6ZW User's Manual

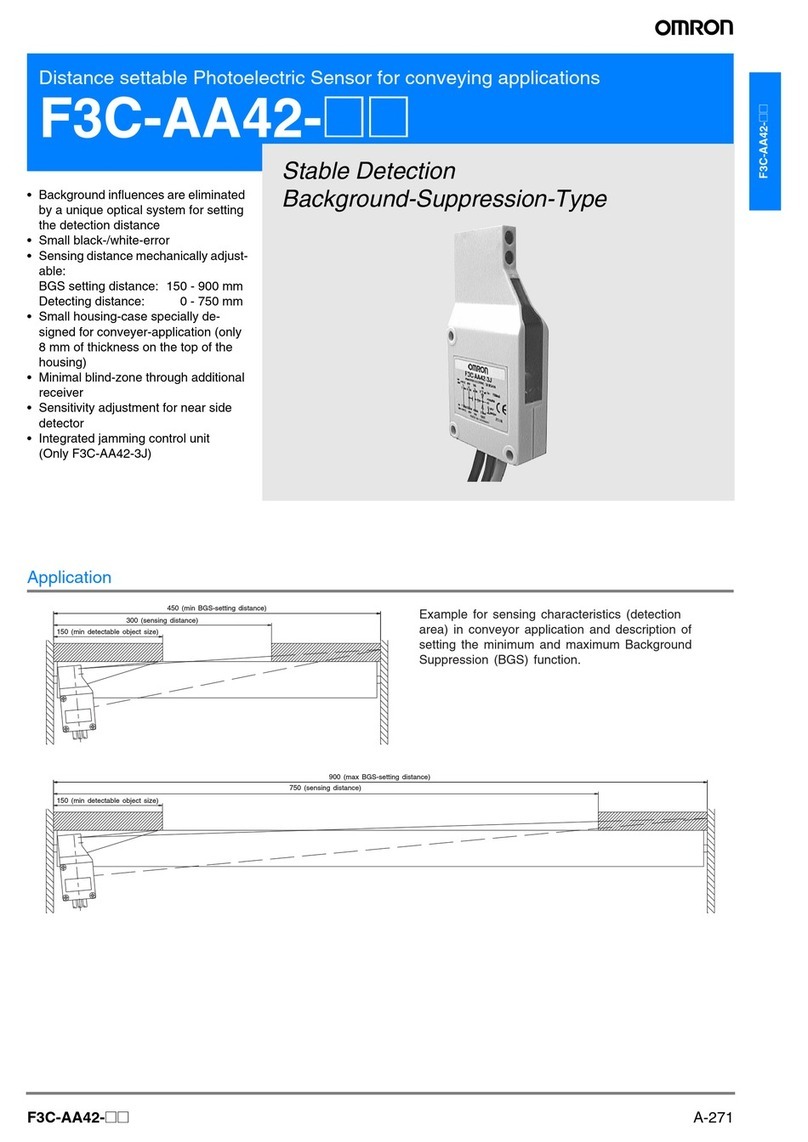

Please observe the following precautions to prevent failure to operate, malfunctions, or undesirable effects on

product performance.

1. Installation Site

Do not install the product in locations subjected to the following conditions:

• Ambient temperature outside the rating

• Rapid temperature fluctuations (causing condensation)

• Relative humidity outside the range of 35 to 85 %

• Presence of corrosive or flammable gases

• Presence of dust, salt, or iron particles

• Direct vibration or shock

• Reflection of intense light (such as other laser beams, electric arc-welding machines or ultraviolet shine)

• Direct sunlight or near heaters

• Water, oil, or chemical fumes, spray or mist atmospherics

• Strong magnetic or electric field

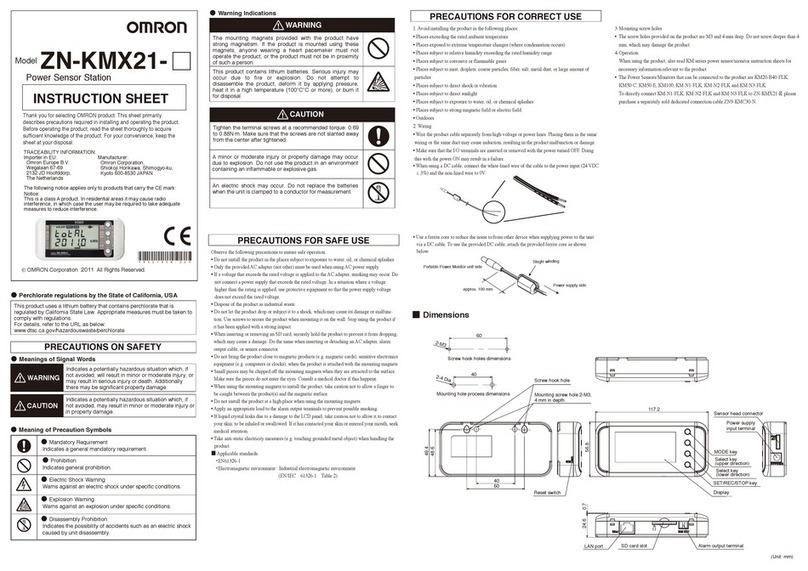

2. Power Supply and Wiring

• When using a commercially available switching regulator, make sure that the FG terminal is grounded.

• If surge currents are present in the power lines, connect surge absorbers that suit the operating environment.

• Before turning ON the power after the product is connected, make sure that the power supply voltage is

correct, there are no incorrect connections (e.g. load short-circuit) and the load current is appropriate.

Incorrect wiring may result in breakdown of the product.

• Use the specified voltage. If voltage exceeding the rating or AC voltage is applied, circuit parts may be burnt

or rupture.

• Use the Extension Fiber Cable (ZW-XF@@R) for extending the fiber cable between the Sensor extension

fiber cable, five total lengths, 2, 5, 10, 20 or 30 m, are available.

• Handling fiber cables

Use them in compliance with the following. This may result in damage to the fiber cable.

-Fiber cable bend radiuses must be at least 20 mm.

- Do not let bending cause stress at the root section of a fiber connector.

- Do not yank hard on a fiber cable.

- Do not step on a fiber cable or place anything heavy on it.

- Do not apply any twisting stress to the fiber cable.

• Be sure to use a Sensor Head and Calibration ROM with the same serial number. A pair with different serial

numbers cannot operate normally.

• Use the configuration software with the combination specified in this manual, or the system may operate

faultily.

• Do not shut down the power supply when saving any data into the memory built in the Sensor Controller, or

the data may be corrupted.

• While a fiber cable is disconnected, be sure to attach the included protective cap on both the Sensor

Controller side and the fiber cable side. Leaving the fiber cable with the protective cap not attached, the

optical fiber may fail due to any adhered foreign matter.

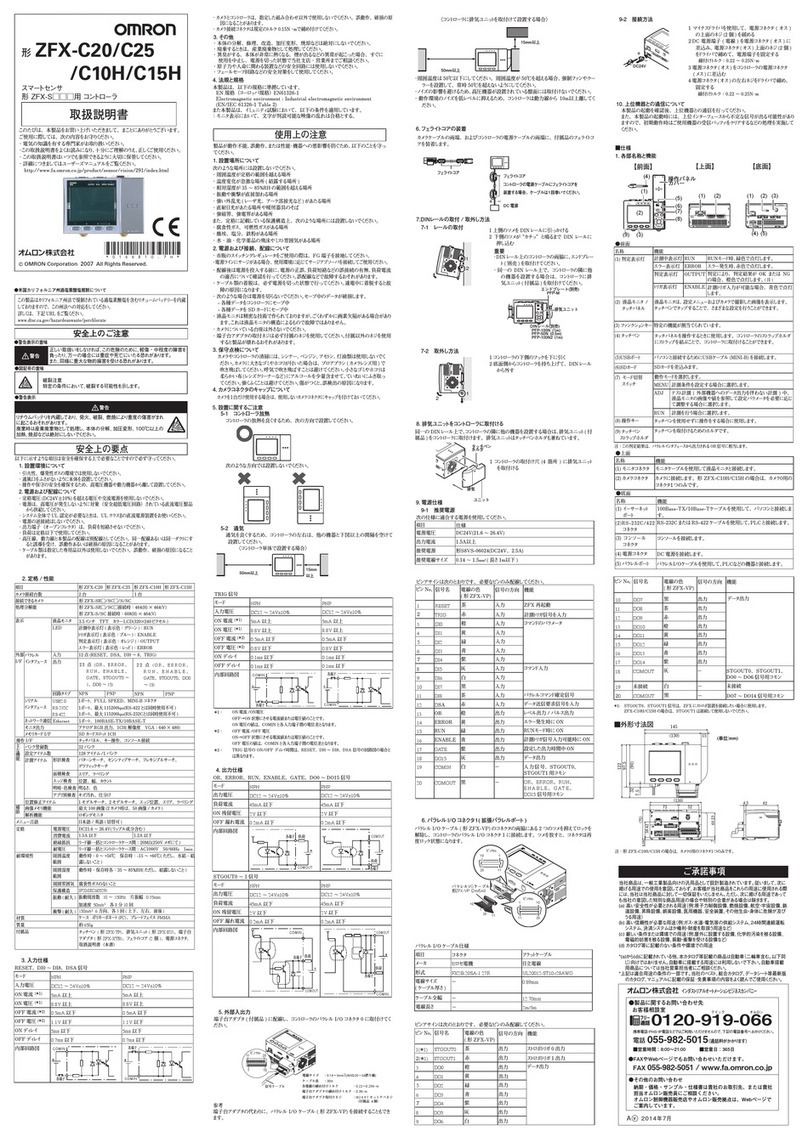

3. Warming Up

After turning ON the power supply, allow the product to stand for at least 30 minutes before use. The circuits

are still unstable immediately after the power supply is turned ON, so measured values may fluctuate gradually.

Precautions for Correct Use