Section 2: Overview

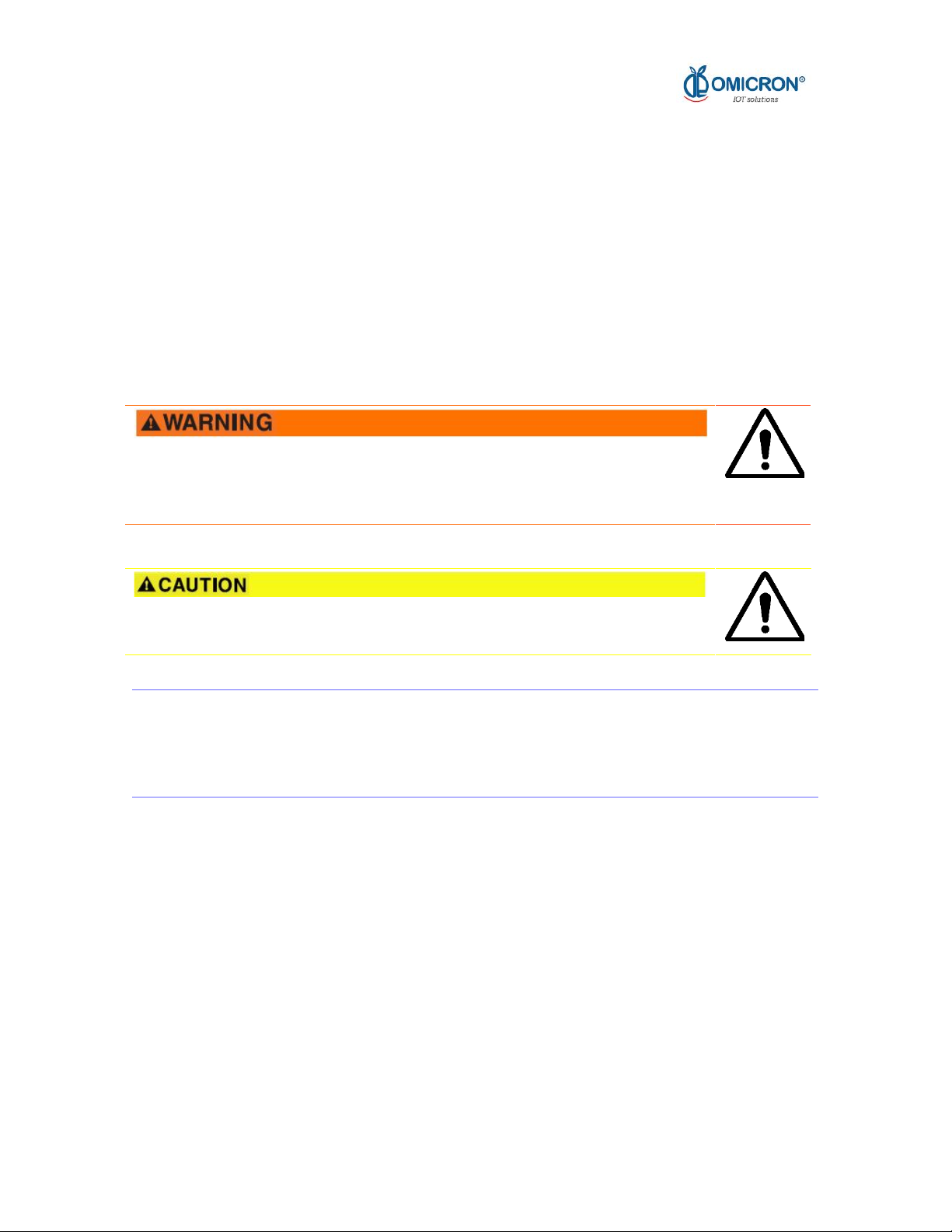

The internet of things (IoT) multisensor wireless device Datalog X-PRO is designed for remote

monitoring of multiple processes requiring high safety and measurement precision. In support of

your automation needs, it is fitted to receive up to 3 sensors of multiple types (listed in Section 5).

The system is delivered with a rechargeable Li-Ion Battery, necessary means to attach the Main

Unit enclosure to where is recommended, its AC/DC adapter, and all purchased wireless

communication modules. In accordance with the philosophy of the release, all complements

referred above can be prescinded, and remote data transmission may be performed by different

popular wireless technologies. Customers are also offered memberships for the use of a platform

for remote monitoring and configuration, supported by the manufacturer. More detail can be

found ahead.

The device is delivered with the necessary means for its mounting, however, it may require

additional initial configuration regarding its sensors or wireless communication configuration.

After initial setup, additional configuration can be made remotely by authorized personnel.

Parameter setting can be password protected.

2.1 Features

Datalog X-PRO has been thought to easily monitor and deliver data about the evolution of the

processes is embedded into. As such, it relies on a series of functionalities, tools and

characteristics, set to offer the user the desired comfort.

Among these, it is worth to highlight the direct link that devices have with Centriomega® Remote

Monitoring Platform through their wireless communication modules: a platform accessible from

any computing device enabled for internet navigation (PC, tablet, smartphone).

Said platform facilitates remote configuration and monitoring tasks, keeps graphic record of the

variables of interest, indicates their maximum and minimum admissible limits, generates alarm

events with visual indications, sends external warning messages through e-mail, SMS, and

Telegram messages, keeps historical record of the evolution of each registered variable, corrective

actions and comments taken when alarms have occurred.

Relevant features include:

➔Wi-Fi®, Sigfox® modules for wireless transmission.

➔Remote monitor; namely PC, Tablet or Smartphone.

➔Historical data records on Centriomega® Remote Monitoring Platform.

➔Email, SMS, Telegram and Webhook notifications.

➔Off-line temporary storage, in case of network connection failure.

➔Remote parameter configuration.

www.omicroning.co March 2020

8