F500

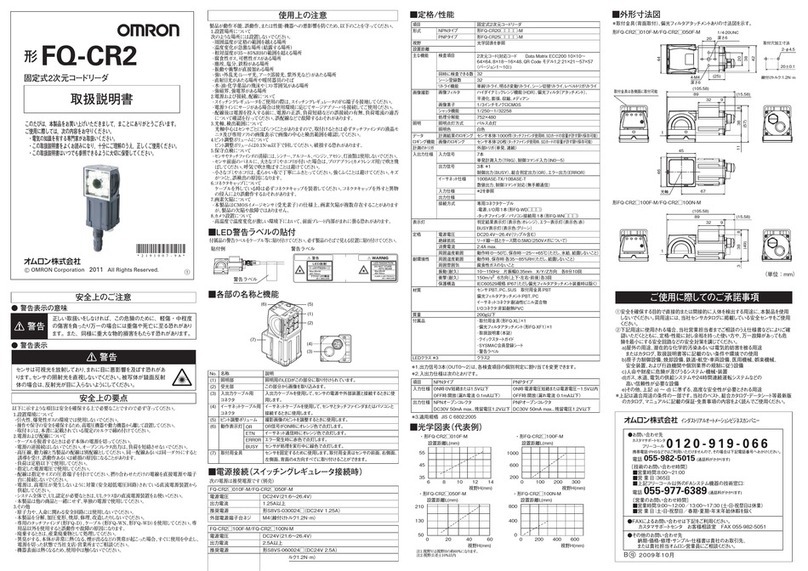

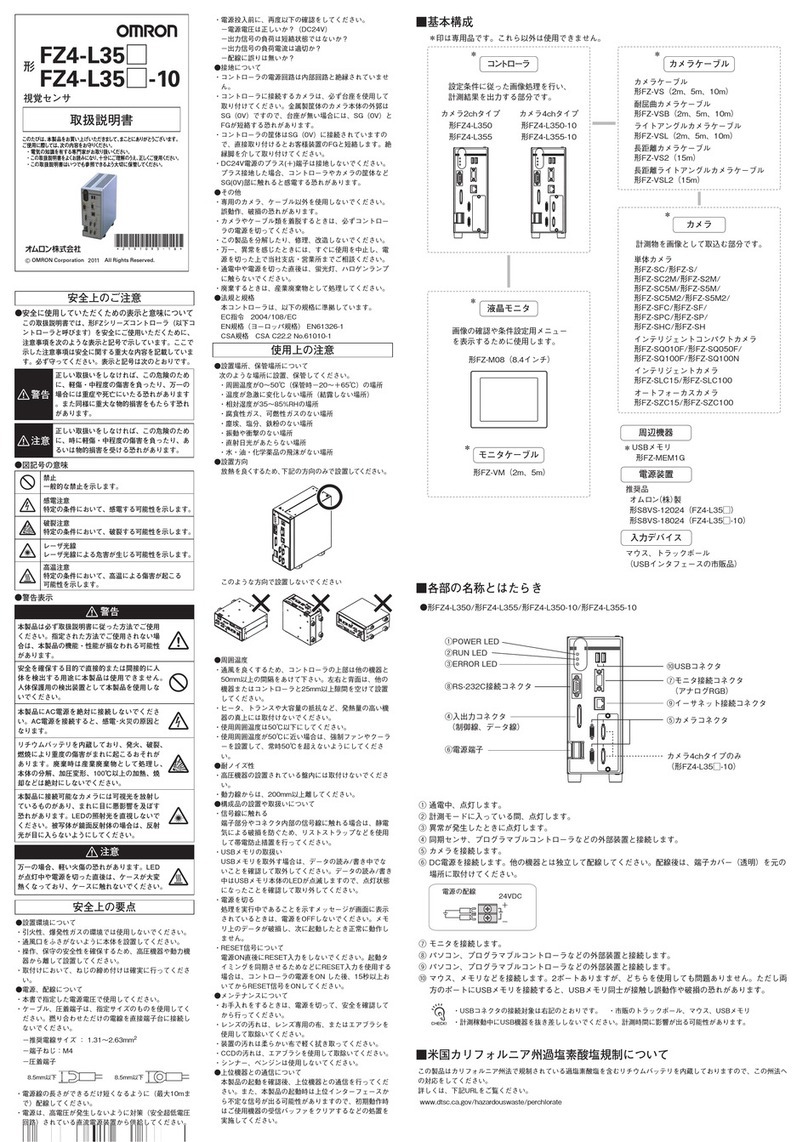

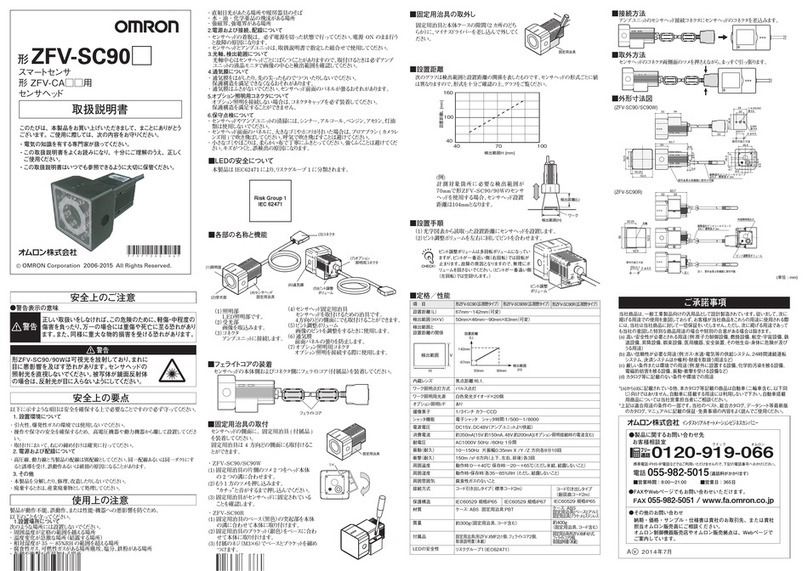

C-59F500

Applications

Connector and IC Lead Inspections

BGA Inspections

Positioning Liquid Crystal Boards

Printing Defects

Molded Product Defect Inspections

Ceramic Board Defect Inspection

Inspecting Electrolytic Capacitor Dimensions

Chip Capacitor Electrode Defect Inspection

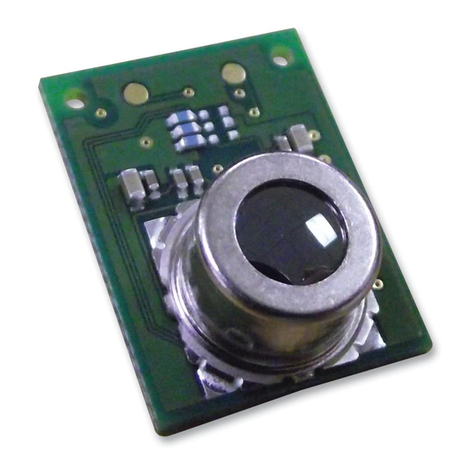

High-resolution inspection over

a wide field of view is enabled

by using a 1-million-pixel high-

resolution camera.

And with macro functions, the

statistics on lead pitch data and

linear approximations of the

lead ends are easily performed.

Length

Pitch

No. of leads

Combining networking enables changing inspection devices, manag-

ing master data, and uploading statistical data files with macros.

High-resolution inspection over

a wide field of view is also ena-

bled by using a 1-million-pixel

high-resolution camera with

BGA inspection software.Var-

iant BGA processing is also pos-

sible.

Quality control data can be used effectively by storing inspection im-

ages in relation to lot numbers. Managing all of the product data on

the host computer makes frequent changes to settings much

smoother.

Number of balls

Deformed ball Offset ball

Incorrect

position Ball size

EC processing, based on an

original algorithm from OM-

RON, enables position inspec-

tions of low-contrast alignment

marks. And using a Digital Inter-

face Camera enables stable

processing.

Macros can also be used to

easily achieve original calibra-

tion methods, inspection data

calculations, and much more.

Managing productivity is also possible by saving and reviewing in-

spection images, detection data, and position compensation data.

Using a 1-million-pixel high-res-

olution camera provides high-

precision inspections over a

wide field of view.

Using macros enables saving

images and inspection data

classified by the type of fault.

For initial system startup, data to determine judgement values and

to troubleshoot problems can be accessed from a remote computer,

reducing costs to a minimum.

Misshapen products, as well as

contamination and scorching

around molded products, can

be detected. Setting is as easy

as specifying the circle size to

detect (i.e., the size of the de-

fects) on limit samples dis-

played on the monitor.

With macros, statistics on good products, NG products, and fault

rates for the inspections performed each day can be calculated and

logged in a Memory Card.

Image

Taken

Filtering

Again

Filtering

Again

EC Defect

Inspection

Inspect for cracks on the sur-

face of ceramic boards. Even if

uneven lighting or rough surfa-

ces show in the images, linear

aspects can be consistently de-

tected.

Using the flow menus enables

conversion to more stable in-

spection by repeatedly filtering

images.

The diameter of round workpie-

ces can be measured at multi-

ple points to determine if they

are round or not.

With macros, deviations in in-

spection values can be stored

in memory and statistics, such

as minimum values, maximum

values, and standard devia-

tions, can be calculated.

Even if the size of the inspec-

tion object changes, the size of

the inspection area adjusts to

the external size to enable

measurement. Misshapen prod-

ucts and contamination and

scorching around products can

be detected.

With macros, production statistics (e.g., number of good products,

number of NG products, and fault rates) can be calculated and moni-

tored onscreen.

F502-EN2-04.book Seite 59 Dienstag, 26. Juli 2005 5:48 17