89

11 inputs and 21 outputs including control I/O points 1 input and 5 outputs including control I/O points

Input/

Output type NPN

PNP F150-C10E-3 F150-C10E-3-DRT

F150-C15E-3

Menu Tree

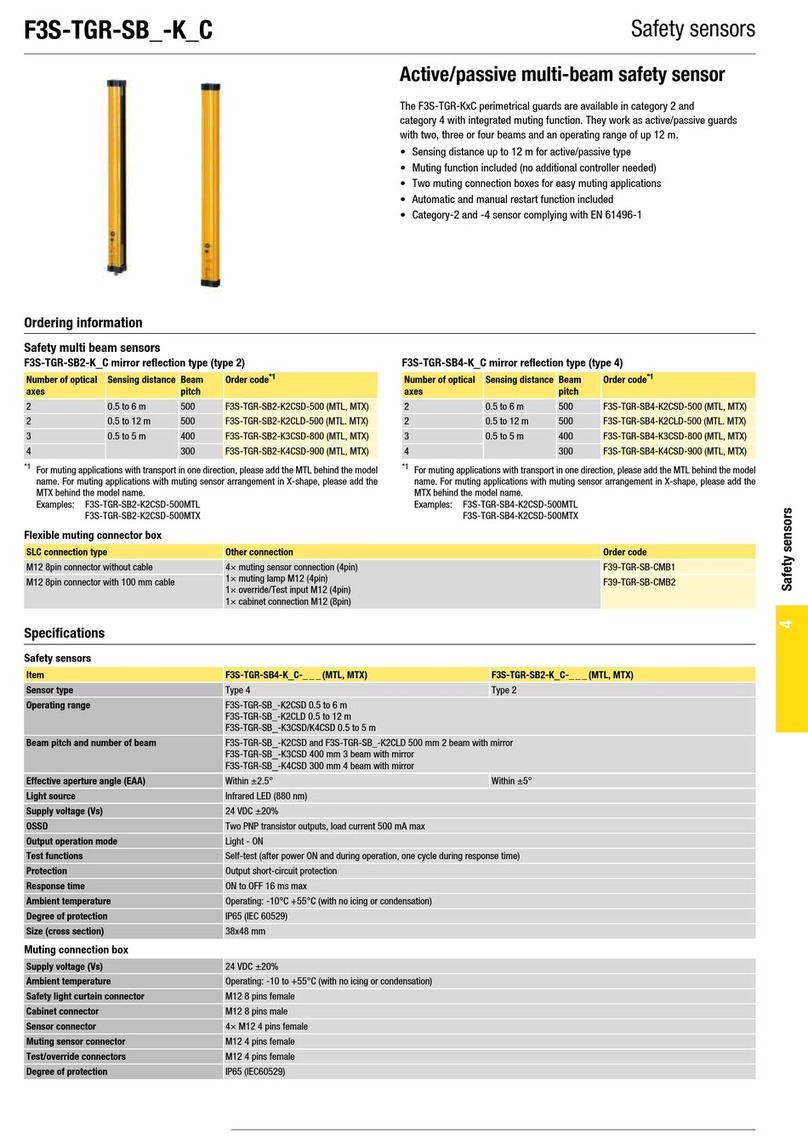

Specifications

Specifications

■Rating/Function

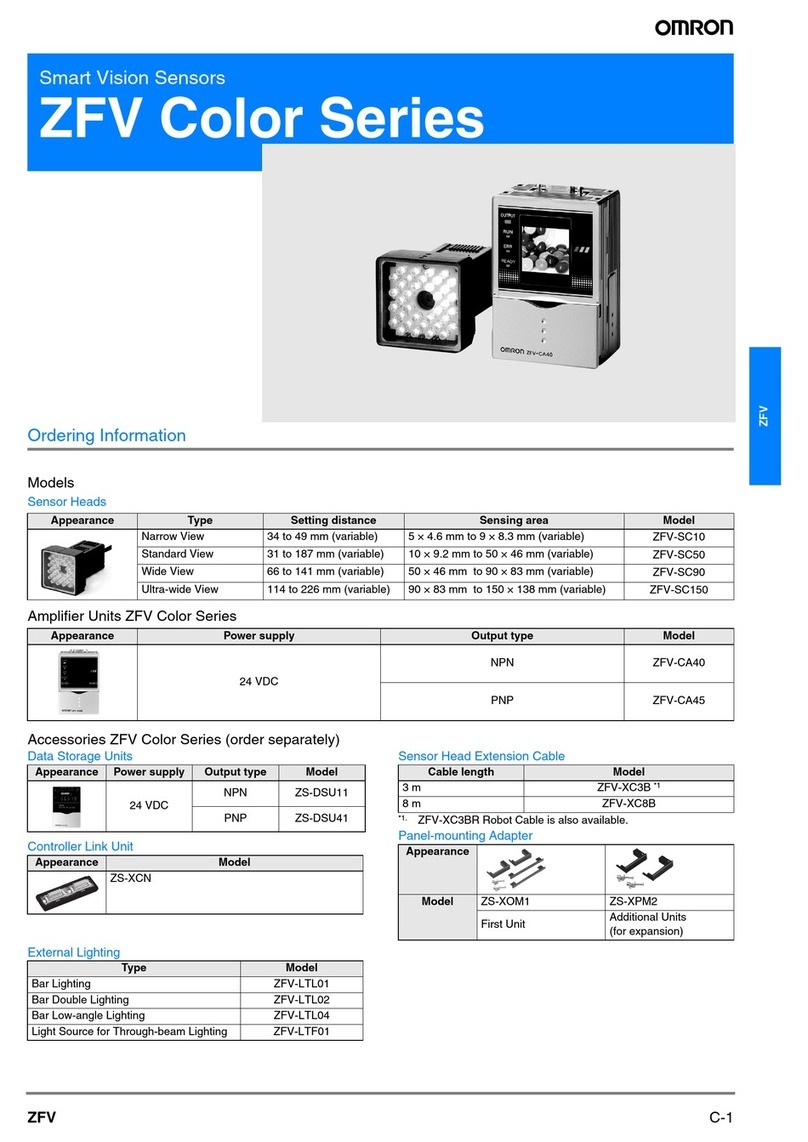

Controllers: F150-C10E-3, F150-C15E-3, F150-C10E-3-DRT

Item

Number of Cameras connectable

Number of pixels

Number of scenes

Image storage function

Processing method

Filtering

Number of binary levels

Position displacement compensation

Number of measurement regions

Measurement data

Data operation functions (expressions)

Results output

Monitor interface

RS-232C interface

CompoBus/D interface

Parallel I/O

Power supply voltage

Current consumption

Ambient temperature

Ambient humidity

Weight (with packaging)

Accessories

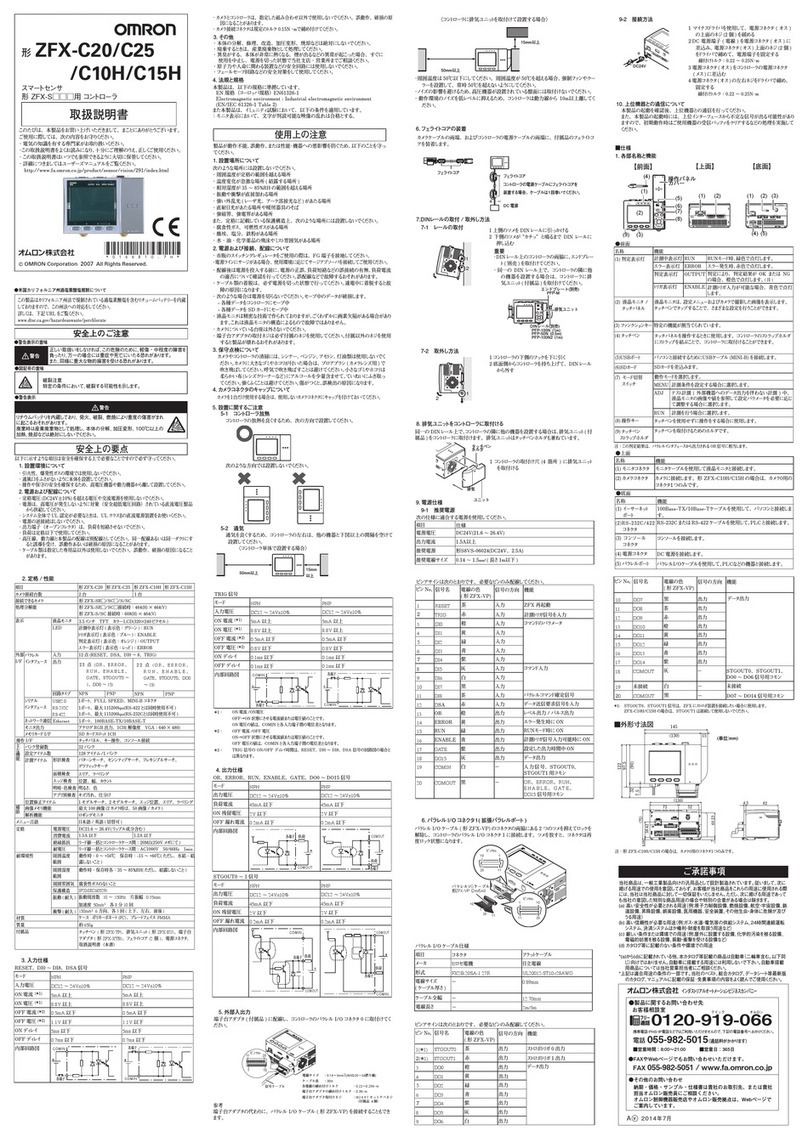

Menu Tree

Set mode

Monitor mode

Run mode

System

Tool

Save

Adjust

Position compensation

Measurement region

(0 to 15)

Expression

Communications

Output

Device settings

Display

Set key operation

Startup mode

Error method

Version

Shutter speed

Filtering

BGS levels

Adjust Filtering

BGS levels

Gravity and area

Gravity and axis

Edge position

Gray search

Calibration

Light control

Gravity and area

Direction

Gravity and axis

Edge position

Edge pitch

Gray search

Precise search

Defect (arc)

Defect (box)

Defect (circumference)

Defect (line)

Density AVG

Relative search

Judge

Data

Terminal block

RS-232C

Normal

Host link

CompoBus/D set F150-C10E-3-DRT only

CompoBus/D ref

Region

(0 to 1)

When the Two-camera

Unit is used, the meas-

urement regions will be

as follows:

Camera 0: 0 to 7

Camera 1: 8 to 15 Depending on the mode,

items may not be

displayed.

When the Two-camera Unit

is used, the measurement

regions will be as follows:

Camera 0: 0, 1

Camera 1: 10, 11

Cameras Cameras with Intelligent Light Sources: F150-SLC20, F150-SLC50

The menu configuration for Set mode will be different if theTwo-Camera Unit is used.

Cameras with Light Sources: F150-SL20A, F150-SL50A

Camera: F150-S1A

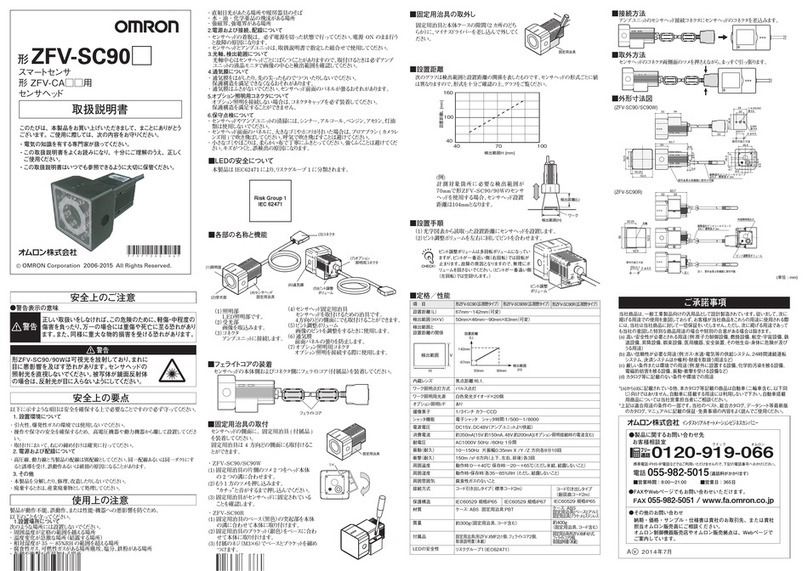

Item Specifications

Camera Picture element 1/3" Interline CCD (reading all pixels)

Effective pixels 659 x 494 (H x V)

Shutter Electronic frame shutter: 1/100, 1/500, 1/2,000, or 1/10,000 s

Lens Camera distances F150-SLC20: 15 to 25 mm, F150-SLC50:16.5 to 26.5 mm, F150-SL20A: 61 to 71 mm, F150-SL50A:66 to 76 mm

Fields of vision F150-SLC20/SL20A: 20 mm, F150-SLC50/SL50A:50 mm

Lighting Light sources F150-SLC20/SLC50:Red LED and green LED, F150-SL20A/SL50A:Red LED

Flash Pulse flash (synchronized with camera shutter)

Ambient temperature Operating: 0 to 50 °C; storage: -25 to 60 °C (with no icing or condensation)

Ambient humidity Operating or storage:35% to 85% (with no condensation)

Weight (Camera only) F150-SLC20: Approx. 310 g; F150-SLC50: Approx. 425 g

F150-SL20A/50A: Approx. 135 g; F150-S1A: Approx. 70 g

Accessories

F150-A20Two-camera Unit

Item Specifications

Number of connectable cameras

2

Camera modes

Two-camera switching; vertical composition,

horizontal composition 1 and 2;

single camera (camera 0 or1)

Power supply voltage 20.4 to 26.4 VDC

Current consumption Approx. 0.3 A

Ambient temperature Operating: 0 to 50 °C;

storage: -25 to 65 °C

(with no icing or condensation)

Ambient humidity Operating or storage:

35% to 85% (with no condensation)

Weight (Camera only) Approx. 220 g

Accessories Instructions manual (one),

Camera Unit Cable (one)

Monitors

Item Model F150-M05L

Liquid Crystal Monitor F300-M09

Video Monitor

Size

5.5 inches; 111.36 x 83.52 mm (H xV)

9 inches; 164 x 123 mm (H xV)

Type Liquid crystal colorTFT

CRT monochrome (long persistence)

Resolution 320 x 240 dots 700 TV lines min.(at center)

Input signals NTSC composite video (1.0 V/75 Ωtermination)

Power supply voltage

20.4 to 26.4 VDC (including ripple)

90 to 110 VAC, 50/60 Hz

Current/Power consumption

Approx.700 mA max. Approx. 30 W

Ambient

temperature

Operating: 0 to 50 °C;

storage: -25 to +65 °C

(with no icing or condensation)

Operating: 0 to 40 °C;

storage: -25 to +65 °C

(with no icing or condensation)

Ambient

humidity

Operating or storage:

35% to 85%

(with no condensation)

Operating or storage:

10% to 90%

(with no condensation)

Weight (Monitor only)

Approx. 1 kg Approx. 5.8 kg

Accessories

Instructions manual (one),

mounting brackets (four)

Instructions manual

F150-SLC20/SLC50: Instructions manual (one), F150-SL20A/SL50A:Instructions manual (one)

Specifications

1 or 2 (when using F150-A20)

512(H) x 484(V)

16 (can be backed up to a personal computer via RS-232C)

Maximum of 23 images stored

Gray/Binary

Smoothing, edge enhancement, edge extraction, background suppression

256 levels per region

Compensation directions: X,Y,and θdirections Detection methods: Binary center of gravity, axis angle, midpoint, gray search (1 model or 2 models), gray edge position

16 regions/scene

Binary center of gravity and area, axis angle, correlation value, gray search position, defect, edge position, edge pitch, density averaging, relative search

Arithemetic calculation, distance, angle, maximum/minimum value, absolute value, etc.

Overall judgement, judgements for measurement/expression results for each region, measurement/expression results (can be output via RS-232C in parallel)

1 channel (pin jack, compatible with over-scan monitor)

1 channel (D-sub, 9-pin, female)

F150-C10E-3, F150-C15E-3 : None F150-C10E-3-DRT: 1 channel

20.4 to 26.4 VDC (including ripple)

Approx. 0.5 A

Operating: 0 to 50°C (with no icing or condensation), Storage: -25 to +65°C (with no icing or condensation)

Operating and storage: 35% to 85% (with no condensation)

Approx. 940 g (Controller only: 390 g)

2 manuals and CompoBus/D connector (F150-C10E-3-DRT only)