LVS-7000 Operations Manual Version 5.6.X

LVS-7000 Operations Manual Version 5.6.X Page 3 of 187

Table of Contents

Safety Instructions ........................................................................................................................ 4

Important Information ................................................................................................................... 4

Introduction.................................................................................................................................... 5

Barcode Read ............................................................................................................................. 6

Barcode Grade............................................................................................................................ 6

Optical Character Recognition (OCR)......................................................................................... 6

Optical Character Verification (OCV) ..........................................................................................7

Blemish Detection ....................................................................................................................... 7

Barcode 1D and 2D Health Check.............................................................................................. 7

Delta E......................................................................................................................................... 7

Log In.............................................................................................................................................. 8

Welcome Screen Overview......................................................................................................... 10

Administration............................................................................................................................ 11

Language .................................................................................................................................. 23

Log In......................................................................................................................................... 23

About......................................................................................................................................... 23

Create a New Job......................................................................................................................... 24

Automatic Setup........................................................................................................................ 26

Manual Setup............................................................................................................................ 29

Load an Existing Job................................................................................................................... 84

Operate Screen: Ready to Run................................................................................................... 85

Make Ready Mode.................................................................................................................... 86

Operate Screen: Running the Job............................................................................................. 87

Error Display ................................................................................................................................ 93

Blemish Error Display................................................................................................................ 96

Delta E Error Display................................................................................................................. 97

Reports / QC File Viewer........................................................................................................... 100

Preventive Maintenance............................................................................................................ 106

Troubleshooting ........................................................................................................................ 107

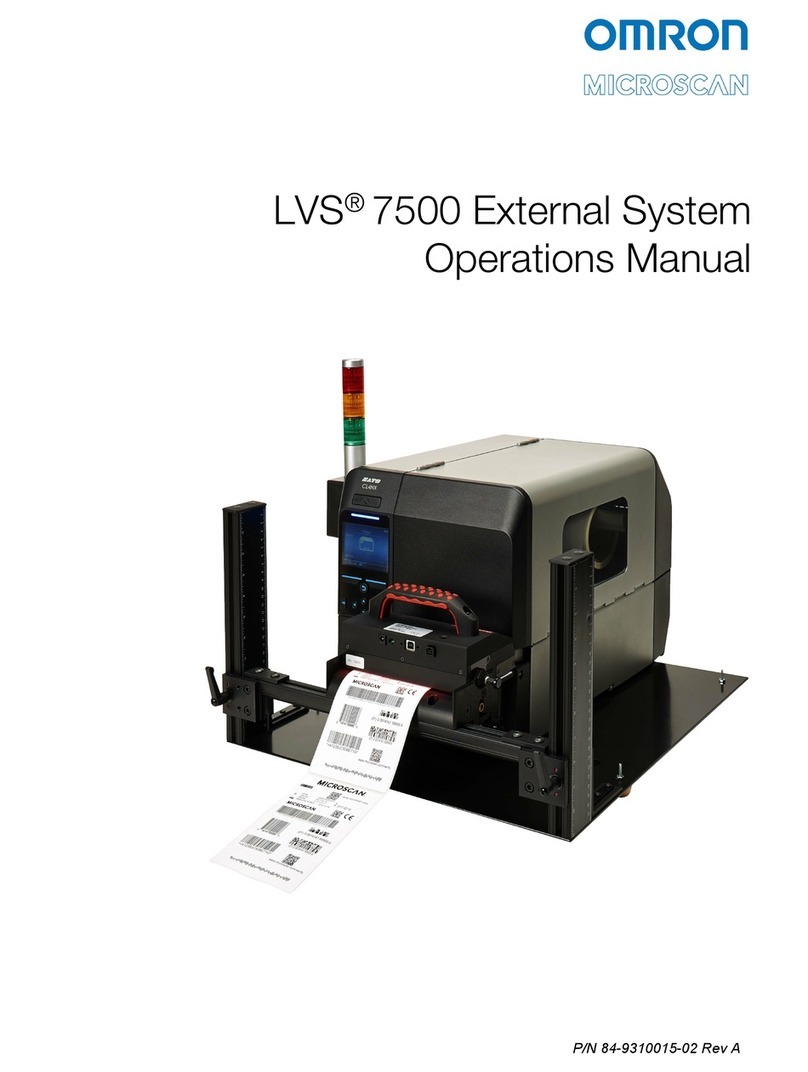

Mechanical Diagrams................................................................................................................ 108

Appendix A: LVS7000.ini File................................................................................................... 130

Appendix B: ePedigree ............................................................................................................. 147

Appendix C: ImageSaver Instructions..................................................................................... 150

Saving Raw Images Without a Label Repeat..........................................................................150

Saving Images With a Label Repeat....................................................................................... 152

Appendix D: Activating Modules.............................................................................................. 154

Appendix E: Upgrading Software ............................................................................................ 156

Appendix F: AutoScan Program .............................................................................................. 161

Appendix G: Automatic Login..................................................................................................172

Appendix H: Using the LVS-7000 PDF Comparator............................................................... 174

Appendix I: AutoStop................................................................................................................ 185