Omron ZG2 Series How to use

Other Omron Accessories manuals

Omron

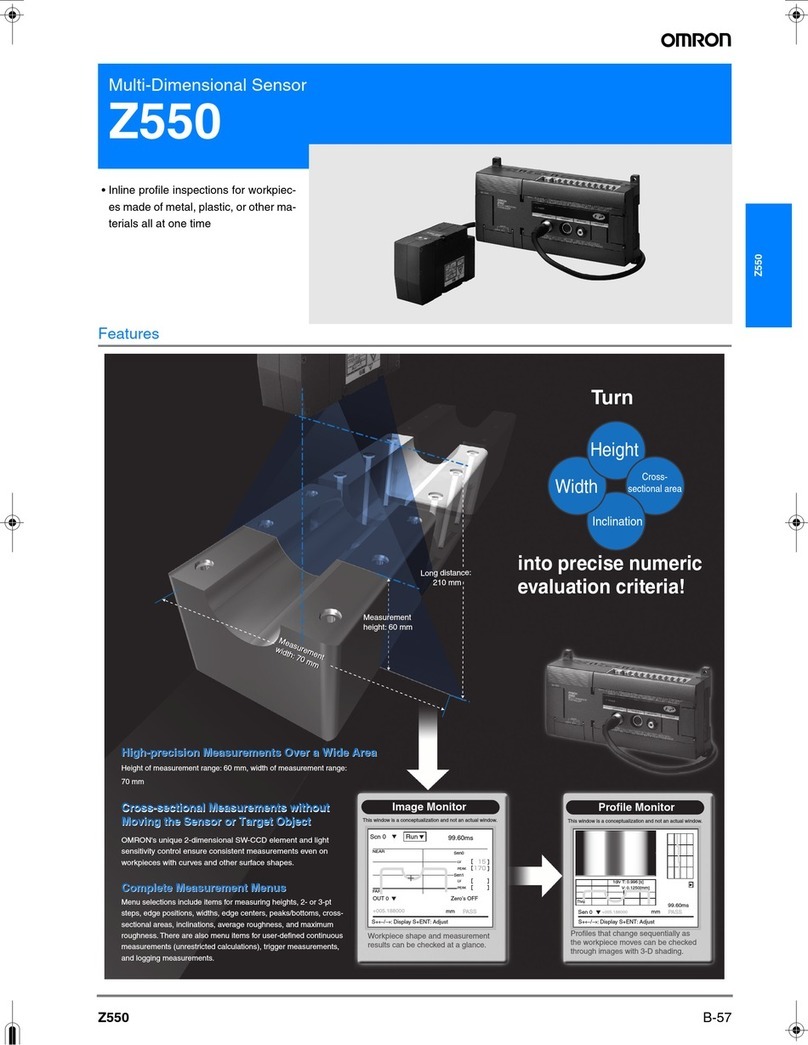

Omron ZG - User manual

Omron

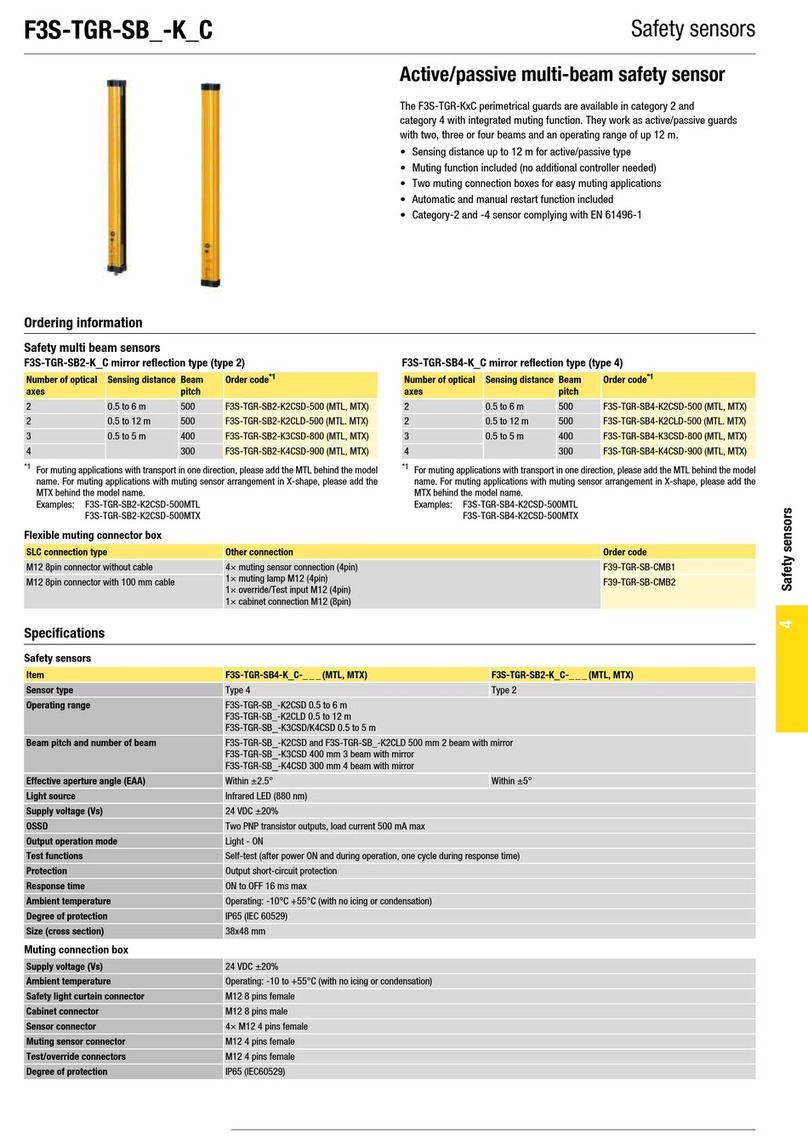

Omron F3S-TGR-SB-K C User manual

Omron

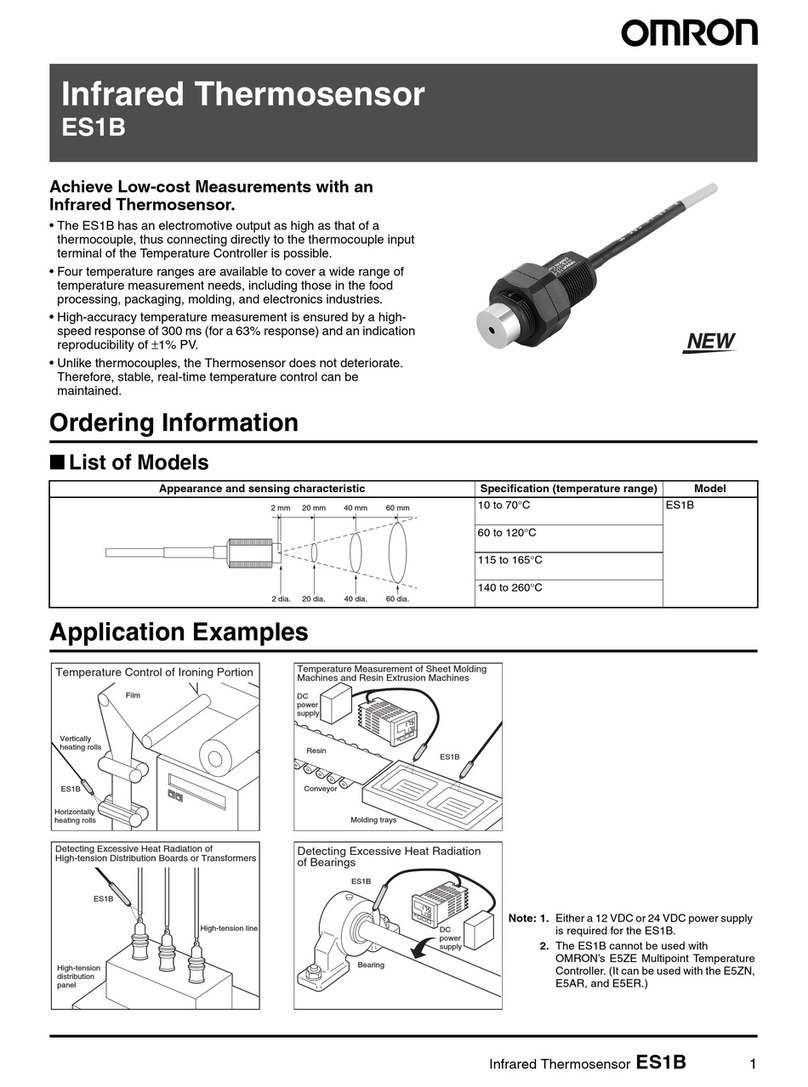

Omron ES1B - DATASHEET 1 User manual

Omron

Omron F3UV-A30 User manual

Omron

Omron E3T - User manual

Omron

Omron E3NT-L User manual

Omron

Omron EQUO Series User manual

Omron

Omron F400 User guide

Omron

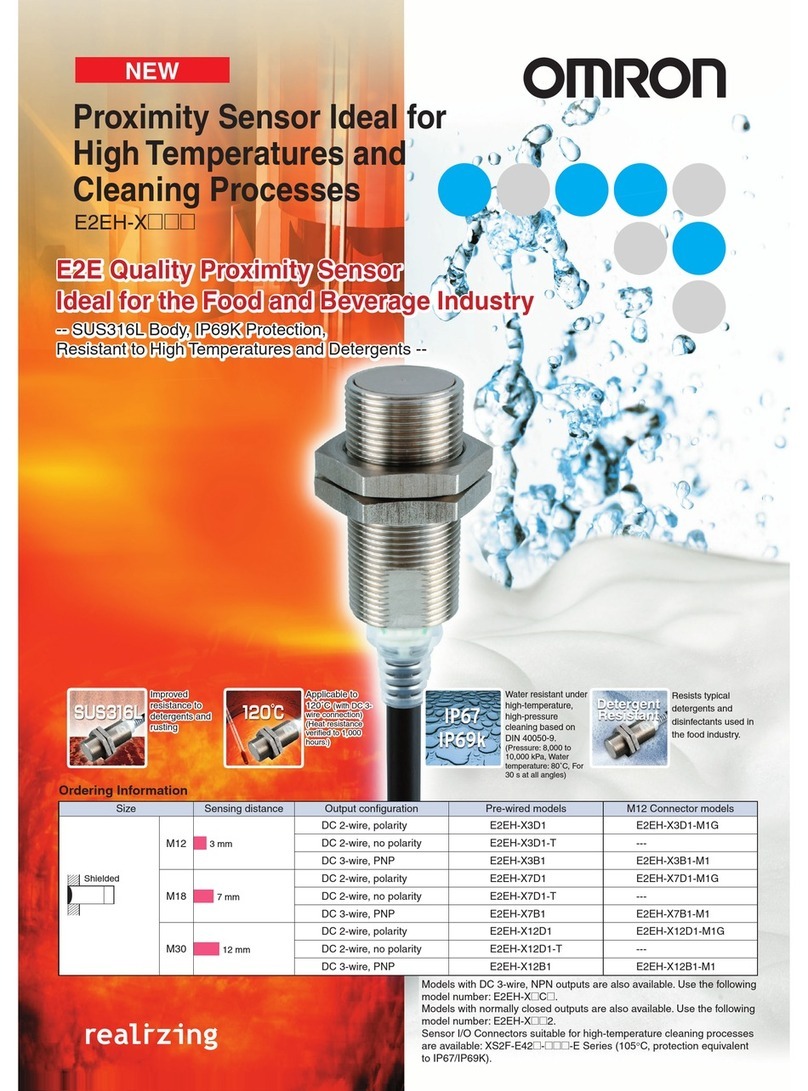

Omron E2EH-X Series User manual

Omron

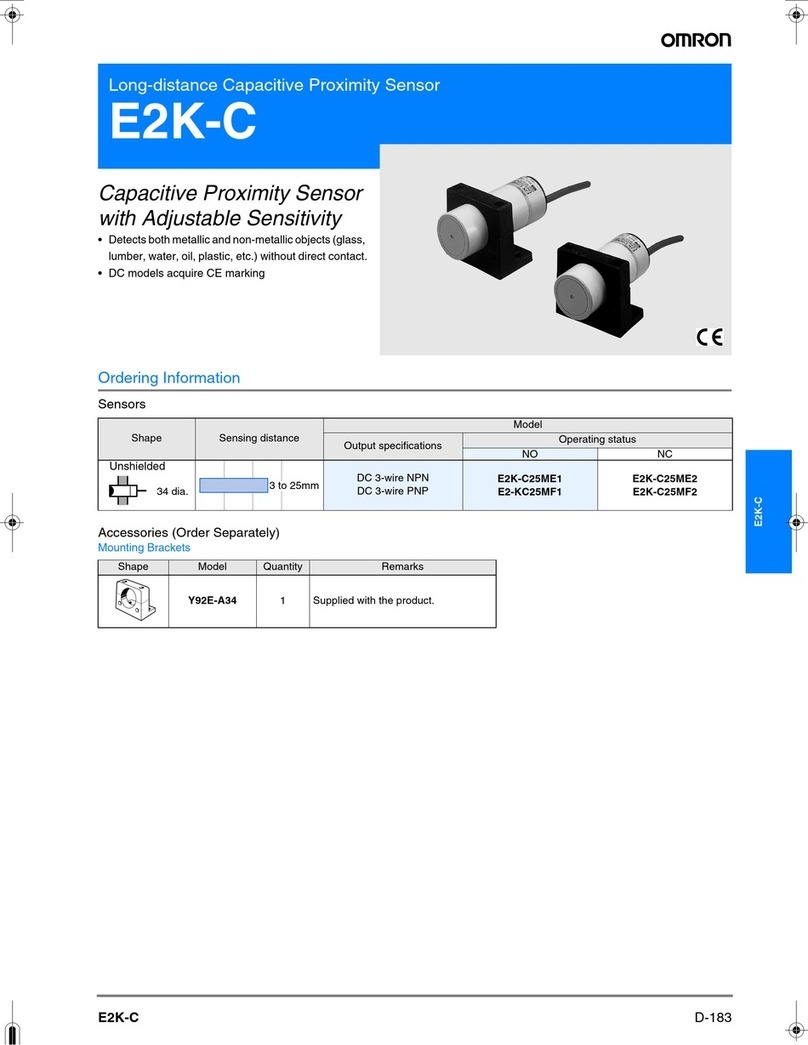

Omron E2K-C User manual

Omron

Omron fh series Instruction Manual

Omron

Omron ZFV-C Installation manual

Omron

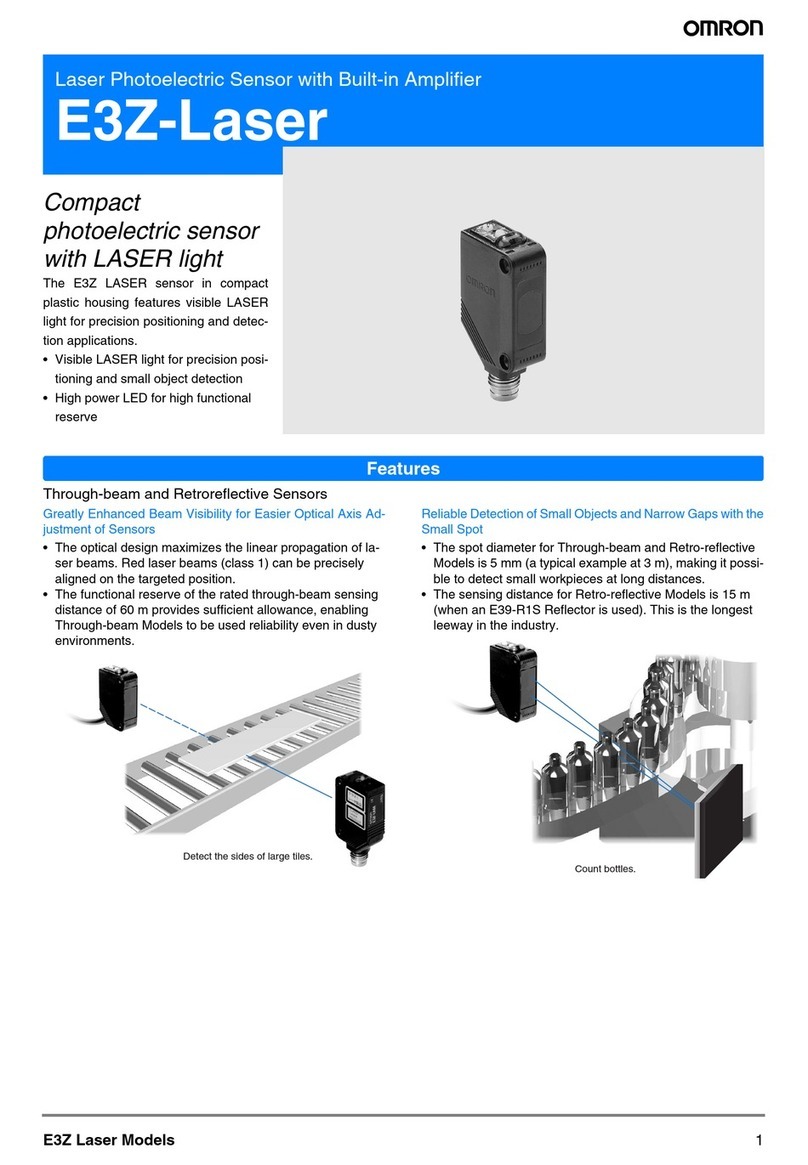

Omron E3Z-LASER User manual

Omron

Omron F3SH-A - User manual

Omron

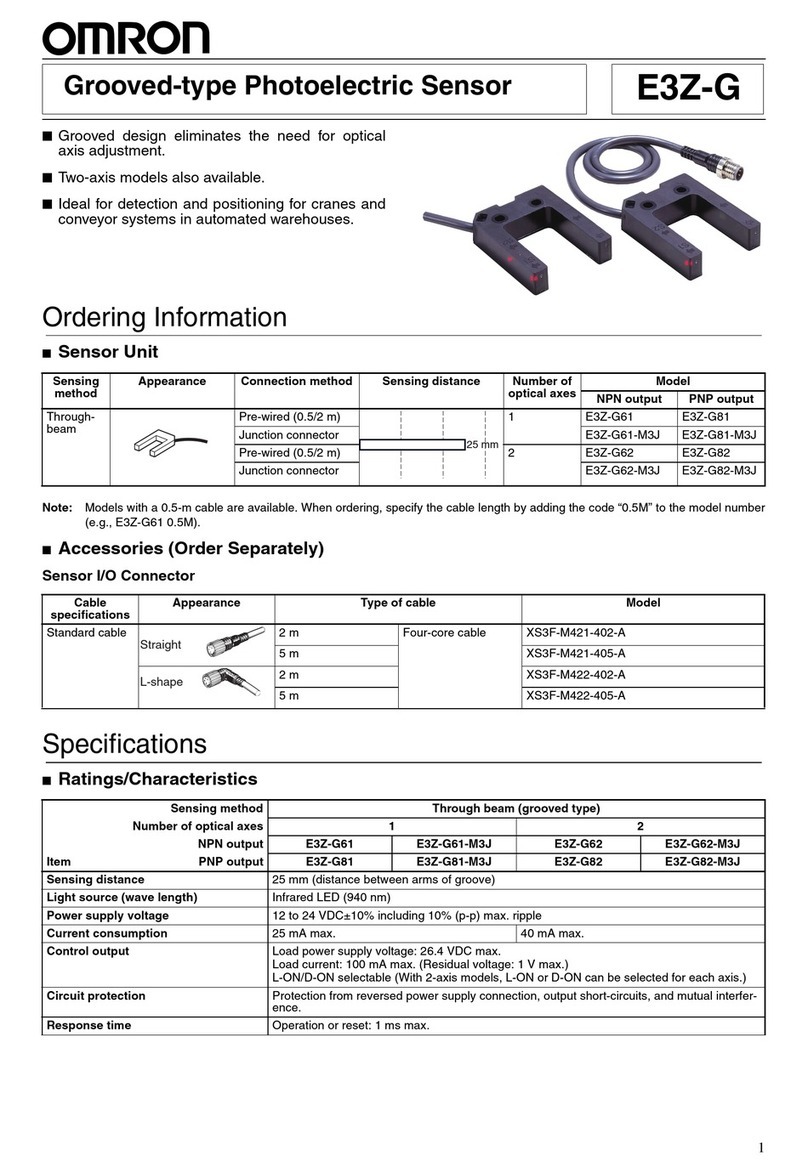

Omron E3Z-G User manual

Omron

Omron SYSMAC CJ2H-CPU6@-EIP Instruction Manual

Omron

Omron F3C-AA42-1 User manual

Omron

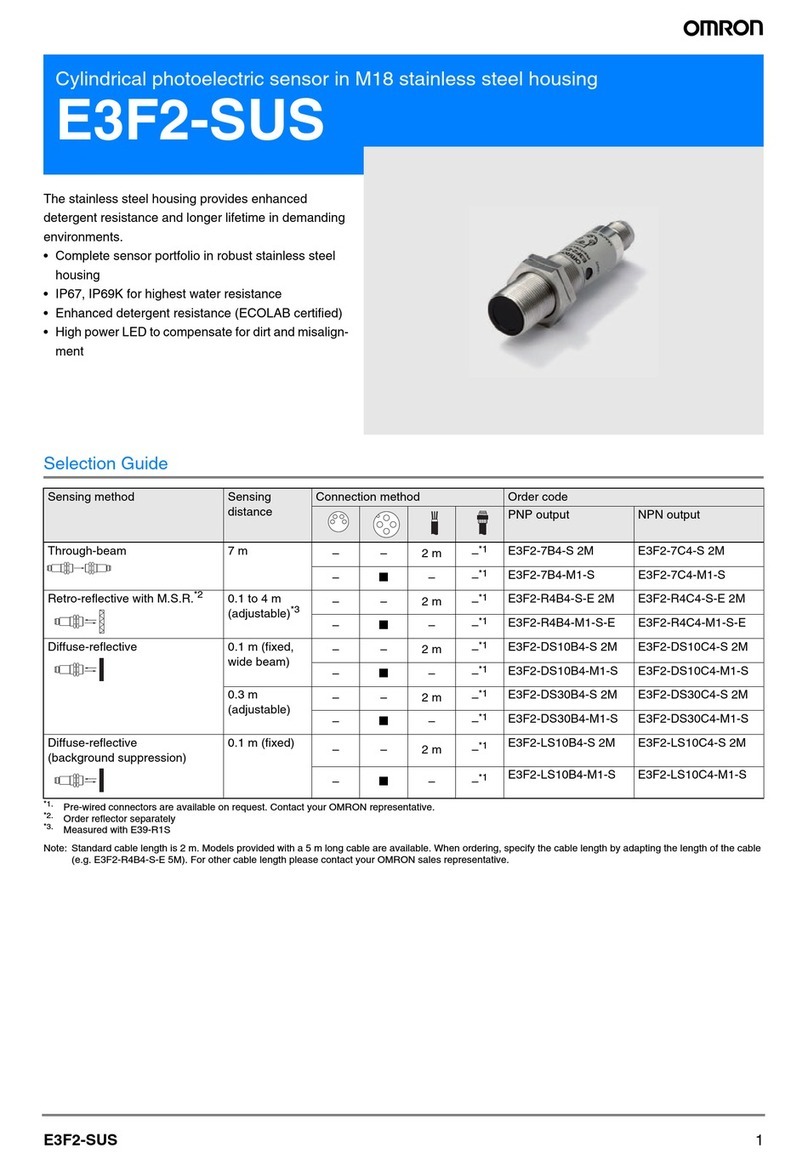

Omron E3F2-SUS - User manual

Omron

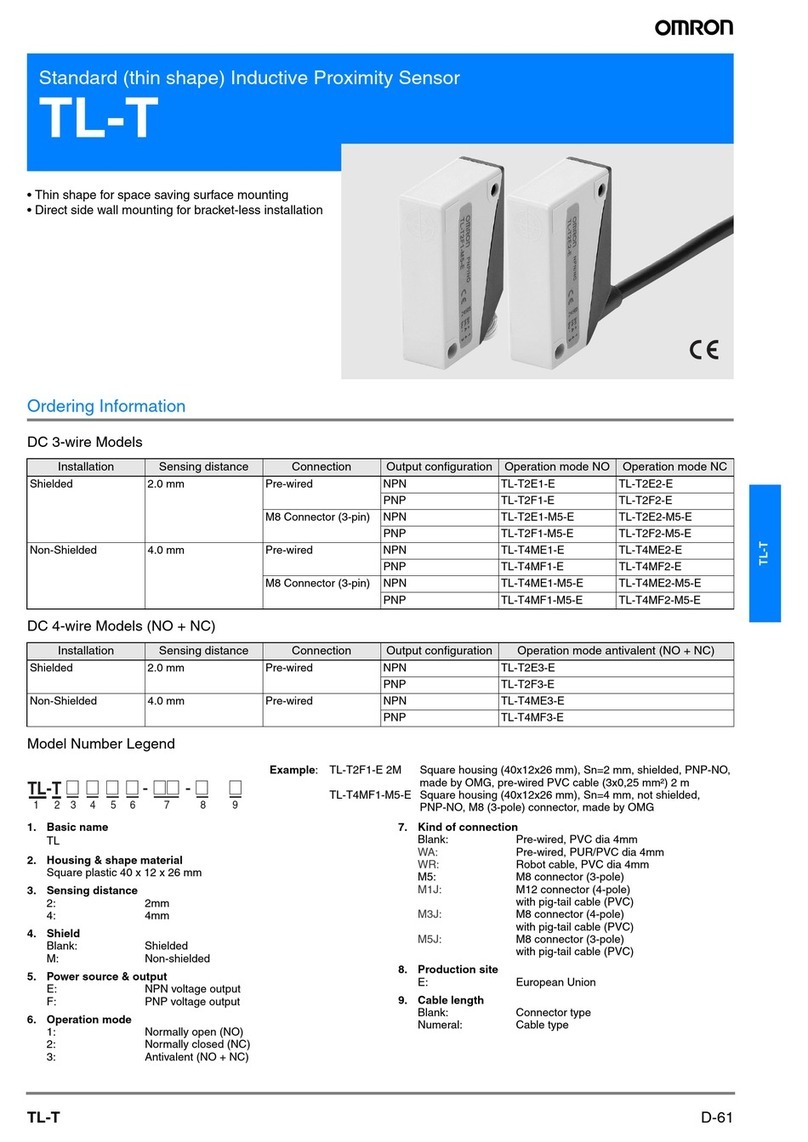

Omron TL-T User manual

Omron

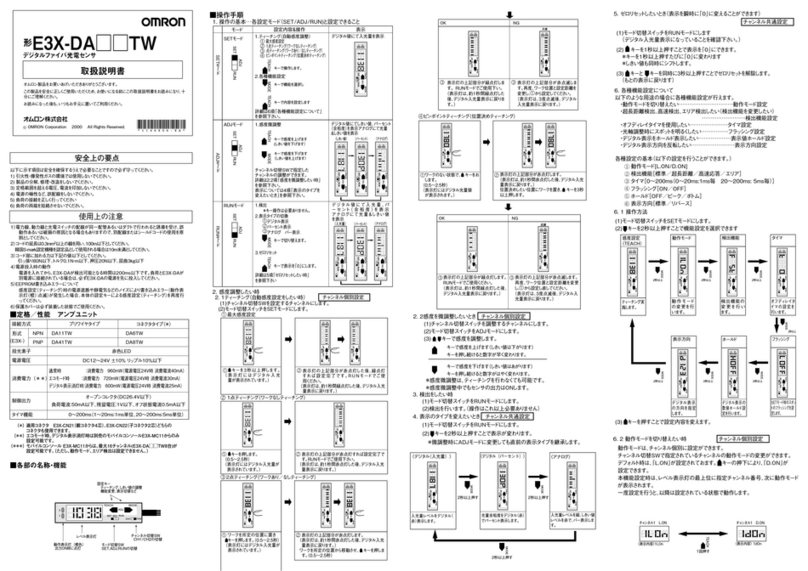

Omron E3X-DA11TW User manual