i

TABL OF CONT NTS

Section Page

S C 1 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

1.1 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

1.2 Standard Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

1.3 Optional Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

S C 2 NOT S, WARNINGS and CAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . .1

S C 3 UNPACKING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

S C 4 SAF TY CONSID RATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

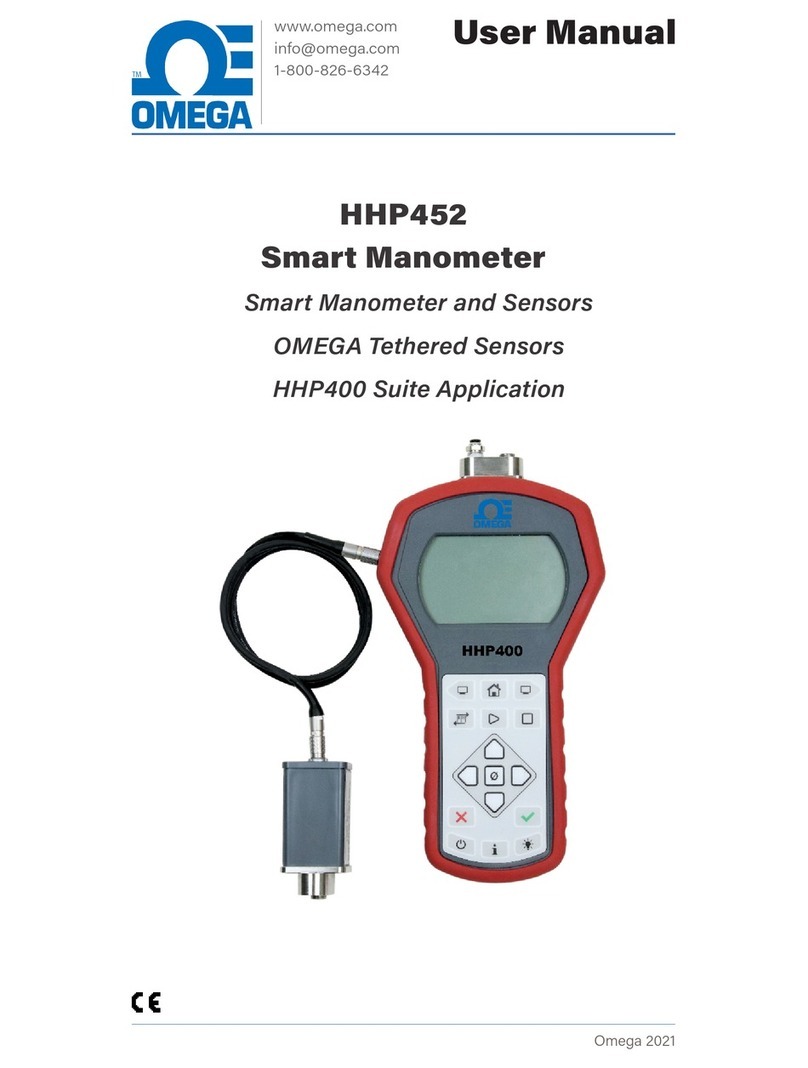

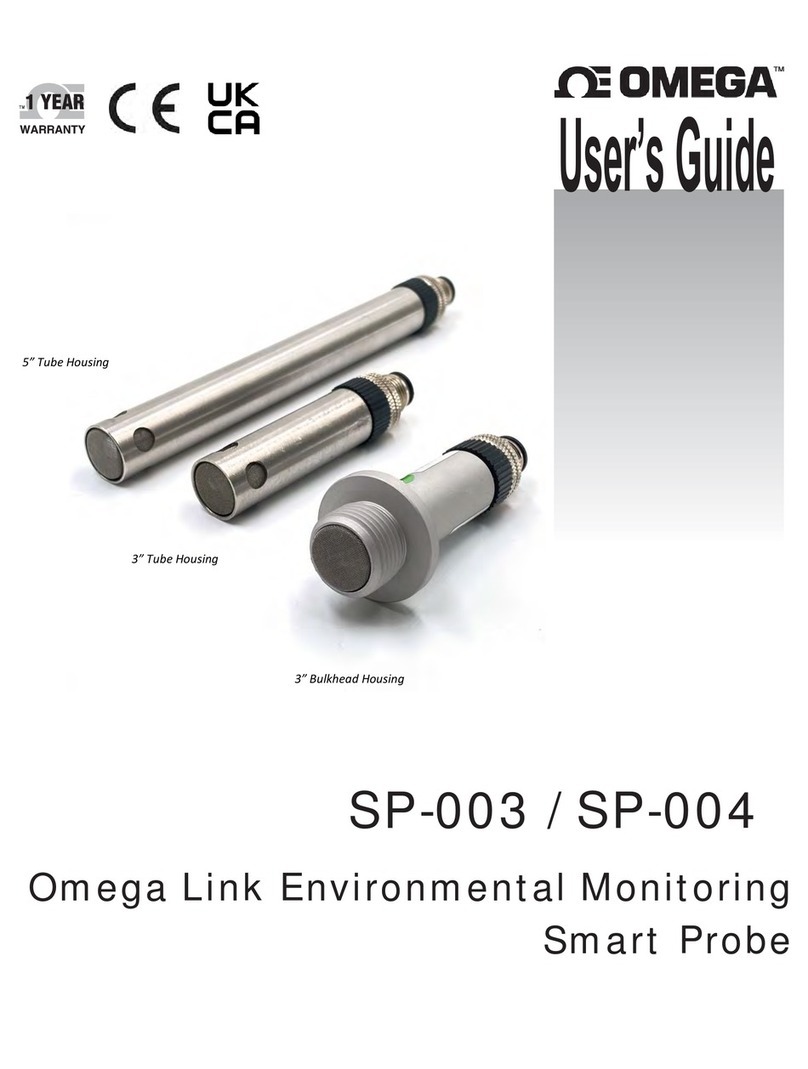

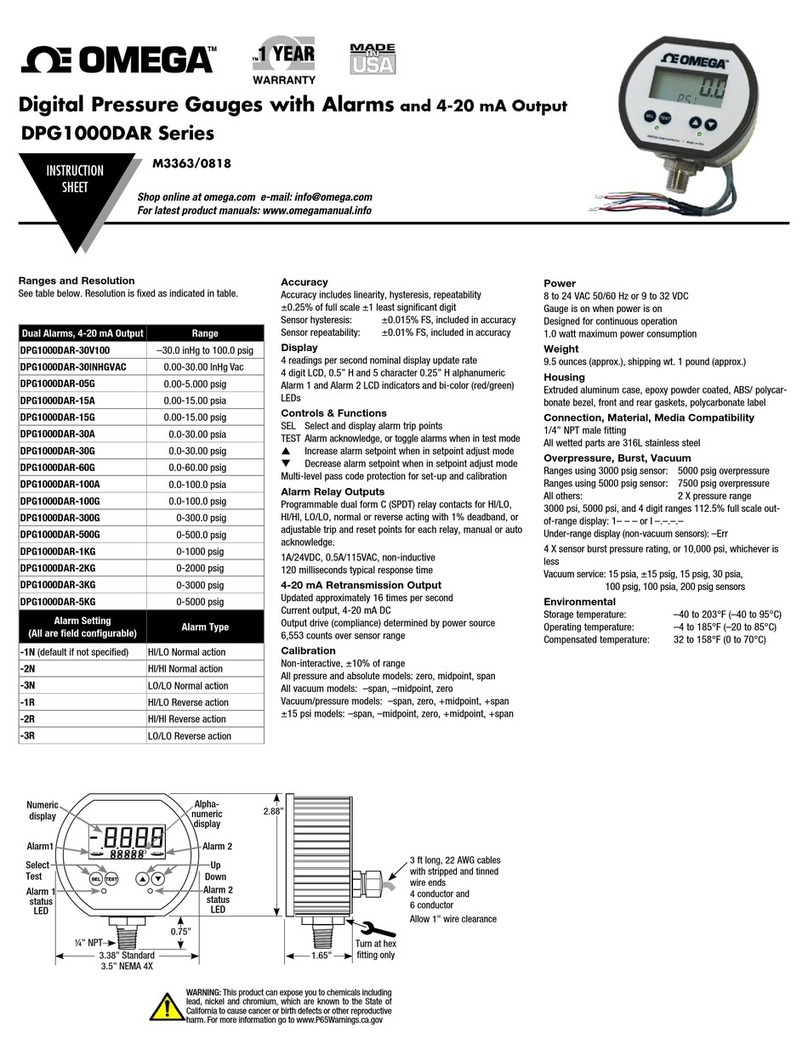

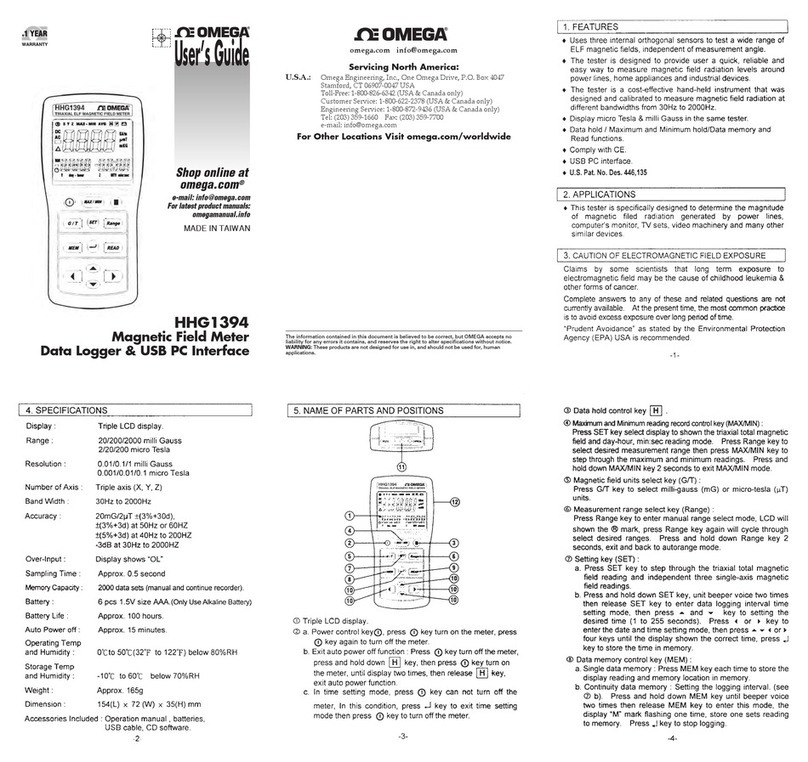

S C 5 PARTS OF TH M T R . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

5.1 Front of the Meter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

5.2 Rear of the Meter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

S C 6 S TUP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

6.1 Conditions Requiring Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . .8

6.2 Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

6.3 Rating/Product Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

6.4 Main Board Power Jumpers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

6.5 Main Board Jumpers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

6.6 Panel Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

S C 7 S NSOR INPUT AND MAIN POW R CONN CTIONS . . . . . . . . . . . .12

7.1 Sensor Input Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

7.2 Main Power Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

7.3 Analog and Relay Output Connections . . . . . . . . . . . . . . . . . . . . . .14

S C 8 INPUT TYP (INPT) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

S C 9 D CIMAL POINT POSITION (D C.P) . . . . . . . . . . . . . . . . . . . . . . . . . .17

S C 10 R ADING CONFIGURATION (“RD.CF”) . . . . . . . . . . . . . . . . . . . . . . .18

S C 11 S TPOINT 1 CONFIGURATION (S1.CF) . . . . . . . . . . . . . . . . . . . . . 18

S C 12 S TPOINT 2 CONFIGURATION (S2.CF) . . . . . . . . . . . . . . . . . . . . . 19

S C 13A S TPOINT 1 D ADBAND (S1.DB) . . . . . . . . . . . . . . . . . . . . . . . . . 19

S C 13B CYCL TIM (Time) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

S C 14 S TPOINT 2 D ADBAND (S2.DB) . . . . . . . . . . . . . . . . . . . . . . . . . 20

S C 15 OUTPUT CONFIGURATION (OT.CF) . . . . . . . . . . . . . . . . . . . . . . . 21

15.1 To Enable/Disable the Analog Output . . . . . . . . . . . . . . . . . . . 21

15.2 To Select Analog Output as Current or Voltage . . . . . . . . . . . . 21

15.3 To Select Analog Output or Proportional Control . . . . . . . . . . . 22

S C 16 PROPORTIONAL BAND (P.BND) . . . . . . . . . . . . . . . . . . . . . . . . . . 23

S C 17 MANUAL R S T (M.RST) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

S C 18 OUTPUT SCAL AND OFFS T (OT.S.O) . . . . . . . . . . . . . . . . . . . . 25

S C 19

COLD JUNCTION OFFS T CALIBRATION (C.J.OF)

. . . . . . . . . . . . . . . 27

S C 20 LOCK OUT CONFIGURATION (LK.CF) . . . . . . . . . . . . . . . . . . . . . . 28

20.1 To Enable/Disable the Reset Button in the Run Mode . . . . . . . 28

20.2 To Enable/Disable Setpoint Changes . . . . . . . . . . . . . . . . . . . 28

20.3 To Enable Display’s Program Version . . . . . . . . . . . . . . . . . . . 28

S C 21 TUNING PROPORTIONAL CONTROLL R . . . . . . . . . . . . . . . . . . . 29

S C 22 DISPLAY M SSAG S . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

S C 23 M NU CONFIGURATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31