A-204 Standard Photoelectric Sensors

Precautions

Fiber Units

Installation

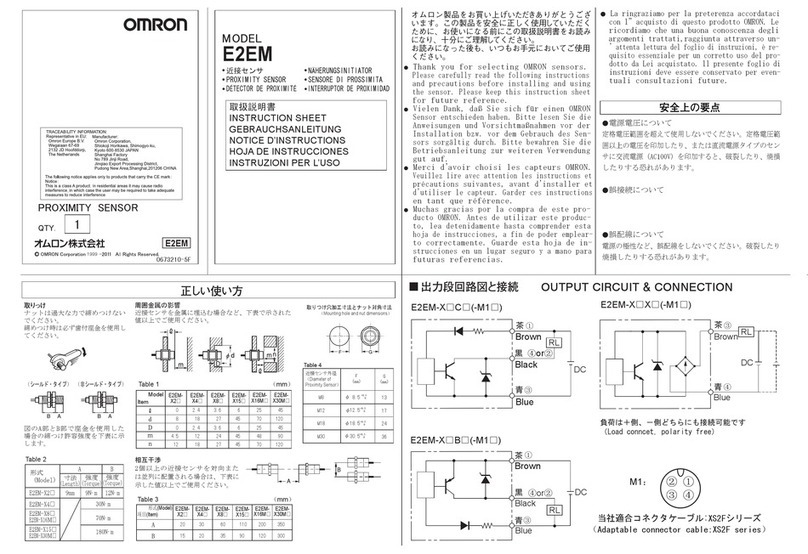

Tightening Force

For the fiber unit installation, tighten it to the torque of 0.3 Nm

max.

Fiber Connection and Disconnection

E3X-NL amplifier has a push lock. Connect or disconnect the

fibers to or from E3X-NL amplifier using the following proce-

dures:

1. Connection

After inserting the fiber into the Amplifier, push the lock button

until a click sound is heard so that the fiber is securely con-

nected.

2. Disconnection

Ensure to press the push lock again to unlock before pulling

out the fiber, otherwise the fiber may be deteriorated.

(To maintain the fiber characteristics, remove the fiber after

making sure that the lock has been released.)

3. The fiber must be locked or released in a temperature

range of -10° to 40°.

Since face-to-face isntallation of the fiber units may cause

mutual interference, mount them so that the optical axes of

the sensors are not opposed.

Monting the sensor

If two or more sensors are used, face-to-face installation of

the fiber units or the regularly reflected light from the sensing

object may cause mutual interference. At this time, adjust the

fiber units to be mounted at the angles where the light of each

sensor is not received by the fiber unit of the other sensor.

●For adjustment

Two-point Teaching and One-point Teaching

Refer to the following information to select the most suitable

sensitivity setting method for the application.

Selection of Teaching Point(s)

Two-point Teaching

If E3X-NL is used to sense sensing objects that are only a little

different in glossiness from the background object and the

sensing objects have color patterns, the difference in glossi-

ness among the inks on the sensing objects may influence the

sensing operation of E3X-NL. Therefore perform two-point

teaching with E3X-NL at a place where E3X-NL can sense the

sensing objects smoothly while considering the characteris-

tics of glossiness versus distance of E3X-NL if the sensing po-

sition of each of the sensing objects is different from each

other.

One-point Teaching

If E3X-NL is used to sense sensing objects different from

each other in glossiness on a single background object, per-

form one-point teaching with E3X-NL using the background

object. If E3X-NL is used to sense identical sensing objects on

a variety of glossy background objects, perform one-point

teaching with E3X-NL using one of the sensing objects.

Operation Level Setting and Control Output for One-point Teaching

Correct Use

Lock button

Fiber insertion mark

Lock button

Locked Unlocked

Sensitivity

setting method Two-point teaching One-point teaching

Difference

In general, use 2-point teach-

ing. The fuzzy teaching func-

tion (refer to Technical Guide)

is activated to set the optimum

algorithms automatically,

drawing an operation level just

about between the two points

taught.

One-point teaching should

be performed for the sens-

ing of different objects on a

single background object or

a single type of objects on a

variety of glossy back-

ground objects.

The operating level will be

set 15% above or below the

teaching point, depending

on the glossiness of the first

sensing object.

The fuzzy teaching function

is not activated for 1-point

Vth selection

+

15%

-

15%

Teaching

ON

Glossiness

OFF

Control output

(L·ON)

Glossiness

Control output

(L·ON)

TEACH mode RUN mode

Vth on

upper side

Vth on

lower side

Vth selection

+

15%

-

15%

Teaching

ON

OFF

TEACH mode RUN mode

Vth on

upper side

Vth on

lower side