Southworth PUN Instruction manual

Southworth Products PUN Manual

PUN Installation,

Operation & Maintenance

Manual

Southworth Products Corp.

P.O. Box 1380 • Portland ME, 04104-1380

Phone: (207) 878-0700 or (800) 743-1000

Fax: (207) 797-4734

www.SouthworthProducts.com

Email: [email protected]

July 2018

Southworth Products PUN Manual2

Contents

1. Introduction..................................................................................................4

1.1 Responsibilities of Owners and Users...................................................................4

2. Safety............................................................................................................5

2.1 Safety Alert Symbols ...............................................................................................5

2.2 Signal Words ............................................................................................................6

2.3 Safety Devices..........................................................................................................6

3. Labeling........................................................................................................6

3.1 Label Part Numbers & Quantity:............................................................................. 6

3.2 Label Locations........................................................................................................7

4. Installation....................................................................................................8

4.1 Preparation ...............................................................................................................8

4.2 Positioning the Machine..........................................................................................9

4.3 Hydraulic Connections............................................................................................9

4.4 Electrical Connections ..........................................................................................10

4.5 Checking the Hydraulic System ........................................................................... 11

4.6 Testing..................................................................................................................... 11

5. Operation....................................................................................................11

5.1 Operator Controls ..................................................................................................12

5.2 Operational Sequence ...........................................................................................12

5.3 Run Time Fault Sequence .....................................................................................13

5.4 Manual Mode ..........................................................................................................13

5.5 Operational Sequence Illustration........................................................................ 14

6. Maintenance...............................................................................................15

6.1 Optional Support Stands.......................................................................................15

6.1.1. Support Stand Use Procedure.....................................................................15

6.2 Periodic Maintenance ............................................................................................16

6.2.1. Weekly Maintenance.....................................................................................16

Southworth ProductsPUN Manual PUN Manual3

6.2.2. Monthly Maintenance ...................................................................................17

6.2.3. Every six months or 500 hours .................................................................. 17

7. Troubleshooting ........................................................................................17

8. Adjustment & Replacement Procedures.................................................19

8.1 Aligning the Photo-Eyes........................................................................................19

8.2 Proximity/Limit Switches: .....................................................................................20

8.3 Setting End of Travel for Tilt Down Function ...................................................... 20

8.4 Inspecting and Cleaning the Control Valve ......................................................... 20

8.5 Repacking a Cylinder.............................................................................................22

8.6 Replacing a Cylinder..............................................................................................23

9. Hydraulic System Information..................................................................25

9.1 Hydraulic Power Unit.............................................................................................25

9.2 Hydraulic Plumbing Schematic ............................................................................26

9.3 Hydraulic Arrangement ......................................................................................... 27

9.4 Hydraulic Connections..........................................................................................28

10. Electrical Information..............................................................................29

10.1 Control Panel........................................................................................................29

10.2 Electrical Schematic ............................................................................................30

11. Warranty & Contact Information ............................................................31

Southworth Products PUN Manual4

1. Introduction

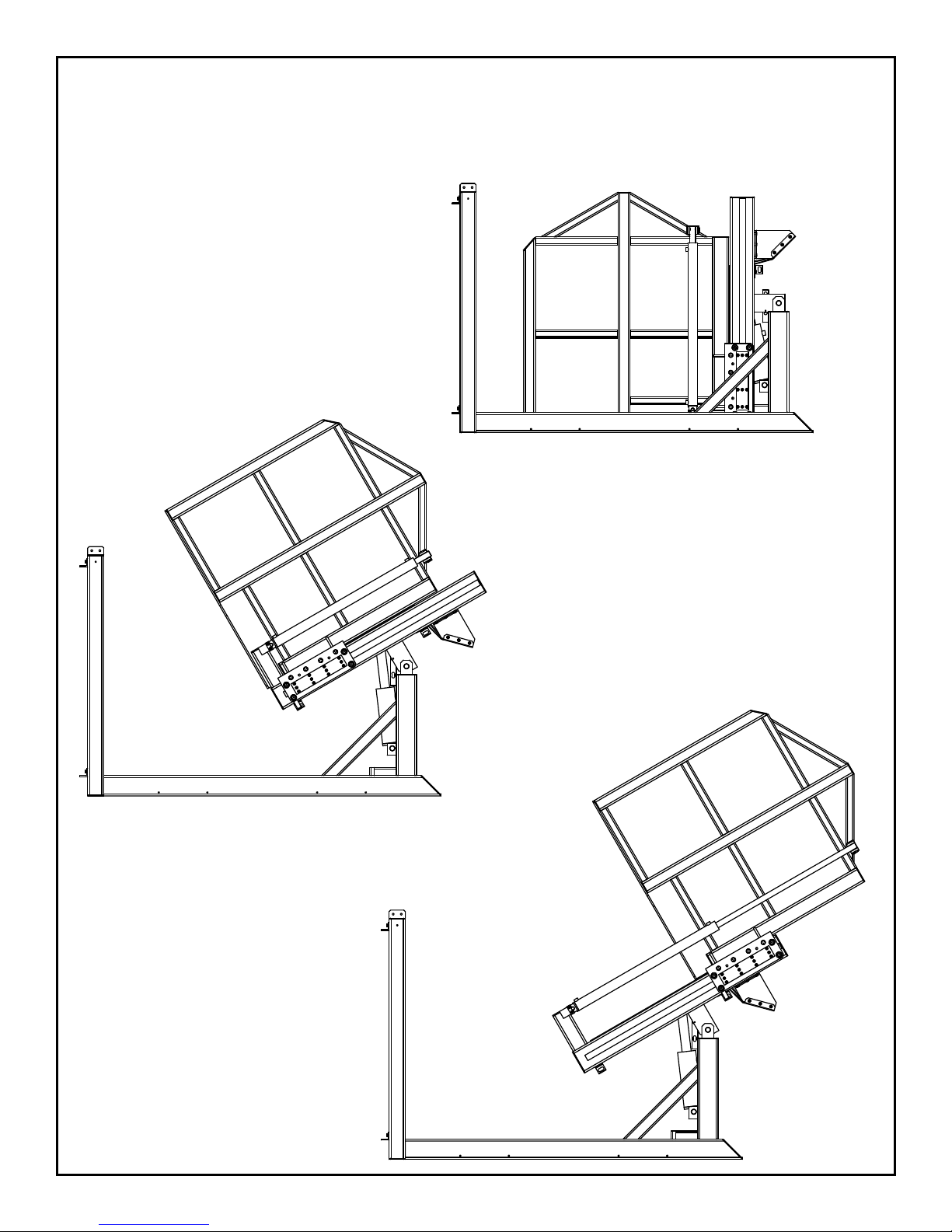

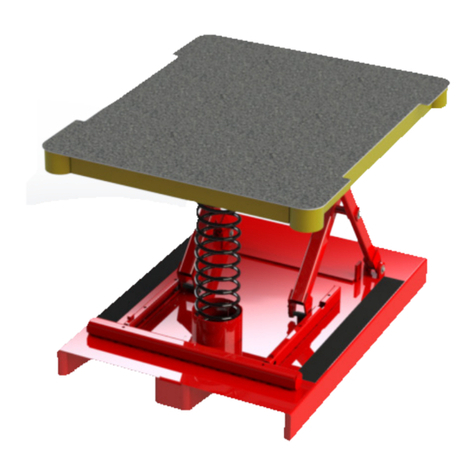

The Southworth Pallet Unloader (PUN) is designed to unload pallets. PUN units are

designed to tilt and lift materials, to be removed from the pallet individually, in a general

indoor industrial setting.

This manual is intended for PUN machines shipped during or

after February 2018 with control panels supplied by Southworth

Products. Please contact Southworth Products for information

about PUN machines shipped before February 2018 or with

control panels not as shown in the manual.

This manual contains instructions on the safe and proper installation, use, and

maintenance of the PUN unit. Be sure that this manual is available to the people who

install, use, or service the unit. Be sure that all personnel read this manual before they

install, use, or service the unit.

The instructions in this manual are not necessarily all-inclusive, as Southworth cannot

anticipate all conceivable or unique situations. In the interest of safety, please read this

whole manual carefully. Please understand the material in this manual before you install,

use, or service the PUN unit. If you have any questions about any of the instructions in this

manual, please contact Southworth Products Corp.

Southworth’s product warranty is shown on the rear cover of this manual. This instruction

manual is not intended to be or to create any other warranty, express or implied, including

any implied warranty of merchantability or tness for a particular purpose, all of which

are hereby expressly excluded. As set forth more specically in the product warranty,

Southworth’s obligation under that warranty is limited to the repair or replacement of

defective components, which shall be the buyer’s sole remedy, and Southworth shall not be

liable for any loss, injury, or damage to persons or property, nor for any direct, indirect, or

consequential damage of any kind resulting from the PUN unit.

1.1 Responsibilities of Owners and Users

Inspection and Maintenance – The device shall be inspected and maintained in proper

working order in accordance with Southworth’s owner’s manual.

Removal from Service – Any device not in safe operating condition such as, but not

limited to, excessive leakage, missing rollers, pins, or fasteners, any bent or cracked

structural members, cut or frayed electric, hydraulic, or pneumatic lines, damaged or

malfunctioning controls or safety devices, etc. shall be removed from service until it is

repaired to the original manufacturer’s standards.

Deection – It is the responsibility of the user/purchaser to advise the manufacturer where

deection may be critical to the application.

Repairs – All repairs shall be made by qualied personnel in conformance with

Southworth’s instructions.

Operators - Only trained personnel and authorized personnel shall be permitted to operate

the lift.

Southworth ProductsPUN Manual PUN Manual5

Before Operation – Before using the device, the operator shall have:

• Read and/or had explained, and understood, the manufacturer’s operating instructions

and safety rules.

• Inspected the device for proper operation and condition. Any suspect item shall be

carefully examined and a determination made by a qualied person as to whether it

constitutes a hazard. All items not in conformance with Southworth’s specication shall

be corrected before further use of the equipment.

During Operation – The device shall only be used in accordance with this owner’s

manual.

• Do not overload.

• Ensure that all safety devices are operational and in place.

Modications or Alterations – Modications or alterations to any Southworth industrial

positioning equipment shall be made only with written permission from Southworth.

2. Safety

Before installing, operating, or servicing this machine read, understand, and follow all

safety instructions and warnings.

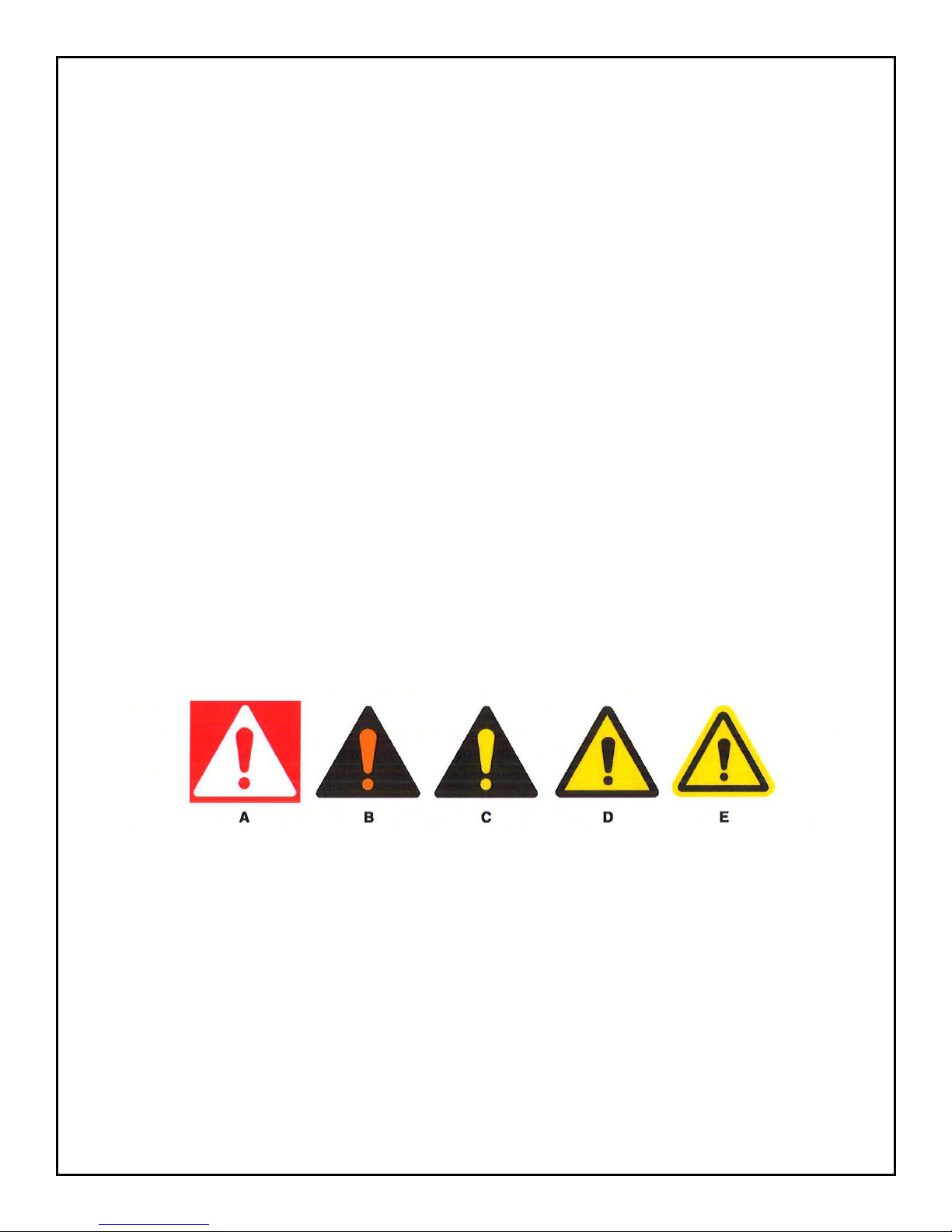

2.1 Safety Alert Symbols

A symbol that indicates a hazard. It is composed of an equilateral triangle surrounding an

exclamation mark. The safety alert symbol is only used on hazard alerting signs. It is not

used on safety notice and safety instructions signs.

A – For use with DANGER signal word; (safety white triangle, safety red exclamation mark,

safety red background)

B – For use with WARNING signal word; (safety black triangle, safety orange exclamation

mark)

C – For use with CAUTION signal word; (safety black triangle, safety yellow exclamation

mark)

D & E – For use with DANGER, WARNING, or CAUTION signal words; (D is a safety

yellow triangle with a safety black border and safety black exclamation mark; [E] is a safety

yellow triangle with a safety black exclamation mark and a safety yellow border around a

safety black band)

Southworth Products PUN Manual6

2.2 Signal Words

DANGER

Indicates a hazardous situation that, if not avoided, will result in

death or serious injury.

WARNING

Indicates a hazardous situation that, if not avoided, could result

in death or serious injury.

CAUTION

Indicates a hazardous situation that, if not avoided, could result

in minor or moderate injury.

NOTICE

Indicates information considered important, but not hazard-

related (e.g., messages relating to property damage).

2.3 Safety Devices

This machine is equipped with devices and features to protect the operator and nearby

personnel from severe injury or death. These features and devices shall be installed and

functioning correctly during operation.

Side Guarding – Protects operator and nearby personnel from moving parts.

Photo-eyes – Protects the operator and nearby personnel from entry into the load area

while machine is operating.

3. Labeling

This machine has labeling to indicate potential hazards this machine may pose when

operating and/or maintaining the machine. All labels must be legible. If any label is missing,

damaged, or otherwise illegible contact the manufacturer for replacement labels.

3.1 Label Part Numbers & Quantity:

1. 2995290T - QTY. 2

2. 2995460T - QTY. 1

3. 2995191T - QTY. 3

4. 2995459T - QTY. 2

5. 2998592T - QTY. 2

Southworth ProductsPUN Manual PUN Manual7

3.2 Label Locations

3

4

APPLY 2995191T TO

BOTTOM OF

ENCLOSURE. SHOULD BE

CENTERED AND WHEN

ENCLOSURE IS TILTED

90

1

2

Southworth Products PUN Manual8

4. Installation

To avoid death or serious injury only trained and/or qualied

personnel shall perform any installation.

4.1 Preparation

Before installation – check for local codes and ordinances which may apply. It is your

responsibility to obtain any necessary permits. Read all of these installation instructions

carefully. Be sure to read and understand all of the warnings.

Select the location where the unit will be installed. Choose a location where the oor is rm,

at and level. As the unit operates, it is very important that the front edge (the load edge) of

the bucket touches the oor at the same time as the rest of the bottom plate touches.

If the middle or back edge of the bottom plate touches the oor

before the front edge of the bucket, the machine may try to raise

itself off the oor causing damage to the machine. This can

happen if the oor surface is not at.

Southworth ProductsPUN Manual PUN Manual9

To avoid serious death or serious injury:

• If the unit is mounted on an unstable surface, it may tip over when in use. You

may be hurt, and the unit and load may be damaged.

• Protect the unit from rain or moisture. If the electrical parts in the power unit

get wet, workers may be hurt by electrical shock. The electrical parts may fail

if they are wet.

• The electric motor on the remote power unit can create sparks. Do not install

the power unit in an area where ammable gases may be present.

4. You will need these tools to install the unit:

• A lift truck that can lift the unit safely.

• Shims and appropriate lag bolts.

• A masonry drill and bit to drill the holes for the lag bolts.

• Extra hydraulic oil for ushing the hydraulic lines and relling the tank.

• Level.

4.2 Positioning the Machine

1. Remove the shipping material and unskid the unit. Move the unit into position,

supporting the base of the unit.

2. Level the machine using shims as necessary. Grout beneath the entire base from –

leave no gaps. Allow grout to fully cure before continuing.

3. Drill holes for lag bolts and install lag bolts.

Do not hang the unit from the bucket. This can damage the unit.

4. Check the movement of the bucket through its full range.

To avoid serious injury

• Pinch points may exist that may cause injury. Keep hands, feet, and loose

clothing away from moving parts.

4.3 Hydraulic Connections

1. Install the power unit. Run the hydraulic line between the power unit and the

PUN but do not make the connections yet. Be sure that the hydraulic line is

protected from passing trafc, and that it will not be damaged.

To avoid death or serious injury:

• Be sure that the hydraulic line will not be pinched by the unit as it raises or

lowers. If you allow the line to be pinched, the unit may not work properly. A

hose may break, the load enclosure may drop suddenly, and someone may be

hurt.

Southworth Products PUN Manual10

2. Before connecting the power unit, blow out the hydraulic lines with compressed

air.

The hydraulic lines must be clear of any contamination or

damage to the hydraulic power unit will occur.

See Hydraulic Information section for specications, plumbing schematic and

location drawings:

1. Connect port A to the top of the tilting cylinders

2. Connect port B to the base of the tilting cylinders.

3. Connect port C to the base of the lifting cylinders.

4. Connect Vent Line from top of lifting cylinders to the tank.

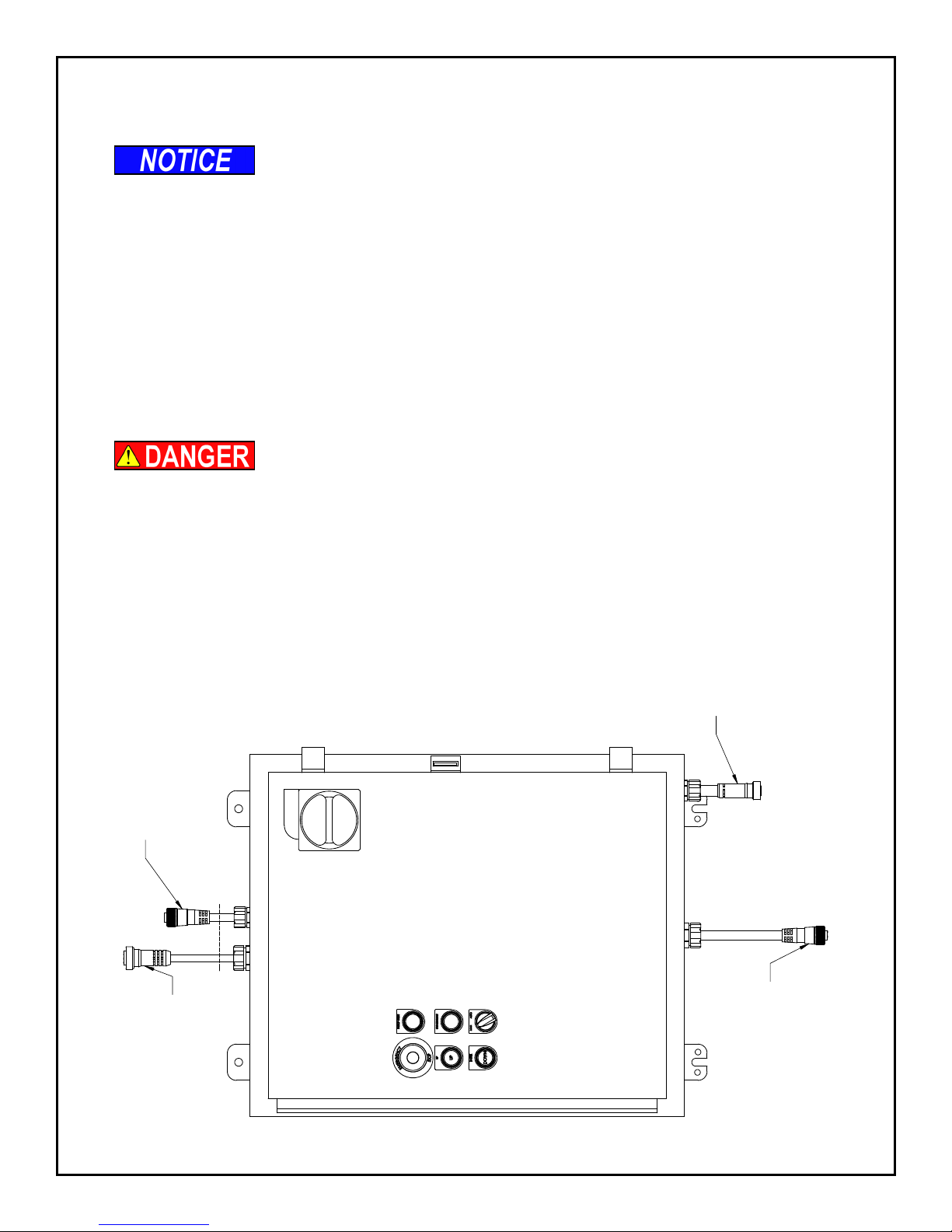

4.4 Electrical Connections

To avoid death or serious injury:

• This unit requires three-phase 460V AC. This voltage can kill you. Don’t work

with the electrical parts unless you are a qualied electrician.

• The fuses or circuit breakers are designed to reduce any re hazard. Be sure

to install the fuses or circuit breakers.

OF THE MACHINE

ON THE CYLINDER END

CONNECT TO MULTI-

PORT BASE LOCATED

CONNECT TO

MOTION ALARM

CONNECT TO

JUNCTION BOX ON

HYDRAULIC POWER

UNIT

CONNECT TO THE

HYDRAULIC POWER

UNIT MOTOR

Southworth ProductsPUN Manual PUN Manual11

The power unit is designed for three-phase AC. If you connect

the power so the motor runs backwards, the bucket will not

move, and you may damage the pump. Do not operate the unit for

more than 2 or 3 seconds if you think the motor might be turning

backwards.

4.5 Checking the Hydraulic System

Check the level of the hydraulic uid in the system. With the bucket lowered completely,

the hydraulic uid can be checked by viewing the sight gauge on the reservoir of the power

unit.

4.6 Testing

1. Clear the area around the unit. Remove any materials which might get in the

way of the bucket as it raises or lowers. Be sure that the safety guards are in

place on both sides of the unit.

2. Warn others to stay away from the unit. Operate the unit through its full range

of travel. The bucket should rise smoothly with a quiet humming sound, and

lower smoothly and quietly. Raise and lower the bucket a few times to check the

operation.

3. As the bucket lowers, notice how the bottom of the enclosure meets the oor.

The front edge (load edge) of the enclosure should touch at the same time

as any other part of the enclosure. If any other part of the base of the bucket

touches before the front edge, the oor is not at. Insert shims above the low

spots on the oor, so that the base is at and level.

If another part of the bucket touches the oor before the front

edge, the machine may not stop automatically at the correct

moment. This may cause the machine to try to lift itself off of the

oor.

If the “Tilt Down” proximity switch is out of adjustment, the

machine may continue to run when it should be stopped. This

may cause the machine to try to lift itself off of the oor. This

could cause damage to the unit.

4. As a nal step, clean up all spilled hydraulic uid. Spilled hydraulic oil is slippery,

and may present a re hazard. If you clean up any spilled uid, you will be able

to tell right away if the unit begins to leak.

5. Operation

To avoid death or serious injury:

• Only trained and/or qualied personnel may operate the machine.

• Crush, pinch, and shear points exist; keep hands, feet, and loose clothing

away from moving parts.

Southworth Products PUN Manual12

To avoid death or serious injury:

• Ensure all safety devices and guarding are installed and operating correctly.

• Verify that area in and around the machine are clear of debris and/or personnel

before operating the machine.

Load shall not exceed the machines rated capacity. Overloading

the machine can cause damage to the machine.

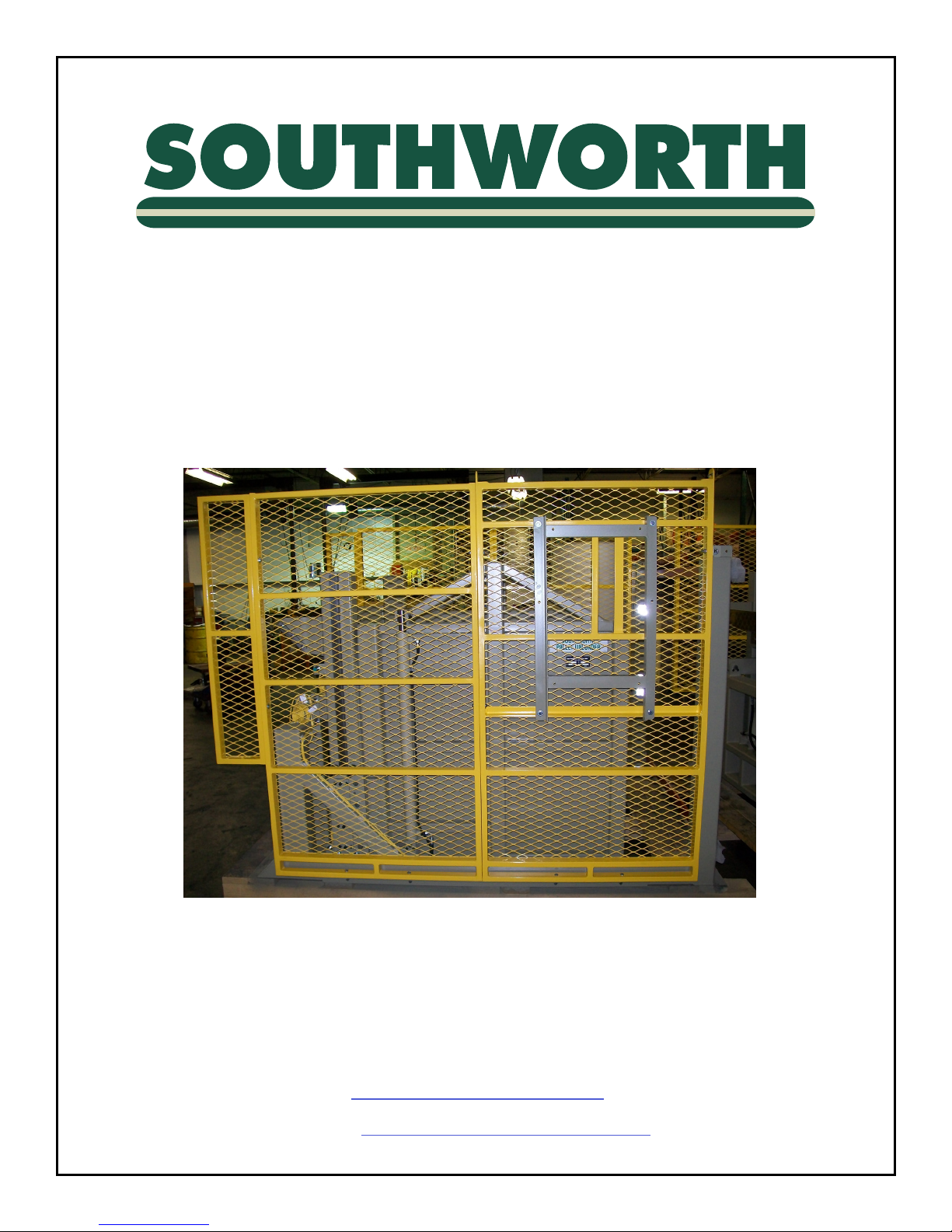

5.1 Operator Controls

• Main disconnect switch – Controls main

power supply to the control panel.

• Emergency Stop – Used to stop the

machine in the event of an emergency.

• E-STOP RESET – Used to reset the

controls system after the Emergency

Stop button has been pressed.

• GUARD RESET – Used to reset the

control system after the photo eyes

detect an obstruction.

• UP – Used to start the tilting and lifting

sequence.

• DOWN – Used to start the lowering

sequence.

5.2 Operational Sequence

With the machine turned off and the bucket in the fully lowered position.

1. Turn the main disconnect switch to the ON position. The red E-STOP light should

turn on.

2. Pull the EMERGENCY STOP button and press the E-STOP RESET button. The

red E-STOP light should turn off, the green E-STOP RESET light should turn on,

and the GUARD RESET light should turn on.

3. Turn the selector switch to the AUTO position.

4. Press the GUARD RESET button. If the photoeyes do not detect an obstruction

the GUARD RESET light will turn off and the machine will be ready to operate.

5. Move load into the bucket. Verify that load does not exceed the machine rated

capacity. Loading will disrupt the photoeyes causing the GUARD RESET light to

turn on.

6. Press the GUARD RESET button. If the photoeyes do not detect an obstruction

the GUARD RESET light will turn off and the machine will be ready to operate.

MAN/AUTO MODE SELECTOR

MAIN DISCONNECT SWITCH

GUARD RESET

E-STOP RESET

DOWN BUTTON

EMERGENCY

STOP (E-STOP)

BUTTON

UP

BUTTON

Southworth ProductsPUN Manual PUN Manual13

7. Press and hold the UP button for one second. The motion alarm with ash and

beep. Release the UP button. The bucket will tilt up until the Tilt Up proximity

switch is reached.

8. To lift the bucket press and hold the UP button until enclosure reaches the

desired height. The UP button must be held for three seconds before the

machine begins to move. The motion alarm will ash and beep. To stop the

enclosure release the UP button. This process can be repeated until the Lift Up

proximity switch is reached.

9. To return the bucket to the full down position press the DOWN button. The

DOWN button must be held for three seconds before the enclosure will begin to

move. The motion alarm will ash and beep. After the enclosure begins to move

the DOWN button can be released. The machine will tilt back until the Tilt Down

proximity switch is reached then lower until the Lift Down proximity switch is

reached.

Note: If the photoeyes detect an obstruction the machine will stop and the GUARD RESET

light will turn on. The machine will not operate again until the obstruction is cleared and the

GUARD RESET button has been pressed.

If the EMERGENCY STOP button has been pressed. Steps 2 & 3 must be performed to

resume operation.

5.3 Run Time Fault Sequence

If the lift lowering motion takes longer than 25 seconds, or the other motions take longer

than 15 seconds, a Run Time Fault has occurred. The fault could be caused by a tripped

overload relay, blown fuses, damaged hydraulic lines, faulty valve, damaged wiring, or a

damaged or faulty proximity switch.

When a Run Time Fault occurs the machine will stop and the GUARD RESET light will turn

on. Trained and/or qualied personnel should examine the machine for the cause of the

problem before it is return to operation.

To return the machine to operation:

1. Ensure the cause of the Run Time Fault has been corrected.

2. Turn the selector switch to the MANUAL position and press the GUARD RESET

button for ve seconds. The GUARD RESET light should turn off and operation

can resume.

5.4 Manual Mode

There are two uses of MANUAL mode:

1. To stop and correct and automatic motion started in error. Turning the selector

switch to MANUAL position will stop all automatic motion. The machine can be

manually operated with the UP and DOWN buttons to return the machine to a

particular starting position.

Southworth Products PUN Manual14

2. To test and diagnose problems with the machine by using the UP and DOWN

buttons

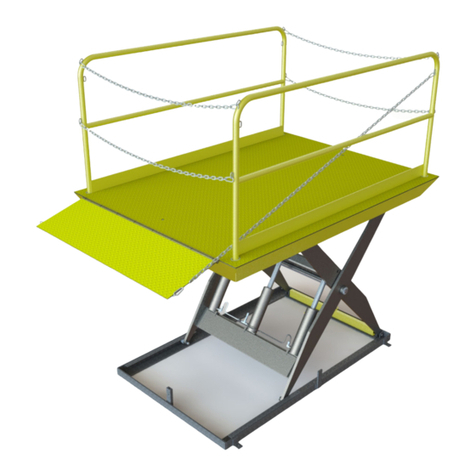

5.5 Operational Sequence Illustration

FULLY LOWERED POSITION

TILTED TO TILT UP

PROXIMITY SWITCH

FULL TILT & FULL

RAISED POSITION

Southworth ProductsPUN Manual PUN Manual15

6. Maintenance

To avoid death or serious injury:

• Only trained and/or qualied personnel shall perform maintenance or repair.

• All maintenance shall be perform with the bucket in the fully lowered position.

• Ensure pressure has been released from the hydraulic system before

performing any maintenance. Pressurized uid can penetrate skin and cause

death or severe injury.

• No adjustment to the hydraulic relief valve shall be made. Changing the relief

valve setting may cause the machine to act in an unpredictable manner.

• All labeling shall be legible. If labels are missing, damaged, or otherwise

illegible contact the manufacturer for replacement labels.

It is important to immobilize parts of the tilt and dump mechanisms before you service the

unit. Please follow all of these steps whenever you work on the unit:

1. Lower the bucket completely to the loading position. The cylinders and other

parts can be removed safely from either the tilt or dump mechanisms when the

bucket is completely lowered. Normally, you should never need to work under

the bucket. Always stay clear of the space under this enclosure.

2. Turn off the electrical power at the main disconnect or circuit breaker. Follow

standard lock-out, tag-out procedures. Do not let anyone else use the controls

on the unit.

3. When you are nished, operate the machine, without a load, through at least

one cycle. Be sure that it is operating smoothly and properly before returning it to

regular operation.

6.1 Optional Support Stands

The PUN Support Stands shall not be used for hydraulic, electrical, or mechanical

maintenance.

Read and understand the Support Stand Use Procedure before

using the support stands. Failure to follow the use procedure

may result in damage to the machine.

6.1.1. Support Stand Use Procedure

To remove the machine from service:

1. Using the control pushbutton raise the tilt frame to the highest position.

2. Turn the main disconnect switch to the OFF position. Follow Lock Out Tag Out

procedures.

3. Set the support stands at the highest extension pin position.

Southworth Products PUN Manual16

Both support stands must be used. Never use only one stand

under the tilt frame.

4. Position each support in the load area as indicated by the alignment label on the

inside of the base frame rail. See Support Stand Placement drawing.

Note: If not present attach alignment label (2998592T) to base frame rails

according to Support Stand Placement drawing.

The load area must be clear of debris. Never have anything under the support

stands when in use.

5. After all personnel are clear of the load area remove the lock out and turn the

main disconnect switch to the ON position.

6. Using the control pushbutton lower the tilt frame until it is within 1/4” of the

stands.

If the frame starts to contact the support stands the machine

motion must be stopped by the operator. Do not over power the

tilt frame on to the support stands. This may damage the machine

and over stress the oor anchors.

7. Turn the main disconnect switch to the OFF position. Follow Lock Out Tag Out

procedures.

8. It is now safe to access the load area.

To return the machine to regular service:

1. Remove the lock out and turn the Main Disconnect switch to the ON position.

2. Using the control pushbutton raise the tilt frame to the highest position.

3. Turn the main disconnect switch to the OFF position. Follow Lock Out Tag Out

procedures.

4. Remove the support stands from the load area.

5. After personnel are clear of the load area remove the lock out and turn the Main

Disconnect switch to the ON position.

6. Using the control pushbutton lower the tilt frame to fully lowered position.

6.2 Periodic Maintenance

6.2.1. Weekly Maintenance

• On the tilt mechanism and dump mechanism, check all of the hydraulic ttings and

hoses, and repair as necessary. Sometimes the ttings can be worked loose by the

vibrations in the hydraulic system.

Southworth ProductsPUN Manual PUN Manual17

To avoid death or serious injury:

• If a hydraulic tting becomes loose, or if a hydraulic hose breaks, the

hydraulic uid may escape from the system under pressure. If the bucket is

elevated when this happens, this can cause it to drop. Someone may be hurt,

or the unit or load may be damaged. Be sure all hydraulic ttings are free of

leaks.

• Check the operation of the three photo eyes on the entry side of the machine. With the

bucket in the fully lowered position, break the beam of each photo eye. Here are the test

conditions for the photo eyes:

• Beam unbroken - LED on photoeye is lit.

• Beam is broken - LED on photoeye is out.

• When you break any beam, this should trigger a stop condition which requires the

controls on the machine to be reset to return to “Ready” condition. The reectors for the

photo eyes should be replaced if they are cracked or otherwise damaged.

• Check and tighten all hardware.

6.2.2. Monthly Maintenance

• On the tilt and dump mechanisms, inspect the main pivot pins and bushings and the

cylinder clevis pins and bushings for signs of wear.

To avoid death or serious injury:

• If you are going to repair the main pivot pins and bushings on either the tilt or

dump mechanisms, you must return the bucket to the loading position.

• Check the level and appearance of the hydraulic uid. When the bucket is fully lowered,

the oil should be at the correct level as viewed through the sight glass on the reservoir.

Add oil as necessary. Change the oil and lter if the oil has darkened, or feels gritty or

sticky.

6.2.3. Every six months or 500 hours

• The hydraulic system includes a replaceable oil lter. Replace this lter as part of your

routine maintenance. Inspect the oil, and replace it if necessary. If the oil is changed,

thoroughly clean the reservoir, including the suction strainer.

• Be sure all of the warning labels are in position and legible. See Labeling Section. The

warning labels are intended to protect your workers. If the labels are missing, or if they

have been painted over, replace them.

7. Troubleshooting

To avoid death or serious injury:

• All maintenance, repair, and diagnosis shall be performed by trained and/or

qualied personnel only.

Southworth Products PUN Manual18

• Follow steps in Maintenance section to make the machine safe to inspect and

maintain.

To avoid death or serious injury:

• All maintenance and repair shall be performed with the bucket in the fully

lowered position.

• Ensure pressure has been released from the hydraulic system before

performing any maintenance. Pressurized uid can penetrate skin and cause

death or severe injury.

Symptom Possible Cause Remedy

Neither lift mechanism is working: CAUTION!

If the tilt function does not begin right away,

don’t continue to operate the “up” control for

more than 2 or 3 seconds. You may damage

the pump.

The power for the unit may be switched

off.

Turn on the “Main Disconnect” switch.

One of the fuses or circuit breakers may

have opened.

Replace the fuse, or reset the circuit breaker. If

the condition repeats, determine the cause of the

problem.

The Emergency Stop switch may have

been pressed.

Reset the Emergency Stop switch, and reset the

control system.

One of the protective light beams at the

front of the unit may be blocked.

Be sure the space in front of the unit is clear.

There may be a problem with one of the

photo eyes.

Check the alignment of each photo eye and its reec-

tor. When the eye can “see” the reector, the LED on

the photo eye should light. Check the power supply to

the photo eye. Replace the part if it is faulty.

The motor for the pump may have

stopped. The motor controls have built-in

over current protection in case of an

overload.

The protective circuit will reset after it has cooled.

Look for anything which may be preventing the motor

from turning.

The motor may be running backwards. If this is happening, the pressure valve will indicate

zero pressure even though the motor is running.

Reverse any two electrical leads on the motor.

The motor may be “single phasing”. This causes the motor to hum, but not turn. Check for

a break in one lead to the three-phase motor. Check

the motor wiring and line fuses.

The motor may be running backwards. If this is happening, the pressure valve will indicate

zero pressure even though the motor is running.

Reverse any two electrical leads on the motor.

The motor may be “single phasing” This causes the motor to hum, but not turn. Check for

a break in one lead to the three-phase motor. Check

the wiring and line fuses.

The voltage to the motor may be too low. Check the voltage at the starter when the motor is

under load. The supply voltage should be within +

10% of the rating.

The level of the hydraulic oil may be low. When the unit is lowered completely, check the oil

level by viewing the reservoir sight gauge.

The ller/breather cap on the hydraulic

tank may be plugged.

Remove the cap and clean the bafes inside it.

There may be a vacuum leak in the suc-

tion line. (This could cause cavitation and

loss of suction in the pump.)

Check the suction line hose and ttings. CAUTION!

Do not allow cavitation to continue -- this may dam-

age the pump.

The coupling between the pump and mo-

tor may be missing.

Remove the pump as described in this section.

Check to see that the coupling is in place.

Southworth ProductsPUN Manual PUN Manual19

8. Adjustment & Replacement Procedures

8.1 Aligning the Photo-Eyes

1. The photo-eyes are part of a system which protects the operators from moving

parts which are potentially dangerous. If an operator moves close to the loading

end of the machine, and breaks any of the 3 light beams, the unit will stop

immediately. The unit will not run again until the control system has been reset.

Each eye sends a light beam to a matching reector. The beam is then returned

to the light sensor.

2. When the machine is turned on, check the LED indicator on the side of the

photo-eye. If the photo eye is properly aligned and is not blocked, with the beam

returning from the reector, the LED will light. If the photo-eye cannot see the

reector, or the beam is blocked, the LED will be out. If necessary, move the

reector until the LED lights.

Symptom Possible Cause Remedy

The tilt mechanism will not raise. The up-proximity switch for the tilt lift func-

tion may be out of adjustment.

Check the adjustment of the switch. (See the section

on “Adjustment and Alignment”.)

The “up” side of the control valve for this

function may not be working.

The “up” side of the valve must be energized and

fully open. Check the solenoid on the “up” side of the

valve with a voltmeter. Check for a problem with the

wiring to the control valve. The valve must be clean

and free to operate. Release the pressure from the

system and clean the valve. (See the section on

“Inspecting and Cleaning a Control Valve”.)

The tilt mechanism raises slowly. The counter-balance valve in this circuit

may be plugged.

Release the pressure from the system and clean the

valve.

The tilt mechanism does not lower. Warning!

Before working under any raised parts of the

unit, support the body of the unit using a set

of strong supports.

The “down” side of the control valve for

this part of the system may not be work-

ing.

The “down” side of the valve must be energized and

fully open. Check the solenoid on the “down” side of

the valve with a voltmeter. Check for a problem with

the wiring to the control valve. The valve must be

clean and free to operate. Release the pressure from

the system and clean the valve. (See the section on

“Inspecting and Cleaning a Control Valve”.)

When the load enclosure is lowered, the

center or rear touches the oor before the

front edge (load edge).

The oor is not at. Insert shims above the low spots in the oor. The

base frame of the machine must be at and level.

The pump motor continues to run after the

front edge (load edge) of the load enclosure

touches the oor.

The proximity switch for the “Tilt Down”

function may be out of adjustment.

Adjust the position of the target for this switch.

The “Tilt Down” part of the cycle begins

prematurely.

The tilt frame may be hitting the stop pads

at the upper limit of travel too hard.

Adjust the position of the target for the “Tilt Up”

proximity switch.

The dump mechanism will not raise. The up-proximity switch for the dump lift

function may be out of adjustment.

Check the adjustment of the switch. (See the section

on “Adjustment and Alignment”.)

The pump motor continues to run after the

load enclosure has reached the upper limit of

the dump travel.

The “Lift Up” proximity switch may be out

of adjustment.

Check the adjustment of the switch. (See the section

of “Adjustment and Alignment”.)

At the end of the cycle, the load enclosure

drops onto the base frame.

The proximity switch for the “Dump Down”

function may be set too high. When the

motor is shut off, this allows the load

enclosure to drop.

Check the adjustment of the switch. (See the section

on “Adjustment and Alignment”.)

Southworth Products PUN Manual20

3. If the LED will not light, yet the reector seems to be aligned, check that the

photo eye is receiving power.

8.2 Proximity/Limit Switches:

1. On this machine, proximity switches are used as limit switches. Each switch has

two parts a sensor and a target. Each switch is a “normally open” type.

2. The nominal distance between each sensor and its target is 3/16”. If the sensor

can see the target, the LED on the side of the sensor will light. If necessary,

change the alignment of the target or sensor until the LED lights.

3. If the LED will not light, yet the target seems to be aligned, check that the

proximity switch is receiving power.

8.3 Setting End of Travel for Tilt Down Function

If any part of the base plate contacts the oor, except for the front

lip, you must shim the base of the machine.

If the motor continues to run after the front of the bucket touches

the oor, the unit may try to lift itself off of the oor. This can

damage the machine. To correct this problem, move the target so

that it activates the switch sooner.

Set the unit so that the loading edge of the bucket is touching the oor.

Position this switch so that the bucket stops lowering when the front lip of the bucket just

contacts the oor. When the bucket reaches this limit, the switch should send a signal to

stop the motor on the hydraulic power unit.

8.4 Setting End of Travel for Tilt Up Function

If the frame of the bucket is allowed to hit the stop pads with too

much force, it will have an erratic motion. It may even bounce off

of the pads and begin the Tilt Down part of the cycle by itself.

Set this switch so that the tilt function of the bucket stops just as the frame of the bucket

hits the stop pads, or just a moment before. When the bucket reaches this limit, the switch

should send a signal to stop the motor on the hydraulic power unit. A clearance of 1/8” from

the pads is acceptable.

8.5 Inspecting and Cleaning the Control Valve

1. Check that the valve is receiving the correct control voltage. When the valve is

supposed to be energized, the solenoid should receive 24V DC.

2. Check the continuity through the solenoid coil. With the power off, check the

resistance through the coil using an Ohmmeter. There should be a low resistance

(a few Ohms). If the meter shows no resistance, the coil may be shorted.

Substitute a coil which is known to be good. If the meter shows an innitely high

resistance, the coil should be replaced.

This manual suits for next models

1

Table of contents

Other Southworth Lifting System manuals

Southworth

Southworth Powered Dandy Lift User manual

Southworth

Southworth PalletPal 360 User manual

Southworth

Southworth UDLV-150 User manual

Southworth

Southworth PLM 250 User manual

Southworth

Southworth ZLS Series User manual

Southworth

Southworth Dura-Dock DDL5-59M User manual

Southworth

Southworth PalletPal Walkie User manual

Southworth

Southworth CLL05-68 User manual

Southworth

Southworth PalletPal 360 User manual

Southworth

Southworth DANDY LIFT User manual