.

4. After assembly, check to ensure that Lift rolls freely

and that the pump operates smoothly before putting

into service. Replace worn or damaged parts and

assemblies with Omega Replacement Parts only.

(See Replacement Parts Section). Lubricate as

instructed in Maintenance Section.

OPERATION

1. Position Lift under appropriate lift point, centering

load on lift saddle.

2. Locate and pump the lift pedal until the lift saddle

comes into contact with an appropriate lift point.

3. Only after centering the load, slowly and carefully

raise the lift arm by pumping the lift foot pedal.

4. Lock both swivel casters by pressing down on the

caster lever marked ‘lock’.

5. Continue pumping until the load has reached

desired height. Secure the load using appropriate tie

down means. Four tie down loops have been

provided on the frame of the Lift. Make sure that the

height locking mechanism is fully engaged before

working on or around the loaded Lift.

6. To lower, disengage height locking lever and depress

release pedal. In some cases it may be necessary

to slightly raise the lift arm before disengaging the

height locking lever.

MAINTENANCE

Important: Keep Lift clean and well lubricated. Apply

a couple of drops of light machine oil to all pivoting

joints as needed. Thoroughly wipe up excess oil to

help prevent slipping and falling. Use only a good grade

hydraulic jack oil. Avoid mixing different types of fluid

and NEVER use brake fluid, turbine oil, transmission

fluid, motor oil or glycerin. Improper fluid can cause

failure of the jack and the potential for sudden and

immediate loss of load. We recommend Mobil DTE

13M or equivalent.

Adding oil

1. To check hydraulic oil level, unload Lift, lower lift

arms completely, then remove hydraulic unit from

Lift. Place hydraulic unit upright on a stable, level

surface. Locate and remove oil filler plug.

2. Ensure the oil level is even with the oil filler plug

hole. Reinstall the oil filler plug, then install

hydraulic unit onto receiver. Secure with provided

bolts.

Changing oil

For best performance and longest life, replace the

complete fluid supply at least once per year.

1. With saddle fully lowered, remove hydraulic unit

from Lift. Place hydraulic unit upright on a stable,

level surface. Remove the oil filler plug.

!WARNIN

Study, understand and follow all printed materials

provided with and on this device. Do not exceed

rated capacity. Ensure load is compatible with lift

pads. Center load on lift pads. After lifting load to

desired height, ensure lift arm locking mechanism

is engaged. Secure load to Lift using apropriate

straps. Engage locking caster mechanism before

working on or around loaded Lift. Move loaded Lift

over smooth, level, seamless surfaces only. Before

moving, ensure load has been lowered completely.

Use only on hard, level surfaces capable of

sustaining rated capacity loads. Lift only on areas

of the load as specified by it’s manufacturer. Do

not use for any purpose other than that for which

this device is intended. Failure to heed these

messages may result in personal injury and/or

property damage.

! SAFETY MESSAGE !

Be sure all tools and personnel are clear before

lowering load. No alterations shall be made to this

device. Only attachments and/or adapters supplied

by the manufacturer shall be used.