2TB8100 Installation Guide

© Tait Electronics Limited June 2005

Contents

1 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.1 Personal Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.2 Equipment Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.3 Regulatory Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.4 Environmental Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.5 Grounding and Lightning Protection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.6 Recommended Tools. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

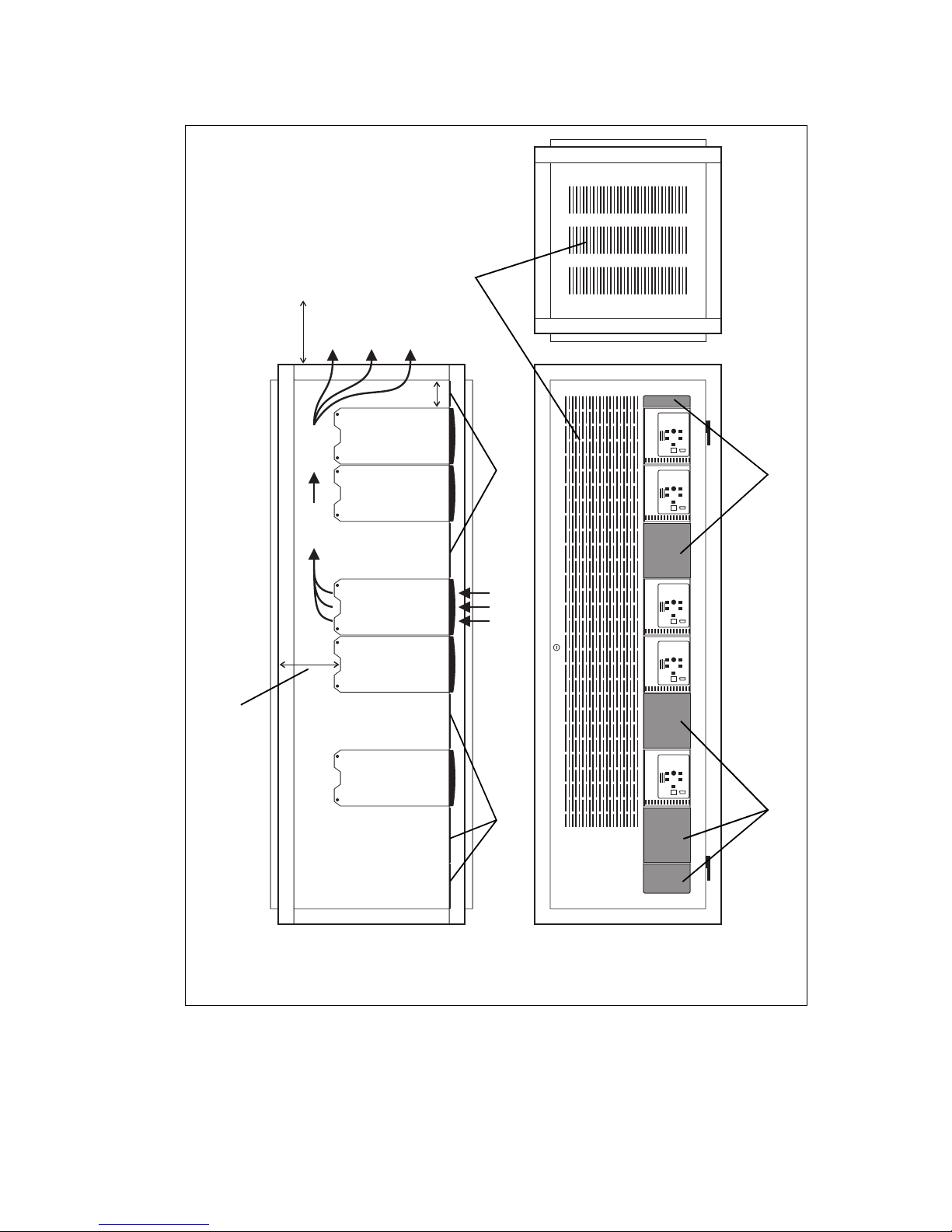

1.7 Ventilation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.8 Installing the Base Station System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2 Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.1 Auxiliary Power Supply Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.2 12V PA Power Saving Control Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2.3 System Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2.4 Service Kit Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

2.5 RF Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

2.6 System Control Bus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Associated Documentation

TB8100 Installation and Operation Manual.

TB8100 Service Manual (service centres only).

TB8100 Specifications Manual.

TB8100 Service Kit and Alarm Center User’s Manuals and online Help.

TB8100 Calibration Kit User’s Manual and online Help.

All available TB8100 product documentation is provided on the Product CD supplied with the base

station. Updates may also be published on the Tait support website. Consult your nearest Tait

Dealer or Customer Service Organisation for more information

Tuning and Configuration

If your TB8100 BSS has not been tuned to your requirements at the factory, you will need to tune

the reciter modules before operating them in your radio system. To do this you will need to use

the Calibration Kit software included on the Product CD, plus the TB8100 calibration test unit.

The TB8100 BSS has been programmed with a default software configuration and default

passwords at the factory. You will need to use the Service Kit software to configure your BSS to

suit the requirements of your radio system. Refer to the Calibration Kit and Service Kit

documentation for full details on these procedures.